The clutch basket is a drive disc mounted on the flywheel of a car engine. Inside the basket there is a driven disk, which is connected to the input shaft of the gearbox using a splined connection. The clutch block of a passenger car consists of a release bearing, a driven disc and a drive disc. Moreover, the leader is called a basket. But it really is very similar to it; this basket contains a driven disk mounted on the input shaft of the gearbox. This is a double-disc clutch, it is used on all passenger cars, as it is very simple and reliable. In terms of reliability, it is much superior to the multi-disc type that is installed on motorcycles.

The clutch basket has some special features. Inside it there is a metal disk, to which the driven disk with linings fits tightly during operation. There are petals around the hole into which the gearbox input shaft is installed. The release bearing, placed on the input shaft, pulls the lobes towards the engine block, while the driven disk disengages from the drive one. At this moment the clutch is disengaged and gears can be changed.

Criterias of choice

First, pay attention to the weight and surface of the part. Inspect the item for various cracks, roughness, and other deformations. Such a ridiculous design can lead to premature failure of the entire mechanism. If the clutch basket has an unpleasant odor, know that the friction material in it is made of poor quality, and it is better to refrain from purchasing such a product. Despite the same design and operating principle, this part is distinguished by size, that is, a specific model has its own spare part. And if you think that the VAZ 2110 clutch basket you purchased will fit perfectly on the Volga, you are deeply mistaken.

The next selection criterion is the manufacturer. Here it is best to focus on reviews from automobile forums, as well as the rating and reputation of the company itself. Next, you should pay attention to the torque. Remember that it must correspond to the manufacturer’s recommendations to within one, otherwise such a clutch basket will not last you even 100 kilometers. An important point is also the springs, which should not “ride” over the entire surface - they should all be tightly secured in the disk. Avoid products with drops of machine oil on the surface.

Adjusting the Kamaz double-disc clutch

Incorrect clutch adjustment on a Kamaz vehicle. The cost of the issue is repeated removal of the gearbox. Or the agony of adjusting without removing the box. How to adjust the clutch This is an eternal question when installing a clutch basket. If you put a basket every day, there is no doubt. There are very important issues that it is better to know about when installing the clutch basket.

The following malfunctions may occur in the clutch basket:

- The petals (otherwise known as pressure plates) may break;

- The pressure plate may be subject to wear;

- Rivets and fasteners may become worn and play may increase.

Basically, when repairing a clutch, the faulty element is always replaced. It should be clarified that experts in this field recommend replacing the clutch basket together with the driven disk, as well as the release bearing. This must be done due to the fact that the clutch part is constantly subject to loads, as well as uniform wear. Therefore, we can conclude that if you replace only one clutch basket, you will still have to replace the driven disk, and after that the release bearing. And when any clutch repair operation is performed, removal of the gearbox is a mandatory factor for this. The only exception is adjustment work.

Thus, we can conclude that it is much wiser to replace the entire assembly at once. Of course, much depends on how the driver drives in the trouble-free operation of the clutch, as well as in correctly made adjustments. In addition, you should not install a clutch basket on your vehicle, which was produced in an unknown place, as people sometimes say, “in artisanal conditions.” You need to purchase car parts only from trusted and good companies. At the moment, the best manufacturers of clutch baskets have proven themselves to be: Kraft, MecArm, SACHS, VIS (Vazinterservice) and LuK.

How to repair a KAMAZ clutch

Repair of the KAMAZ clutch cylinder should be carried out after the problem with the tightness of the PGU and its pumping has been eliminated.

After bleeding is completed, press the clutch pedal, turn the air bleed valve all the way, and then remove the hose from the head of this valve and put on the cap for protection.

The fluid level inside the master cylinder is then set to the correct level. Repair of the KAMAZ clutch master cylinder and replacement of the KAMAZ clutch master cylinder imply this operation as mandatory. The brake fluid released from the hydraulic system during bleeding can be used again after it has settled and further filtered. The quality of pumping is determined by the stroke of the pneumatic hydraulic booster pusher.

It is necessary to check the presence of condensation inside the power cylinder of the pneumatic hydraulic booster. To drain the condensate, you need to unscrew the plug of the aluminum housing of the pneumatic power steering. To drain completely, lightly press the clutch (pedal).

At least once every 3 years, the hydraulic system in the clutch drive should be flushed with methanol or brake fluid, the master cylinder and pneumatic hydraulic booster should be disassembled, and fresh brake fluid should be added.

Source

Replacement and repair of clutch basket

Replacing the clutch basket is an operation that skilled drivers carry out in the garage, using a jack and support blocks. If it is possible to use a lift, then you should use it.

The work of replacing the basket and repairing the clutch is not an easy task for the uninitiated person. The technological features of removing the gearbox and disconnecting the clutch are different for different models, so we describe the principle and sequence of the operation for replacing the basket.

- First, you need a manual, namely, a repair manual for your car. Necessarily. Namely, the method of repair and maintenance.

- The second thing you need is to get a catalog of parts (something may be superfluous, something may be missing).

- It is important that when disconnecting the gearbox, before removing the clutch, you need to mark the position of all rotating parts so that during reassembly (if installed incorrectly), vibrations do not occur.

- Disconnect the gear shift lever in the cabin.

- We get to the gearbox and disconnect it.

- Unscrew the bolts securing the basket to the flywheel. If the flywheel turns, then hold it with a mounting tool.

- Remove the clutch basket and driven disc.

- The clutch release clutch is dismantled along with the bearing. As the repair progresses, evaluate the condition of the clutch fork, and other parts, the bushing, and so on.

- The release bearing will need to be pressed out of the clutch. This is a labor-intensive operation. After pressing out, the clutch bearing is changed. For lubrication, use only those lubricants recommended by the manufacturer.

Before assembling the clutch, thoroughly wash all parts in kerosene and at the same time troubleshoot them. Never reinstall damaged clutch parts.

We assemble the clutch after cleaning the parts from old lubricant and applying new one. Naturally, we install the clutch and gearbox strictly in the reverse order.

Important! Pay attention to the tightening of the bolts. It is necessary to clarify the tightening torque parameters of the basket bolts to the flywheel, and so on.

Removing the clutch discs

Replacing a KAMAZ clutch disc requires its removal. KAMAZ has a friction 2-disc clutch, pressure springs and a device for automatically bringing the middle drive disk to the middle position.

When removing the flywheel, it is necessary to take into account the specifics of its design: the drive middle disk is installed in the grooves of the flywheel, which are located around the circumference of this disk. To ensure heat dissipation in the clutch and its ventilation, the disc in its “body” has holes that separate the ribs (spikes). These cleats have a lever that adjusts the position of the driving middle disc. Both the pressure and middle drive disks are located on spikes in grooves located in the flywheel.

The other side of the disk has protrusions that are designed for pressure springs. You should remember the order in which they are placed. The driven disk includes a hub, a spring, a rivet, linings, and a torque vibration damper. The hub with the disk does not have a rigid connection, there are only 8 springs. The space between the driven and driving disks is where the release springs are located, as well as the intermediate disk adjusting bolt.

Some tricks

Experienced drivers advise, when performing the process of replacing the presented unit, to place evenly small dots of glue (moment or high-quality analogues) on the working surface of the basket. The disk is placed on the basket with the springs facing away from you and aligned along the edges. The glue will help secure the parts while they are attached.

Considering how to place the clutch disc correctly and which side, this method involves a slight continuation. After installing the gearbox, you need to engage the gear and squeeze the clutch and turn the mechanism with the starter. This method is suitable for most machines.

Instructions for adjusting the clutch on KamAZ trucks

It is necessary to adjust the clutch on KamAZ 5320 and other models to maintain the good condition of the truck. Sometimes the need to carry out such work may arise on the road, so it is advisable for the car driver to know the basic conditions for independently and correctly setting up the mechanism.

Design features of the clutch

How is the adjustment carried out?

Debugging the full stroke of the amplifier pusher

Adjusting the KamAZ clutch basket

When is clutch replacement required?

Video “Adjusting the clutch on KamAZ”

Design features of the clutch

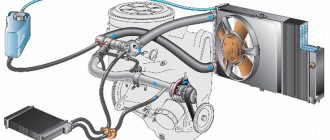

The bulk of KamAZ trucks use a double-disc clutch with a radial arrangement of power springs. To operate the mechanism, a hydraulic drive with a pneumatic amplifier is used. Thanks to this design, the force required to press the clutch pedal is significantly reduced. During the operation of KamAZ, wear occurs on the clutch discs, which must be compensated for by adjustment. Correct adjustment of the mechanism ensures the fuel consumption declared by the factory and confident acceleration of an empty or loaded vehicle.

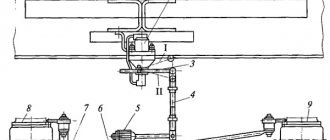

KamAZ clutch drive mechanism diagram

The main components of the drive, which is shown in the photo, are:

- pedal (1);

- hydraulic unit (2) with reservoir (3);

- highway (6);

- executive pneumatic cylinder (16).

The KamAZ clutch of models 55111, 5320, as well as 43118 and 740 consists of the following structural units:

- clutch housing (A);

- release disc with stamped metal casing (B);

- pressure springs (B) and levers (D);

- one drive disk (E);

- two driven disks (D) with linings (W).

Clutch diagram for KamAZ 740 with diesel engine

The driven discs in the clutch design of a KamAZ truck are made using heat-resistant friction linings, which ensure a long service life of the mechanism. The design of the disks provides a damper for vibrations that occur when the motor shaft rotates. The drive pedal is mounted on special bushings and rarely requires lubrication during operation.

On more modern KamAZ models, single-disc clutches of the so-called Euro type are used. This mechanism is found, for example, on models 6520 or 4308. The supplier of elements for such units is Sachs, and amplifiers made by Wabco are used. There are several clutch models that differ in the amount of transmitted torque. One of the differences between imported amplifiers is the built-in indicator of friction lining wear. Wear is measured by the distance between the amplifier body and the washer on the rod. When the linings are completely worn out, this distance ranges from 23 to 25 mm. In this case, driving a car is still possible, but repair work must be carried out urgently.

Wabco CCGT unit, the wear indicator rod is visible in the upper left part

On some KamAZ models, for example, on 43114, there may be a PGU manufactured by the Volchansky Automotive Unit Plant, in which there is no possibility of adjusting the rod. Typically, such a PGU is either replaced with a customizable one or another rod with adjustability is installed.

Installation of clutch discs.

Clutch disc hubs have a protrusion in one direction more than in the other. When installed, their large sides should face in different directions. Toward the flywheel

and towards the clutch basket. The first disk is installed with its larger side towards the flywheel. Next comes the intermediate clutch disc.

The second disc is installed with the larger side of the hub facing the basket. If at least one disk is installed incorrectly. They will bump into each other and the basket will not work.

How to choose a side?

We figured out how to install the clutch disc , but it is also important not to make mistakes when choosing the side of the disc. The following methods will help you figure out which side needs to be installed:

- Certain manufacturers indicate which direction the disc should face on the damper spring housing. The letters are written in different languages, based on who and where the car part was made;

- You can apply the disk first with one side and then with the other side to the flywheel in order to check which of them will easily lie on the surface and will not touch anything. True, this method is often ineffective, since many disks fit equally on either side:

- If there are no markings, it is worth performing an independent inspection of the mechanism using a caliper. It should be taken into account that on the engine side the disc should protrude a quarter less than on the gearbox side.