Brake master cylinder (MBC) is a device for converting the force from the brake pedal into hydraulic fluid pressure for further transmission of force through the hydraulic fluid (brake fluid) to the brake caliper piston. The GTZ is located in the upper part of the vacuum brake booster (VUT). Above the master cylinder there is a reservoir filled with brake fluid.

In general, the part is quite reliable and has a long service life. However, brake cylinders wear out during operation, as a result of which they require inspection, replacement or repair. Read more in our article.

The design of the brake cylinder and the principle of operation of the GTZ

On the vast majority of cars, the cylinders are two-section, each section is responsible for a separate circuit of the brake system.

This is necessary for safety, since in the event of damage, the effectiveness of the braking system will decrease, but performance will remain intact.

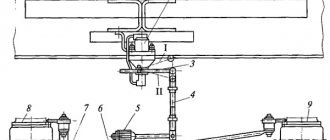

Brake master cylinder design:

- brake booster rod;

- retaining ring;

- primary circuit bypass hole;

- compensation hole of the primary circuit;

- first section of the tank;

- second section of the tank;

- bypass hole of the secondary circuit;

- compensation hole of the second circuit;

- return spring of the second piston;

- master cylinder body;

- cuff;

- second piston;

- cuff;

- return spring of the first piston;

- cuff;

- outer cuff;

- anther;

- first piston.

How does the master cylinder work?

There are 2 pistons located one behind the other in the housing. When the driver presses the brake pedal, the force is transmitted through the rod to the first piston, which moves forward. Due to this, the brake fluid is compressed, thereby forming pressure in the first brake circuit.

Also, the first piston pushes the second piston forward. This piston creates pressure in the second circuit. The compartments that appear when the pistons move inside the housing receive liquid from the compensation tank.

After releasing the brake pedal, the return springs return the pistons to their original position, and the pressure inside the cylinder is again equalized by the brake fluid in the reservoir. This scheme of operation of the GTZ makes it possible to very quickly transfer force through practically incompressible brake fluid to each of the brake cylinders on the wheels.

By the way, the compensation tank also has two sections. If leaks occur, fluid will remain in at least one section. There is an additional brake fluid level sensor inside the reservoir. When the level drops significantly, the corresponding indicator lights up on the instrument panel. To increase reliability, some gas turbine engines use two tanks at once.

How does the GTZ function?

The unit consists of the following parts:

- metal housing with holes for supplying brake fluid, pedal rod and connecting the expansion tank;

- 2 pistons with rubber seals;

- 2 return springs;

- guide bushings;

- end plug with gasket.

An expansion tank is attached to the top of the main distributor body, where excess fluid goes through compensation holes. Inside, the element is divided into 2 cylinders with separate pistons standing on the same axis.

The blind end of the housing is closed with a threaded plug; on the other side there is a flange for attaching to the vacuum booster. The brake pedal rod is attached to the first piston. The brake circuit pipes are connected to the lower holes - separately for the front and rear wheels.

The operating principle of the master brake cylinder looks like this:

- When you press the pedal, both pistons simultaneously move forward and push fluid into the circuit tubes. Under its pressure, the wheel cylinders are activated, compressing the pads on the discs.

- Part of the liquid that does not have time to pass into the tubes flows into the expansion tank through special bypass holes.

- When the driver releases the pedal, the springs push the pistons back, returning them to their original position. Liquid from the tubes and reservoir refills the cylinders.

- To compensate for the expansion of the liquid (for example, from heating), another pair of holes is provided leading to the expansion tank.

Note. The GTZ acts in conjunction with a vacuum booster (not shown in the diagram), which helps put pressure on the pistons. This allows the system to respond faster and make the driver's actions easier.

Symptoms of problems

The general technical condition of the car (including the brake system) can be checked using a personal diagnostic adapter - a car scanner. These types of devices are widespread and have a wide price range. We would like to draw your attention to the budget model of Korean production Scan Tool Pro Black Edition.

The fluid brake system consists of many parts that can become unusable: pipes, wheel cylinders, calipers, drums and pads. Typical signs of a faulty master cylinder:

- After pressing the pedal, the car stops slowly. The reason is that the cuffs of one or two pistons have lost their tightness - they have cracked or “floated”.

- To slow down, you need to press the brake pedal hard. The phenomenon occurs due to swelling of the rubber of the piston seals.

- The brake pedal travel is too short. The fluid inside the cylinder has nowhere to go because the compensation hole is clogged. Another option is that the passage is blocked by a swollen rubber seal.

- A common symptom is pedal failure, the brakes coming on at the end of the stroke. This indicates complete wear of the cuffs; as a result, liquid penetrates behind the piston and rushes into the expansion tank - the cylinder “bypasses.”

- The pads do not release the brake discs and drums and get very hot when driving. Options: one of the pistons is jammed or the bypass hole is clogged.

The listed symptoms of a GTZ malfunction are similar to malfunctions of other elements.

Pedal failure also occurs when a large amount of air enters the tubes or loss of fluid in one of the working cylinders.

Sluggish deceleration and increased force on the pedal are often caused by a breakdown of the vacuum booster - a cracked membrane or a lack of tightness at the joints of the hose that takes off engine vacuum.

- during braking, the car pulls to the side - the problem lies in a certain circuit or wheel;

- jamming of the brake mechanisms of one wheel;

- creaking and squeaking when braking;

- heating the discs and pads on one wheel.

If you eliminate these symptoms, it will become easier to check the brake master cylinder in a garage. This also includes obvious brake fluid leaks and the knocking sound of worn calipers.

Diagnostics and repair

From the signs listed above, it is easy to understand that in most cases there is only one source of problems - rubber products that have become unusable. The cuffs crack and swell, as a result they leak liquid and close the discharge holes. Hence the recommendation: all “rubber bands” of the brake system should be changed at intervals of approximately 100 thousand km, without waiting for critical wear.

Reference. Many auto mechanics express the opinion that after replacing the cuffs, the main hydraulic cylinder will not last long. The statement is true if the car owner purchased cheap, low-quality spare parts or installed new o-rings in the cylinder, where internal wear has formed in the walls.

Before checking the GTZ for operability, make sure there are no other faults:

- Inspect the wheel assemblies from the inside for leakage of brake fluid from the working cylinders.

- Check the integrity of the expansion tank and the fluid level in it.

- Start the engine and at idle speed, press the vacuum take-off pipe to the amplifier. If the engine speed has increased noticeably, there is an air leak and the master cylinder is most likely working.

A clear symptom indicating a breakdown of the main hydraulic cylinder is drops of brake fluid on the body . If you discover a leak, feel free to dismantle the unit and disassemble it to look for the cause. Another common problem - fluid flowing through the seals - is diagnosed as follows:

- Open the cover of the expansion tank and place an assistant in the driver's seat.

- Listening to sounds in the tank, give the command to an assistant to press the pedal.

- If the pedal moves easily and gurgling is heard in the reservoir, liquid is entering there. The reason is that worn cuffs are unable to create pressure in the circuits; liquid seeps through the leaks and enters the container.

To replace or repair the master brake cylinder, you need to remove the unit from the vehicle. Work is carried out in the following order:

- Suck out the liquid from the tank with a syringe. If the cuffs are leaking, press the pedal several times and suck out the excess fluid.

- Remove the expansion tank.

- It is not necessary to drain all brake circuits. Substituting a small container, unscrew the nut of the first tube and carefully move it to the side, plugging it with a wooden stick.

- Repeat the operation with the second tube, unscrew the fastening of the GTZ flange and remove the unit.

Further actions depend on the design of the master cylinder. If the element is completely disassembled, change the rubber seals. Otherwise, you will have to replace the pistons assemblies. Pre-wash the body and all openings with alcohol; do not use gasoline. After assembly, add fluid and bleed the brake system to remove air.

Brake master cylinder: signs of malfunction

The GTZ is a reliable device, but over time, individual elements in its design fail. The list of main signs of problems with the brake master cylinder includes the following:

- the brake pedal fails;

- the brakes are applied at the end of the pedal stroke;

- brake pedal travel reduced;

- braking requires a lot of force;

- the brake pads are constantly pressed against the brake discs;

At the slightest sign that the brake system's response to pressing the brake pedal has changed, it is necessary to diagnose and repair the problem. Please note that such problems do not always indicate that the brake master cylinder is faulty.

In some cases, it may be necessary to completely replace the turbocharger or repair the master brake cylinder, while in others a completely different element turns out to be faulty.

For this reason, it is necessary to pay attention to how the car behaves when braking:

- a clear deviation from a given trajectory when you smoothly press the brake when driving on a flat road. This symptom usually indicates problems in one brake circuit or on one wheel.

- A creaking or grinding sound is heard when braking, a beating is noticeable. The problem is in the pads or brake discs.

- Significant overheating of the brake discs is noticeable. In this case, you need to pay attention to the brake calipers themselves.

If no such signs are found, then there is a high probability of problems with the master brake cylinder.

Checking from inside the car

Stop the engine and press the brake pedal. That's right when it barely moves, even with great force from your leg. If the pedal is too hard, the compensation hole may not be functioning.

If there is a lot of play, press the pedal vigorously (several times in a row). Firmness indicates excess air. Look for a leak.

The vacuum booster is checked in the same way, only at the end it is necessary to fix the pedal in the pressed state and start the internal combustion engine. If the element being tested is working correctly, the pedal will “fail”. If not, replacement is necessary.

The handbrake is checked as follows:

lift it up;

count the clicks at the same time.

Three or four sounds is a good sign. If the lever rises too much, tighten the drive cable. Remember to keep an eye on the indicator on your dashboard. It should light up in two situations:

with the handbrake raised;

5 seconds after ignition simultaneously with the battery light.

Put the car on the handbrake and in neutral. Go outside and try to move the car. If this happens, the pads need to be replaced.

Causes of GTZ failure

As a rule, among the main causes of failure of the main brake cylinder, experts identify:

- Using low-quality/inappropriate brake fluid, resulting in damage to rubber seals and seals. The result is that the gas turbine engine is leaking.

- Brake fluid is replaced irregularly; the fluid “accumulates” moisture and loses its properties. As a result, metal parts oxidize, rust appears, valves become clogged, etc.;

- After poor-quality repair of the GTZ, the functionality of the device is not restored or partially restored. In this case, the brake master cylinder may leak, valves may not function properly, bypass may occur, etc.

For example, if brake fluid flows inside the main brake cylinder, and the required pressure is not created, then the main brake cylinder is bypassed.

We also recommend reading the article about why the engine stalls when you press the brake. From this article you will learn about the reasons for the unstable operation of the motor when you press the brake pedal, as well as how to fix this problem.

In this case, the level of brake fluid in the reservoir does not decrease, but the brake pedal sinks (as if there was a leak). If checking the VUT (with the car turned off, press the brake pedal 3-5 times) gives a positive result and the amplifier is in order, then the GTZ is bypassed.

This occurs because the cuffs are worn or damaged. In this case, pressing the brake pedal does not create the necessary pressure and the brakes do not work.

The process of replacing the VAZ-2110 brake cylinder

If the cause of the non-functioning brakes on one of the rear wheels is determined, then you need to begin the replacement process. First you need to dismantle the old part. It happens like this:

- First you need to remove the rear wheel.

We unscrew the wheel by jacking up the car and placing additional support under the bottom.

It is better to unscrew the tip of the brake pipe with a slotted wrench.

It is more convenient to unscrew the brake cylinder mounting bolts using a ratchet head.

When working with fittings and tubes, the main thing is not to break the threads, otherwise you will have to change them too.

Old brake cylinder.

If the parts are difficult to unscrew, it is better to spray them generously with WD-40 . When rotating the nuts, you need to make sure that they rotate without tubes. If the tube turns together with the nut, it means it is rusty and stuck to the nut. This part is not allowed for use and must be replaced.

The process of installing a new cylinder

Before you begin the cylinder installation procedure, it is imperative to clean the entire rear wheel brake mechanism from dirt. If you really had to climb into the drum, then you need to carefully examine its condition, at the same time inspecting the pads . If worn, they must be replaced .

- If there has been a cylinder leak, then before installing it you need to thoroughly clean the pads from all traces of brake fluid . To do this, you can use a file or sandpaper. Under no circumstances should stripping machines be used, as the pad can be seriously damaged.

- The inside of the rear brake drum also needs to be cleaned of dirt, rust and degreased from traces of brake fluid . If the liquid remains in the drum, the shoe will slide during operation. Only after thorough cleaning of all mechanisms can a new cylinder be installed. The assembly procedure takes place in the reverse order of disassembly.

Master brake cylinder repair

The main brake cylinder is repairable; GTZ repair kits are available for sale. Kits may be complete or incomplete. An incomplete kit usually includes only seals and cuffs for cylinder repair.

The complete kit allows you to perform a comprehensive overhaul of the device and includes:

- GTZ protective cap and fitting cap;

- seals for the piston and piston head;

- sealing cuffs;

- pistons, return springs;

- spring holder, screw.

We also recommend reading the article about why a driver may hear a squeaking, whistling or grinding sound when braking. From this article you will learn about the main reasons for the appearance of extraneous noise during braking, as well as what to do in such a situation.

Before starting repairs, it is first necessary to troubleshoot the GTZ. It is important that there are no chips, scratches, holes or other damage on the inside of the case. If such defects are present, a complete replacement of the master brake cylinder will be required.