Many drivers are interested in the question of what a differential lock is and what it is for. In fact, this is another design solution that helps eliminate its disadvantages. For example, when driving on a flat road surface, the differential helps to maneuver safely. But as soon as the car goes on a slippery road or off-road, it can “turn off” the possibility of comfortable movement. This point can be easily dealt with if you set restrictions on the functionality of the node or turn it off completely. Let's consider what methods of differential locking exist.

Is it differential?

Before you understand why differential locking is needed, you need to understand the concept itself. In simple words, this is a mechanism that is connected to the wheel axles. Its main function is to transmit torque to these axes. All this happens due to the “planetary mechanism”.

There is another function - to provide the ability to rotate the wheels asynchronously when turning the car or while driving off-road. Every car has at least one differential. Any all-wheel drive vehicle has two differentials, each of which belongs to a pair of wheels. In addition, there is also a center differential installed for better movement on uneven roads.

We can say that the differential is a transmission part. Its basis is a planetary gearbox, and its functional elements are gears and satellites. All of them are located in the unit body. Which part of the car the differential is located in depends on the drive.

A locking differential can be installed on any car

Through the efforts of designers and enthusiasts from many countries, more advanced systems have been created in the last decade - both forced and automatically activated systems for distributing torque between the axle shafts of the drive axle. Modern differential lock designs make it possible to ensure stable vehicle maneuverability and controllability even in the most difficult road situations. Now many car models, in particular SUVs, are equipped with a differential with a locking mechanism initially, during the assembly process.

Typically, a rear differential lock is present in almost any rear-wheel drive vehicle designed for off-road use or in regions with long winters and snowy, icy roads. To improve the performance characteristics of some off-road vehicles with two drive axles, manual or automatic locking of the center differential is also provided - a mandatory design element of all such vehicles.

Vehicles whose drive axle was not equipped with such a system at the factory can be modified. To achieve this, various manufacturers offer compatible units designed to replace the standard differential. At many service stations, you can upgrade the rear or front axle of not only any of the popular foreign cars, but also install a differential lock on the Niva, VAZ, UAZ, Gazelle, and other samples of products of the domestic automobile industry.

Like any other technical solutions, all existing locking designs have certain advantages and disadvantages. Before you begin upgrading the transmission of your existing vehicle, it is useful to study the properties and characteristics of all solutions offered by manufacturers. Knowledge of the technical nuances of the differential design of a modern car will help you accurately assess the prospects of the proposed locking solution and make the right choice.

Concept of differential lock

Before we start talking about what differential locking means, we need to consider the principle of its operation according to the classical type. A standard differential has the ability to transfer power from the engine to the axle. This helps the wheels spin when the car turns at different speeds. The fact is that each wheel must travel a different distance during a turn due to differences in the outer and inner turning radii. It is the differential that makes it possible to solve this problem so that the car moves normally and turns smoothly.

But any modern mechanism has negative features. The fact is that when wheels slip on one axle, more torque is transmitted, which reduces the vehicle's maneuverability. This is an unacceptable phenomenon, especially for SUVs. This is why differentials have a locking option. If it is activated, both axles receive the same torque. Thus, the car can easily overcome “dangerous” places.

Conclusion

All-wheel drive in a modern car, and especially in an off-road model, is almost a natural phenomenon, for the simple reason that this system actually makes the trip safer. However, we should also not forget about those sections of the road where there are off-road conditions and difficult sections of the road surface, and, as a result, serious obstacles. To cope with them, the differential is not fully suitable, nor is a conventional all-wheel drive system. That is why manufacturers have provided for their vehicles such elements as differential locks, which allow the redistribution of torque between the axles, so that it is much easier for the car to deal with the next obstacle encountered on the way.

Author: Oleg Mokrov

Types of locking devices

There are different types of locking devices. We list the most important of them:

1. The cam device creates a lock through the clutch, which, in turn, locks the mechanism, connecting it to the housing with the loaded axle shaft.

2. An automatic device is also called self-locking. It operates by the method of increasing friction force when the load on the axle shaft changes.

3. The disk device is based on a clutch that operates on the principle of self-locking at the moment of changing the angular speeds of the axle shafts.

4. The worm mechanism consists of axle shafts with satellites having a worm gear. The differential is locked when there is a difference in torque.

5. Blocking with viscous coupling is considered the most common, since it is built according to a planetary scheme.

There are other types of locks, for example Torsen. It includes a housing, semi-axial gears, shafts and satellites. Experts say that this design is the most advanced compared to others.

What is samoblok

21.02.2017 08:00

What is a self-locking worm differential?

A self-locking worm differential (self-locking) is a device that allows you to partially compensate for the main disadvantage of a free differential, namely its complete helplessness when one wheel hits a slippery surface. According to the principle of operation, self-locking differentials can be divided into two types: speed sensitive, that is, triggered by the difference in the angular speeds of rotation of the axle shafts, and torque sensitive, triggered by the difference in the torque transmitted to the axle shaft. To understand the operation of a self-block, first we will understand the operating principle of an ordinary differential and its disadvantages.

A differential is a mechanical device that transmits torque from one source to two independent consumers in such a way that the angular speeds of rotation of the source and both consumers can be different relative to each other. This transmission of torque is possible through the use of a so-called planetary mechanism. In the automotive industry, the differential is one of the key transmission parts. First of all, it serves to transmit torque from the gearbox to the wheels of the drive axle.

The principle of operation of an ordinary differential

Why do you need a differential for this? In any corner, the path of a wheel on an axle moving along the short (inner) radius is less than the path of another wheel on the same axle moving along a long (outer) radius. As a result of this, the angular speed of rotation of the inner wheel must be less than the angular speed of rotation of the outer wheel. In the case of a non-driving axle, this condition is quite simple to fulfill, since both wheels may not be connected to each other and rotate independently. But if the axle is driven, then it is necessary to transmit torque simultaneously to both wheels (if you transmit torque to only one wheel, then the ability to control the car according to modern concepts will be very poor).

If the wheels of the drive axle were rigidly connected and torque was transferred to a single axis of both wheels, the car would not be able to turn normally, since the wheels, having equal angular speed, would tend to cover the same path during the turn. The differential allows you to solve this problem: it transmits torque to the separate axles of both wheels (half shafts) through its planetary mechanism with any ratio of the angular speeds of rotation of the axle shafts. As a result of this, the car can move and control normally both on a straight path and when turning.

However, due to the physics of the device, the planetary mechanism has a very bad property: it tends to transfer the resulting torque to where it is easier. For example, if both wheels of an axle have the same traction and the force required to spin each wheel is the same, the differential will distribute torque evenly between the wheels. But as soon as there appears a noticeable difference in the adhesion of the wheels to the road (for example, one wheel hits the ice and the other remains on the asphalt), the differential will immediately begin to redistribute the moment to the wheel whose spinning force is the least (that is, to the one that is on ice). As a result, the wheel located on the asphalt will stop receiving torque and will stop, and the wheel located on the ice will take on all the torque and will rotate with an increased angular speed, and the planetary mechanism will play the role of a gearbox, increasing the speed of rotation of this wheel. Naturally, this phenomenon greatly impairs the vehicle's maneuverability and controllability. Indeed, according to the logic of things, in the situation considered, it is desirable to transfer the moment to a wheel located on the asphalt so that the car can continue moving.

In all-wheel drive vehicles, two axles are usually equipped with a differential, and often a differential can also be found between the axles (center differential). Thus, we get a transmission scheme in which there are as many as three differentials: two bridge differentials and one center differential. The latter is necessary for constant movement with all-wheel drive and torque transmission to all four wheels. After all, when turning, the wheels of the steering axle (usually the front one) have completely different angular velocities than the wheels of the rear axle. The center differential is designed to transmit torque from the gearbox to both drive axles with different ratios of angular speeds. This scheme with three differentials is one of the most common schemes for permanent all-wheel drive (Full time 4WD).

Returning to the above-described problematic property of the planetary mechanism, it is interesting to consider the situation when an all-wheel drive vehicle with a center differential got one of its four wheels onto the same ice (or into a slippery hole). What will happen then? The differential of an axle whose wheel is on ice will transfer all the resulting torque to that wheel. The center differential, in turn, also strives to transfer torque to where it is easier. Naturally, it is easier for the center differential to transfer torque to an axle with a wheel spinning on ice than to an axle whose wheels have good grip on the road and can move the car. As a result, all the torque from the engine and gearbox will be used to spin the only wheel located on the ice. The remaining three wheels will stop and will not receive any torque from the differentials. Result: of the four driving wheels, only one remains, which slips on the ice - the all-wheel drive vehicle is “stuck.” How can you make differentials transfer torque to wheels with better road grip? For this purpose, various methods of partial and full, manual and automatic differential locking have been developed, which will be discussed below.

The main purpose of the differential lock is to transmit the required torque to both of its consumers (axle shafts or cardans). There are fundamentally different methods for solving this problem. In this section we will look at the partial locking method using a limited slip differential. Other methods of partially locking a differential can be found here, and the method of fully locking a differential can be found in the section “What is forced locking?”

Self-locking worm differential "Quaife" type

The author of this design is the Englishman Rod Quaife. In this case, the axes of the satellites are parallel to the semi-axes. The satellites are located in peculiar pockets of the differential cup. In this case, the paired satellites do not have spur gearing, but form another hypoid pair between themselves, which, when wedged, also participates in the locking process.

Operating principle of a self-locking differential

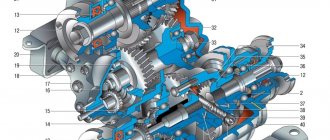

The figure shows a sketch of a self-locking differential. Let's look at its elements and operating principle.

When one of the wheels (for example, the right one) begins to lag, the side gear 4 associated with it rotates slower than the housing 1 and turns the satellite 5 engaged with it. It transmits the movement to the associated satellite 5 from the left row, which, in turn, , to the left side gear 3. This ensures different angular speeds of the wheels when turning. Due to the difference in torque on the wheels in the screw engagement, axial and radial forces arise, pressing the semi-axial gears 3, 4 and satellites 5, 6 with their ends to the housing 1, 2. The satellites 5, 6 are also pressed against the surface of the holes 8 in which they are located. Due to this, forces arise that carry out partial blocking. The degree of blocking is determined by the corresponding coefficient.

— We produce and sell self-locking differentials for the following brands and models of cars:

- UAZ UAZ 3160

- UAZ 31512

- UAZ 469

- LADA

- GAZ 3110 and newer

- Ranger

- BT-50

- Jimny, Samurai

- Frontera

- TAGAZ

- Admiral

- GREAT WALL Hover

- Safe

- Deer

- Sailor

- Amigo/Rodeo/Mu/Axiom

- Pajero

- LandCruiser 71, 76, 78, 79, 100, 105 Series, Lexus LX470

- HYUNDAI Accent

- Elantra

- Getz

- i20\ i30\ i40\ix20

- Solaris

- Terracan

- Tucson\ix35

- Veloster

- Carens

- NP-300 (Pickup)

- Jeep

- Duster

Complete blocking 100% and partial

A 100% block is called complete. In other words, it is a complete coupling that helps transfer the torque completely to the axle with the best grip. When driving on bad roads, this type of locking is the most optimal. This type of locking hardly does its job, but is simply a clutch. Full blocking is performed manually by the car owner himself, but it is still not recommended, since the engine becomes heavily loaded. In addition, gearboxes and tires with transmission are subject to rapid wear. All this negatively affects their condition.

As for partial blocking, it works in the same way as hard blocking. However, it produces a KM transmission where you feel not full clutch, but a specific percentage. Partial blocking mechanisms operate in automatic mode or using forced activation.

Without differential bridge

Strictly speaking, this type of blocking is a drum installed instead of the differential box, on which the driven gear of the main gear is mounted and the axle shafts are inserted, that is, the right and left axle shafts are constantly interlocked with each other.

There is thus no differential. Such a system has no right to life in the front axle - it is impossible to drive a car, but on rear drive axles, for example, such a mechanism is used more often than a conventional cross-axle differential. Disadvantages: rapid wear of tires on paved roads, high loads on the transmission, poor handling. Advantages: simplicity and reliability.

Automatic blocking

The differential limitation in automatic mode starts when the driver presses on the gas. For this reason, the element is customized to the driving style of a particular person. This is probably why many car enthusiasts do not like automatic locking.

The advantages of auto-locking include the following:

1. The lock always functions when required.

2. This type of lock is simple and convenient.

The disadvantages of automatic locking include the fact that it is strongly felt when driving. For example, the driver notices noise from the tires when turning, and also feels strong resistance during sharp maneuvers.

Pros and cons of self-locking

A very serious disadvantage of self-locking is its inappropriate operation. The differential is locked even in cases where this is completely inappropriate. An example of this would be a sharp turn where a car can easily skid. In this case, manual activation of the lock wins, when the driver makes the decision himself if the wheels begin to slip.

However, self-locking also has its advantages. Firstly, it improves the vehicle's cross-country ability in any case. Secondly, the design of such a differential is simple, low cost, simplifies the installation process and reduces the risk of its breakage as a result of inexperienced handling. Thirdly, the process of turning on and off is completely automated and does not require control.

Automatic or manual?

Having understood in more detail the principle of operation of the differential lock, drivers wonder whether it is useful in operation. Yes, it is really useful, but it has different types. All of them are described above.

As for the main types of blocking, it can be automatic and manual. Automatic is a complete shutdown of the differential, and manual is just a limitation of functions.

Manual locking is the simplest way to disengage the differential and occurs by pressing the switch and activating the limiter assembly. It is this that prevents the force from being distributed between the wheels. The advantages of the manual block include the operation of the differential in normal mode with the limiter turned off. Also, the car owner is able to independently decide when he needs a lock and when not.

The negative aspects of control include the fact that operation of the switch distracts the driver from driving. This process usually occurs when driving in difficult conditions. And in order not to break the differential through negligence, the driver should turn it off in a timely manner. Before choosing the type of lock, the driver will need to install the limiter, the mechanism for its operation, and the button as well.

If you compare manual locking with automatic locking, you can identify several features. As long as the driver's foot is on the gas pedal, the lock remains active, adapting to driving. This means that the main advantage of auto-locking is that it is already enabled in “difficult conditions”. The driver will not have to be distracted and take his hands off the steering wheel. Also, compared to the manual type, the automatic lock is easy to install.

The main disadvantages of the auto unit include continuous operation, which manifests itself in the resistance to turning the steering wheel, as well as the sound in the tires.

It is quite difficult to answer the question which types of differential locks are better. The point is that the best type depends on the vehicle itself.

diff

When starting in the “mixed” mode, the steering wheel of the car with the differential lock tries to escape from your hands.

The car is pulled towards the surface with poorer grip properties. When starting in the “mixed” mode, the steering wheel of the car with the differential lock tries to escape from your hands. The car is pulled towards the surface with poorer grip properties.

“Kalina” starts noticeably easier (the main thing is not to suddenly break off the drive wheels), accelerates faster, both in mixed mode and in a situation where there is snow or ice under all the wheels. In general, the car has become more collected, follows the steering wheel more willingly, and makes turns more clearly. The steering is also clearer - the stabilizing force has increased. Although, after changing the speed a little, you notice: the skid has become sharper than in the version with a free differential.

Advantages and disadvantages of a limited slip differential

A self-locking differential is a device that transforms torque from the “engine” to the wheels using transmission elements. An alternative option is forced blocking.

Many drivers are interested in which self-locking differential should be installed on a Russian-made SUV. Experts say you need to pay attention to a mechanical, pneumatic or electronic self-block.

The advantages of a limited-slip differential include:

1. The car gets the opportunity to move freely over bad terrain.

2. The design of the car remains unchanged, since the self-block is installed in the area of the standard part.

3. The mechanism operates automatically; you do not need to have special skills to operate it.

The disadvantages of installing a self-locking element include the fact that vehicle control becomes worse. The driver will have to make an effort to steer. The working life of this element is less than the factory one. Driving style changes when cornering, but there is no 100% guarantee of blocking.

diff

A worm-type self-locking differential of the original design was installed on the Kalina, a car with a front-wheel drive layout and corresponding habits typical of most current cars. We drove more than a thousand kilometers on roads with different surfaces, tried the locking in various situations, and looked at how the car behaves on slippery winter roads and dry asphalt.

Do-it-yourself blocking

Homemade differential locking is not a myth. It is needed in order to create a uniform distribution of CM power. Experts believe that the rear axle differential lock functions better, since the rear wheels have the same traction as the front ones.

To begin with, the driver should decide on the type of lock. Manual and automatic are described above. Each of them has its own characteristics. But between them there is also a partial blocking, which operates automatically, eliminating wheel slip.

Having decided on the type of block, the driver can proceed directly to installation:

1. The car is placed over the pit.

2. The drums are removed along with the wheels.

3. The axle shafts are dismantled.

4. Next you need to pull out the cardan and unscrew the gearbox.

The driver just has to install the lock and then return all the dismantled parts to their place. Using differential locks, you can restore an inaccurate gearbox. This is the main goal of the method.

Installing the lock yourself will help you save on the services of specialists. In the work you will have to use your own skills, as well as purchase special tools and adjusting rings.

diff

On slippery roads, driving a car with a locked differential is more difficult; the driver requires good racing training.

On slippery roads, driving a car with a locked differential is more difficult; the driver requires good racing training.

During intense acceleration and, to a lesser extent, during steady motion, the Kalina reacts more sensitively to uneven road surfaces: it becomes nervous, it is pulled towards looser surfaces, and it has to work harder with the steering wheel. A dynamic corridor of about a meter and a half requires greater concentration and precision from the driver. On a long journey, you begin to fondly remember the more comfortable factory version.

SHOULD WE INSTALL OR NOT?

Whether a limited-slip differential is needed on a front-wheel drive car is a controversial issue. Those who consciously, and most importantly, competently tune their car in order to get a sharp driving experience, will benefit from this modification. Moreover, we considered only one of the options for a self-locking differential. It is possible that someone will prefer a unit of a different design and with different settings. Experiment for your health, just remember: driving skills must also be at the appropriate level, because correcting piloting errors in a car with a limited-slip differential is much more difficult.

And drivers without special driving fantasies probably don’t need such modernization. It is unlikely to be able to fully use the specific advantages in handling, but it will definitely lose in comfort. A limited-slip differential will give a slight advantage off-road, but will not turn a passenger car into an all-terrain vehicle. In this case, you will have to pay several tens of thousands of rubles for the unit and installation. So is it worth it? I think no. However, no one forbids you to find out from your own experience whether we are right.

diff

Thanks to the self-locking differential, the Kalina moves almost 2 km/h faster (95.6 vs. 93.8 km/h).

Compared to the behavior of standard vehicles, the steering angles and lags are smaller, when performing a maneuver there is almost no skidding and no subsequent vibrations occur. Thanks to the self-locking differential, the Kalina moves almost 2 km/h faster (95.6 vs. 93.8 km/h). Compared to the behavior of standard vehicles, the steering angles and lags are smaller, when performing a maneuver there is almost no skidding and no subsequent vibrations occur.

In extreme situations, the VAZ baby becomes even more disobedient and worse predictable. During the first laps on a closed track, you manage to drive faster, managing to compensate for the spontaneous slips that arise, either with the front axle or the rear - a very sharp skid, and sometimes, on the contrary, a rather long drift. You have to work harder with the steering wheel and gas than on the Kalina with a free differential. However, despite the fact that there are more errors and the trajectories are far from optimal, the lap times are better.

diff

Without a differential lock, the car behaves more sluggishly.

Due to the less informative steering and slower reactions, it is more difficult to steer the Kalina into turns, but it is easier to control when sliding. Without a differential lock, the car behaves more sluggishly. Due to the less informative steering and slower reactions, it is more difficult to steer the Kalina into turns, but it is easier to control when sliding.

The surface rolls out, the traction of the wheels with the road drops - and not only the time, but also the behavior of the car deteriorates. It is very difficult to achieve controlled lateral sliding from it, and it manifests itself as characteristic of an all-wheel drive rather than a front-wheel drive vehicle. When releasing the gas and turning the steering wheel, the Kalina responds with drifts, which do not end until you feel with the gas the moment when the drift abruptly gives way to a skid. Often the car goes where he wants, and not the person sitting behind the wheel. More unambiguous behavior can be achieved if you use your favorite rally technique - braking with your left foot.