Lada Kalina is already equipped from the factory with a special on-board computer mounted directly into the instrument panel. Thanks to this, you can react as quickly as possible and diagnose the problem that has arisen. There is a self-diagnosis mode for this. Unless the previous owner was motivated by selfish goals and “turned out” these light bulbs, in which case they need to be replaced.

Errors are shown as a digital code and in this article we will tell you how to read them correctly and make the right decision.

How to reset error codes

After automatic diagnostics, errors must be reset. This is done so that they do not interfere or confuse the user during subsequent diagnostics. You can find out how to reset everything from the manufacturer's recommendations. But in practice, for example, an ECU error is reset by running a new check on the dashboard. In the service station, the controllers are reset in a slightly different order. There are other options:

- The ECU error is reset using the device and software. Therefore, we recommend that you stop by and check your car more often. It is during such checks that common breakdowns specific to this vehicle can be discovered.

- Code 0171 may be constantly displayed. This indicates that the fuel is of poor quality. Such a signal serves as a reason to think about changing it.

- Other than that, p1545, 0422, and 1426 are very common codes, so they're worth looking at. If they appear again after a reset, you must contact technical service for more accurate diagnosis and troubleshooting.

Specialists will help you sort out the problems if you yourself don’t know how to get rid of them.

Correction of internal control programs (chip tuning)

Chip tuning

Chip tuning, like ECM modification, also involves changing the factory settings of the software in order to eliminate certain errors in the operation of the software. But the ultimate goal of chip tuning is somewhat different, and is to significantly increase torque and obtain maximum performance from the engine.

The cost that a car owner has to pay to obtain additional power is quite high. Often, as a result of chip tuning, fuel consumption increases significantly and the life of the internal combustion engine decreases.

Taking into account the above information, every car owner should know the answer to two questions before adjusting the injector:

Decoding combinations

Below we will look at the decoding of error codes. We will not consider all codes: only the most common combinations that indicate a breakdown are given.

Self-diagnosis

When the instrument panel enters self-diagnosis mode, all arrows on it will show the maximum value and drop back down

So, what codes can be seen when self-diagnosing Lada Kalina.

| Code | Error interpretation |

| 2 | Code 2 means excess voltage in the vehicle's on-board network. |

| 3 | This code indicates a malfunction of the gasoline level sensor in the fuel tank. Possible circuit break. |

| 4 | When this code appears, the car owner needs to pay attention to the operation of the antifreeze temperature sensor. There is also a possibility of a circuit break. |

| 5 | There is a problem with the outside temperature sensor. |

| 6 | The control unit (CU) detected engine overheating. It is recommended to deal with this problem before further operation of the car. |

| 7 | Emergency lubricant pressure in the internal combustion engine is reported. |

| 8 | If you see this code on the dashboard, then you need to check the functionality of the brake system. The on-board computer recorded an error or breakdown in its operation. |

| 9 | The on-board computer reports that the battery charge is too low. It is recommended to perform a more thorough check of the battery. |

| E | An error has been reported in the data packet stored in the EEPROM. |

Diagnostics using equipment

Error number “4” that appears during self-diagnosis of Lada Kalina

If you check your car for errors using special equipment, then, as stated above, the combinations will be four-digit, and the code will be preceded by a letter.

First, let's look at what the letters and numbers mean.

- B - indicates a malfunction of the body, that is, we are talking about airbags, central locking, electric windows. Of course, this is true for Lada Kalina cars equipped with these devices;

- C - means an error in the operation of the chassis;

- P - indicates a malfunction in the functioning of the engine or automatic transmission.

What does the second number mean:

- 0 – common code for OBD-II;

- 1 – number of the car manufacturer;

- 2 – number of the car manufacturer;

- 3 – reserve code.

The third symbol directly indicates the type of malfunction:

- 1 – malfunction of the fuel system or air supply;

- 2 – malfunctions in the fuel system or air supply are also reported;

- 3 – malfunctions in the ignition system were detected;

- 4 – auxiliary control;

- 5 – malfunctions in idle speed;

- 6 – malfunction of the ECU or its circuit;

- 7 and 8 – errors in the operation of the transmission system.

Check Engine Light - starts flashing on the dashboard when any problems occur

| Code | Decoding |

| P0036 | Errors in the operation of the oxygen sensor are reported. It is recommended to check the device for operability, and also check the circuit for opens and short circuits. |

| P0102 | This error code tells the driver about a malfunction in the mass air flow sensor. It's also worth checking the chain. |

| P0441 | Incorrect air flow through the canister purge valve was detected. You should check the valve itself, as well as the entire gasoline vapor recovery system. |

| P0444 | The control unit registered a break in the wiring of the canister purge valve. The circuit should be checked. |

| P0445 | The on-board computer reports a short circuit in the control wiring to ground or the on-board circuit. |

| P0480 | A broken fan relay wiring has been detected. This code can also directly indicate a relay failure. |

| P0504 | A problem has been reported with the brake pedal sensor. |

| P0830 | Malfunctions have been reported in the operation of the clutch switch. It is necessary to diagnose the clutch and identify the breakdown. |

| P2187 | Literally means: the fuel supply system is too lean at idle. Here, first you need to adjust the idle speed. If this does not help, then look for the problem in the fuel supply system itself. |

| P1115 | Incorrect data was recorded in the operation of the oxygen level control sensor. The circuit should be checked. |

| P1123 | In idle mode, the on-board computer registered a too high combustible mixture index. |

| P1124 | At idle, the on-board computer reported that the fuel mixture was too low. |

| P1127, P1128 | The control unit reports too high or too low a fuel mixture indicator in partial engine load mode. |

| P1135 | The Lada Kalina control unit has detected a short circuit or an open circuit in the heater circuit of the oxygen level control sensor. |

| P1136, P1137 | The fuel mixture level is too high or low in low load mode. The internal combustion engine should be checked. |

| P1141 | The on-board computer detected malfunctions in the functioning of the heating device of the oxygen level control sensor. |

If you have discovered and eliminated a breakdown, you can reset the error code so that it does not appear again during the next diagnosis. To do this, hold down the daily mileage button and hold it in this position for more than three seconds.

We recommend: Possible malfunctions and their independent elimination on Eberspacher autonomous heaters

Air flow sensor VAZ 2107

The VAZ 2107 has been produced for a very long time and during this time has remained virtually unchanged, with the exception of the engine. Initially, the seventh Lada model rolled off the assembly line with an engine with carburetor fuel injection, but time passed and AvtoVAZ needed to modify the car and adjust it to EURO standards. Therefore, the carburetor engine was replaced by an injector.

As you know, injection engines have a large number of different sensors that are involved in the operation of the internal combustion engine. Failure of at least one of the sensors can lead to a malfunction of the engine and a change in its characteristics.

In this article we will talk about the mass air flow sensor on the VAZ 2107, namely its purpose, signs of malfunction, design, cost, methods of self-checking and replacement.

DMRV VAZ 2107

This sensor is installed on the VAZ 2107 by the German company Siemens. This brand is well known in the market and makes fairly high-quality parts, so the mass air flow sensor of this company works for a very long time and reliably.

The sensor is installed on the air filter housing and an inlet corrugation is attached to it, through which air passes and enters the engine.

Purpose and design

The purpose of the mass air flow sensor is to count the air that enters the engine to mix with fuel to form the fuel mixture. In order for fuel and air to be mixed in the required proportions, it is necessary to determine how much air enters the engine at a certain point in time - this is the main task of the mass air flow sensor.

Structurally, the sensor has a cylindrical shape inside, which contains a special sensitive element, which determines the volume of air passed through the sensor. On top of the mass air flow sensor there is a connector to which the power and control circuit is connected; this circuit is connected to the electronic engine control unit.

Symptoms of a problem

Signs of a malfunction of the mass air flow sensor may be similar to the breakdown of other sensors; computer diagnostics using ADC channels will help to more correctly identify a faulty mass air flow sensor.

Signs of a faulty mass air flow sensor:

- Increased fuel consumption;

- Unstable operation of the internal combustion engine in all modes;

- Difficulty starting the engine;

- Loss of power and dynamics;

If your car has such breakdowns, then most likely you need to check the mass air flow sensor.

Checking the mass air flow sensor

Checking the air flow sensor can be divided into 4 stages: shutdown, using a multimeter, visual and computer.

Disconnection test

This test is the simplest and most accessible, but does not provide 100% information about the performance of the sensor.

So, to check you need to disconnect the connector from the sensor and start the car. Then you need to drive the car and evaluate its dynamic performance. If the car begins to accelerate better and operate more stably, then it is most likely that the mass air flow sensor is still faulty.

Checking with a multimeter

This test is more complex, but every owner of a VAZ 2107 can do it. To carry out diagnostics using this method, you must have a regular household multimeter that is capable of measuring DC voltage.

- We set the multimeter switch to measure DC voltage.

- We connect one multimeter probe to ground, and the second to the terminal on the mass flow sensor connector numbered “5” (the wire block is numbered). The voltage between these two points when the ignition is on should be 12V.

- Next, we move the probe to pin “4”; the voltage at this pin should be 5V.

If the readings differ, the sensor is faulty or the battery is discharged.

Visual inspection

The condition of the sensor can be assessed visually after its dismantling. When the sensor is removed, it is necessary to evaluate its internal parts, they should be intact without traces of dirt, dust and oil. In some cases, simply cleaning the sensitive element helps bring the sensor back to life.

Decoding error codes Kalina 1.6 8 and 16 valves

Many owners of this model will be interested in knowing how error codes for Kalina 1.6 8 and 16 valves are deciphered. The on-board computer installed in the car not only controls the operation of the car's systems, but can perform self-diagnosis and inform the driver about any malfunctions in the car. This significantly increases safety and increases the service life of machine components and assemblies. Every driver of this model must be able to deal with emerging alarms in a timely manner.

Decoding error codes for Kalina 1.6 8 and 16 valves will be shown in this article.

You can make a printout and take it with you. If suddenly an alarm signal appears during a trip, it will be much easier for the driver to make the right decision about what to do in the situation that has arisen, continue the trip or wait for help from specialists. The system works in such a way that errors from problems that arise are stored by the on-board computer. They can be read later using special diagnostic equipment.

How to perform diagnostics yourself?

Sometimes even the most reliable and smart cars malfunction during operation. This can fully be attributed to Kalina. The on-board computer of this model is capable of analyzing the current situation and telling the driver about problems. You can test the car in specialized centers or yourself. There is a possibility of errors during self-diagnosis, but it is advisable to carry it out.

Self-check procedure:

- Turn off the ignition;

- It is necessary to press the daily mileage button and hold it in this position for some time;

- While holding this button, turn on the ignition;

- After this, all the indicators on the dashboard should move, they should travel from the zero mark to the maximum. Now you should press the button on the steering column wiper switch. This makes it possible to display readings on the dashboard.

Adjustment process

After connecting the laptop to the car’s on-board computer, you have the opportunity to monitor all the parameters of the vehicle in its various systems and see a list of errors that negatively affect the operation of the internal combustion engine. To identify errors, the data obtained in this way must be checked against the basic parameters. In most cases, the program itself indicates a deviation from the norm. If not, then you need to look for the error by its code in the catalog.

After determining the causes of deviations from the norm, errors can be easily eliminated by adjusting certain parameters that affect the operation of the injector.

How to decipher errors?

During testing, fault codes on the Lada on-board computer are displayed in four-digit form. In this case, the error itself is usually preceded by a letter.

Designation of the first character that appears in the code:

- B - problems with the car body. In particular, we can talk about electric windows and airbags, if the car is equipped with them, as well as central locking.

- C - malfunction in the suspension or chassis of the car or the power steering.

- P is the letter that is displayed more often than others during verification. It means a malfunction in the power unit or transmission system.

The second symbol in the combination means:

- 0 - general code for OBD-2;

- 1 — symbol of the vehicle manufacturer;

- 2 - designation similar to the previous one;

- 3 - reserve code.

The symbol that comes third in the combination determines the type of breakdown:

- 1 - malfunction in the functioning of the fuel unit or air supply system;

- 2 - code designation similar to the previous one;

- 3 - the on-board computer has detected problems with the functioning of the ignition system;

- 4 — auxiliary control symbol;

- 5 - problems associated with the idle speed of the vehicle;

- 6 - errors in the functioning of the ECU or the electrical circuit to which the device is connected;

- 7 and 8 - malfunctions in the operation of the transmission unit.

The 24 Hours channel talked about the verification and decoding of the resulting combinations.

Self-diagnosis

When performing independent testing, the ECU will generate errors in a clear code; their interpretation can be seen in the table.

| Malfunction | Description |

| 2 | The microprocessor module has detected an increase in voltage in the machine's electrical network. A detailed check of the generator set as well as the battery is required |

| 3 | This code indicates a malfunction in the functioning of the fuel level controller in the tank. There is a possibility of a break or damage to the electrical circuit. You need to check the device contacts |

| 4 | Malfunction of the coolant temperature controller. The instrument panel may display incorrect data. The reason may be acidification of the contact elements on the connector or damage to the wiring |

| 5 | Errors appear in the operation of the outside air temperature controller. A check of the device and its wiring is required. |

| 6 | The microprocessor module has detected overheating of the power unit. There are many reasons for such a malfunction; it is necessary to perform detailed diagnostics before further travel. |

| 7 | Increased oil pressure has been detected in the engine lubrication system. The reason may be that the sensor is not working. You need to check the operation of the motor |

| 8 | Diagnostics of the vehicle's braking system is required. Sometimes the error appears due to lack of fluid |

| 9 | Low car battery charge. It is necessary to perform a detailed check of the battery, measure the voltage with the engine running and turned off. |

| E | The microprocessor module detected errors in the operation of the data packet stored in the EEPROM memory |

EMUR malfunctions

Lada Kalina cars are equipped with an electromechanical power steering wheel. If malfunctions occur in the operation of this system, they are displayed with the index C.

The interpretation of errors in the operation of EMUR is presented in the table.

| Fault codes | Description and recommendations for elimination |

| 1011, 1012 | Errors in the operation of the rotation sensor of the amplification device. It is necessary to test the operation of the controller, check its wiring and the electrical circuit to which it is connected. If the sensor breaks, it must be replaced |

| 1013, 1014 | The supply voltage parameter is outside the permissible range. There can be many reasons for the problem, from the operation of the microprocessor module to a malfunction of the generator voltage regulator |

| 1021, 1024 | Problems in the functioning of the torque controller; a detailed check of the sensor is required. It is necessary to diagnose the contacts, as well as the integrity of the electrical circuit |

| 1031, 1033 | There is no signal from the steering shaft position controller. Sensor, contacts and wiring need to be checked |

| 1041-1045 | One of these errors indicates that the control unit was unable to determine the position of the auxiliary motor rotor mechanism. Need to check the node |

| 1050-1061 | These fault combinations indicate a break or short circuit in the winding of the electric motor of the power steering pump. |

| 1070-1079 | Malfunctions in the functioning of the control module of the power steering system |

User CompsMaster talked about repairing the electromechanical power steering on Kalina.

ABS errors

Malfunctions in the operation of the anti-lock braking system can occur as a result of sensor failures.

Deciphering ABS error codes.

| Code | Description |

| 0035, 0040 | Malfunctions in the operation of speed controllers installed on the front wheels. More detailed device diagnostics are required. It is necessary to check the quality of their connections and the integrity of the connectors. Problems may occur as a result of damaged wiring |

| 0045, 0050 | The same malfunction, only indicating problems in the operation of the sensors installed on the rear wheels |

| 0060, 0065, 0070, 0075, 0080, 0085, 0090, 0095 | The microprocessor unit detected malfunctions in the operation of the valves located in the anti-lock unit module. A detailed check of the devices, as well as the unit itself, is required. If testing shows that the valves are faulty, they must be replaced |

| 0161 | Stop light bulbs malfunction. The reason should be sought in the contacts and wiring. Sometimes the problem lies in a damaged or burnt-out safety device. If necessary, light bulbs must be replaced |

| 0550, 0640 | Malfunctions in the functioning of the anti-lock braking system control module. Detailed diagnostics of the device is required. Sometimes the problem is caused by poor contact between the unit and the wiring as a result of a clogged connector |

| 0800 | Low voltage in the electrical circuit of the ABS control module. The problem may be with the wiring or the generator unit. |

We recommend: Vibration at idle: causes and consequences

User Sasha42Rus spoke about diagnosing the ABS system in a Lada Kalina car.

Sensor malfunctions

The table shows a list of controller errors that in practice occur most often when diagnosing the Lada Kalina.

| Fault code | Description and recommendations for elimination |

| 0030-0032, 0036-0038 | The microprocessor module detected malfunctions in the operation of the lambda probe heating device. We are talking about sensors installed before and after the neutralizer. The problem may be a burnt-out spiral or a short circuit of the device to ground or ground. A detailed check of the controllers, including wiring, is required |

| 0101-0103 | Malfunctions in the operation of the sensor responsible for supplying air to the cylinders of the power unit. Its parameters may be out of tolerance or the signal may be too high or low |

| 0112-0118 | The microprocessor module detected malfunctions in the temperature controller. The signal coming from the sensor may be too high or too low. Also, the device sometimes produces incorrect data. A detailed check of the regulator is required |

| 0122, 0123 | Malfunctions in the operation of the throttle angle controller. The signals produced by the sensor can be increased or decreased. It is necessary to check the device as well as the electrical circuit |

| 0130-0134 | Problems with the first oxygen controller. There may be problems with the sensor itself, as well as the wiring. |

| 0132 | Malfunction of the crankshaft position regulator. If the controller fails, detailed diagnostics will be required. With such a breakdown, the engine will not be able to start. The problem may be a clogged sensor connector |

| 0135 | The heating device of the first oxygen regulator is not working correctly. Detailed check required |

| 0365 | The microprocessor module detected a short circuit of the second oxygen regulator |

| 0137, 0138 | An incorrect signal is coming from the same sensor. You need to check the wiring of the device |

| 0140, 0141 | The heating element of the second oxygen sensor is not working properly. Detailed device diagnostics required |

| 0326-0328 | Malfunction of the knock controller or camshaft sensor. Detailed check required |

| 0335-0338 | The microprocessor module has detected damage to the electrical signal circuit from the crankshaft controller. Wiring diagnostics required |

| 0340 | The camshaft sensor has failed. There may be malfunctions in the machine's engine. This error is accompanied by the appearance of a Check indicator on the dashboard. It is typical only for power units equipped with 16 valves |

| 0342-0346 | The control unit has detected a fault in the phase controller. The problem appears only in 16-valve units |

| 0500 | The microprocessor module reports problems in the operation of the speed controller |

| 0504 | Brake pedal position sensor malfunction. Possible wiring problems |

| 0511 | There is no signal from the idle speed controller. It is necessary to check the serviceability of the wiring and connector |

| 1135 | The electrical circuit of the heating device of the first oxygen sensor has shorted. Check the wiring with a multimeter |

| 1171, 1172 | The CO sensor does not work correctly, a violation of its operating parameters is reported |

| 1386 | Problems in the electrical data transmission circuit from the detonation controller |

| 1606, 1616 | Malfunction of the rough road sensor. You need to check the device itself and the wiring |

| 2122-2128 | Problems with the gas pedal position controller. A detailed diagnosis of the mechanism is required. Possible damage to wiring |

| 0720 | Malfunction of the output shaft controller. The error is specific only to vehicles equipped with an automatic transmission. |

| 0717 | Damage to the turbine speed control sensor. This error also appears only on cars with automatic transmission. |

| 0711-0713 | Malfunction of the automatic transmission oil temperature controller |

User Alexander Skripchenko spoke in detail about troubleshooting the Lada Kalina, as well as reading combinations.

Engine malfunctions

Separately, we should highlight the explanations of problems characteristic of power units of the Lada Kalina.

| Code | Description |

| 0171, 0172 | The microprocessor module has detected depletion or re-enrichment of the combustible mixture that is formed in the cylinders of the internal combustion engine. The problem may be due to a malfunction of sensors, for example, a lambda probe |

| 0201-0204 | There is a break in the injector control wiring. One of the errors reports malfunctions in the functioning of elements of cylinders 1-4 |

| 0217 | An excess of the permissible engine temperature has been recorded; it may overheat |

| 0230 | Malfunctions in the operation of the fuel pump relay; diagnostics of the part is required. With such a problem, difficulties will arise in starting the internal combustion engine. |

| 0261-0271 | The microprocessor module detected a breakdown to minus or plus in the injector control circuit. We are talking about elements installed in one of the four cylinders. It is necessary to carry out detailed diagnostics of the devices |

| 0300-0304 | Interruptions in the ignition of one or all cylinders are reported. You need to check the engine |

| 0351-0354 | The microprocessor module detected a breakdown of one of the ignition coils. Such error codes appear only when diagnosing 16-valve engines. |

| 0363 | As a result of misfires, the fuel supply to form the air-fuel mixture is limited. Possible malfunctions in engine functionality |

| 0422 | Incorrect operation of the motor neutralizer. You need to check the unit in detail |

| 0441-0445 | The microprocessor module detected malfunctions in the functioning of the adsorber. Trouble code P0441 requires a detailed check |

| 0480, 0481 | There have been problems with the functioning of the fan unit of the radiator unit. Possible wiring problems |

| 0500 | Problems with the speed controller. The dashboard may display incorrect information for this parameter. |

| 0506, 0507 | Malfunctions in the idle speed maintenance system. The power unit of the machine may not function correctly |

| 0560-0563 | There have been problems with the voltage in the electrical network, surges are possible. Battery and alternator check required |

| 0601 | The microprocessor unit reports a memory error in the ECM. Detailed module check required |

| 0615-0617 | Malfunction of the starter relay. Possible difficulty starting the engine |

| 0627-0629 | A detailed diagnosis of the fuel pump relay is required. If this element fails, the engine will not be able to start. |

| 0645-0647 | Malfunctions in the electrical power supply circuit through the relay to the clutch of the compressor device activation system |

| 0650 | Problems with the indicator designed to alert you to problems |

| 0654 | The electrical circuit of the car's tachometer has been damaged. Engine speed may be displayed incorrectly |

| 0685-0687 | Short circuit of the main relay wiring. Detailed check required |

| 0691, 0692 | Short circuit in the operation of the relay of the ventilation device. You need to check the electrical circuit |

| 0102, 0115 | The microprocessor unit registered a decrease in the resistance level of the oxygen sensor heating system spiral |

| 1123-1128 | A violation of the proportions during the formation of a combustible mixture is reported when the engine is idling or at medium load |

| 1335, 1336 | The microprocessor module has detected an incorrect position of the throttle valve. The node needs to be diagnosed |

| 1136, 1137 | At medium engine speeds, a violation of the parameters for the formation of a combustible mixture occurred |

| 1410, 1425, 1426 | Malfunction of the adsorber purge device |

| 1500-1502 | The control unit has detected an open or shorted circuit in the fuel pump relay circuit |

| 1509, 1513, 1514 | There is damage to the wiring to which the idle speed controller is connected. Possible engine malfunctions |

| 1620-1622 | The microprocessor module reports problems in the operation of its memory units. A detailed check of the device is required. Perhaps the only way to solve the problem is by reflashing it. |

| 2070, 2071 | Malfunctions in the operation of the valve for changing the length of the intake ducts |

| 2100-2103 | The control unit has detected an open circuit or a short circuit on the electric drive of the throttle valve. Detailed check required |

| 2187, 2188 | When the engine was running at idle speed, a violation of the composition of the combustible mixture was detected. |

| 2135, 2138 | Asynchronous operation of throttle position controllers |

| 2187, 2188 | There was a violation in the composition of the air-fuel mixture when the engine was idling. |

| 2301-2310 | Short circuit in the control wires connected to the ignition coils |

| 2500, 2501 | The microprocessor module reports that the operating parameters of the electrical circuit of the generating device are outside the normalized limits. There may be surges in the vehicle's on-board network. A detailed inspection of the unit is required |

| 0706, 0705 | A malfunction was detected in the operation of the contact elements in the automatic transmission selector. The error is typical only for vehicles equipped with automatic transmission |

| 0962, 0963 | The control unit reported a breakdown of the pressure control solenoid in the automatic transmission. It is necessary to test the operation of the device in detail |

| 0973, 0974 | Failure of the solenoid element for activating and deactivating gears in an automatic transmission. Unit diagnostics required |

| 0731-0734 | Gear malfunction in automatic transmission |

| 0744, 1744 | Problems with the automatic transmission clutch. Need diagnostics of the unit |

| 0830 | Malfunctions in the functioning of the clutch system |

| 0863 | The microprocessor module reports a communication error with the automatic transmission unit via the CAN bus |

| 1735-1738 | Gear selection locked |

| 062F | Resetting the memory of the microprocessor control unit of the automatic transmission |

| 263-272 | Malfunctions in the operation of the control device of the engine injection injector driver |

| 650 | The wiring of the Check Engine light bulb has burned out or the indicator itself has been damaged |

We recommend: Car chassis design

User Ainur Volk spoke briefly about troubleshooting engine problems, as well as car diagnostics.

Security system and other errors

Fault codes that are not included in other sections are presented in the table.

| Combination | Description |

| 9000 | Microprocessor device malfunction |

| 9001, 9002 | Malfunctions in the functioning of seat belts have been recorded. The problem may be with the sensors |

| 9042 | Incorrect parameters in the power system are reported |

| 9003, 9004 | The microprocessor unit reported a failure in the functioning of the front airbags. Detailed system diagnostics required |

| 9501 | Malfunction of the windshield drop control controller |

| 9502 | The microprocessor unit reported incorrect functioning of the device designed to adjust the sensitivity of the sensor |

| 9503-9506 | The control module has detected errors in the operation of the windshield wiper system. Possible malfunctions in the operation of the wiper motor |

| 9504 | Malfunctions in the operation of the optics activation relay |

| 9244-9251 | One of these errors indicates problems with the electric side mirror tilting system. Relevant only for machines that are equipped with such equipment |

| 0001-0004 | Failure to operate the light indicators installed in the turning lights. A detailed check of the light bulbs is required |

| 0005-0018 | Malfunctions in the functioning of electric window motors. Possible oxidation of contacts or damage to wiring |

| 0019-0026 | Malfunctions in the electrical power circuit of the mirror rotation system |

| 0027, 0028 | The microprocessor module reports malfunctions in the functioning of the fog lights. Possible damage to lamp contacts |

| 0039-0043 | Break in the electrical circuit of the systems:

|

| 0044-0046 | Malfunctions in the functioning of the engine blocker. The immobilizer may not be able to read the chip installed in the key. |

| 1375-1378 | Malfunction of the evaporative controllers of the air conditioning system |

Communities Lada Priora Lada Priora Club Blog Trouble check and blinking

Why does the check light up? The most common and common malfunctions

So, we figured out the general scheme. Now let's look at what problems lead to the check light coming on and the engine stalling. Often a p0300 error occurs, which indicates that a misfire (misfire) is occurring. There are several reasons for these omissions, and to determine them it is necessary to carry out a step-by-step diagnosis, taking into account certain individual symptoms.

You should start by checking the ignition system. The most common cause of tripping is the failure of spark plugs and armored wires. Candles can wear out their service life, break down, or become heavily contaminated. Armored wires suffer from insulation damage and breakdowns. One way or another, the result is either no spark at all, or there is a spark, but it’s weak.

If everything is in order with the spark plugs and wires, you should pay attention to the ignition module or ignition coils, which may be shorting. In this case, it is better to entrust the check to experienced specialists, since unprofessional actions lead to the fact that you can burn the switch or damage other important elements

It should also be added that you need to carefully inspect the spark plug wells themselves. Quite often, the engine fails if water accumulates in the wells or engine oil gets there. In some cases, lubricant gets into the wells due to problems with the valve cover gasket.

Having dealt with the ignition system, it is necessary to check the power system. As a rule, incorrect operation of injection nozzles or malfunctions in their operation lead to engine tripping. At the same time, the check will light up or flash.

We also recommend reading the article about what misfires in engine cylinders are. In this article, you will learn about the causes of misfires and errors, as well as how to identify and fix the problem.

The best option would be to check the injectors on a special stand. Such diagnostics allows you to determine the need to clean, repair or replace injectors. At the same time, specialists check the power supply to the injectors, the condition of the injector O-rings, etc.

As for compression, a burnt-out valve often leads to an unexpected decrease in the indicator. If the valve burns out, the engine starts to run rough. In this case, tripling is constant and occurs in all modes of engine operation. Engine thrust drops significantly, and significant excess fuel consumption is observed.

Please note that in this case you cannot drive the car, as there is a high risk of damaging the catalyst and oxygen sensor (lybda probe). To confirm the diagnosis, you need to measure the compression, and to solve the problem itself, you need to remove the cylinder head, troubleshoot the head and change the valve.

Reasons for unstable operation of the VAZ 2114 engine cylinder block

In most cases, we hear as a diagnosis that the cylinder has failed. In fact, this formulation is not correct. The cylinder didn't work, that's it. Alas, you will like a lot about the circumstances of this incident:

- the spark plug is faulty or partially damaged;

- low compression in cylinders;

- the valves have not been adjusted for a long time or they do not fit well;

- the injectors are overfilled or clogged and require replacement;

- the high-voltage spark plug wire is broken;

- the oxygen sensor has failed;

- malfunction in the ignition coil;

- the electrical control unit has failed;

- The crankshaft position sensor (CPS) has failed;

- The timing belt, as it is also called, fell off completely; the timing belt moved several notches;

- The air filter is not working well or is very dirty.

The consequences of stopping the operation of the cylinder can be detected both immediately, that is, specifically when inspecting the machine, and in a delayed mode; these consequences are no longer safe for the machine.

- excessive vibration, which manifests itself due to a rhythm disturbance during the operation of the valves and, accordingly, all rotating parts of the engine and gearbox;

- significantly increased fuel consumption due to irregularities in the injection system and the appearance of a corresponding aroma of exhaust gases due to an increase in the concentration of harmful impurities and unburned fuel here;

- a noticeable drop in the power of the power plant and, accordingly, the maneuverability of the vehicle.

The check is blinking and the VAZ 2114 engine is tripping.

If, after detecting signs of engine “triple”, measures are not taken to identify and eliminate the circumstances of this phenomenon, this leads to wear and tear of the entire unit and its serious repair or replacement. It exists that gasoline is constantly injected into the idle cylinder, which, without burning, mixes with the incoming oil and goes into the crankcase. If this condition continues for a long time, the oil dilutes, loses its lubricating characteristics, and engine parts work in extreme conditions, wearing off and forming chips. The consequences will be felt in a short time and the engine will need to be sent to capital.

Diagnosis of errors

When you begin to notice something unusual in the behavior of your car, or there are obvious problems in its operation, then it certainly makes sense to have it diagnosed. Naturally, the OBD-II diagnostic connector will show errors most efficiently and accurately, however, not everyone has sockets to control this connector and has to use the standard one.

In order to enter self-diagnosis mode, you must:

- Turn off the ignition.

- Click on the daily vehicle mileage button.

- Then, continuing to hold it, turn the key in the lock.

- Thanks to this, all available indicators will light up, and the dial indicators will go into self-test mode and show data from zero to maximum.

- When this happens, use the button located on the steering column switch and use it to switch the data on the instrument panel.

- To read the fault codes, we need the last one - the third screen. Unambiguous error codes will be displayed there.

Displaying the error code on the third screen of the bookmaker. The photo shows error 4 (faulty coolant temperature sensor).

ECU firmware

Firmware update of the electronic control unit is an opportunity to expand the capabilities of your on-board vehicle and make its operation more efficient. It must be said that the first versions of programs for firmware (or chip tuning) of the VAZ 2107 appeared back in 2008.

For most G7 owners, software chip tuning is simply necessary, since this operation allows:

- improve machine performance in all respects;

- optimize the functions of the ECU;

- reduce fuel consumption;

- extend engine life.

ECU firmware must be performed exclusively at a service center and after a complete technical inspection of the motor by specialists. Special service equipment is provided for this procedure. Self-firmware can only be performed if you have experience and modern equipment.

Diagnostics

If you notice that something is wrong with the operation of the Lada Kalina vehicle, then it makes sense to diagnose the car. As a rule, all breakdowns appear immediately after checking the car. You can ask for help in carrying out diagnostics at a service station, where you will pay a certain amount for this service, or you can do everything yourself. Of course, with the help of special equipment there is a greater chance of identifying a malfunction, since when checking independently there is a possibility of obtaining inaccurate data.

So, let's start diagnosing the car ourselves. For this:

- Turn off the ignition.

- Press and hold the daily mileage reset button.

- While holding the button, turn the key in the ignition.

- Having done this, all sensor indicators on the dashboard will light up, and the arrows of the tachometer, speedometer, antifreeze temperature sensor and gasoline level in the fuel tank will move on a scale from zero to maximum. Next, press the button located on the steering column wiper switch. This way you can switch the data on the instrument panel screen. On the first one you can see the process of checking the functionality of the instrument panel. The second will show the version of the software installed in the car, and the third will show combinations of faults.

To check your car for breakdowns, hold down the daily mileage button and hold it while turning on the ignition key. At this time, all arrows will go from zero to maximum.

Then press the button located on the steering column wiper switch. This is done in order to switch the data mode on the instrument panel screen.

To read combinations of faults in a car, you will need the last screen. It will display clear codes. To obtain four-digit combinations of faults, use special equipment or the services of specialists at a service station.

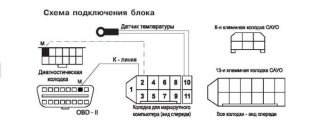

Diagnostic connector

The ECU on the “Seven”, like on other cars, is also equipped with a diagnostic connector. Today, all connectors are manufactured according to the same OBD2 standard. That is, the “on-board vehicle” can be checked for errors and malfunctions using a conventional scanner with a standard cord.

What is it used for?

The OBD2 diagnostic connector is equipped with a certain number of contacts, each of which performs its own function. By connecting the scanner to the ECU connector, you can carry out several diagnostic modes at once with high accuracy:

Where is

The diagnostic connector on the VAZ 2107 is located in the most convenient place for work - under the glove compartment in the cabin under the instrument panel. Thus, there is no need to disassemble the engine compartment mechanisms in order to connect the scanner to the ECU.

Tags: m7.3

Comments 51

It feels like two cylinders are failing while driving, but after turning the ignition key off on it starts to work normally

I had the same problem. Replaced the ignition unit. And I also changed the wires for the spark plugs. One wire almost fell off there. This is not visible visually, but when I pulled it, it tore without much effort. It helped...

hello dear, please give me a hint VAZ 21 07 inzhetor you pick up speed 90 fifth goes km 2 then there is a loss of power while driving, turn off the ignition key after a second, turn on the car again normally

While walking around a Chinese online store I came across this thing: ELM327 OBDII V1.5 CAN-BUS Bluetooth for $9. The device supports: ISO15765-4 (CAN) ISO14230-4 (KWP2000) ISO9141-2 J1850 VPW J1850 PWM Will this thing work on a VAZ 2107 2008?

Location of relay and fuse boxes

The location of the VAZ 2107 fuses and relays is located in the engine compartment, its article number is 2107-3722020-10. It is in an accessible location. In injection cars, an additional relay and fuse block is installed that serves the engine's electronic control unit. It is located under the glove box.

In cars of early years of production, the main relay and fuse box has a different design and arrangement of elements.

Basic engine malfunctions

VAZ 2107 cars are equipped with three main types of power units with a displacement of 1.5, 1.6 and 1.7 liters. The second engine is equipped with a distributed injection system, which differs significantly from carburetor engines. During long-term operation, parts and components of the unit are subject to wear, which can cause the following malfunctions:

Diagnosis of injector or ECU malfunctions is carried out using a special tester, which is available at specialized service stations. Repair and restoration work on the engine is classified as complex and requires high qualifications and special skills.

Relay on fuse box

The fuse block relays and the VAZ 2107 relays are located in the same fuse block. Their purpose:

Checking the serviceability of the relay can be done using a multimeter. To do this, it is necessary to test the armature winding. Its resistance usually ranges from 50 to 200 ohms. It is safer to test connect the winding to the vehicle's on-board voltage. To do this, the relay must be removed from the relay and fuse block. If one terminal of the winding is connected to the positive terminal of the battery, and the other to the negative terminal, you should hear a characteristic click of the activated relay. The main causes of relay malfunction:

Numbering, ratings and purpose of fuses

Each of the fuses in the VAZ 2107 can serve one or more electrical circuits of the car. If a fuse fails, a specific device or vehicle system (or several) will not receive power. As a result, a particular device becomes inoperable.

Fuse failure is not always the cause of a malfunction. In many cases, a blown fuse is the result of a component or system malfunction. Such cases include:

In the event of a failure of any of the vehicle systems, according to the table below and the fuse location diagram, determine the fuse number and its location in the block. If this fuse is responsible for several systems, you should check the functionality of the other system. If it works correctly, the fuse is most likely good and is not the problem. After this, using a multimeter or other measuring equipment, the functionality of the fuse is checked by measuring its resistance (continuity).

Testing the fuse should only be done on a dismantled (removed) fuse. The resistance of a good fuse is close to zero. In most types of fuses, the thread of its working area is visible through the light or is located outside the body part. You can check the fuse visually, but there are often cases of erroneous inspection when the working area has a microcrack.