The design of the VAZ 2110 fuel system

The fuel supply systems on cars with carburetor and injection engines are somewhat different. The design of the fuel system of VAZ 2110, 2111, 2112 does not differ depending on the model.

In the period from 1996 to 2000, carburetor engines were installed on these series. Fuel is pumped from the tank through a filter by a mechanical fuel pump driven by a camshaft eccentric and supplied to the carburetor. This element is designed to prepare a fuel-air mixture that enters the intake manifold and is ignited using spark plugs.

Diagram of the fuel system of a VAZ 2110 carburetor engine.

Unlike carburetor cars, in injection cars the gas pump is installed in the gas tank, and the fuel enters the ramp, which is equipped with a mechanical valve that regulates the pressure in the system. At the command of the electronic control unit, the injectors open and gasoline is injected into the intake manifold, where it mixes with air and, entering the combustion chamber, is ignited by the spark plugs.

The fuel supply system on eight- and sixteen-valve injection engines is not much different.

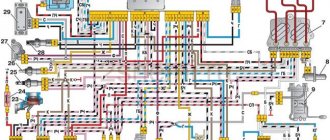

Diagram of the fuel system of the “tens” injection engine.

All places for mounting the mass of the VAZ of the tenth family

Location of masses in the car interior

1 – fuse block. 2 – near the driver’s right leg there is a shield that is attached with a couple of screws; after removing it, you will see that everything is there as in the picture. 3 – in principle, the situation is similar to the point described above, except that the shield is located next to the navigator’s left leg.

The stud in the dashboard behind the mounting block, in order to find it, you need to bend in a certain way. The headlight hydraulic corrector is shown there for reference; the ground pin is located above and to the left of it. Through this mass, the windshield wipers, heater fan (21124) and door lock activators are powered.

The console is on the right side, from here it is more convenient to check the very important ground pin, through which the bracket under the ECU is connected to the car body, and accordingly the reliability of the ground of the ECM and the cooling fan depends - this nut also holds the corner that supports the far part of the left panel of the console.

Weight of the Electric Fuel Pump (EFP) module and fuel level indicator. A black and white wire is attached to the left rear handbrake lever mounting bolt under the floor tunnel. The fuel pump is powered through this mass, and the accuracy of the fuel level reading also depends on it.

The ground is on the stud of the fuel pump flange; this wire most likely connects the pump housing to the fuel filter bracket and this was done for safety reasons to equalize the potentials of these two devices.

It is easy to find the ground of the electric fuel pump module without removing the tunnel; just fold back the mat, slightly bend or carefully trim the carpet of the floor behind the driver's seat below the ashtray of the rear passengers, without damaging the ground wire itself. Then the carpet easily falls into place and the cut is almost invisible.

Location of masses under the hood of a car

The battery terminal is large and thick with a large cross-section wire (approximately 16 sq. mm). Its thick part, about the thickness of a little finger, connects the negative battery and the engine. If the contact of this wire is unreliable, there may be a deterioration in the battery charge, a decrease in the starter rotation speed when starting, as well as problems in the ECM system, because the minus comes from the engine, from the studs on which the ignition distributor hung on carburetor cars.

The thin wire connecting the battery negative and the car body is the main connection for all electricity consumers in the car, and in carburetor modifications also for the engine. Through this connection, all the car's lighting equipment, radio and other devices are powered, depending on the year of manufacture of the car.

The connection point for the negative terminal of the battery to the engine block is connected to the upper stud of the thermostat, if you look behind the air filter. The cross-section of the wire was chosen based on the large current consumption of the starter; this wire can easily be traced by hand if it is led from the battery. The starter current flows through this wire, charging the battery, some sensors screwed into the engine block are connected through it

Nearby there is another ground connection point to the engine block, it is slightly higher and to the left. The 2112 engine has two brown wires connected to this place - this is the mass of the ECM, that is, the mass of the sensors, ignition module, ECU and cooling fan. The arrow below shows the engine (starter) ground wire from the battery.

The mass point under the adsorber is the mass of the right headlight and the mass of the right fog lamp.

Frequent breakdowns

A fuel pump malfunction can be caused by: poor quality fuel, clogged fuel filter, simple emptying of the gas tank, or how intensively the vehicle is used. Mechanical damage to internal components due to wear or poor quality of workmanship and materials cannot be ruled out.

Helping the fuel pump last longer is within the capabilities of any car enthusiast who follows a number of rules:

- refuel with high-quality fuel at proven gas stations;

- change the fuel filter in a timely manner;

- periodically clean the gas tank from accumulated impurities;

- Make sure that the fuel level in the tank is sufficient for the system to operate.

The last point is due to the fact that running the pump idle will lead to overheating and failure.

Principle of operation

The operation of the element is practically no different from the principle of operation of a mechanical pump. So, the element operates thanks to a core that is pulled into the solenoid valve. This action occurs until the system turns off the contacts for supplying voltage to the network. The element starts when the ignition is turned on (turning the key to the appropriate position). So, the VAZ-2112 fuel pump with 16 valves is supplied with 12V power. The mechanism creates in a couple of seconds the required pressure necessary to inject fuel into the injectors.

At the outlet, this indicator (pressure) reaches 0.4 MPa. The design of the element itself is modular. In addition to the pump, the unit contains an anti-drip glass, wires and tubes protected by a solid spring.

The pump itself has a diaphragm that moves up and down. As a result, a vacuum is created in the system. This helps open the pump suction valve. As the diaphragm moves upward, the inlet valve closes under pressure. This opens the injection element. It pushes fuel under pressure further to the injectors. The system also provides a return line. It serves to bleed unnecessary fuel back into the tank. Separate lines are provided for the return line.

Signs of fuel pump wear

A faulty fuel pump either works intermittently, that is, incorrectly, or does not function at all. Problems may occur due to severe wear or failure of other system elements.

Signs of a fuel pump malfunction that require checking its functionality are:

- engine failure to start;

- uneven operation of the power unit, it stalls and loses power;

- extraneous noises in the operation of the fuel pump or their complete absence.

Without diagnostics, it will not be possible to determine the nature of the malfunction, and during the test you must always move from the simplest to the most complex.

The vehicle makes noises you have never heard before

It is unlikely that you will be able to solve this problem yourself without disassembling and examining this element of the car in detail. Noises may occur due to the fact that the pump is nearing the end of its life and will soon have to be replaced. The second option, in which vibrations as well as extraneous sounds may appear, is that the filter mesh is dirty or a non-original filter is used in the system. In any case, extraneous sound will be one of the first reasons for the need to seek help from a professional auto repair shop. Contacting professional experts is recommended even if you have not noticed any other signs.

Diagnostics

If it is impossible to start the car, when the starter turns the flywheel perfectly and there is a spark, you should check the fuel supply. If the pump works and gasoline enters the ramp, then the cause should be looked for further. To initially check the operation of the pump, just open the tank lid and, turning on the ignition, listen, the characteristic pumping noise should sound.

You should not immediately change the unit; first you need to check the fuse responsible for the operation of the electric motor of the fuel pump. Even if it is working properly, you need to check the power supply with a multimeter or probe and examine the relay. If power is supplied, then replacing the pump cannot be avoided.

It is more difficult when the pump is running, that is, it buzzes when turned on. First you need to check the condition of the filter, clean it if it is clogged with foreign impurities. Interruptions in operation can also be caused by faulty spark plugs, injectors, sensors, or a decrease in pressure in the fuel line. The pressure in the ramp, in turn, depends on the tightness of the main pipeline connections and the serviceability of the bypass valve.

It would be a good idea to measure the pressure using a pressure gauge with the fuel pump on but the engine stopped. Absence or significant deviation from the norm will indicate a malfunction.

Troubleshooting the VAZ 2107 fuel pump

Before checking the fuel pump, it is advisable to stock up on M8 bolts or other products of a similar diameter that can serve as plugs for fuel hoses.

To check the VAZ 2107 fuel pump, you must perform the following steps:

- Loosen the hose clamp that supplies gasoline to the carburetor and remove the hose from the fitting.

- Plug the fuel hose to prevent fuel from spilling out.

- Pump the fuel pump manual drive lever several times. If a stream of gasoline comes out of the outlet fitting, the fuel pump is working. If not, the check should continue.

- Loosen the inlet hose clamp, remove the hose and plug it in the same way as before.

- Close the inlet fitting with your finger and pump the hand drive lever several times. If there is a noticeable vacuum, the problem is not in the fuel pump. If the finger does not “stick”, it is necessary to remove and repair or replace the fuel pump.

Replacing the fuel pump on a VAZ 2110 injector

Before replacing the fuel pump on a VAZ 2110 with an injector injection system, you should prepare a new spare part and the tools necessary for the job. With the right approach, the procedure itself will not take much time, 20–30 minutes, a maximum of an hour if things don’t go quite smoothly.

Tools

The set of tools for replacing a fuel pump is small, but should be on hand so that during the repair process you don’t have to run around and look for a suitable wrench or screwdriver.

When dismantling and installing a new fuel pump you will need:

- a wrench for loosening the terminals on the battery, the size depends on the installed fasteners;

- flathead and Phillips screwdrivers;

- key to 17;

- tubular wrench or deep socket 7 with ratchet or wrench.

Having prepared the tool and a new part, you can begin metalwork.

How to choose a new part

The standard fuel pump installed on injection engines has catalog number 2112-1139009. If desired, you can replace it with a similar part from other manufacturers. In some cases, such a choice will be dictated by the greater reliability of analogues, in others - by relatively affordable cost.

The following are offered for replacement:

- Bosch 0 560 454 035, which has higher quality and wear resistance;

- Fenox EFM33006O7 with low cost;

- Ween 192-0262, inexpensive like Fenox;

- Pekar 2112-1139009 - will be slightly more expensive than the previous ones, but cheaper than the original;

- ATS 53453 has a higher cost, but car owners do not complain about the quality.

Which one is better, the car owner will have to choose on his own, based on his own preferences, requests, and availability of funds.

Removing the old fuel pump

The procedure for dismantling the VAZ ten electric fuel pump is standard for the entire family of the series.

Step by step steps to eliminate the faulty part:

- The terminal on the battery is disconnected.

- The pressure in the fuel system is checked and, if necessary, released through a special valve on the ramp, covered with a protective cap.

- The rear seat cushion is removed and the trimmed part of the carpet is moved away.

- The hatch cover is retracted to the side. To do this, unscrew two mounting screws.

- The power supply is disconnected by separating the wire block from the connector.

- The fuel line clamp is loosened or removed.

- Use a key to unscrew the two lines from the fuel pump.

- The gaskets at the ends of the fuel lines must be replaced.

- The 8 fastening bolts are unscrewed.

- The pressure ring is removed and the fuel pump housing is carefully pulled out.

- The seal is removed and inspected. If necessary, it is replaced.

Particular attention should be paid to compliance with safety regulations, including fire safety.

Installing a new

Installation of a new electric fuel pump is carried out in the reverse order.

The following actions are performed sequentially:

- The seal is installed.

- The new pump is carefully inserted.

- The pressure ring is installed and 8 fastening bolts are tightened.

- The fuel lines are screwed on.

- The power supply is connected to the connector.

- The hatch cover is installed and closed with the folded carpet flap.

- The rear seat cushion is installed.

- The battery terminals are connected.

When installing, remember that the arrow stamped on the housing must be directed backwards.

Symptoms that clearly indicate a faulty pump and rod

The main sign of a faulty fuel pump is that the engine begins to stall at high temperatures, and after stopping it does not start. It sits for a while, cools down, and only then is it possible to start the engine. Of course, another breakdown has a similar symptom - a violation of valve adjustment. Only in this case does it feel as if the engine is trying with all its might to pull the car, but cannot, it is beyond its capabilities. And when the fuel pump starts to malfunction, the engine simply stalls.

The reason for this is excessive heating. As we said, the VAZ 2101 fuel pump consists of two valves. Well, one or both became warped due to heating and stopped opening. Cool them slightly and you can continue moving. Remember how often you saw a wet rag thrown over a gas pump? Now you know what purpose this is for.

But there is also a VAZ 2101 fuel pump rod, a truly wonderful contraption. It is made of steel. And if in the Soviet years it was hardened, now no one needs it. The price of the stock is at least 25 rubles. Well, who will spend kilowatts of energy on a part whose final cost is 25 rubles? Nobody! What happens then? But an unpleasant picture emerges - the fuel pump lever simply erases the rod, reducing its length.

And if you have gaskets under the fuel pump housing, then you are just lucky! When you pull one out, the rod will protrude from the insert more. And that’s it, the pump will continue to pump gasoline normally. But what if there are no gaskets? Who knows what could happen, for example, they forgot to put them on? And that’s why the rod was worn out. What to do then? Try taking it out and inserting it the other way. You know, this action helped several times.

A sign that the fuel pump rod has worn out is that the car accelerates to a certain speed. I had such a thing that I drove around the city normally, but as soon as I got on the highway, my maximum speed was 90 km/h, and that’s all. You step on the gas, but the engine stalls, it doesn’t have enough gasoline. I released the pedal a little - it drives calmly and shows no signs of breakdown. Moreover, a pump rod malfunction cannot always be detected when driving around the city or at idle speed. A short-term increase in engine speed will not give the same effect as long-term driving at high speed.

Replacing the fuel pump filter

To replace the VAZ 2110 fuel pump filter, you will have to carry out the procedure of completely removing the unit from the gas tank. Removal and replacement should be carried out after detecting interruptions in engine operation and jerking in first gear.

Some experienced motorists recommend changing the fuel pump screen at the next oil change, and establishing such a rule. This approach will allow the fuel pump itself to last longer and the engine will perform better.

To change the filter on a removed fuel pump:

- The plastic cup is removed, depending on the model, either simply from the body, or along the guides with preliminary disconnection of the two wire blocks.

- There is a filter inside, which can be removed by prying it off with a screwdriver.

- A new one is placed in its place and securely fixed in the seat.

- Reassemble and install the pump in the reverse order.

Mechanical fuel pump repair

The functionality of a mechanical fuel pump can be restored by replacing its faulty elements. You can buy them at any automobile store. But it is better to buy not individual spare parts, but a repair kit. It includes all the elements that can fail:

- intake and exhaust valves;

- diaphragms with spacers, “plates”, rod;

- pusher;

- thermal spacer;

- gaskets

Replacing valves

To replace the pump valves you will need a slotted impact driver and a small hammer. The valves are held in their seats by punching at three points. These areas must be carefully knocked off with a screwdriver. After this, the valves can be removed. Having installed the new parts, we secure them with cores. To do this, place the tip of the screwdriver on the edge of the housing along the circumference of the socket and strike it lightly with a hammer. We fix each valve in three places.

Replacing valves

How to change apertures

To replace the diaphragms, you need to unscrew the nut by 10 in the upper part of the rod. Next, we remove the damaged elements, and in their place we install parts from the repair kit.

The kit includes three diaphragms: two working and one safety. The latter serves to prevent unauthorized fuel from entering the carburetor if the first two are damaged. It is installed at the very bottom of the rod immediately after the lower “plate”. We place spacers on top of it on the rod: first a small one, then a large one. We place the working membranes and the upper “plate” on them. We secure the resulting structure with a nut.

The mechanical fuel pump has 3 diaphragms

Replacing the pusher, thermal spacer and gaskets

The thermal spacer does not need to be replaced unless it is damaged. Inspect its mating surfaces, especially the outer one, to which the lower part of the pump housing is attached. It should be perfectly smooth. Otherwise, oil leakage may occur at the junction of parts during engine operation.

Replacing the pusher is carried out by removing the old one and installing a new rod in its place. There is no difference in which end where it will be installed.

Now about the gaskets. There are only three of them in the repair kit, and they have different thicknesses:

- “A” – 02.27–03 mm;

- “B” – 0.7–0.8 mm;

- “C” – 1.1–1.3 mm.

The first is intended for installation between the thermal spacer and the auxiliary drive housing, and the gaskets “B” and “C” are used to adjust the protrusion of the pusher above its mating surface.

The adjustment is made as follows:

- We install the thermal spacer with the first gasket and a new rod into the auxiliary drive housing.

- Place gasket “B” on the mating plane of the spacer. Next, you need to rotate the engine crankshaft to the position of the pusher until it is recessed as much as possible. This can be done using a large slotted screwdriver. We insert its end into the clutch housing window and slowly push the flywheel clockwise.

- We periodically check the position of the pusher and measure its protrusion. When it enters the auxiliary drive housing to its maximum length, we measure how much it protrudes above the mating plane of the spacer with the gasket already installed on it. This value should be 0.8–1.3 mm. If it is larger, replace gasket “B” with gasket “C”. If the protrusion length is less than specified, swap gaskets “A” and “B”.

After the adjustment is completed, the fuel pump is installed in place and secured with nuts.