How to check the ignition coil (IKZ) with your own hands

The car jerks, there is no traction, vibration is felt, or the engine is rough; all these are symptoms of improper operation of the individual ignition coil (IIC).

Other signs of a faulty ignition coil are the presence of errors 0301, 0302, 0303 and 0304, indicating misfire in one of the cylinders. Let's look at a few simple ways to check the ignition coil with your own hands. It is worth noting that the process of checking IKZ on modern Lada cars (XRAY, Vesta, Largus, Granta, Kalina and Priora) does not have significant differences. All actions are performed in the same way.

Operational check of the serviceability of the Lada Kalina ignition system

The cause of misfires in the operation of the power unit may be not only damage to the high-voltage wires, but also to the ignition module. The article gives recommendations on how to check the ignition coil on a Lada Kalina car with an 8 and 16 valve engine.

Malfunctions of the ignition module lead to unstable engine operation and the inability to start the car. The module's task is to generate high-voltage pulses and transmit them to the spark plug (SZ). The plus of the unit receives + 12V power from the on-board network, the minus is taken from the car body.

Visual inspection of the IKZ

Remove the ignition coils from the engine using a 10mm or Torx E8 socket wrench (depending on the powertrain model). Carefully inspect the removed coils. There should be no cracks, damage to the rubber cap, melting or leakage of plastic. The spring located inside the coil must be in the correct position.

Addresses of companies providing ignition replacement services (Moscow, St. Petersburg, Kyiv regions)

| See all advertisements in the archive |

| № | Name | Address |

| 1. | "EuroSTO on Motorny" | lane Motorny 3, Kyiv |

| 2. | "AUTO" | st. Krasnotkatskaya, 42-E, Kyiv |

| 3. | "Vilgud car services in Moscow" | lane Seversky, 24 - 125 |

| 4. | "Car service 24 hours" | Moscow, 2nd Vyazovsky pr-d, 4 building 5 |

| 5. | "Car service Person" | St. Petersburg, Kurskaya st. 28 m. Obvodny Canal |

| 6. | "PIT STOP" | PARNAS, SH. VYBORGSKOE, 33, ETC. MARSHAL BLUCHER 41 BOLSHEVIK Ave. 10 ETC. ISKROVSKY, 7 |

Checking the ignition coil with a multimeter

Checking the voltage at the terminal block of the wires

:

- Disconnect the block with wires from the ignition coil (on the H4M engine, to access the coils of cylinders 1 and 2, remove the intake pipe).

- Turn on the ignition and measure the voltage at terminal 3 of the wiring harness block (the numbering of the terminals is on the ignition coil).

- The voltage at the terminal must be at least 12 V. If it is less or absent, it means the battery is discharged, there is a fault in the power circuit, or the engine control unit (ECU) is faulty.

- Turn off the ignition.

How to check ignition coil resistance

:

- We set the switch on the multimeter to the 200 Ohm position and close the probes (the instrument error will be displayed on the screen, which will need to be subtracted from the readings during testing).

- We check the primary winding of the ignition coil by connecting the probes of the device to the contacts.

- The resistance between pins 1 and 3 should be close to zero (about 1 ohm).

- The resistance between pins 1-2 and 2-3 should be high (tend to infinity).

- Set the switch on the multimeter to the 2000 kOhm (or 2 MOhm) position.

- We check the secondary winding of the coil by connecting the red probe to the spring inside the rubber cap, and the black probe to pin 2.

- For good contact, it is best to remove the rubber cap from the coil and connect the probe directly to the coil contact, having first cleaned it of deposits.

- The resistance should be about 300-400 kOhm.

Attention! The resistance of the secondary winding of the ignition coil is highly dependent on its temperature. Carry out the test when the coil is completely cool. Compare the resistance of all four ignition coils to each other. A faulty ignition coil can be identified by very different values, provided that all coils are from the same manufacturer.

The process is also shown in the video:

Causes of ignition coil failure

Let's look at the reasons why the ignition coil fails.

Natural wear and tear

Like all electrical and electronic units, the reel has a certain trouble-free operation life. The average service life of ignition coils is approximately seven to ten years of operation or 150,000 - 200,000 thousand mileage. The device is operated in extreme conditions with large differences in temperature, humidity, and the possibility of ingress of moisture, dirt, and foreign liquids. In this case, large currents flow through the primary winding, and a high-voltage pulse is formed in the secondary winding.

Electrical breakdown

Let's figure out why the ignition coil breaks. Firstly, over time, as a result of high temperature changes, the dielectric insulation cracks, and salty moisture, which is a conductor, can enter microcracks. For voltages of more than 15,000 volts generated in the secondary winding, even pure undistilled water acts as a conductor. Secondly, during operation, the physical properties of the dielectric and rubber insulation of the tips of high-voltage wires, especially those of dubious production, change. High-voltage breakdown can be caused by the installation of non-standard high-voltage wires in which there is no distributed current-limiting resistance. A breakdown can occur as a result of severe contamination or waterlogging. Even in the event of a single breakdown, irreversible changes occur in the structure; further operation is not recommended.

Overheat

Some vehicles have ignition coils installed directly at or near the top of the engine. If there is no air access to their structure for natural ventilation (this is possible when installing additional equipment), the device may overheat and fail.

Mechanical load.

The coil mount must be standard. Some car enthusiasts neglect these requirements by “hanging” it on homemade structures.

Wear of spark plugs, high-voltage conductors

Despite the fact that the circuit has a limiting resistance, wear of spark plugs and high-voltage conductors can cause electrical breakdown in them. Then the load current increases and the bobbin may overheat.

Generator voltage regulator relay malfunction

Sometimes it leads to an increase in the voltage of the vehicle’s on-board network and failure of the electronic amplifier (switch).

Malfunction of the contact group of the lock, electronic switch

If, during parking, +12 Volts are constantly supplied to the coil in the event of an abnormal closure of the lock contact group, the device may overheat and fail. The same situation is possible if the switch is faulty.

Checking the ICP with a spark gap

- Disconnect the IKZ from the spark plug.

- Install a spark gap on the IKZ.

- Apply ground (from the battery terminal) to the spark gap using a wire.

- Turn the crankshaft with the starter.

- If there is a spark, then the IKZ is working.

Let us remind you that you can find a problem in engine operation by independently measuring the pressure in the fuel rail, or by checking the compression in the cylinders.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

see also

Comments 41

Here's what to do if the spark plugs are changed 3-4t.km. back (to maintenance) When the problem arose for the first time, they changed the coil in the second cylinder, but after 3 days the problem came out again - they cleaned all the injectors, replaced the fuel filter, but after 3 days the same problem again...

does the CHECK appear on the dashboard?

Yes, it appears when starting it cold and warming up for a couple of minutes and there it is. I turned it off, started it, and it seemed to be running fine. It started even without checks, it just started and stalled right away, there were still frosts (automatic start), it started again normally. Then it started to start and stalled not immediately, but after some time (also with autostart) it was back to normal. Then I started it with the key - and saw a check; when I start it again, it disappears. The check came out about 10 minutes later, everything was fine again. And it simply stalled in traffic. Well, here’s the fun part - pp.userapi.com/c639719/v6...444/44518/bajmD9S-lkk.jpg The tidy allows you to connect an external temperature sensor, but of course I don’t have one, and I was very surprised. There are two options - either -40 or points

1) Regarding the temperature sensor, not all trim levels have it. Buy and connect) What is the error number?

2) Regarding the stalling, this is a jamb of the factory firmware, specifically for Grants with automatic transmission. Here is an excerpt from the Za Rulem magazine article “The same Jatco JF414E automatic machine works on the Grant and the mi-DO hatchback. The editorial mi-DO made me suffer: sometimes when braking or even in leisurely walking mode, the engine suddenly stalled. To restart it, it was necessary to put the machine into “parking”, and this can only be done by stopping completely! The reason for the vagaries lay in the fact that initially the engine calibrations were calculated for the version with a manual transmission, but for a car with an automatic transmission they were not the best fit: the mechanical losses of the transmission were not taken into account, which are much higher in hydromechanics. ————-We managed to push through solution to the problem at the factory level: a diagnostic unit was installed in the editorial car, which we drove with for several months. Decryption made it possible to catch errors, and mi-DO received new firmware for the engine control unit. Now this program has gone into series: with its appearance, other unpleasant symptoms of automatic Datsuns have disappeared. The engine speed no longer drops during heavy braking, and the cramps that shook the car when the air conditioning was turned on have disappeared.”

I have the same errors as in the subject - P0363 and P1302. I know that I don’t have a sensor, but why the hell did it start showing something there for the first time in 3.5 years? How did he see a non-existent sensor? Again, for 3.5 years I withstood hundreds of traffic jams and drove in all possible modes - no problems were observed. So the editors probably had problems with Mido. Although, of course, I would also like to get rid of cramps with Conder)

In general, they advise buying Bosch coils, but I also bought standard ones. Did you change it yourself or did they change it for you? Have you tried rearranging the coils? If you swapped the coils and the problem remained in the same pot, then unplug the wiring harness and check it, maybe a wire is broken somewhere.

1. 60t.km maintenance at the service center (changed spark plugs) 2. replacing the coil there 3. cleaning the injectors there. yes, but the wires have not been changed...

Read more: All about Motul oil

Honestly, I’d rather try to change places myself! I know these officers. dealers, they can also supply a coil from another car (

Granta luxury with automatic transmission In the evening I started the engine when it was cold for 30 seconds, in the morning the car started up and these errors popped up. Started it the third time. The engine was shaking quite a bit. I had a hard time getting to work. I read it at work)) D2. I ordered a Bosch coil and a set of spark plugs from Exist. After work, I start the car, and it, my beauty, picks up and starts in half a click, no shaking or errors. And to this day everything is fine. Apparently, after a short start, the spark plug was flooded when cold, but when driving and warming up, it dried out and everything worked well. By the way, the spark plugs are not cheap and I had to buy a set of spark plugs, they are kept in reserve.

On my car, 2 coils were changed, the spark plugs were not changed, now everything is fine. I don’t think 100% that the coils are flying because of the spark plugs. Defective coils

Unstable engine operation at idle and under load, detonation, jerking are the first signs of a malfunction in the car’s ignition system.

The process of self-diagnosis and repair is within the power of every car enthusiast.

( 1 rating, average 4 out of 5 )

Checking the ignition coil and its circuits on VAZ 11183, VAZ 21116 and VAZ 11186 Lada Granta engines

Parts and consumables:

- Probe with 1-2 W lamp

- Ignition switch contact group (if necessary)

- Ignition coil (if necessary)

- Bare wire

1. With the ignition switch OFF, disconnect the engine management wiring harness connector from the ignition coil as described here.

2. To check the coil power circuit, connect the tester probes to the middle terminal of the harness block and the engine ground. When the ignition is turned on, the device should record a voltage approximately equal to the battery voltage.

If there is no voltage at the middle terminal of the wiring harness block, then the wire connecting the block to the ignition switch is probably faulty or the lock contact group is faulty.

3. To test the coil control circuits, you can use a probe with a 1-2 W lamp. Relieve pressure in the engine supply system and do not replace the fuel pump fuse. Connect the probe probes to the middle and one of the outer terminals of the wiring harness block. If the control (and power) circuit is working properly, the probe light should blink frequently when cranking the crankshaft with the starter.

Otherwise, check for a break or short to ground in the wire connecting the outer terminal of the block to the controller terminal.

4. Similarly, by connecting the probe probes to the middle and other extreme terminals of the block, check the other ignition coil control circuit.

5. You can check the serviceability of the ignition coil itself on the engine by disconnecting the wiring harness block and high-voltage wires from it. For clarity, we show the test on a dismantled coil. It is necessary to connect the device wires to the module contacts, which are located at the edges. That is, to the extreme left and right. Using an ohmmeter, check the circuit for an open circuit.

If the multimeter readings do not change after connecting the wires, this indicates that there is an open circuit in the circuit.

6. To check for breakdown (short to ground) of the primary windings, connect the tester probes to the middle terminal of the coil and to the metal part of the coil body.

Checking the primary circuits of the ignition module for open circuits

In this case, you will need to carry out a different sequence of actions. And below I will try to describe this procedure in more detail:

- It is necessary to connect the device wires to the module contacts, which are located at the edges. That is, to the extreme left and right. You can take a closer look at the photo below.

How to check the 8 valve grant ignition module

On a Lada Granta car, 1 of 2 ignition systems can be installed, so one of them uses 4 individual ignition coils for each spark plug (for engine 21126 - Lada Priora). More detailed information about this system and operations for removing ignition coils from spark plug wells can be found in the article “Removing and installing ignition coils on a VAZ 2170 2171 2172 Lada Priora.” The second option is when all 4 coils are installed in one housing. This design is used for 8 valve engines of Lada Granta cars; further details about this option

To remove and check the ignition coil of 8 valve engines VAZ-11183, VAZ-11186 and VAZ-21116 installed on a Lada Granta car, do the following.

Symptoms of a problem

It happens quite often that the ignition coil fails for one reason or another. Most often, coil failure is caused by moisture, and due to the low location of the part itself, moisture quite often gets on it.

Malfunctions:

- Two cylinders (1-4; 2-3) do not work at once;

- The car jerks and accelerates poorly;

- Difficulty starting the internal combustion engine;

If your car has such malfunctions, then most likely the ignition coil is faulty.

Operations for removing and installing the ignition coil and checking it on a Lada Granta car

1. Disconnect the wire from the negative terminal of the battery.2. By pressing the plastic clip, disconnect the ignition coil power wiring harness block.

3. Disconnect the high-voltage wires from the ignition coil.

4. Remove the four screws securing the ignition coil to the bracket...

5. ...and remove it from the bracket.

This is what the ignition coil looks like when removed from the car. Pay attention to its markings so that you can purchase a similar one for replacement.

6. Perform the following checks. Checking the short to ground of the ignition coil windings of a Lada Granta is performed as follows: connect one ohmmeter wire to terminal “15” of the ignition coil (middle terminal of the coil), and the other to the metal part of its body. If the ohmmeter shows infinity, then there is no short circuit and the circuit is working.

Checking for an open circuit in the primary circuits of the ignition coil is performed as follows: connect one ohmmeter wire to terminal “1a”, and the second wire to terminal “15”. If the ohmmeter shows infinity, then there is an open circuit in the circuit and the coil is faulty.

Checking for a break in the secondary windings of the ignition coil is as follows: connect one ohmmeter lead to the high-voltage terminal of the 1st cylinder, the second one to the high-voltage terminal of the 4th cylinder. If the ohmmeter shows infinity, it means there is an open circuit and the coil is faulty. Carry out a similar check for the chain of the 2nd and 3rd cylinders.

Checking high-voltage wires of Lada Granta

is performed as follows: connect the ohmmeter wires to the terminals of the high-voltage wire, the resistance of the wires should be less than 15,000 Ohms. If the resistance is greater, then the wire is faulty.

Connect high-voltage wires to the coil terminals in accordance with the cylinder numbers indicated on the coil body.7. Install the ignition coil in the reverse order of removal.

The ignition system (IS) is the most important unit of a modern car, which ensures the timely occurrence of a spark. The system consists of a large number of parts, on the serviceability of which the entire operation of the system depends. The article discusses the main components of the SZ Lada Largus and Granta: ignition lock (IZ), ignition coil (IC).

Wiring diagram

Many people wonder how to connect high-voltage wires; most often this question arises after replacing spark plugs. It is necessary to connect the wires in strict sequence, but if they are mixed up, the car may not operate correctly or may not start at all.

To connect the wires correctly, you need to know the cylinder counting order. On the Grant, the cylinders are counted from the timing belt from left to right, that is, the leftmost cylinder will be number one, and the rightmost cylinder will be number 4.

There are 4 pins on the coil, which are marked with numbers. Each number indicates a cylinder number. The wire of the first terminal should be connected to the spark plug of the first cylinder, etc.

Ignition switch and features of its replacement

The ZZ is secured with one screw and is located on the steering column on the right under the steering wheel. Its design includes a locking device and a contact group. They are interconnected, working synchronously, and are activated using the ignition key.

When diagnosing faults in the electrical circuit, it is necessary to check whether the contacts close correctly when the position of the key changes. If any irregularities in the operation of the ignition protection are detected, it should be replaced (the author of the video is Renault Repair).

The procedure for replacing the ZZ on the Lada Largus consists of the following steps:

- Before work, disconnect the negative terminal from the battery to turn off the power supply to the car.

- Next, remove the steering column casing.

- At the next stage, by releasing the latch, we disconnect the connector with the wires of the contact group.

- Then, inserting the key into the ignition switch and setting it to the first position, remove the 33 wires from the dashboard.

- Next, unscrew the bolt that secures the ZZ.

- Use a screwdriver to press out the latches and remove the 3Z from the housing.

- We dismantle the faulty unit.

- Having installed a new spare part, we assemble it in the reverse order.

After replacement, we check the operation of the locking device by changing the position of the key.

Instructions for repairing and replacing the ignition coil

Removing and replacing short circuits is carried out according to the following algorithm:

- First you need to de-energize the car by disconnecting the negative terminal of the battery.

- Having released the latch, you need to disconnect the block with the wires coming from the controller.

- Then the high-voltage wires should be disconnected from the short circuit.

- Next, unscrew the screws securing the ignition module to the bracket and remove it from the bracket.

- The new module is installed in place of the old one. Next, perform the reverse steps of removal.

Photo gallery “Replacing the ignition coil”

Brand tour

A significant number of OEM reels are in fact produced by the companies that will be listed. This does not mean that there is no point in taking the original. Rather, you gain time by almost immediately selecting the spare part you need, installing it and getting back on the road.

Of the expensive goods, it is worth paying attention to those that are in boxes with the names of the following companies : Valeo (France), Beru (Germany), Magneti Marelli (Italy). The quality of the coils from these companies is very high, but the price, as they say, is steep.

Coils from these companies are very popular: Bosch (Germany), NGK (Japan), Tesla (Czech Republic).

A budget solution can be reels from the Czech company Profit, as well as the well-known Danish JP Group. They will have to be replaced more often than more expensive devices, but even in this case their purchase will be profitable.

Self-diagnosis of the module

You can check the module in the following ways:

- Checking for weight. To carry out the test you will need a multimeter. The tester should be set to resistance measurement mode. One probe of the tester must be connected to pin 15, and the second one must be shorted to the housing. If the unit is working properly, the resistance should tend to infinity.

- Checking the primary windings of the short circuit. The primary windings are checked for breaks using a tester. To check, you need to connect the probes of the meter to the outer contacts on the short circuit. If the resistance tends to infinity, this indicates the presence of a break in one of the windings.

- Checking secondary windings. Since there are two windings, the test is carried out in two stages. First you need to check the short-circuit winding of cylinders 1 and 4. To do this, the multimeter probes must be placed in the appropriate terminals. A resistance of about 5.4 kOhm is considered normal. If the resistance tends to infinity, then there is a break in the winding. The short-circuit winding of cylinders 2 and 3 is checked in the same way.

In case of malfunction, the ignition module is replaced with a new one.

Checking the ignition module of the injection VAZ 2110 8/16 valves

The top ten may have an eight-valve engine 2111, with a volume of one and a half liters, or an engine 21114, with a volume of 1.6 liters. The difference between them is in the ignition modules.

The module for a one and a half liter engine has the article number 2112-3705010, and the module with a volume of one thousand six hundred cubic meters has the article number 2111-3705010. They also differ in price. If the cost of the first ranges from one and a half thousand rubles to 2100, then the cost of the second is cheaper by about five hundred rubles.

Which one should you choose? The most reliable ones are produced in the city of Stary Oskol.

Module structure

It consists of two ignition coils and two high-voltage switch switches. The coils are designed to create high-voltage pulses.

In essence, it is a simple transformer that has two windings: a primary winding, with an induction voltage of approximately five hundred Volts, and a secondary winding, with an inductive voltage of at least twenty kiloVolts. Everything is placed in one housing with one connector for signal wires and four for high-voltage.

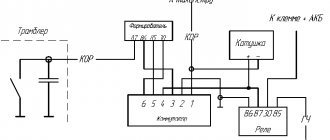

Schematic diagram of the VAZ 2110 module

The operation of the ignition module is based on the “idle spark principle”. The module is capable of distributing a spark in pairs: to the first and fourth, second and third cylinders when transmitting pulses from the electronic control unit.

Possible faults

You can ring the VAZ-2110 ignition module yourself.

The main task of the module is to supply current to the spark plugs. A high-quality spark is enough to ignite the working mixture. If there is no spark, then problems with the engine are inevitable in the form of a decrease in power, an increase in fuel consumption, dips during acceleration, the speed fluctuates, and the engine refuses to work during startup.

Symptoms and check

If one coil fails, two cylinders stop functioning. This is easy to notice, since the engine becomes heated at idle, starting is difficult, gasoline consumption increases sharply, and dynamics are lost.

We remove the connector from the VAZ 2110 module by slightly moving the latch and pulling the wire.

We check the voltage between pin 15 and the block ground.

Circuit for checking the primary windings

Secondary winding test circuit

Scheme for checking the module for short circuit

You need to make sure the spark plugs are working. They are unscrewed and the spark is checked separately on each of the spark plugs. A high-voltage wire is placed on the spark plug head. The spark plug is placed in such a way that the threaded part of the spark plug and the engine mass are in contact. If, when cranking the engine with the starter, the spark is very weak or absent altogether, then it needs to be replaced. If there is no result, you need to check the high-voltage wires. This excludes spark plugs, caps and high-voltage wires from the list of faults. This means it’s time to move on to checking the ignition module. How to do this?

Ignition module Lada Granta

The engine ignition system uses one ignition coil. It consists of two two-terminal ignition coils, made in a single housing. Sparking occurs in two cylinders simultaneously (1–4 or 2–3).

The ignition coil is connected to the spark plugs by four high-voltage wires with permanent tips.

2. Having released the latch, disconnect the wiring harness block 1 from the terminals of the ignition module 2.

3. Turning on the ignition, use a voltmeter to measure the voltage between terminal 15 and the ground of the wiring harness block. After taking measurements, turn off the ignition.

4. Disconnect the high-voltage wires from the spark plugs.

5. Using a 13 mm socket wrench, unscrew the two bolts of the upper fastening of the ignition coil bracket.

6. Using a 17 mm wrench, loosen the tightening of the lower bolt securing the ignition coil bracket and remove the bracket together with the coil.

7. Disconnect the high-voltage wires from the ignition coil.

8. Using an ohmmeter, we measure the electrical resistance between the central terminal 15 and the housing (bracket).

The device should show that there is no short circuit of the primary winding of the coil to ground. We sequentially measure the electrical resistance between the central terminal 15 and the outer terminals -1a and 1b. The resistance of each of the primary windings of the coil should be about 0.5 ohms.

When measuring small values of electrical resistance (about 1 ohm), it is necessary to take into account the internal resistance of the device, which can be determined by shorting the ohmmeter probes.

9. Using an ohmmeter, measure the resistance between the high-voltage terminals of the coil 1 and 4, and then 2 and 3. The resistance of the windings should be about 5.4 kOhm.

10. Using a 5mm hex wrench, unscrew the four screws securing the coil to the bracket and remove the coil

11. Install the ignition coil in the reverse order.

We connect high-voltage wires in accordance with the cylinder numbers marked on each wire and on the coil body next to the terminals.

This article will discuss replacing the ignition coil of one of the Lada Granta ignition systems. This ignition coil, as mentioned in the previous article, consists of two electrical coils that are controlled by the engine controller. It converts 12V pulses into high voltage voltage of several kV to produce a stable spark on the spark plugs.

One of the symptoms of a malfunction of the ignition coil of the 8 valve VAZ-11183, VAZ-11186 and VAZ-21116 engines installed on the Lada Granta is its unstable idle operation, decreased power, high fuel consumption and difficult starting at any temperature. If one of the ignition module coils partially fails, chaotic misfires in the cylinders are possible, usually in pairs.

So, let's start removing and checking the ignition coil on the Lada Granta step by step. Sequence of work

| 1. | When carrying out work on the electrical part of the car, do not forget to de-energize the on-board network by removing the terminal from the battery. |

| 2. | The control wiring harness from the controller is connected to the ignition coil. It must be removed by pressing the latch. |

| 3. | After this, disconnect all high-voltage wires from the ignition coil |

| 4. | The ignition coil module is mounted on a bracket and secured with four screws. Unscrew them. |

| 5. | We remove our reel from the bracket |

| 6. | There is a marking on the end of the ignition coil module. Remember it or write it down if you are going to buy a new one, so as not to make a mistake when choosing a similar one. |

Below are several procedures for checking the Lada Granta ignition coil for serviceability.

Reviews

| № | Positive |

| 1. | Victor: I’ve been driving Grant for the second year, no complaints, the ignition works properly. Even in winter the car starts with a half turn. |

| 2. | Vasily: I strictly adhere to the manufacturer’s recommendations, carry out scheduled technical inspections, and buy original consumables. |

| 3. | Gennady: at 50,000 km the spark plug of the second cylinder failed. I don’t consider this a defect, since the deadline for domestic parts is quite acceptable. |

| 4. | Ignat: I’m pleased with the build quality of the Lada Granta; for a budget car it’s very good. Minor flaws are always present, but they can be eliminated. |

| 5. | Vitaly: during the next maintenance, the mechanic pointed out the need to replace the spark plugs. Relatives traveled 65,000 km. The store advised me to buy BREMI 20466. I've been driving it for two months, no complaints. |

| 6. | Igor: in two years of driving the Lada Granta, I replaced several spark plugs once, and there were no more breakdowns. I believe that careful treatment of the car and original parts are the main factors that ensure long service life. |

| 7. | Vasily: I’m happy with my car, it hasn’t let me down once in two years, I haven’t made any investments other than scheduled maintenance. |

| Negative | |

| 1. | Victor: the first time the ignition module flew for 45,000 km, it was replaced under warranty. Second time at 75,000 km. I bought BREMI 20466 in the store. The cost is 300 rubles more, but the quality is good. |

| 2. | Gennady: I do not recommend purchasing a domestic Lada Granta. The car is crude, there are many flaws and defects. I am considering the option of Renault Logan. |

| 3. | Dmitry: I’m dissatisfied with the car, there are a lot of comments, shortcomings, there is a defect. |

Ignition coil malfunction factors

When the first signs of a breakdown appear, inexperienced owners first of all suspect the ignition switch or high-voltage wires as the culprit. Owners of Lada Kalina with experience recommend a balanced approach to resolving the issue. How to check the fault? If the coil fails, the dashboard will remind you of this by means of an indicator light.

A voltage surge or a short circuit inside the unit can cause damage to the spark plugs. In this case, the spark will not be able to generate correctly between the electrodes.

Device failure can also be caused by the following factors:

- the car getting into an accident, as a result of which you can observe the destruction of some components of the ignition unit;

- the car was struck by lightning;

- the previously completed repairs turned out to be of poor quality;

- use by the owner of non-original components in the designated system;

- ignoring maintenance intervals.

Regardless of the reasons, the owner of the Lada Kalina should diagnose the ignition system in detail. Sometimes a problem can be generated by the influence of several negative factors at the same time. This situation warns an inexperienced driver to tend to independently search for and eliminate breakdowns, because there is a likely risk of forced failure of other known-good components.

Signs of breakdown

Below we will consider the main signs and symptoms of malfunctions, as a result of which the coils heat up due to the passage of current and voltage through them, burn and burn out:

- From time to time the engine starts to misfire, if the problem is not solved, failures appear more often. Sometimes dips can appear at certain speeds.

- Another sign is that when the driver presses the gas pedal sharply, a loss of power may be felt.

- If there is no pulse, another symptom of a malfunction will be signals from the on-board computer. If the Check Engine light comes on on the dashboard, you should perform a more thorough diagnosis of the car yourself.

- The device itself gets quite hot.

- If you start the engine in cold weather, the unit will start to stall when you try to start it. These triplets are especially pronounced in rainy weather.

- At some point, if the device stops receiving impulses in the form of current or voltage and the weak coil simply burns, it will be impossible to start the engine at all (video author - vassilij pavliuk).

Operational Aspects

Frequent cases when owners call for service are when the coil fails or does not function correctly. You can also diagnose the ignition module yourself. To do this you will need to acquire the appropriate equipment. One such diagnostic tool is a multimeter. It is used to measure the actual resistance value at the coil terminals in the 8-valve versions of the Lada Kalina, as well as in the 16-valve version. In order for the results of measuring actions to have maximum correctness, the procedure should be followed at least twice.

Damage to the ignition system can occur in any part of the circuit. This circumstance requires maximum care and attention during diagnostic procedures. The check begins with making sure that the winding is connected correctly to ground. Now let's diagnose the central terminal of the coil. We apply the positive contact of the device to it, and connect the negative contact with the vehicle ground. We look at the screen. If there is a symbol of infinity resistance, then this indicates the absence of a short circuit on this section of the circuit. From this information, the owner must conclude that the ignition module is working.

Now we connect the device with the terminals of the module located at the edges. A specific parameter on the screen indicates the presence of a malfunction inside the LADA Kalina ignition switch. If a defect is not found here either, then the next step will be to diagnose the secondary winding of the coil. We place the ignition module in front of us so that both contacts are facing us. We connect the diagnostic device with the terminals for the 4th and 1st cylinders. Having made sure that there is no malfunction (short circuit), we proceed to checking the circuit for the 2nd and 3rd cylinders. There should also be no short circuit here.

Symptoms of malfunction

More often than not, the bobbin does not suddenly fail. This is usually preceded by a number of warning symptoms.

The main symptoms of a faulty ignition coil:

- misfires in one or more cylinders, they can be determined using a scanner by the presence of the “triple” effect of the engine;

- the appearance of “breakdown tracks” on the housing can be determined visually when starting the engine in the dark;

- the occurrence of cracks and chips in the dielectric zone;

- overheating of the structure;

- burning of rubber tips of high-voltage wires;

- oiling, contamination.

If the above symptoms appear, you should consider purchasing a replacement device. You can't stand by and watch an ignition coil die. In the event of a sudden coil failure, further independent movement will be impossible (unless you have individual coils installed).

Ignition coils