Linear dimensions of Lada Granta

Dimensions of Lada Granta door connectors

Dimensions of the engine compartment of the Lada Granta car

Dimensions of the windshield frame of the Lada Granta car

Dimensions of the rear window frame of the Lada Granta car

Dimensions of the trunk door opening of the Lada Granta car

Dimensions of the underbody of the Lada Granta car

From this article you will learn the dimensions of the Lada body and its features. Our domestic designers have finally managed to carry out high-quality body engineering that meets international standards. Finally, the torsional rigidity (TR) of the bodies of Lada Largus, Kalina, etc. and other features, to the envy of previous VAZ models, have become much higher. This means that now domestic models can easily compete with foreign cars in terms of body endurance.

Fuse and relay block: decoding

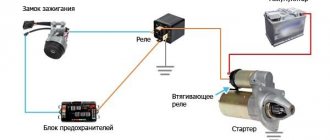

Priora is equipped with three mounting blocks, two of which contain both fuses and relays.

The first of them is located at the driver’s left foot, near the dashboard. To open it, you need to turn three latches 90 degrees. There is another block under the hood. Its place is near the expansion tank. As with the following, you will need a Phillips screwdriver to remove the cover. The last additional unit occupies a place near the central tunnel on the front passenger side. Fuses are designated by the letters F, and relays by K.

Features of the bodies of “Ladovo” models

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Since we started with QOL, let’s continue this topic. For the frame of Ladovsky models without glued glass, the quality of life is 14 thousand N*m/degree, which is a very good mark. And with glass this figure is even higher.

The testing of the Lada body in the rear turned out to be especially good. Thus, in the rear door opening, after a tough diagonal pressure test, the changes were recorded as only 1.5 mm, whereas on most foreign cars the same figure was 5-6 mm.

The body design of the Lada Largus and other similar models fundamentally complies with current European standards in terms of protecting passengers and the driver. The front subframe on Ladovsky models is one of the most important body elements responsible for this indicator. It is even considered an auxiliary spar, significantly increasing the strength of the body, as well as absorbing impact force.

The high quality of life of the Ladovsky body also has a beneficial effect on obtaining high-quality sound comfort in a car showroom. The frame does not twist over bumps and bumps, no deformations or anomalies occur between the interior and body elements, which ultimately has a positive effect on the absence of squeaks.

Note. Of course, in addition to the quality of life indicator, the quality of interior elements also affects the high level of sound comfort. They were obtained through proper calculation so as not to come into contact with the body in places where squeaking might occur. This was achieved by fixing the plastic components with special fasteners and minimizing the various gaps that arise one way or another between them and the body.

A lot of original parts, interchangeability of interior elements between Ladovsky models, enlargement of some parts of the body - all this was only a plus. In particular, the increase in some body elements led to a decrease in their number, which reduced production time and had a positive effect on performance.

Lada Largus

Called a budget station wagon with increased cross-country ability. The body was assembled based on Dasia/Renault Logan. The car was initially adapted for the market of Eastern European countries.

Even in the basic version of Logan, engineers took effective measures to enhance anti-corrosion protection, using protective inserts for the wheel arches. In addition, anti-corrosion and anti-gravity protection is installed over larger areas than before (at Samarov’s vehicles), with a thicker layer of mastic.

Here are some more innovations:

- The engine compartment is well protected. Additional protection was used correctly;

- The front suspension reinforcement has been increased. This was achieved through the use of leverage;

- The washer reservoir has become larger and holds more fluid;

- The wheels received protective aprons;

- The change got a torpedo;

- The bumper and radiator grille have been modernized.

It is noteworthy that the station wagon is made in 2 body versions: 5-seater and 7-seater. In addition, a van is also produced. The price of cars is low - only 350 thousand rubles and good comfort. When compared with foreign cars, the cost is heaven and earth.

In general, the Largus exterior is designed in such a way that it makes it possible to rightfully call the car roomy. A large family, along with bags and suitcases, as well as pets, fits comfortably inside. As for the design, the abundance of straight lines gives the car some speed and dynamism to the slightly clumsy family station wagon.

Height with rails is 167 cm, which is 10 cm more than Dasia Logan. The remaining sizes are also quite individual and do not copy “anyone”.

Lada Kalina

A car with 4 body types: sedan, regular 5-door hatchback, station wagon and sports hatchback.

"Sedan" version

Let's start with the sedan:

- From the new family of Kalina cars, AvtoVAZ is produced;

- The modern elegant appearance and comfortable interior are called the root reasons for the sedan's good sales;

- It has good handling at high speeds;

- It maneuvers well in the city traffic rhythm;

- Practical and incredibly convenient for daily use;

- The sedan body received wedge-shaped silhouette lines, visually creating the image of a strong, brutal car;

- The opening angle in the luggage compartment has been increased by 120 degrees, which makes loading easier. Inside the trunk, the manufacturer has wisely provided special loops that allow you to secure the cargo being transported.

The device of the VAZ 2170 Priora car

- Repair manuals

- Repair manual for VAZ 2170 (Priora) 2004+.

- Car device

1.0 Car structure General information about the car Passport data Car keys Controls Instrument panel Instrument cluster Trip computer Heating and interior ventilation Device features Interior ventilation Cleaning windows from snow and ice Quick step...

1.1 General information about the car Small class car VAZ-2170 Lada Priora with a four-door sedan-type body (class C according to the international classification) is designed for operation at ambient temperatures from –40 to +50 °C on public roads with hard surfaces. The Lada Priora car is equipped with…

1.2 Passport data In the engine compartment, vehicle numbers are located in the following places: 1 – body identification number; 2 – identification plate; 3 – engine model and number. Vehicle identification number (VIN), engine model, manufacturer name, year of manufacture and information...

1.3 Car keys The car comes with two sets of keys, each of which contains two keys: one for the ignition switch (lock), the second for the door locks and trunk lid. This is what a set of car keys looks like: 1 – key for door locks and trunk lid; 2 – ignition key (learning key);…

1.4. Controls (Category). See the list of materials inside...

1.5. Interior heating and ventilation (Category). See the list of materials inside...

1.6 Ensuring a comfortable air temperature in the cabin If the windows in the cabin are cleaned, but the temperature in the cabin has not reached the desired temperature, do the following. 1. Set the desired temperature using knob 2. 2. Set knob 1 to the vertical position. 3. Select the required intensity of warm air supply into the cabin using a...

1.7. Doors (Category). See the list of materials inside...

1.8. Passive safety equipment on a car (Category). See the list of materials inside...

1.9. Seats (Category). See the list of materials inside...

↓ Comments ↓

1. Car structure

1.0 Car structure 1.1 General information about the car 1.2 Passport data 1.3 Car keys 1.4. Controls 1.5. Heating and ventilation of the cabin 1.6 Ensuring a comfortable air temperature in the cabin 1.7. Doors 1.8. Passive safety equipment on the car 1.9. Seats

2. Recommendations for use

2.0 Recommendations for use 2.1. Safety rules and recommendations 2.2 Running in the car 2.3 Operating the car during the warranty period 2.4. Preparing the car for departure

3. Problems along the way

3.0 Malfunctions along the way 3.1. The engine does not start 3.2 Malfunctions of the fuel injection system 3.3 Idle speed has disappeared 3.4. Interruptions in the operation of the 3.5 engine. The car moves jerkily 3.6 The car accelerates poorly 3.7 The engine stalled while driving 3.8. Oil pressure dropped to 3.9. Engine overheating 3.10. The battery does not recharge 3.13. Knocks in the engine 3.16. Wheel puncture

4. Maintenance

4.0 Maintenance 4.1. General provisions 4.2. Inspection work 4.3. Lubrication and filling works 4.4. Diagnostic work 4.5. Repair and adjustment work

5. Engine

5.0 Engine 5.1 Design features 5.2 Possible engine malfunctions, their causes and solutions 5.3 Useful tips 5.4 Checking compression in the cylinders 5.5 Removing and installing the decorative engine casing 5.6 Removing and installing the engine splash guard 5.7 Installing the piston of the first cylinder to the TDC position of the compression stroke 5.8 Replacing the drive belt gas distribution mechanism and tension roller 5.9 Replacing the power unit supports 5.11. Replacing engine seals 5.13. Engine cylinder head 5.15. Engine repair 5.16. Lubrication system 5.17. Cooling system 5.18. Power supply system 5.19. Design Features

6. Transmission

6.0 Transmission 6.1. Clutch 6.2. Gearbox 6.3. Front wheel drives

7. Chassis

7.0 Chassis 7.1. Front suspension 7.2. Rear suspension

8. Steering

8.0 Steering 8.1 Design features 8.2 Possible steering malfunctions, their causes and solutions 8.3. Steering column 8.4. Steering linkage 8.5. Steering gear

9. Brake system

9.0 Brake system 9.1 Design features 9.2 Possible malfunctions of the brake system, their causes and solutions 9.3 Bleeding the brake system hydraulic drive 9.4 Removing and installing the vacuum brake booster 9.5 Replacing the brake pedal axle bushings 9.6. Main brake cylinder 9.7. Front wheel brakes 9.8. Braking mechanisms of the rear wheels 9.9. Pressure regulator 9.10. Brake hoses and tubes 9.11. Parking brake

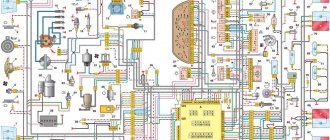

10. Electrical equipment

10.0 Electrical equipment 10.1 Design features 10.2. Battery 10.3. Mounting block (relays and fuses) 10.4. Generator 10.5. Starter 10.6. Ignition switch (lock) 10.7. Electronic engine control system (ECM) 10.8. Ignition system 10.9. Lighting, light and sound signaling 10.10. Windshield cleaner 10.11. Washer reservoir 10.12. Electric fan of the engine cooling system 10.13. Electric motor of the heating and ventilation system fan 10.15. Cigarette lighter 10.16. Instrument cluster 10.18. Electronic anti-theft remote control system 10.19. Immobilizer 10.21. Replacing sensors and switches

11. Body

11.0 Body 11.1 Design features 11.2 Possible body malfunctions, their causes and solutions 11.3 Removing and installing windshield frame lining 11.4 Removing and installing soundproofing upholstery in the engine compartment 11.5. Removing and installing bumpers 11.6 Removing and installing the fender liner and protective wing cover 11.7 Removing and installing the front fender 11.8 Removing and installing decorative sill trims 11.9. Hood 11.10. Trunk lid 11.11. Doors 11.12. Seats 11.13. Seat belts 11.14. Rear view mirrors 11.15. Interior fittings 11.16. Instrument panel 11.17. Heater 11.20. Body care

12. Applications

12.0 Appendix 12.1 Appendix 1. Tightening torques of threaded connections, Nm 12.2 Appendix 2. Fuels, lubricants and operating fluids 12.3 Appendix 3. Nominal filling volumes 12.4 Appendix 4. Basic data for adjustments and monitoring 12.5 Appendix 5. Spark plugs used on vehicles 12.6 Appendix 6. Lamps used on a car 12.7 Appendix 7. What you need to have in a car 12.8 Appendix 8. Tools used when repairing a car

13. Electrical diagrams

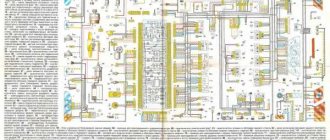

13.0 Electrical Diagrams 13.1 Diagram 1. Instrument Panel Harness Connections 13.2 Diagram 2. Vehicle Front Wire Harness Connections 13.3 Diagram 3. Engine Electronic Control System (ECM) Harness Connections 13.4 Diagram 4. Vehicle Rear Wire Harness Connections 13.5 Diagram 5. Light Harness Connections license plate light 13.6 Diagram 6. Left front door wiring harness connections 13.7 Diagram 7. Right front door wiring harness connections 13.8 Diagram 8. Rear door wiring harness connections

Lada Priora is becoming a thing of the past

AvtoVAZ is discontinuing the Lada Priora, or VAZ-2170, a model that replaced the tenth Lad family 11 years ago. In total, during this time, more than 860 thousand Priors were sold in Russia, and more than a million were produced. What do you remember about this car? Has this car become an independent cultural phenomenon? Is an era in the automotive industry passing away with Priora? “Kommersant” was looking for answers to these questions.

Despite the fact that there was no official message from AvtoVAZ regarding the discontinuation of Lada Priora cars, on May 22 the news became one of the most read on the Internet. Earlier, this information was disseminated by the Vedomosti newspaper with reference to a letter received by dealers: Priora will leave the assembly line in July 2022, it is not in the production plan. This scenario, we note, was previously discussed in a number of media at the end of last year.

One of the first “Priors” produced in 2007

Production of the VAZ-2170 sedan (official Lada Priora index) began 11 years ago, in 2007, and development began in 2002. The car became the successor to the VAZ-2110: in fact, the Lada Priora was a deep modernization of the “ten” family (the VAZ-2110 sedan, popularly called the “matryoshka”, as well as the VAZ-2111 station wagon and the VAZ-2112 hatchback), produced in the mid-1990s. x and replaced the 2108 family, or “chisel”.

In addition, the model used some technical innovations that were not available in the tenth family (for example, a 98-horsepower engine instead of the old 78-horsepower). The interior was designed by the Italian engineering firm Carcerano Creative Engineering.

One way or another, in 2008 the five-door Lada Priora hatchback entered the market, a year later the Lada Priora station wagon appeared, and in 2010, production of the small-scale Lada Priora Coupe model began at AvtoVAZ pilot production. In 2011 and 2013, the popular family of cars underwent a slight restyling, and in 2015, Lada Priora received an AMT robotic gearbox for the first time.

Auto expert Philip Berezin on Kommersant FM:

Priora could be called a people's car. A people's car in the Russian sense is still primarily about price. It is cheaper than the vast majority of comparable machines. They turned a blind eye to the fact that it still relates more to AvtoVAZ’s past than to its future. AvtoVAZ still has a very good wide network of dealers throughout Russia, which means that anyone who is not ready to repair a car on their own, if they wanted to turn to some knowledgeable people, could do it in almost any region of Russia. Accordingly, she was popular."

The cheapest Priora (Standard package, 87-horsepower engine) now costs 424.9 thousand rubles, the most expensive (Image package, 106-horsepower engine, power steering, climate system, daytime running lights) - 533.4 thousand rubles.

During its existence, Lada Priora managed to make its mark on the international arena in auto racing. In 2009, the Lada Sport team made its debut in the world racing championship in the Touring class WTCC (World Touring Car Championship), first using Lada 110 cars, which were then replaced by the more modern Lada Priora. Driving a Lada Priora in 2009, British racer James Thompson brought Lada Sport its first points in the WTCC, twice finishing in sixth position in races at the Italian Imola circuit. And earlier in the same season 2009, Lada Priora became the official safety car of the WTCC stage in Portugal on the street circuit in Porto - before that, Russian cars had not been represented in official positions in races of this level.

How to remove and replace the relay and fuse mounting block on a Lada Priora

Removing the fuse head located in the engine compartment is quite simple. The procedure should be followed.

- Open the panel cover by unlatching the fasteners.

- Unscrew the housing mounting bolts.

- Remove all fuses in sequence.

- Using a paperclip or awl, unclip the wire terminals.

- Remove the wiring from the housing.

- Remove the panel from its slot.

For ease of reassembly and simplified maintenance of the unit, the location of all wires and their installation sequence should be marked.

Sound insulation of the Priora engine compartment is done independently

Priora soundproofing of the engine compartment, starting from the partition

Soundproofing a Priora is a process that does not require you to have car repair skills, so anyone can do it themselves in a matter of hours. You just need to know the necessary materials, tools and the procedure to perform the actions. You also need to be attentive; the resulting quality of sound insulation depends on your attentiveness when performing the work, and our instructions will help you deal with the rest. Lada Priora is today the newest model in the VAZ family, however, Priora, like other domestic car models, has such an inherent drawback - too high a noise level inside the cabin. The main source of this noise is, of course, the engine. To cope with this nuisance and make your car trips more comfortable, the solution would be comprehensive sound insulation for the Lada Priora engine compartment. When soundproofing the engine compartment, the following feature is taken into account - in order to achieve maximum effect, it is necessary to insulate the engine shield on both sides - both in the engine compartment and inside the cabin. To do this, you will have to remove the dashboard and disassemble everything that prevents you from gaining access to the shield.