Torque from the axle or crankshaft to the wheel is transmitted using a hub unit that secures the structure to the suspension. After driving more than 80-100 thousand km, most cars require replacement of the rear wheel bearing, which fails under high loads and metal fatigue. Also, over time, the properties of the lubricant deteriorate. As a result, heating and destruction of the bearing occurs.

Types of bearing assembly designs

Based on the design features, the following types of single- and double-row bearings are distinguished:

- angular contact balls;

- conical roller.

As technology improves, Hub Unit Bearings (abbreviated as HUB) come in generation zero and from generation one to generation five.

Class 0 parts are no longer found in foreign cars, since they need to be adjusted and lubricated. Some domestic manufacturers continue to produce cars with such bearings.

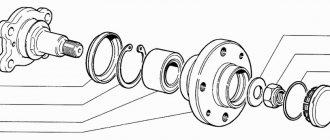

HUB-1 consists of two rows of ball or roller units. Its main elements are 1 outer ring, 2 inner rings, balls or rollers with gaps. Sensors are installed on vehicles with ABS. Contact angles are optimized for loads depending on the vehicle model. HUB-1 is equipped with seals and filled with lubricant for the entire period of operation. It can be changed separately from the hub.

HUB-2 is developed on the basis of the first generation and is characterized by equipping the outer ring with flanges with fasteners for fixing with a suspension. Used on non-driving axes.

HUB-3 plated units have flanged inner and outer rings. In order to distribute the load, the inner ring is connected to the axle shaft using a spline, and the outer ring is mounted on the hub. This design effectively reduces vibration during braking due to low radial runout.

HUB-4 are combined with constant velocity joints, and generation 5 are combined with brake discs. But so far these designs have not found wide application and are operated in a pilot-industrial mode.

Drawings and diagrams of rear wheel hubs

To make replacement and removal easier, let's now learn what the rear wheel hub looks like: drawing

drawing of the hub and rear spacers for extending the wheelbase of the VAZ 2108-21112

Rear wheel hub ZIL 5301

Rear wheel hub with brake drum, shoe brake

The hub of the rear (drive) wheel of a mini-tractor.

How to determine when an element is time to change?

The main signs of a wheel bearing malfunction are a metallic hum and/or wheel play while driving. The last criterion is difficult to notice on your own. A video taken from a car behind you may help.

In order for the driver to determine where the fault is located, it is necessary to turn sharply at speeds of up to 15 km/h. If the noise disappears, the element on the opposite side has broken. To check, it is recommended to make a similar turn in the other direction.

When grinding and crunching noises are heard, the driver is advised to stop. This is a sign of complete failure of the bearing, which may result in the wheel flying off.

In stationary conditions, the malfunction is determined after the vehicle is placed on a lift. Deviations on the drive axles are checked by accelerating to 70 km/h and listening to the hum near each of the wheels. If the wheel is not driving, it is turned by hand and rocked. The play will be felt.

Signs of bearing wear

Signs of wear on the rear wheel bearings are very easy to recognize. When driving, a hum appears in the cabin at the rear of the car. At low speeds, a creaking noise can be clearly heard.

In cases where the bearing has begun to fail, a crunching sound may occur when the wheel rotates, indicating that broken pieces have begun to fall between the rollers.

Checking the condition of this element is also not difficult. It is enough to jack up the rear wheel and check for axial play by rocking the wheel.

Then the wheel should be rotated, listening for the presence of squeaks. If the bearing begins to deteriorate, the wheel will most likely bite when rotating.

Further actions depend on the element used. The design of the bearing may differ on different cars. For example, on the VAZ-2110, an angular contact double-row ball bearing of a closed type is used on the rear hub; in appearance it is similar to the front hub bearing. But Daewoo Lanos uses a tapered roller bearing consisting of two halves. Further we will consider everything using the example of these two cars.

So, if the VAZ-2110 wheel bearing shows signs of wear, it is simply replaced.

In Lanos, you can try to eliminate the hum, squeaks and play by tightening the hub nut. Often it is enough to carry out this operation to eliminate play and hum.

But if a crunching sound is heard when the wheel rotates or tightening the hub nut does not produce results, the rear hub bearing is replaced.

Bearing replacement options

There are several options for replacing the rear wheel hub bearing. In all cases, work must be done on a flat, hard surface. Cars with a manual transmission are placed in first gear. Having determined during the diagnostics which side the part needs to be changed, loosen the nuts with a car wrench on the wheel rim. Then jack up the car to its maximum height. A support is placed under the rear part, onto which the body is lowered with a jack. A stop is installed at the front, after which the wheel is removed.

Standard replacement instructions

After removing the wheel, the screws or pins securing the brake disc are unscrewed. On foreign cars you still need to remove the caliper (the device that presses the pads to the brake disc) by unscrewing the 2 bolts on it. At the same time, you can change the pads if necessary. Then the brake drum is removed.

Next, unscrew the central hub nut with a 30mm wrench or another size depending on the car model. To apply less force, increase the lever on the wrench in the form of a pipe. First, remove the cap with a chisel and a screwdriver, and remove the cotter pin with pliers. After the nut, the pressure washer is disconnected. By tapping with a hammer, the hub itself and the bearing are knocked out of the axle. This may require a chisel and a pry bar.

The hub is also removed with a screw puller, which is a long threaded rod onto which the grips are screwed.

Puller procedure

An impact hammer is installed on the hub studs, and after several blows the axle shaft is removed from the knuckle hole. The bearing retaining ring is removed from the socket.

A screw puller consists of a long bolt, a washer and a metal plate (plate) that rests against the hole in the knuckle. A plate with the diameter of the outer race is mounted on the other end of the puller. The bolt tightens and moves the bearing forward.

To remove the hub assembly completely, you need to disconnect the ABS sensor, unscrew the bolts of the rods, levers and shock absorbers attached to the knuckle axles, and release the handbrake cable.

Option using a pressing machine

It is possible to use a pressing machine to remove the bearing. To do this, first remove the locking ring. Then, using a press, pressure is applied to the bearing. It should pop out, after which the new part is pressed into the hub.

Reassembling all components is done in reverse order.

How to check the rear wheel hub

Let's first find out what signs can be used to determine that a part is living its last days:

- If the hub part has become unusable , then a characteristic grinding sound will be heard from under the tire while driving. This “symptom” is the main one, and with its help you can determine the presence of a malfunction with almost 100% probability.

- When turning, the tire slows down and/or becomes hotter than normal. In some cases, a clicking clicking sound may also be heard when turning.

If you suspect a breakdown, you need to check it. To do this, place the flywheel on the jack and turn it - if a metallic grinding sound appears during rotation, then you must make a replacement, since otherwise such a breakdown could damage the car while driving.

Recommendations for further use

Careful driving can extend the life of the wheel bearing. Avoid driving over potholes and other obstacles at high speed. It is also not recommended to sharply increase speed unless necessary and install wheel rims with a diameter different from the factory version. The optimal tire sizes are written on the bottom of the driver's door.

When the car is operated on bad roads, it is necessary to diagnose the chassis more often at service stations. Specialists will identify and fix the problem, which will prevent a possible accident.

Rear wheel bearing for VAZ 2108: price, part numbers, dimensions – which one is better?

Today there are many offers on the market, sometimes significantly different in price. Which rear wheel bearing for VAZ 2108 is better to buy? The answer is simple - it corresponds to the basic characteristics. Attention should be paid not to the price, but to the dimensions and manufacturer of the bearing.

In addition, the product must have a certificate of conformity to GOST 520-2002 or ISO 15:1998, protective holograms and be well packaged.

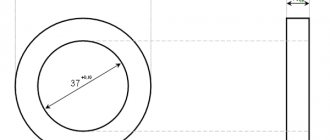

- The VAZ 2108 rear wheel bearing number in the international system is VA2B633313С.

- Marking (number) according to GOST: 6-256706AC17.

NOTE: Low-quality Chinese counterfeits should be avoided, giving preference to original Saratov Bearing (VBF) or Samara-made (SPZ-4) parts. The table below will help you choose the right spare part.

Method one, how to dismantle the bearing

There are a large number of special devices that, even at the factory, received a single purpose - to quickly dismantle the bearing, without requiring power investments and financial costs from the auto mechanic or the car owner. Using special tools to remove the bearing from the shaft is an excellent and easiest solution to carry out repairs. You can save yourself from unforeseen situations. And to do this you just need to follow the instructions. Typically, a standard puller is a threaded shaft that is screwed onto special auxiliary holders. They act as fasteners. Using such a simple puller, the bearing is fixed and removed. Everything ingenious is simple!

Bearing puller

Stages of working with the puller

- We take a puller and bring it to the worn bearing.

- We clamp the bearing with a puller.

- We begin with moderate rotational movements to “pull” the bearing from its seat. Remember that movements should be progressive, without much pressure, so as not to damage the elements of a coherent system.

Thus, the question of how to remove the wheel bearing in car services is resolved. The use of special tools and auxiliary equipment makes the work easier, reduces the cost and speeds up the repair process.

Which way is better

There is no definite answer, because every repair is a special case. It all depends on the age of the car, the wisdom of the vehicle owner, and his responsibility for the technical condition of the car. If a person bought a car to ride and then sell the “tortured steel horse”, then the auto mechanic will have to work on such a car for quite a long time, almost all components of the system will be worn out. In this case, the second or third option is suitable. Ideal car repairs are carried out in a short time and do not require additional financial investments. The first method - the most professional and effective - is used by a car mechanic and will very quickly return the car to operation.

Thus, we have outlined three main ways to remove a bearing, but each craftsman chooses the most optimal one, that is, the one that is most suitable in a particular case. Good luck to everyone with their DIY repairs. If you are not sure, then contact a specialist.

An important part of a car's chassis is the wheel hub. For its free rotation on the axis, a bearing is placed in it. During operation, it wears out and the wheel bearing needs to be replaced. A signal that the wheel bearing is worn out can be a crunching sound, vibration, and the car deviating from the course when moving in a straight line.

The third way to remove the bearing

If it is not possible to use the first method when deciding how to remove the bearing with a puller, then use the third method. It will require skill and the use of force and auxiliary tools. What is the procedure for action?

- Study the features of the procedure, how to remove a bearing, evaluate your capabilities and level of skills.

- Select the necessary tools: a sledgehammer with a soft tip, wooden stands, a vice.

- Fix the removable shaft in a vice and use a hammer and wooden blocks to knock the shaft out in the opposite direction. Be careful not to damage the entire structure of the part with an awkward blow, because it can be used in the future.

Thus, the third method is used if the bearing is completely worn out and does not come out of its seat, so force must be applied. There are times when it is difficult to solve the problem of how to remove the rear bearings from the shaft, so you simply have to cut them out. This radical method is resorted to by experienced craftsmen who have received a completely worn-out chassis system for repair, and there is no other way to get a bearing to replace it. Beginners are not recommended to use the third method, because they simply will not cope and can damage other elements of the chassis system. In this case, a simple bearing replacement will cost a pretty penny.

Why is there a bearing in the hub?

The wheel rim or the wheel rim itself is attached to the hub flange. Elements of the brake system are also installed on it. If the wheels attached to the hub are driven, it acts as part of a car transmission. The front steering wheel hub is a steering element. The diameter of the hub is significantly larger than that of its internal hole, where the bearing is pressed. Its length usually exceeds the diameter of this hole.

The high strength and design of the hub does not require frequent replacement. At the same time, replacing the wheel bearing pressed into it should be done more often. This part, together with other similar bearings, holds the weight of the machine, allowing the wheels to rotate. In the hubs of driven axles that do not experience heavy loads, single-row tapered bearings are usually used. For driving applications, tapered bearings with two rows are used, which can withstand twice the load than single-row bearings.

Wheel bearings have a closed design, which means they can be used until they are almost completely worn out. They do not need to change the lubricant. However, timely replacement of the wheel bearing is necessary, first of all, because it ensures safe movement under the influence of severe radial and lateral loads.

Causes of wheel bearing failure

Friction is the main enemy of balls or rollers. Over time, the lubricant loses its quality and abrasion begins on the spherical surface of the elements enclosed inside the cages. A sign is excessive heating, an increasing hum while driving, a metallic grinding sound.

Failure of one of the assembly elements: the axle or hub will certainly affect the operation of the bearing: the force of impacts on the cages will increase, and excessive axial and radial loads will appear.

Other reasons:

- extreme riding;

- poor road and climatic conditions: dirt, dust, potholes;

- improper installation, adjustment, use of impact methods when assembling the unit.

TABLE OF RECOMMENDED MANUFACTURERS

| No. | Manufacturer | Catalog number | Price 2022, rub. | Equipment | |||

| Retaining ring | Dirt cap | Lock-nut | Instructions | ||||

| 1 | VBF Russia | 2108-3104020 | 500 | – | – | – | – |

| 2 | SPZ Russia | 2108-3104020 | 520 | – | – | – | – |

| 3 | SKF Sweden | VKBA1307 | 1900 | 2 | – | + | + |

| 4 | FAG Germany | 545312A | 600 | – | – | – | – |