This article will help answer all the questions about switching from one brake to another. It will also help you figure out what kind of brakes you currently have. To do this, consider the stock front brakes for front-wheel drive VAZ: 2108-21099, 2110-2112, 2113-2115, Kalina, Priora, Granta

R13 not ventilated

They were installed on the SAMAR and SAMAR-2 families, as well as on the 10th family (only with an 8-liter carburetor engine).

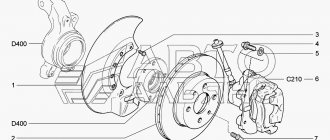

Explosion diagram Caliper

Visually, they can be distinguished by the lack of ventilation on the brake discs, in addition to the characteristic 2108 boot.

R13 ventilated

They were placed on families 10, Kalin, Grant exclusively with 8kl.

engine. Explosion diagram Caliper

Visually, it is easy to distinguish from 08 by a wider disk with ventilation. Brakes from R14 can be visually distinguished by the brake disc boot ratio.

R14 ventilated

They were installed on families 10, Prior (even with 8kl. ICE), Kalin, Grant with 16kl.

engine. Explosion diagram Caliper

Visually easily determined by the ratio of the brake disc boot. The disc will completely cover the boot. There is another option, remove the fixed bracket and 2112 should be stamped on it. In addition, it is simply impossible to install wheels of 13 radius.

R15 ventilated

They were placed on the Kalin and Grant families from 16kl.

engine in the sport version. Explosion diagram

Standard R13″ ventilated calipers are used (movable caliper 2110, fixed caliper 2110 which is machined to fit a wider brake disc).

And to extend the guide to a larger radius, the plant uses “bone” adapters

When installing them, you need to file the ears on the fist

There is another option that is almost factory-made. Install the Volga calipers using a special spacer. They have their own brake pad, which, in addition to everything, has an even larger area compared to the VAZ one.

RESULT:

1) When moving from R13 non-ventilated to R13 ventilated, you will need: - Caliper bracket 2110 movable 2110-3501017 - Caliper bracket 2110 fixed 2110-3501155 - Brake disc housing right VAZ-2110 (14 inches) 2112-3501146 - Brake disc housing left VA Z -2110 (14 inches) 2112-3501147 — Brake disc VAZ 2110 (13 inches) 2110-3501070 As you can see, we will need brackets, boots and the brake discs themselves. You can leave the old calipers.

2) When moving from R13 non-ventilated to R14 ventilated, you will need: - Caliper bracket 2110 movable 2110-3501017 - Caliper bracket 2112 fixed 2112-3501155 - Brake disc housing right VAZ-2110 (14 inches) 2112-3501146 - Brake disc housing left VA Z -2110 (14 inches) 2112-3501147 — Brake disc VAZ 2112 (14 inches) 2112-3501070 As you can see, we will need brackets, boots and the brake discs themselves. You can leave the old calipers.

3) When switching from R13 ventilated to R14 ventilated, you will need: - Caliper bracket 2112 fixed 2112-3501155 - Brake disc VAZ 2112 (14 inches) 2112-3501070 As you can see, we only need a movable bracket and the brake discs themselves. The calipers can be left as old, the boots were originally designed for R14 brakes, the movable caliper remains the same.

4) When switching to R15 ventilated ones, you will need: - Movable caliper bracket 2110 2110-3501017 (but it needs to be sharpened) - Fixed caliper bracket 2112 2112-3501155 (only if you have R13 not ventilated) - Spacer for the fixed bracket - Disc 15 inch brake

IMPORTANT: after installing R14 brakes, you will definitely have to switch to R14 wheels or a larger radius!

Minimum permissible thickness of brake discs:

For ventilated 17.8 mm For non-ventilated 10.8 mm

Brake pads

For all the brakes described above, there is only one type of pad - 2108. All other differences: (the presence of a wear sensor, friction material,

but not thickness

, its location, various grooves and grooves already depend on the manufacturer).

From personal experience I will say that after switching to R13 ventilated brakes, braking became more effective, squeals when braking almost disappeared. Due to better cooling of the brake disc, its volume and weight increase and heat dissipation becomes faster. When switching to R14, braking becomes even better, especially noticeable at high speeds, due to the increase in the friction surface (the volume and mass of the disc still increases) and the removal of the point from the center of rotation (to put it roughly and simply, the “effect of increasing the shoulder”). If you install a brake disc with perforations and grooves, the braking performance will further increase due to the removal of water and friction material of the brake pad from the contact patch.

Expensive foreign cars are equipped with disc brakes on all wheels as standard, which allows them to confidently brake from high speeds. An obvious disadvantage of domestic cars is the not very effective braking system, especially during dynamic driving. How can this state of affairs be corrected?

Analogs

Below is a table that contains data on the most popular manufacturers of foreign similar spare parts. They are distinguished not only by diameter and price, but also by quality; Almost all of them are sold in sets.

| Brand | Country of Origin | vendor code | About the product | Price |

| Design Service | Russia | 2172-3502000 | An inexpensive set of wheels for the VAZ 2112 modification with ABS, the parts are fully certified, the set includes, in addition to the main products, all consumable components | 21-22 thousand |

| Tornado | Russia | 2108-3502200-12, 2108-3502200-08 | Products with the first article are installed on VAZ 2112 equipped with ABS, and parts with the second number are installed on cars without this system | 15-15 thousand depending on the type of part |

| Lucas | Germany | FR-00000627 | Wheels of size R14, designed for cars with a simple parking brake, are highly reliable, have a long service life, and are fully compatible with a number of AvtoVAZ models | 18-18.5 thousand per set |

Analogs

When choosing front discs, you can also pay attention to more expensive similar parts from foreign manufacturers. Information on them is collected in the table below.

| Brand | A country | vendor code | Peculiarities | Price in rubles |

| Brembo | Italy | 09.8903.75 | Corrosion-resistant products, the surface has a wear marker, the parts provide effective braking even over a short distance, do not deform upon impact, and are therefore suitable for car owners who value aggressive driving | 3000-3200 per piece |

| ATE | Germany | 24.0320-0142.1 | Improved design with a multi-functional groove, the part provides comfort when decelerating, wears out slowly | 2700 per unit |

| Allied Nippon | Japan | ADC 1712V | Lightweight, wear-resistant and corrosion-resistant products, designed for harsh operating conditions, slightly susceptible to the negative effects of high temperatures | 1800 per piece |

| Hofer | Germany | HF130218 | Inexpensive, but high-quality perforated discs with notches and grooves, have good resistance to friction and mechanical shocks | 2000-2100 per part |

Did you like the article?

Like and subscribe to the channel!

This way you will receive more interesting and useful information.

This question is often raised on various automotive forums. Unfortunately, there is no easy answer to this question, so we will show you the pros and cons and leave the choice up to you.

For example:

A typical large sedan, weighing 1690 kg, is traveling on the highway at 134 km/h and you need to brake suddenly. Let's assume that a regular average tire can withstand an acceleration of about 0.85 G until it skids out. We will brake at 0.81 G to avoid wheel lock-up. The car will travel about 87 meters to a complete stop and will generate 1170 kW of kinetic energy. All this energy must be transferred through the braking system to stop the car. When you transfer that much energy in such a short period of time (4.7 seconds), a significant amount of heat is generated and the mass of the brake rotor plays a critical role in this case.

Original

Factory wheels are produced by the Autoreal plant, they have article number 2112350107002 and are sold both individually and in sets. The cost of one part is 850-1000 rubles, depending on the store and city. In addition, in the assortment you can find disks with code 21123501070, they are produced by the same company, the price of such a set varies between 2.2-2.5 thousand.

The products are of good quality and can be found both in regular spare parts stores and online catalogues. Many car owners argue that it is better to purchase parts in a simple store, where you can personally check them for quality.

How much do 17-inch wheels weigh?

What is the difference in kilograms between stamped, cast and forged wheels, the scale will show. A stamped iron wheel in size 7.0×17 weighs 12 kg 880 g. In the same size, a cast alloy wheel weighs 10 kg 780 g. The weight of a forged alloy wheel in size 7.5×17 is 9 kg 700 g.

The difference in weight between a stamped and forged wheel is 3 kg 180 g. The cast one beats the stamped one by 2 kg 100 g. If you multiply the difference by four, you get a mass that can be thrown off the car. And this difference will affect the dynamics of the car.