Replace self-locking nuts.

You only need to tighten the threaded connection with a nut.

| Version with extendable coupling: |

Unscrew the clutch a few turns using special tool 26 1 040 .

After installation, tighten the coupling using special tool 26 1 040.

The key function of the described part is shock absorption. An elastic coupling on the VAZ 2107 is needed to minimize the effects of shock loads that occur when the crankshaft rotates. The part performs the following functions:

- Protects drives and mechanisms during crankshaft rotation;

- Smoothes out shocks and shocks at the moment of starting the mechanism;

- Connects misaligned shafts.

The coupling is the simplest option for compensating for shock loads that arise during the operation of the cardan. The device is capable of not only absorbing the kinetic energy of rotating elements, but also compensating for the displacement of individual parts. Thanks to its outstanding damping properties, the coupling is able to perform its function even if the engine runs for a long time in intensive mode.

Design features and operating principle

The elastic coupling of the driveshaft of the VAZ 2107 in terms of design is identical to similar parts used on other cars. The absorbent section of the coupling is made of durable rubber. Along the contour there are technological holes with bushings, which, in turn, contain holes for bolts.

Three middle bolts secure the clutch to the transmission output flange, and three more bolts are needed to secure the clutch to the driveshaft flange. Thus, the described part is directly involved in the transmission of torque to the drive axle.

Signs of a part failure

Two types of faults are widespread:

- Wear of the VAZ 2107 elastic coupling flange: the junction of the coupling with the driveshaft or gearbox is most susceptible to shock loads.

- Wear of flexible coupling flange bushings.

Breakdowns cause the drives and rotating parts adjacent to the driveshaft to wear out faster. A breakdown can be identified by increased extraneous noise and vibrations; strong shocks appear while driving, namely when turning on and changing gears. When the clutch fails, wear increases on the drives and rods that are adjacent to the driveshaft.

Algorithm for replacing an elastic coupling on a VAZ 2107

Before carrying out repair work, study the instruction manual to remember the location of the element and the types of fasteners used. If you are not confident in your own qualifications, use the services of experienced servicemen. Poor quality repairs can lead to deterioration in the driving performance of the vehicle, which potentially increases the risk of an accident.

To replace the part you will need a set of screwdrivers and a set of spanners. Before starting work, remove the terminals from the battery.

First, the cardan drive is dismantled (work to remove the cardan drive is carried out on a pit or a lift):

- Using a chisel we mark the joint of the cardan with the flange of the main gear drive gear;

- Using the 13th wrench, unscrew the 4 nuts that secure the position of the propeller shaft;

- Next to the elastic coupling there are so-called “retaining whiskers” that hold the seal cage. We bend the “antennae” and move the clip to the side;

- Use the 13th key to remove the safety bracket;

- Now the cardan drive must be supported manually. We unscrew the two nuts and “pull off” the cross member of the intermediate support;

- Now the cardan drive can be removed freely.

Features of the mechanism

The driveshaft transmits the torque generated by the car's engine to the rear axle, causing the wheels to rotate. It is located under the bottom of the VAZ-2107 car, which is why you can find a raised floor in the cabin.

The cardan on the VAZ 2107 consists of two main parts, which are connected to each other using a cross. This design of the device is necessary because the rear suspension constantly “plays” when driving due to shock absorption. The device is a hollow tube, which is the “arm” connecting the engine to the wheels. Despite the simplicity of the product, the shaft, like other car parts, fails and requires repair or replacement.

Currently, cardans on CV joints, rather than on crosspieces, have the least vibration and increased service life. If desired, such a shaft can be installed on the seven by purchasing it at the car market, or ordering it from an online store.

Main cardan malfunctions

The main malfunction of the driveshaft is that elements such as the spider and the outboard bearing fail. It is these parts that are the most loaded. The crosspiece and bearing fail for a simple reason - lack of lubrication. Over time, it is necessary to periodically diagnose these elements with the obligatory addition of lubricants. In rare cases, a cardan malfunction may be associated with a defective crosspiece, which requires its replacement.

The malfunctions of the mechanism in question are as follows:

- failure of crosspieces;

- destruction of the outboard bearing;

- violation of the configuration (imbalance) of the shaft;

- breakage of flanges, splines and couplings, which happens under heavy loads;

- excess moisture and dirt inside the crosspieces.

At the slightest sign of malfunction, it is necessary to diagnose the mechanism and eliminate all resulting damage. The malfunction can be identified by the following signs:

- the appearance of a knocking sound when the clutch is engaged, which may indicate wear of the splines or damage to the elastic coupling;

- the occurrence of a grinding noise when the car is moving indicates a lack of lubrication;

- the appearance of vibration when the car is moving, which indicates a violation of the alignment of the product;

- knocking noise during sudden acceleration or braking, which indicates wear of the crosspieces.

We will discuss how to replace the VAZ 2107 driveshaft in the next paragraph.

The process of removing and replacing the cardan

The mechanism is removed for the purpose of carrying out repair work or replacing it with a new product. Often the driveshaft itself is an unpretentious device, but it is important to periodically check the condition of the bearing, splines and crosses. These are the weak points that you need to periodically pay attention to and monitor their condition.

To avoid misalignment during disassembly, it is necessary to apply marks with chalk or a core, which will avoid incorrect assembly of the product.

Work on dismantling the cardan is carried out in the following order:

- First, you need to secure the car by placing stops under the front wheels, and place the gearshift lever in the “neutral” position.

- Next, jack up the rear of the car, while suspending one of the drive wheels.

- We proceed to disconnect the device from the mount to the differential. To do this, you need to unscrew the 4 fastening nuts and then remove the bolts.

- After unscrewing the fastener, you can separate the product from the differential flange.

- It remains to unscrew the two nuts securing the cross member on which the suspension bearing is mounted. After unscrewing, you can remove the cardan from the VAZ 2107.

- Using a wooden hammer, it is necessary to knock out (if necessary) the shaft from the engagement of the splines with the elastic coupling.

- After the shaft is repaired or replaced, you can install it in place. The installation process is inversely proportional to removal. When installing the product, it is important to ensure that the shaft is positioned correctly.

After repairing or replacing the shaft, check the rotation of the product. At this point, the work on removing and replacing the propeller shaft on the “seven” is completed. It remains to make sure that extraneous noise has disappeared after the work has been completed. We also recommend reading the article on replacing crosspieces.

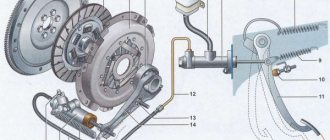

Flexible coupling absorbs driveline noise and vibrations

It is made of six rubber elements, between which there are metal liners with holes for bolts.

There are six projections on the liners, three of which fit into the grooves of the gearbox secondary shaft flange, and the rest into the grooves of the elastic coupling flange.

This ensures that the flexible coupling is centered on the flanges.

To replace the flexible coupling:

Using a 13mm socket, unscrew the two nuts securing the gearbox cross member to the body.

Replacing an elastic coupling on a VAZ 2107:

- Using the 13th wrench, unscrew the nuts securing the gearbox cross member to the body. The box will settle a little;

- Using keys “19”, unscrew the nuts securing the elastic coupling bolts;

- We rotate the gearbox shaft, simultaneously knocking out the coupling bolts;

- We dismantle the coupling and flange. We disconnect the coupling and the flange by unscrewing the 3 nuts;

- We install a new coupling on the flange, without removing the tightening clamp from the new coupling;

- Insert the bolts into the gearbox flange;

- We install the coupling so that the flange pins fit into the grooves of the coupling.

The renovation is complete. We recommend watching a useful thematic video

VAZ 2107 is a rear-wheel drive car. The transmission of torque from the gearbox to the rear axle gearbox is carried out via a cardan shaft. The shaft itself is considered a fairly reliable unit and can serve for decades. However, some of its elements, such as the elastic coupling and the suspension bearing, require constant attention and periodic replacement.

How to properly lubricate the cardan?

We'll tell you about proper lubrication of the driveshaft without removing parts from the car.

First, as usual, we put the VAZ 2107 on the inspection hole, tighten the handbrake, put the gearshift lever in the “neutral gear” position, manually remove dirt and dust from the cardan drive, then check how tight all the available bolts and nuts are and tighten what "dangling"

- You can insert a screwdriver and wiggle it, this way you can determine the play in the hinge bearings. In this case, the part will have to be removed from the car, as described above, and the crosspiece replaced or the O-rings replaced.

- In addition, we grasp the front shaft firmly with one hand and rotate (pump), inspecting the coupling: is there any angular play?

- To lubricate the driveshaft splines, you need to take an 11 mm wrench, unscrew the plug on the coupling flange and take an oiler in which you can supply oil under pressure. Then, using a syringe, squeeze the grease (CV joint - 4, Fiol - 2u) into the splined joint until it “comes out” from under the oil seal, then put the plug in place.

These simple tips will allow you to keep the VAZ 2107 transmission in good condition for a long time, without having to repair the driveshaft.

Elastic coupling for driveshaft VAZ 2107

The driveshaft of the VAZ 2107 consists of two parts (front and rear), connected to each other by a articulated coupling (cross). This design allows you to avoid loads on the shaft while driving, when the body and chassis of the car begin to “play.”

The end of the rear shaft is connected to the axle gearbox, and the end of the front shaft is connected to the gearbox shaft. The connection to the gearbox is made through an elastic coupling, which is a kind of buffer for leveling shock and dynamic loads on the driveshaft and gearbox shaft.

Flexible coupling location

The elastic coupling is located in the lower front part of the car on the rear side of the gearbox. You can see it if you remove the engine protection and climb under the car. The coupling is easily recognizable due to its hexagonal shape.

Coupling design

The basis of the coupling is a cushion made of especially durable rubber. Along its circumference there are six steel bushings fused into rubber, through which the bolts connecting the cardan flanges and the gearbox secondary shaft pass. The coupling kit also includes a special tightening clamp, which is put on it during installation or dismantling.

Diagnostics of elastic coupling faults

The coupling may fail as a result of:

- wear of metal bushings;

- body wear;

- rupture of the body.

In each of these cases, the malfunction will manifest itself in the form of body vibration and extraneous sounds coming from the gearbox.

The condition of the coupling can only be checked by inspecting it and assessing the size of the play between the flanges of the gearbox and cardan shafts. This is done as follows.

- The car is driven onto an overpass or inspection hole;

- The engine protection is removed;

- The coupling body is inspected and the condition of the bolted connection is assessed.

- By loosening the cardan, the presence or absence of play is determined.

If signs of wear or mechanical damage are found on the coupling body (the body is partially or completely torn), the part must be replaced. A slight play (provided the body is intact) is eliminated by tightening the nuts of the connecting bolts. If the play is large, the elastic coupling will have to be replaced with a new one.

Diagnostics

Balancing the driveshaft with your own hands: how to do it correctly

When carrying out such a procedure in car services, they take into account the fact that the first sign of natural wear of such a part is vibration, as well as a knocking sound in the area of the driveshaft at the moment when the car starts moving. If previously there were no problems with balancing the axle, but the knocking still appeared unexpectedly, then the first thing you should do is check the outboard bearing

The diagnostic procedure in car services is carried out in the following order:

First, the machine is installed on an overpass, lift or inspection hole. Next, they find the driveshaft itself under the bottom. First of all, mechanics

check the play. To do this, move the part by hand in the axial direction. Free movement in such a situation is unacceptable.

Next, the diagnosticians rotate the cardan and listen to how the bearings behave. If there is vibration, rattling, knocking, or rolling, the part must be replaced immediately. The next step is to inspect the body of the part. The degree of tightness of all bearing mountings is checked

Even the slightest leakage of lubricant is not allowed. Then the car service workers pay attention to the bearing bracket. The fastening must be reliable.

Important! Such an algorithm allows you to fairly accurately determine whether the outboard bearing is in good condition or requires replacement. It is best that the described procedure be performed by an experienced person who is not the first time to see a faulty outboard bearing

Suspension bearing for propeller shaft VAZ 2107

The suspension bearing (or idler bearing) is designed to ensure uniform rotation of the driveshaft while driving. In addition, it is an additional point for attaching the cardan and is included in the design of the intermediate (suspended) support. In fact, it itself is a support, since it comes complete with a bracket, with which it is attached to the bottom of the car through a transverse bracket.

Outboard bearing location

The bearing is installed in front of the spider at the end of the front of the driveshaft. It can be seen from the inspection hole in the axial recess of the bottom behind the exhaust pipe at its junction.

Hanging bearing design

The hanger bearing is an ordinary closed type ball bearing. It consists of an inner and outer race and seven steel balls. For mounting on the bearing housing there is a steel bracket with holes for bolts.

Diagnosis of outboard bearing faults

The causes of outboard bearing failure are usually wear or mechanical damage. The service life of the bearing is about 150 thousand km. However, exposure to moisture, dirt, as well as stress caused by poor road conditions can significantly reduce it.

Signs of bearing wear are:

- slight vibration;

- hum emanating from the place where the cardan is “suspension”;

- shaft play.

It is quite difficult to accurately diagnose bearing failure; this will require dismantling the driveshaft.

Outboard bearing selection criteria

Suspension bearings for the VAZ 2107 in Russia are produced under catalog numbers 2101–2202080 and 2105–2202078. The requirements of GOST 6–180605 apply to them. Imported analogues must comply with the requirements of ISO 62305.2RS. If there are no such markings on the packaging of a new part, it is most likely a fake, and it is better not to purchase it. The average retail price of a VAZ 2107 suspension bearing is 450–500 rubles. When choosing a manufacturer, it is better to give preference to the Vologda Bearing Plant. Bearings produced at VPP are considered to be of the highest quality and most durable.

Table: technical characteristics of the VAZ 2107 suspension bearing

| Characteristics | Indicators |

| steel grade | ШХ 15 |

| Outer diameter, mm | 62 |

| Internal diameter, mm | 25 |

| Height, mm | 24 |

| Rated rotation load, rpm | 7500 |

| Load capacity static/dynamic, kN | 11,4/22,5 |

| Ball diameter, mm | 11,5 |

| Weight, g | 325 |

Which crosspieces to put on the “six”

If you listen to the opinion of service station specialists, they recommend replacing both universal joint crosspieces, even if only one of them fails. But not everything is so simple. The crosspiece located at the front of the driveline travels much longer than the rear one. There are situations when a part in the shank is changed three times, but near the outboard bearing there is no need to replace it. When choosing crosspieces for your car, you should not chase a low price, since repairs will ultimately cost more. Let's look at some hinge manufacturers that you can trust with your choice:

- Trialli. Made of high carbon steel and evenly hardened over the entire surface. The product is able to withstand high impacts of dynamic and static nature. The seal has an improved design, which increases reliability and protection against dust and sand getting inside the bearings.

- Kraft. The part is made of a special stainless alloy that is resistant to corrosion. The manufacturer provides a guarantee of high quality, which is embedded in multi-stage control during manufacturing.

- Weber, GKN, etc. The crosspieces of these and other imported manufacturers are of good quality, but sometimes the stoppers have to be adjusted to the location.

- The most affordable option for a universal joint is a domestically produced part. There is no need to talk about the quality of such a product, so it depends.

Before purchasing and installing a universal joint, be sure to consider the size and shape of the cups

Attention should also be paid to the hinge pins. They should not have any burrs, marks or other defects.

For domestic cars, it is better to give preference to crosspieces with a grease fitting, i.e., serviceable ones, which will allow you to periodically renew the lubricant in the bearings. The seals must not have any defects, such as visible tears or manufacturing defects.

When choosing a cross, attention should be paid to the size and shape of the cups

Table: parameters of the universal joint for the “classic”

| Number | Application | Dimensions DxH, mm |

| 2101–2202025 | Cardan crosspiece VAZ 2101–2107 | 23.8x61.2 |

| 2105–2202025 | Cardan crosspiece VAZ 2101–2107 (reinforced) | 23.8x61.2 |

Replacing the VAZ 2107 driveshaft coupling

The coupling is replaced on an overpass, a lift or from an inspection pit. Tools you will need:

- two 13mm wrenches;

- two 19mm wrenches;

- head or key 27;

- set of heads;

- pliers;

- chisel;

- hammer;

- slotted screwdriver;

- awl;

- steel beard;

- round nose pliers with thin curved ends;

- vice with workbench;

- special puller for bearings (preferably);

- CV joint type grease.

Replacing the suspension bearing VAZ 2107

To replace the propeller shaft outboard bearing, you must:

- Disconnect the handbrake cable and remove the driveshaft in accordance with paragraphs. 1–13 instructions for replacing the flexible coupling.

- Using round-nose pliers, remove the retaining rings of the crosspiece needle bearings.

Video: replacing the suspension bearing on a VAZ 2107

Checking the condition of the cardan drive without disassembling

We clean the shafts, coupling and support from dirt.

We check the cardan joints for ease and smooth rotation of the forks and for the absence of radial and axial movements.

If damage to at least one of the shafts is detected, it is advisable to replace the cardan transmission assembly, since its balancing is carried out in the assembled state on a special stand.

The rubber parts of the elastic coupling and elastic support must not have cracks, tears or separation from the metal.

When operating a car, you should lubricate the splined joint of the propeller shaft near the elastic coupling within the prescribed period (10 thousand km).

Instead of a plug on the flange of the elastic coupling, we wrap the grease nipple and lubricate the spline joint with Fiol-1, Fiol-2U or CV joint grease.

Balancing the driveshaft VAZ 2107

After disassembling and replacing any element, the driveshaft must be balanced. This is done on a special stand, so for balancing it is easier to contact the nearest car service center. The balancing itself consists of measuring and eliminating the imbalance on the three shaft supports. Its permissible value at a shaft rotation speed of 5500 rpm should not be more than 1.62 N*mm. The imbalance is eliminated by welding small weights (metal plates) onto the surface of the front driveshaft.

If vibration appears after repairing the driveshaft, you can try to balance it yourself. Naturally, there can be no talk of any accuracy here, and the balancing itself will be only temporary. This is done as follows.

- Drive the car onto a viewing hole or overpass.

- Inspect the driveshaft.

- Conventionally divide the front universal joint into four sectors (if you imagine it in cross-section).

- Find a small weight weighing 30-50g and attach it to the front of the shaft using tape or tape.

- Drive along a flat section of road, paying attention to your choices.

- If the vibration does not disappear or increases, move the weight to another sector and repeat the checking process.

When the load is in its place, the vibration should stop, unless, of course, it is caused by an imbalance of the shaft.

What faults occur in this connection?

Typically the bearings will tell you when they need to be repaired or replaced. The sound of the outboard bearing indicates a failure. It can send the following signals:

- Various knocks and noises, such as humming, buzzing or crunching;

- Vibration, such as beating or jerking;

- Play of the outboard bearing if it is subject to visual inspection.

If you hear that the suspension bearing is humming, you need to contact a car service as soon as possible.

As a rule, such elements of the driveshaft do not fail on their own. They break for the following reasons:

- Natural wear and tear of a

structural element, gradual destruction of the rubber that holds the bearing. - Features of operating conditions, for example, low or high temperature conditions, contact with dirt and dust on the bearing, movement over rough terrain, hard gear shifting, increased loads.

- An installation error that can easily be made if an inexperienced person is working.

- Reduced quality characteristics of the components used. The fact is that the installed spare parts must be original or have proven themselves in the market.

Important! If the driver tries to exclude the maximum number of reasons during operation, then he can rest assured that the part will serve him for a very long time. More rare transmission malfunctions of the VAZ 2107:

More rare transmission malfunctions of the VAZ 2107:

- Damage and misconfiguration (hitting rocks when driving in the mountains);

- Abundant amounts of dirt in parts and bearings;

- Failure of flanges, splines and couplings under load.

For lubrication, maintenance, if a part needs to be replaced, first of all, you need to properly remove it from the car and put it back. Repair of the driveshaft is also possible only after removal.

Useful tips

To increase the service life of the VAZ 2107 driveshaft, you need to follow a number of simple recommendations.

- Avoid excessive contamination of the driveshaft couplings.

- Systematically check the tightness of the fastening elements and the presence of lubricant in the connecting units.

- If shaft malfunctions are detected, do not delay repairs.

- When purchasing spare parts for a cardan, pay attention to the manufacturer and compliance with GOST or ISO requirements.

- After repairing the driveshaft, be sure to have it balanced at a service station.

Diagnosing a malfunction, repairing and replacing the suspension bearing and elastic coupling of the VAZ 2107 propeller shaft with your own hands is quite simple. This requires minimal plumbing skills, a standard set of tools and careful adherence to the recommendations of professionals.

How to diagnose wear on crosspieces

Replacing the crosspiece in a VAZ 2106 is carried out after diagnostics:

When, during rapid acceleration or braking of a car, when changing gears, a knocking sound from the cardan transmission or vibration of the axle is heard, all this indicates wear of the crosspiece and its bearings

There is an urgent need to replace the VAZ 2106 crosspiece, which has become unusable.

If you don’t pay attention to these signs in time, then the result will be destruction of the bearing and the cardan falling out directly onto the road. The axle gearbox and the underbody of your car can also be damaged.

Tool required for replacement

Replacing the driveshaft crosspiece of a VAZ 2106 requires the following tools:

- Two open-end wrenches 13 and 12

- Socket wrenches 27 and 13

- Copper or aluminum extension

- Hammer

- Compression pliers with thin jaws to remove circlips

- Two mandrels for pressing out the cardan cross bearings.

- Universal puller

- Ticks

- Chisel

- Large screwdriver