Throttle sensor malfunctions lead to unstable operation of the car engine. That the TPS is not working correctly can be understood by the following signs: unstable idle, decreased car dynamics, increased fuel consumption and other similar troubles. The main sign that the throttle position sensor is faulty is jumping speed. And the main reason for this is wear on the contact tracks of the throttle valve sensor. However, there are a number of others.

Checking the throttle position sensor is quite simple, and even a novice car enthusiast can do it. To do this, you only need an electronic multimeter capable of measuring DC voltage. If a sensor fails, repairing it is most often impossible, and the device is simply replaced with a new one.

Purpose of the throttle position sensor

This sensor transmits data to the electronic engine control unit about the position of the bypass valve in a certain time period. The operation of this unit is based on the interaction of AC and DC converters.

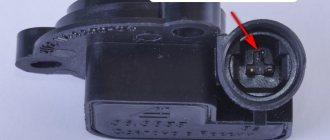

The highest value of the total resistance of the converters is at the level of 8 ohms. The design of the remote sensing sensor has three contacts. The first and second contacts receive a current of about 5 V, and the third contact is connected to the controller and performs a signaling function.

DPD3 is located on the throttle body. The device receives signals about the opening and closing of the passage channel. The resistance index of the part changes to satisfy the following conditions:

- when the damper is open, the voltage on the third contact will exceed 4 V;

- if the air passage is blocked by the remote control damper, then at the 3rd contact the current does not exceed 0.7 V.

The device controls all fluctuations in contact voltage and thus regulates the supply of fuel necessary for the formation of the air-fuel mixture.

Due to a malfunction of the sensor, the voltage reading most often goes beyond the established limits. This leads to disruption of the normal operation of the internal combustion engine, which can ultimately lead to breakdown of the unit.

Important: a sensor malfunction often causes the transmission to malfunction. Every car owner understands that restoring an engine and transmission is a process that requires a large investment of time and money. If symptoms indicating a breakdown appear, it is necessary to carry out a diagnosis.

Differences between an electric damper

How does this part differ from its mechanical counterparts? Its main differences lie in the absence of a mechanical connection between the gas pedal and the throttle valve, as well as in the regulation of idle speed by moving the damper itself.

But that's not all of its features. Since there is no rigid connection between the gas pedal and the throttle valve, the electronic system itself can influence the amount of torque of the internal combustion engine, even if the driver does not press the accelerator. All these changes occur due to the actions of the input sensors, control unit and actuator.

In addition to the TPS, the electronic control system contains an accelerator pedal position sensor, as well as a brake and clutch position switch. Thus, the engine control unit responds to all signals from the sensors and converts these impulses into control actions on the damper module.

Types of remote control position sensors

Today, the automotive industry presents two types of sensors:

- Contact potentiometer. Used by all vehicle manufacturers. The design has a slider and resistive tracks. It is rigidly mounted on the throttle pipe and connected to the axle. It works based on voltage dynamics, which contributes to the correction of the fuel supply ECU. When pressure is applied to the accelerator, the throttle opens, which turns the axis and moves the slider, changing the length of the resistive tracks of the electrical circuit.

- Contactless. Produced as an alternative potentiometer. It works based on dynamic changes in the influence of the magnetic field. The slider does not contact the working part because it has a permanent magnet. The electronic element reacts to changes. It is believed that such sensors are more durable and less likely to break. However, it is worth considering that they cost an order of magnitude higher.

It is believed that magnetoresistive sensors are more durable and less likely to break. However, it is worth considering that they cost an order of magnitude higher.

Replacing TPS

- Removing the sensor from the car is necessary to install a new one. First of all, you need to turn off the electrical power by disconnecting the battery terminals. The wires that are connected to the device also need to be disconnected. After unscrewing the mounting bolts, the TPS can be removed. When installing a new, original spare part, no adjustment is required.

- Direct installation of a new device. To begin with, the spare part is connected to the electronic control unit, after which the terminal is put on the battery. With this algorithm of actions, all factory settings will be saved. Attention: it is important to install only original devices. A sensor from another car model is not suitable. The necessary device can be purchased in special stores or from an official representative of the car brand. Buying online or on the market most often leads to the acquisition of counterfeit goods. The choice of seller should be taken carefully and seriously.

Types of TPS faults

Problems with the operation of the throttle sensor are associated with its design design, and are generally characteristic of most variable resistors. Car enthusiasts identify three main problems:

- Wear of the moving contact or film resistance.

- Backlash of fastenings.

- Oxidation of active contacts.

During the operation of the moving contact and interaction with the film resistance, constant friction arises, which, with prolonged exposure, wears out both the resistive layer and the surface of the active contact itself. Practice shows that the degree of wear directly depends on driving style and manifests itself extremely unevenly. Because of this, only in some places places are formed where the active contact does not reach the resistive layer, causing the voltage to disappear at the output of the throttle position sensor.

In this case, in older fuel-injected vehicles, fuel delivery is reduced and the risk of engine detonation increases. In modern fuel-injected internal combustion engines, the system blocks the operation of the power unit and activates the “check engine” indicator.

Oxidation of working contacts occurs exclusively under conditions of high humidity under the hood. As a result, the resistance may increase and the electrical contact may be completely broken.

Causes of malfunction of contact sensors

The main reason for failure is wear of the resistive tracks, leading to a complete or partial break in the electrical circuit. This leads to the transmission of incorrect data to the ECU.

Causes of malfunction of contact sensors:

- Wear of the resistor layer leads to loss of electrical contact. This can happen either at the beginning of the slider’s movement (typically when the voltage at the sensor output is low), or on another section of the tracks.

- Broken or worn tip.

- Wear of drive gears.

- Short circuit of signal or electrical circuits.

- Broken wiring, especially for VAZ cars, whose wires are not reliable.

- Oxidation of contacts and contamination of connectors.

Most causes can be diagnosed visually after disassembling the device and using a multimeter.

Regarding error P2135, which was mentioned in the previous section, its causes:

- poor ECU contact ground;

- oxidation of contacts in the connector;

- main relay malfunction;

- short circuit and other reasons.

Symptoms of a malfunctioning throttle position sensor

The throttle position sensor in the fuel system plays a “smoothing” role, and therefore, if it is working properly, then the car drives without jerking, smoothly, and demonstrates “responsiveness” when you press the gas pedal. If the TPS is faulty, then this can be determined by the following signs:

- The engine begins to start poorly;

- Fuel consumption increases significantly;

- The car drives jerkily;

- The number of engine revolutions at idle increases significantly;

- When a car accelerates, it happens with some delay;

- “Popping” sounds are heard from the intake manifold;

- The engine stalls at idle;

- The Check Engine light either stays on or comes on intermittently.

If at least one of the above symptoms appears, then it is likely that the TPS is faulty. As practice shows, in most cases, the breakdown of this part is associated with its natural wear. The fact is that the variable resistor present in the design of the throttle position sensor has a sprayed base layer, which the metal contact moving over it wears out over time. Accordingly, the TPS begins to produce incorrect data.

Experienced experts say that the surest sign that the throttle position sensor is faulty is the “floating” speed of the power unit in idle mode. If such symptoms are detected, then you need to contact a service station, or make the diagnosis yourself.

Non-contact TPS

Non-contact throttle position sensors can be of two types - with a Hall sensor and inductive.

Hall effect sensor

TPS with a Hall sensor allows you to receive a signal about the throttle position without physical contact. This makes such sensors more reliable and wear-resistant.

The Hall effect TPS consists of Hall sensors and permanent magnets that rotate around them. There is an air gap between the magnet and the Hall sensor.

The magnet is attached to the throttle shaft, whose angular movement is monitored by Hall sensors. When the damper turns, the magnets change their position.

Hall sensors detect changes in magnetic flux caused by the movement of magnets. The signal is transmitted to the circuit board, which is located in the electronic throttle body, and then to the engine control unit.

The signal sent to the ECU can be analog or digital.

Inductive sensor

Another way to measure rotational position non-contact is with a non-contact inductive type throttle position sensor. Such a TPS consists of a stator and a rotor.

The conductive rotor is a rotating part and is mounted on the throttle shaft. The rotor consists of one or more closed loops with a specific geometry, made of electrically conductive material. May be a round printed circuit board.

The sensor and board with signal processing chip are installed inside the electronic throttle body and are stationary. The stator consists of a standard printed circuit board and an application-specific integrated circuit.

The board contains the receiving excitation coils, as well as electronics for converting the input signal. When the rotor turns, a voltage is induced in the stator, which is transmitted to the ECU to determine the throttle position.

Comparison table of different types of TPS

| Resistive | Inductive | Magnetic | |

| Reliability | Contact principle, prone to wear | Contactless, good | Contactless, good |

| Price | Low | Average | High |

| Size | Big | Big | Average |

| Interface | Analogue only | Analog and digital | Analog and digital |

| Linearity | Very good | Very good | good |

| Reservation | Additional tracks but parallel wear | Additional tracks, sensors | Easy to install two redundant sensors |

Checking the performance of the TPS

If during operation of the vehicle at least one of the signs of malfunction of the throttle position sensor was detected, its functionality must be checked. To do this, the car owner does not require any special knowledge. It is enough to have a multimeter and know a clear sequence of actions.

The main thing to remember is that the Check Engine is a light that is installed specifically to signal the driver about a faulty engine. If it lights up, then you need to immediately contact a service station or fix the problem yourself.

If there are no problems, the light will light up when the engine starts and go out instantly when the diagnosis is complete. If the Check Engine light remains on, there is a problem with the system. In this case, you cannot do without an experienced specialist.

Regarding the identification of throttle valve malfunctions, the symptoms of which were identified during the operation of the car, there is a certain algorithm of actions:

- The first thing you need to do is turn off the ignition, inspect the instrument panel, notice whether the Check Engine indicator light is on or not, which signals the presence of problems. If the indicator does not light up, you need to climb under the hood and check the TPS.

- Next, you will need a multimeter - a special device to check the operation of the throttle sensor.

- It is necessary to determine the presence of a “minus”. In order not to discard each wire separately, it is worth piercing the necessary wires and measuring them.

- The search for “mass” is carried out in the same way. There is no need to turn on the ignition during the mechanism check period.

The purpose of performing preliminary actions is to check the availability of power to the PD sensor. The voltage depends on the make of the car. For example, for some machines it may be only 5 V, while for other models it may be 12 V.

Algorithm of actions for identifying TPS faults, the symptoms of which were identified while the vehicle was moving:

- you need to turn on the ignition and pierce the wires of the required chain one by one using a multimeter. The device display should show a voltage reading of 0.7 V;

- the throttle valve opens manually: the voltage value must be greater than 4 V;

- The ignition is turned off, one connector is discarded. In the area between the slider terminal and the wire (which remains), a multimeter probe is connected;

- Now you need to manually scroll the sector and observe the readings of the measuring device. If there is a smooth increase in values without sudden jumps, it means that the PD sensor is working normally. In the opposite situation, we can talk about damage (scuffing) of the resistor track.

These indicators affect the proper functioning of the electronic control unit (ECU), which controls the main operating processes of a car engine and the supply of fuel mixture to the injectors. If inaccurate numbers are supplied to the ECU, then the control unit will make incorrect decisions.

For example, the throttle valve is fully open, but the electronic device shows that it is closed. If such symptoms are present, this is an obvious malfunction of the throttle sensor and must be replaced.

How to clean and check injectors yourself

To clean the injector with your own hands, you need to prepare the following elements: a special means for cleaning injectors and a tube with an internal diameter of no more than 5 millimeters, as well as two identical wires, a car battery and any button equipped with large contacts, or better yet, a relay.

The injector is removed from the rack and connected to the battery. Before you close all the wires, you need to break the positive wire and install a button with a built-in relay in this place. After this, a small tube of cleaning agent is inserted into the nozzle, reinforced with a thick tube measuring up to 5 millimeters. After this, the button applies voltage, the nozzle opens, and the cleaning agent is released into the nozzle.

It turns out that during this process a complete simulation of the operation of the fuel injector occurs. Firstly, it is driven, and secondly, in this way its suitability for further use can be determined. A suitable injector is considered to be one from which fuel is sprayed and not poured. A leaking injector must be replaced or repaired.

The liquid must be run within 3 minutes. During this time, the part will be completely cleaned and will be suitable for further use. After cleaning, the nozzle is installed on the rail and inserted into the intake system. Before installation, do not forget to check the reliability of the seals. If they are visually in poor condition, then they need to be replaced. Try not to bypass the problem of rubber bands, as this will result in a fuel leak for you, and, as a result, an accelerated and useless increase in fuel consumption.

Never put off purchasing new seals until tomorrow. This must be done in advance and in accordance with the make and model of your car. Externally, a repair kit for two slightly similar injectors may differ noticeably.

How to fix a problem by cleaning the throttle body

Let's look at how to properly clean the damper step by step:

- First of all, you need to get to the throttle valve. The design of different modifications of the internal combustion engine is different, but, as a rule, it is first necessary to dismantle the air duct running from the damper to the air filter.

- Then you need to remove the throttle valve. You should unscrew the fastening bolts (from 2 to 4 pieces), and then disconnect all the connectors, including the one that goes to the absorber purge valve.

- You can clean the throttle body using carburetor cleaner. Specialized auto chemical stores offer a wide selection of different formulations, so you can always choose the best option in terms of cost.

- Thoroughly wipe the throttle body inside and out using your chosen product and a rag.

- If the car is designed with a protective grille, it also needs to be cleaned.

- Reassemble the assembly in reverse order.

Cleaning the throttle valve is carried out in such a way that its metal surface becomes completely light. Such cleaning will help improve the dynamic characteristics of the engine.

- How to clean the throttle body without removing it

Many car enthusiasts are interested in how to clean the throttle valve without removing it. Some service stations actually offer this service, but it should be borne in mind that effective cleaning of this part can only be done after dismantling the damper.

To clean the throttle valve without removing it, use a special intake tract cleaner. In addition, this procedure can be performed using EGR valve cleaning fluid, as well as WD-40 or solvents.

Algorithm for cleaning the throttle valve without removing it:

- Remove the air duct to provide access to the throttle valve.

- Spray the surface of the damper, which is in the closed position, with cleaning agent and wipe with a rag.

- Open the damper and clean the dirt from the side surface.

- It is necessary to ensure that the cleaning agent reaches all channels (rags are also used for cleaning).

Let us note once again that high-quality cleaning of the throttle valve can only be performed after its dismantling. When installing the part after cleaning, we recommend using a new damper gasket (its cost is quite affordable).

Manufacturers of cleaning products note that the procedure for servicing throttle valves without removal should be carried out every 7,000 - 10,000 km. Cleaning the damper with removal should be carried out at intervals of 30,000 - 50,000 km.

It is important to note that in most situations, after cleaning the damper, it is necessary to adapt it. For this, a special computer is used that connects to the machine's ECU. In addition, “learning” of the throttle valve can be carried out by performing certain manipulations with the ignition and accelerator pedal. In the latter case, it is impossible to give universal instructions, since the procedure will differ for cars of different brands. You need to keep this in mind when adapting the throttle valve.

Do-it-yourself TPS restoration

Graphite glue

I decided to remove and disassemble the sensor to check the integrity of the graphite tracks by eye. Having taken it apart, I saw that the graphite tracks were indeed erased; I cannot determine the degree of wear. It was decided to purchase graphite glue to restore the board tracks. I found the most suitable one in the Chip and Dip store, costing 150 rubles.

Restoring sensor tracks with graphite glue.

I removed the damper sensor and carefully cut it with a hacksaw because... There is no other way to open it, I carefully bent the board and applied a thin layer of glue to the tracks. I assembled and glued everything together, all that remained was to adjust the throttle position sensor, which I actually couldn’t do myself, even with a diagnostic adapter, a multimeter and probes on hand.

The next day I went to the service station to adjust the throttle position sensor. The slipping of the car was terrible; when changing gears in different positions, the revolutions jumped from 2500 to 4000 thousand.

The photo shows very worn tracks

At 100, the technician reset everything to the car’s factory settings and adjusted the throttle position. At idle everything was fine, but on the way home I noticed slipping from 2nd to 3rd gear. It wasn’t strong, for example, if switching occurs at 1800 it increases to 2000, if at 1700 it increases to 1900 thousand, but if you apply gas this does not happen.

I started reading because I had thoughts in my head about burnt (worn out) clutches because... On the day of visiting the service station, I had to drive for a couple of hours with terrible slippage, but soon I immediately discarded this reason.

I called the service station and again spoke in detail about the problem, the master suggested that I check the wiring and automatic transmission, and not blame the damper sensor, since I was only thinking about it, I went to disassemble it again.

The method that helped

This time, I did not remove the throttle position sensor itself, so as not to have to go adjust it again, but removed the damper completely from the car, bent the board with the tracks and carefully cleaned it of the graphite glue that I had applied before.

Inside the TPS there are graphite tracks along which the brushes move. The most effective way to repair

- this is to bend these brushes to the sides along a whole part of the paths, this must be done very carefully, I used thin tweezers and flat tweezers.

Don’t think of degreasing the tracks or lubricating them with anything special using cotton swabs and sponges. These brushes need to be carefully bent.

This time, I planned to solve the problem

bending the brushes onto entire parts of the TPD tracks. I assembled it, started it and went to check it out. The ride is smooth, there is no slipping, the speed remains at 1400, 1650 at 1900 thousand, etc. in general, everything is as it should be, you can make the repair yourself and revive the damper sensor before buying a new one, the main thing is to do everything carefully and slowly.

Damper cost, service life and measures to maintain it in good condition

Prices for throttle valves vary depending on the car model and the manufacturer of the spare part. On average, their cost ranges from 3,000 to 10,000 rubles. The resource of this part is designed for the entire service life of the vehicle. The need to replace the throttle valve may arise due to breakdowns of the motor and its systems, as well as due to a faulty sensor.

Most often, improper operation of the throttle valve is caused by carbon deposits on its elements. Contamination of the remote control leads to accelerated wear of its axis and loose fit of the part in the channel. As a result, control of the volume of air entering the engine is lost. To maintain the throttle valve in working condition, it is necessary to observe the frequency of cleaning it, as well as monitor the condition of the engine and its systems.

The service for replacing the emergency protection at a service station will cost from 900 to 1,500 rubles. In addition, for adaptation of the node you will need to pay from 500 to 700 rubles. Some car repair shops may offer restoration of your car's worn-out electronics or exchange for a refurbished spare part. The price of a restored part ranges from 5,000 to 6,000 rubles.

How to check TPS yourself?

It is quite possible to diagnose the throttle sensor without the help of specialists. All you need in terms of tools is a multimeter. So, turn on the ignition and look at the instrument panel. If the “Check Engine” light is not on, lift the hood and look for the damper sensor.

Now we take a multimeter in our hands and check for the presence of a “minus”. To do this, you need to turn off the ignition and find ground among the wires. This is not difficult to do. Then turn on the ignition again and find the power wire. This will ensure that the sensor is receiving power.

Replacing the throttle position sensor and adjusting the new device

In most cases, replacing the sensor is quite simple and you can do it yourself. The whole procedure consists of three main parts: dismantling the old faulty device, installing a new TPS, resetting the error from the ECU memory. In some cases, you will need to adjust the new device.

Actions must be carried out with the ignition off and the sensor de-energized. Unscrew the two fastening screws and remove the connector from the device. Hurray, the old sensor has been removed.

To install a new sensor, you must carefully connect the end of the throttle axis to the device seat. The holes must be aligned while turning the device in a circle. Next, you need to screw in the mounting screws and secure the connector.

To correctly reset the error from the ECU controller, you must leave the terminals disconnected from the battery for at least 8 hours. Within approximately this period, the controller's memory should be reset to zero. The most reliable option, if the first method does not help, is to contact a service center, where the problem will be corrected using a motor tester. On the other hand, you can risk continuing to use the vehicle in a “gentle mode”, hoping that sooner or later the ECU will reset the error on its own.

What to do next?

After this, we check the opening of contacts XX. They are located on the sensor connector at the top or bottom. We connect one of the wires on the multimeter to the contact, and we will move the damper with the second. If everything is fine, then with the slightest movement the voltage level on the device will change to the value on the battery. If the multimeter needle remains in place on the scale, you should check the serviceability of the variable resistor, which is located inside the TPS. What is this element and how to diagnose it? This resistor is a component of the damper sensor, which changes its resistance depending on the level of the pedal position. And it is checked as follows. To begin with, connect a multimeter to the remaining wire, turn on the ignition, and after that the flap is moved back very slowly. In this case, you need to carefully monitor the state of the needle on the instrument scale. There shouldn't be any jumps here. If they are, most likely the engine is malfunctioning.

Adjusting the new throttle position sensor

In most cases, modern sensors need to be configured after installation in the car. To do this, after installation, you should completely close the damper and connect the multimeter probes to ground and the TPS output. The device must be in voltmeter mode and connected with respect to polarity. Next, the sensor is rotated so that the tester shows the minimum voltage. In this position, the sensor must be firmly secured.

Sometimes, after this, you may notice high idle speeds. In such a case, it is necessary to “train” the ECU with new sensor settings. To do this, remove the terminals from the battery for 20–25 minutes and install them back only with the throttle valve closed. Then the ignition turns on for a few seconds, but the engine does not start. After 15–20 seconds of ignition operation, it can be turned off. The procedure must be repeated for the second round. During this time, the ECU controller will have time to save the new sensor parameters. The main thing is to use only original, good quality devices when replacing the throttle position sensor. Items of lower quality may be affected by temperature and distort the data.

The principle of operation of TPS with a potentiometer

The TPS sends information to the controller about idle speed, deceleration, acceleration rate and wide open throttle (WOT) status.

The TPS is a three-wire potentiometer. The first wire supplies a voltage of + 5 V to the resistive layer of the sensor, the second wire is ground. The third wire is connected to the potentiometer slider, which changes the resistance and therefore the voltage of the signal returned to the ECU.

Based on the received voltage, the control unit can calculate idle speed (below 0.7 V), full load (about 4.5 V) and throttle opening speed.

At full load, the ECU ensures that the fuel mixture is enriched. In deceleration mode (closed throttle and engine speed above certain rpm), the controller disables fuel injection. Fuel delivery is resumed when the engine speed reaches its idle speed or when the throttle valve opens. On some vehicles these values can be adjusted.

Instructions for adjusting and replacing the element

Adjustment

How to adjust the throttle position sensor (the process is described using the example of QG motors):

- First of all, you need to completely discharge the vacuum device; to do this, you can simply clamp it; if possible, you can use a compressor.

- Next, you need to disconnect the device connector.

- Using a multimeter, you need to check the resistance between pins 1 and 2. The tester probe, 0.1 mm thick, is connected to the device itself, as well as to the thrust bolt. As a result of the connection, the tester should show the presence of a circuit, and the resistance parameter on it will be 0 Ohm.

- At the next stage, the 0.25 mm probe is placed in a similar position. Thus, the electrical circuit should be interrupted, and accordingly, there will be no resistance on it.

To adjust the mechanism, loosen the bolt securing the regulator. By adjusting its position by rotating, you need to make sure that during further testing the tester produces the correct values, which we described above. When the adjustment is completed, the TPS must be securely fixed by tightening the bolt, and the readings must be diagnosed again.

Photo gallery “Do-it-yourself adjustment”

1. A tester is connected to the TPS contacts.

2. Readings are taken and adjustments are made.

Replacement

Replacing the throttle position sensor is done as follows:

- First you need to disconnect the power from the engine ECU.

- Then you should unscrew the bolt securing the device.

- The next step will be to remove the old and install a new regulator.

- Next, the TPS needs to be connected to the ECU, only after that you need to turn on the power.

Conclusion

A TPS failure is a serious situation for a car. This device is responsible for supplying fuel to the engine and, if malfunctioning, can lead to a critical situation. If signs of failure are detected, it is advisable to replace the sensor, but in some cases, repairs can solve the problem faster and cheaper. Follow the procedure and use only original spare parts.

Previously, we wrote about the symptoms that may appear when the throttle position sensor breaks down. But such symptoms often cause breakdowns of other sensors or engine components. Therefore, before purchasing a new TPS, the existing sensor must be checked for functionality.

The TPS is mounted on the throttle body. This sensor contains a variable resistor (or contact points, depending on the model) that transmits a signal to the electronic engine control unit. The sensor readings depend on the throttle position.

When the driver presses the gas pedal, the damper rotates, increasing the flow of air into the intake manifold. When the engine is running, throttle position (and data from other sensors) tells the computer how much fuel the engine needs at a given moment.

Therefore, without the correct signal coming from the TPS, problems arise with the fuel-air mixture. Note that checking the throttle position sensor is not very difficult. You will need information about the factory settings of the sensor, after which it is checked using a digital multimeter.

You can buy a multimeter in many stores; this simple diagnostic device will come in handy more than once.

The most common malfunction of the throttle sensor is wear, short circuit or open circuit in the electrical circuit or resistor. With the help of this article, you can understand how to check the TPS with a multimeter in just a few minutes. This will help you understand whether the element needs to be replaced or whether the problem is not with it.

Symptoms of a TPS malfunction:

- lean or rich fuel mixture;

- ignition problems;

- incorrect signals for other actuators;

- rough idle;

- failures during acceleration;

- twitching;

- stopping the engine.