The problem with standard Niva wheel bearings (VAZ 2121, 2131) is that they need to be constantly adjusted during vehicle operation. If this is not done in time, they will fail, creating a howl or hum when moving. You can save yourself from such problems by installing non-adjustable hubs or double-row bearings.

Replacing standard front hub tapered bearings

Many owners of the domestic Chevrolet Niva SUV know that the front hub requires special attention. There are two tapered bearings on it, which are tightened with a certain torque. If all work is carried out according to the instructions, you will need a micrometer to control the runout of the brake disc and a torque wrench.

In addition, the unit should be checked every 5 thousand km, and if you constantly drive on uneven roads, diagnostics are carried out more often. There are often situations when the hub is overtightened during repairs, which can also cause premature wear.

Today, many owners of domestic SUVs agree to a small modification - the installation of bearings produced for Iveco cars. They win in many respects and have a longer service life.

Symptoms of a problem

Bearing wear manifests itself as the following symptoms:

- Vibration of the front wheels, which can be reflected in the steering wheel or felt in the cabin.

- Knocking or crackling sounds in the front of the car when driving;

- Heating of the front wheels in the axle area.

If such manifestations occur, you need to check the condition of the wheel bearings. To do this, jack up the car and rock the wheel in different directions. Play and knocking in the bearing area indicates the need for replacement and adjustment. The malfunction may also manifest itself in the form of noise when the wheel rotates.

1. The hubs get hot. It is important to understand that when braking, the kinetic energy of the car is converted into thermal energy. As a result, the brake discs and the hubs on which they are attached become very hot. Heating of the part during movement, and not during braking, indicates wear of the bearing or its incorrect adjustment.

The second option is typical for adjustable hubs. The adjusting nut must be tightened with a force of 2 kgf*m. If you tighten it further, the tapered bearings will be too tight.

Their rotation will be difficult. Prolonged operation of the machine in this condition leads to bearing failure and wheel jamming.

Also interesting: Renault Duster and Chevrolet Niva - video tests

2. The adjusting nut is unscrewed while moving. Sometimes this happens literally after 20-50 kilometers. The phenomenon is observed in three cases: the master forgot to tighten the nut, there was a misalignment between the bearing races, or play appeared in the coupling of the CV joint with the hub.

Advantages of Iveco non-adjustable bearings

The new modification of 2123 hubs for the installation of non-adjustable bearings is gaining popularity - it is convenient and practical, and if you have certain skills, you can do all the work yourself.

The advantages of installing Iveco parts are obvious:

- long service life - about 100 thousand kilometers;

- the units can withstand high loads, which are three times higher than those of factory bearings;

- You can install wheels with a large offset on the car;

- the bearing does not need adjustment and does not require maintenance during the entire period of operation;

- you can do the alteration yourself.

If you decide to remake, immediately check the brake disc, CV joints and side seals of the front gearbox. When replacing them, you will have to disassemble the hubs again and press in bearings, which will become unusable.

How to choose a bearing?

The conversion is very simple. If you have a familiar turner, all the work can be easily done with your own hands. In addition, you can buy a ready-made set - bearings with boots, hubs and steering knuckles.

When choosing, it is important not to make a mistake, since the number of splines on the front hub depends on the year of manufacture of the car - there can be 22 or 24 of them:

- on the series from September 2002 to October 2003 there is a 22-spline hub;

- on other models a set of 24 splines is installed.

If you don't want to buy a whole set, you can go to a turner and have the hub and steering knuckle bored to new sizes. To do this, you need to buy a bearing, disassemble the assembly, wash the parts in gasoline and take it to a turner for adjustment.

For Chevrolet Niva, you can choose one of the following options for Iveco bearings, depending on the width of the car hub:

- 37 mm - the same hubs are found on some Fiat and Opel models, Moskvich 2141;

- 50 mm – similar parameters on the BMW unit;

- 55 mm - classic dimensions for Chevrolet Niva, no modification of the unit is required;

- 57 mm are the “original” bearings of the axle shafts of the rear axle 2121.

The classic replacement option is to install parts from the Moskvich. When purchasing, tell the seller the spare part numbers: bearing No. 2141-3103020 and retaining ring No. 366553-15. You can buy their imported analogues.

Russian variant

These bearings can be found in several versions. The most important thing is to find series A. What is it? This is a series with increased load capacity. Don't be afraid of these words. It’s just that in ordinary bearings for cars, the rollers in the cage are installed one after another, but in this series (industrial), “roller to roller”. That is, there is virtually no distance between them. There are two good options on the market. The first option is 15-gauge bearings, and you can still find them in the Soviet version on the market. This will be visible by the markings on the bearings. The second option is EPK (European Bearing Corporation) bearings.

hub assembly repair kit, EPK bearings

Installation

When the turning work is completed, we begin assembling the unit. Everything is simpler here - no adjustment is required, and the locknut is tightened “from the heart.” There is no need to worry about over-tightening the hub; it is almost impossible.

- place the steering knuckle on a flat, hard surface;

- install the support washer and, using a head or steel pipe, carefully press the bearing into place;

- install the second support washer, then use the same tools to carefully hammer in the oil seal;

- repeat these works on the opposite side of the steering knuckle;

- put the steering knuckle on the hub and tighten the locknut to a torque of about 200 Nm or with moderate force;

- put on the wheel, rotate it and check the functionality of the bearing;

- We fasten the steering rack and ball joints.

During installation, installing an oil seal is not necessary, because the Iveco bearing is a closed type, dust and dirt do not penetrate there. However, to increase the service life of the unit, it is recommended to install at least the cheapest oil seals.

We carry out similar work on the opposite side of the car. After the installation is completed, we go and enjoy - now replacement may be required no earlier than after 100 thousand kilometers, and maybe later. The manufacturer provides the same warranty provided that the installation was carried out correctly.

And finally, if you contact a turner, do not forget to take the drawings with you. They are presented below:

Source

Reinforced, non-adjustable hubs

For Niva 4x4 you can find on sale reinforced, non-adjustable hubs with double-row bearings from the Iveco Daily truck. According to the manufacturer, this modernized unit has the following advantages over Nivovsky:

- there is no need to adjust (the bearing tightening is precisely set during its production);

- no need for regular lubrication;

- eliminates rotation of bearings on the hub;

- eliminates wear of bearing seats on the steering knuckle and hub;

- a ball bearing reduces friction in the hub assembly;

- The service life of the hub is increased due to thickening (see photo).

Instructions for installing steering knuckles with non-adjustable bearings are included. To download files you need to log in to the website. There is at least one drawback of such a modified Niva hub - high cost.

Algorithm of actions

Since the advent of double-row bearing designs, everything has fallen off the chain. Let's straighten everything out. I know 5 different designs and maybe only one does not cause serious complaints in its operation. Now a specific algorithm of actions. If you are lucky and your standard unit has driven more than 20-30 thousand km, the car has a roll and only needed tension adjustment, then your knuckles are bored out coaxially. If necessary, provide good Russian or German bearings and good hubs, and continue to live happily ever after. The most important and important thing is that the Niva wheel bearing must have a steel cage. If you are unlucky and the wheel bearings are “consumable”, or the car does not roll without replacement, your knuckles are misaligned and therefore it is better to think about other projects, since you have nothing to lose. There is an article on the website about the hub version of the IVEKO truck.

Converting the hub to a double-row bearing

Do you want to modify your Niva, but have a small budget? Then we’ll show you how to remake the front hubs on a Niva with your own hands. Required:

- double-row bearing from Moskvich 2141 (catalog number: 2141-3103020), or an analogue from Craft (article: CR4172370);

- two retaining rings from the same vehicle (part number 366553-15).

We take the drawings and seek the services of a turner. The master must bore the hub to fit new bearings, grind the steering knuckles and make parts according to the diagram. By the way, some Niva 4x4 owners also use an AUDI 74x40x74 wheel bearing, in this case only the steering knuckles are ground.

After the parts are manufactured, all that remains is to press in the double-row bearing and reassemble the already non-adjustable hubs. At the end of the work, tighten the hub nut with a large torque “from the heart”. Their adjustment is no longer required, you can forget about the hum and howl while driving!

Have you ever encountered a similar modification to the Niva hub? Leave recommendations and reviews about your options for upgrading the VAZ 2121, 2131. Let us remind you that the domestic SUV has other shortcomings, which are also eliminated by modifications. You can also find information about the car you are interested in by its content.

Key words: Niva front suspension

International NIVA Club

Forums

| Photo gallery | NIVA-SHOP | Files | Video |

- List of forumsAuto - EquipmentTechnical section Lada 4x4 NivaOff-road

- Search

- Links

- Unanswered topics

- Active topics

- Search

Which steering knuckles are best for Niva?

We have already begun to discuss the suspension of Niva and Niva Chevrolet cars, when we looked into the issue of choosing ball joints. The topic of today's conversation is hubs and steering knuckles. This suspension unit does not often require attention, but as “fatigue” begins to appear, it is better to take it up and completely renew it.

Content

- The purpose of the steering knuckles on the VAZ-2121

- What troubles can a “tired” hub unit cause?

- "Bumpiness" when driving on asphalt

- Excessive noise in the Niva car interior

- Poor handling or even wheel separation

- Which fists are better to put on the Niva?

- Hubs for Niva car

- Serial products

- Reinforced hub unit

- TOP steering knuckles for Niva

When I got my hands on the hubs: I updated the steering knuckles on the Niva

In the suspension of a VAZ 2121 car there is a hub unit, and specifically the steering knuckles have quite a significant “weight”. Both literally and figuratively. The ball joints are attached specifically to the steering knuckle. Up and down. As such, the fist rarely becomes a cause for concern for car owners, but the bearings, which in modern models are pressed into the fist itself, of course, require attention from time to time. Just like hubs, which today are presented in the auto parts market in a wide variety. We'll talk about everything separately.

The purpose of the steering knuckles on the VAZ-2121

The name of the suspension element “steering knuckle” immediately makes it clear that it is through the steering arms that the force comes to it, which turns the car’s wheels in the desired direction after the driver has turned the steering wheel.

When figuring out which knuckle to buy for the Niva, it is worth considering that until September 2009, absolutely all variations of the Niva car in Tolyatti (VAZ-21213, VAZ-21214 and VAZ-2131) and Niva Chevrolet cars were equipped from the factory with slightly different steering knuckles and hubs. Moreover, these parts from the Chevrolet Niva were unified. Only the upper ball joints remained original, and the lower ball joints on VAZ SUVs had to be replaced with Shnivy bearings numbered 2123-2904192-02.

Therefore, speaking about hubs and steering knuckles for a Niva car, we will constantly touch upon the related question of which steering knuckle is best for a Chevrolet Niva.

What kind of troubles can a “tired” hub unit cause?

Every Niva driver has more than once encountered the need to remove and install the front wheels, replace ball joints and other routine maintenance on their car. Accordingly, it is not difficult to imagine what the Niva’s steering knuckle looks like and what tasks it performs. This weighty steel structure can be compared to some kind of Atlas, bearing a significant load when the car moves even on a flat surface.

It is designed simply as a monolithic, durable piece of iron with several technological holes without any additions. Except that recently, as mentioned above, a double-row wheel bearing has been pressed into it. The engineers' approach is clear - the more serious the load on a part, the more destructive the consequences of neglect of its condition can be.

“Bumpiness” when driving on asphalt.

Even on a flat road, a hub with a damaged bearing, and, consequently, a slightly “walking” steering knuckle, will not ensure uniform linear movement of the front wheels of the car. On the steering wheel, such a defect will be felt as a barely noticeable twitching, which can be felt when driving quietly on good asphalt. Off-road, of course, the Niva shakes quite a bit and is in completely good condition, so the driver may not notice much of a difference.

Excessive noise in the interior of a Niva car.

It is probably possible to break the steering knuckle itself, but this will require a lot of effort. But bearings, even on reinforced hubs, are a weak point. Even with a sufficient amount of lubricant, relatively high-quality materials and good assembly, they eventually become unusable. When driving, a characteristic noise appears inside the car, bordering on an annoying hum. It doesn’t remind you of the “crunch” of a worn-out “grenade,” but it does hint at possible troubles. What other problems could there be?

Poor handling or even wheel separation

Ignoring a failed wheel bearing or severe wear on the steering knuckle is not a good idea. Of course, the possible loss of a wheel is a rare case, but if the ball joints are in order, they will do their job until the last minute. But experienced guys who actively operate Niva cars in the harshest conditions still recommend periodically inspecting the front hub assembly. When driving quietly around the city, you can safely forget about this suspension part for 100 thousand kilometers, or even more.

Which fists are better to put on the Niva?

The modern spare parts market offers a good selection of steering knuckles. We recommend paying attention to the branded reinforced SV-PARTS hubs, and now we will explain why.

Included with this product is a manual for installing the part and a warranty card, as well as the steering knuckles and hubs themselves. Open the video that we specially recorded for you and watch it live.

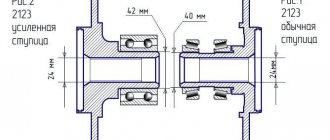

Reinforced hubs differ from the standard hubs of the VAZ 21214 or any other Niva model in their diameter - the size of the original product is 40 mm, and the reinforced one is slightly larger - 42 mm. To protect against counterfeiting, the SV-PARTS logo is applied to the surface of the hub, so it can be easily recognized among analogues.

In our case, an SKF bearing, which is produced in Korea, is integrated into the steering knuckle itself. This element deserves special attention, since it has undergone serious testing on the SV-PARTS company’s own racing car.

The bearings, together with the steering knuckles and reinforced hubs, went through a full racing season in the 2022 Hills of Russia rally-raid series, having completed local races in several regional competitions, in particular, the Ulyanovsk Regional Rally-Raid Championship! The car, under the kind nickname “Yolk”, passed all the races of the season with dignity. There have never been any problems or complaints regarding the suspension. The bearings did not require replacement and ended up in the hands of the team mechanic only at the end of the season during a mandatory rebuild.

In auto racing, when servicing a car, everything is changed at once before the new season in order to minimize the likelihood of leaving the race due to the fact that they hoped and left the old part to save money under the slogan “It’s still good!” Doesn't fit. The rebuild of the racing Niva SV-PARTS is carried out as expected - for reliability, the car is simply built from new components and assemblies.

The video clearly shows the bearings removed from the combat "Yellow" and shows the process of disassembling them. And also all the insides are shown - “live” videos and the excellent condition of the internal and external lenses.

These knuckles are also equipped with an oil seal inside and outside. The oil seals, by the way, appeared after the first reviews from people who purchased and tested these steering knuckles on their cars.

The SV-PARTS assortment includes reinforced non-adjustable hubs for any Niva car - 22 and 24 splines:

Converting knuckles to fit Iveco bearings

Converting knuckles to fit Iveco bearings

Post by Magellan » Mar 22, 2016 6:55 pm

Useful video, watch, learn and redo it yourself.

Re: Converting knuckles to fit Iveco bearings

Posted by Unicel » Mar 22, 2016 8:14 pm

Re: Converting knuckles to fit Iveco bearings

Posted by LLI_H_Y_P » Mar 22, 2016, 10:23 pm

Front wheel hub bearing BTH 1227 manufactured by SKF from IVECO for NIVA 2121-2123. Good price of IVECO bearing for NIVA 2121-2123. Delivery throughout Russia.

Double-row roller bearing BTH 1227 (part of the VKBA 3551 repair kit) from an IVECO DAILY truck. Installed in the front reinforced hub assembly NIVA 2121-21214, Chevrolet Niva 2123, produced by VolgaAvtoProm, as well as for self-boring standard NIVA cams.

IVECO bearing size for NIVA hub 2121-21214, Chevrolet Niva 2123

| External diameter | 73 mm |

| Inner diameter | 40 mm |

| Width | 55 mm. |

By clicking on the button you will receive all the information on delivery and payment of the method convenient for you to receive the goods. Our employees will calculate for you the most profitable method of delivering the goods you have chosen.

Pickup for everyone who is convenient in Moscow to independently pick up and pay for the goods you have chosen.

Delivery by mail or EMS Post. It is preferable for buyers who live in areas where there are no branches of transport companies nearby. Some goods can be sent by mail (restrictions on weight and dimensions). We will advise you on a more convenient delivery method.

We deliver by courier only in Moscow and the Moscow region. The buyer provides the address and telephone number of the place of delivery of the goods, full name. person responsible for receiving the goods, his phone number. When transferring the goods to the Buyer (Representative), the quality, quantity, and completeness of the transferred goods are checked.

Delivery by transport companies is the most convenient and profitable and often the only way to receive the spare parts you ordered. We work with any Transport companies convenient for you. Which are located in Moscow.

Product Installation

I wanted to describe in more detail the assembly technology of this product, but decided not to. Let this be done by a specialist or car services that have an idea of how THIS should work. Now if a client takes a kit and installs it himself, I do not give a guarantee. I'll just say one thing. In the latter versions, I prefer to give people the entire module assembled: a fist, a pressed bearing, installed shims, a brake disc, a hub. Of course, this is extra money from the client’s point of view, since he installed the brake discs “yesterday”, and the hubs “haven’t even passed six months”. But I really liked the phrase of one of my friend mechanics, who has 40 years of experience in auto repair and, as a result, spends the same amount of time communicating with people. It says: don’t feel sorry for the client, no one will remember later that you saved him a thousand rubles, but he will always remember whose fault, in his opinion, the unit broke down. I now give a six-month warranty on this unit on a stock car. You can, of course, give more, but compared to the phrase in well-known stores: 10 days on a receipt, it’s still an eternity. Mean time between failures. At the moment, I know of only TWO cases of structural failure during work. In both cases, the installation technology was violated and the bearings failed. I personally did one thing during the first installation. When installing without mandrels, the races moved apart, dirt got in and the bearing lasted 500 km. Second case, client installation. The adjusting washers are installed on the other side, but oddly enough the unit lasted about six months. This is all due to the fact that even though the bearings are crowbar bearings, they require tenderness and a certain amount of care during installation. And of course, be mentally prepared to immediately change the brake pads, torn CV joint boots or the broken CV joints themselves. Because if the hub is new, and the CV joint is with an old spline, then nothing good will happen either. The bearing will fit perfectly on the hub, and it will hang freely on the CV joint splines.

Reg.: 02/03/2009 Messages: 2543 From: M.O. Fryazino Age: 32 Car: VAZ 2121 1994 1.7i

Reg.: 11/13/2012 Messages: 360 From: Novosibirsk Age: 28 Car: 21214M, 2011; Ya5.1 2111-1411020-61

By the way, the optimal bearings were 72.96 mm in outer diameter - first it is better to buy bearings, measure their dimensions with a micrometer, and then sharpen the fists for them.

Added after 6 minutes 53 seconds:

I bought a foreign car - I betrayed my homeland.

Reg.: 02/03/2009 Messages: 2543 From: M.O. Fryazino Age: 32 Car: VAZ 2121 1994 1.7i

That's right, that's exactly what I was going to do. But I couldn’t even imagine that the bearing would be in the red by as much as 4 acres!! It turns out that if you grind at 73 -0.015, the optimal bearing will fly through!! Right? ZreN

Since you responded, let me shoot you with questions: 1. What diameter was the fist sharpened to, since the fit turned out to be 72.96, what was the tension? VVA wrote about the fit -0.03, and in the drawing that I got -0.015 2. What size did you make the spacer ring D,d,s? 3. Did Nissan take the oil seal on the inside or leave it original? 4. What size snap rings did you use? 75x2? 5. The work was carried out according to this drawing. The link is outdated.

Added after 7 minutes 18 seconds:

Guys, who installed SKF, NK, how are their outer diameters? Just like Optimal in the red? I was thinking about installing nk, but have not yet found information about their quality.

Reg.: 04.11.2008 Messages: 1631 From: Krasnoyarsk Age: 64 Car: 2123 -2007

Well, you are familiar with the concept of compromise. It's up to you to choose. When I ordered the hems, they were in the mid-price category. I don’t know right now if Exist has sets for more than four grand. I believe they had a standardized axial clearance (and something else), which cannot be said about the optimal one. However, there are many cases where backlash occurs. Let me ask you a question. What is taken as the base (position of the bearing axis) for turning by a turner. MVN

, for example, bores, then grinds on a boring machine.

Asd25

uses special imported cutters and an amazingly experienced boring machine on a luxurious globe boring machine. He uses a good measuring instrument, and also made gauges for finishing control. He says it's not easy to get the dimensions right. Please share your thoughts on how you plan to disassemble. Because if you install Optimal, then it seems logical to throw out the disks and pads. Perhaps (IMHO), an advantage would be a lower tightening force with the nut.

Added after 7 minutes 6 seconds:

Bask

The amount of interference depends on the quality of the surface. Crushing cutter marks, or landing on a polished surface. The SKF hems are “zero” sizes, Optimal - it is optimal Price - quality, however.

Reg.: 10/23/2011 Messages: 105 From: Moscow region. Voskresensky district village. Beloozersky Age: 44 Car: VAZ 21213 99 ICE 1.8l 2011 onwards (was.) Now VAZ 2131 2013 onwards Honeysuckle.

Reg.: 06/28/2010 Messages: 37 From: Chelyabinsk Age: 42 Car: VAZ-2121, 1984/81; Lada GRANTA 219060, 03/2012

Reg.: 10/23/2011 Messages: 105 From: Moscow region. Voskresensky district village. Beloozersky Age: 44 Car: VAZ 21213 99 ICE 1.8l 2011 onwards (was.) Now VAZ 2131 2013 onwards Honeysuckle.

Reg.: 02/03/2009 Messages: 2543 From: M.O. Fryazino Age: 32 Car: VAZ 2121 1994 1.7i

Reg.: 11/13/2012 Messages: 360 From: Novosibirsk Age: 28 Car: 21214M, 2011; Ya5.1 2111-1411020-61

VVA

All aviation is essentially a compromise. I don’t plan to disassemble this unit. If this design “runs” 60-70 thousand km (my mileage for 3-4 years) without complaints, this design has paid for itself. Pressing out - simply by squeezing out the hub - let this oil seal fly out of the bearing along with one of the races - if it doesn’t work again then I’ll buy a bearing - it’s not such a huge amount of money. I'm ready to pay for good things (next time maybe I'll try SKF).

I have no doubt at all about the professionalism of the comrades you mentioned above, but we did it with what we had - regular 16K20, T15K10 cutters, I couldn’t even find Dinov’s retaining ring in Novosibirsk - I made it from the UAZ retaining ring that is in the hub. Surface cleanliness - I don’t know why, with such a bearing area Ra 1.6 - 0.8, if my Niva lasts another 120 thousand with my operation on 31 wheels - in gratitude, I will not only make it new fists, I will buy it a new engine. The seats of the original bearings were taken as the base, and their alignment with the seal on the hub side was also checked. Everything turned out well - today I finally pressed in the second hub with the brake disc - I can’t say that there was a fierce tension there (maybe the micrometer was lying?!) - everything went in and not by hand, and it doesn’t seem like it was under a 50-ton press - it was just crushed with a quill lathe. It turns smoothly, with little effort, the brake calipers fit just like on the original bearings. Tomorrow I’ll finish the mount for the SRPM and I think I’ll break it in at the weekend.

Added after 25 minutes 30 seconds:

Bask

1. The tension was made at 2 hundred square meters (0.02) - it seemed to me unnecessary to “pull” more with such a contact area. 2. Outer - 55 mm, inner 40.05 mm, thickness - 2 mm. 3. Nissan, of course, from CORTECO. 4. I remade the retaining rings from a UAZ hub - 95x3.5 - I would have gotten the Dinov ones (they asked for 5-7 weeks for delivery) - I would definitely have installed them. A 77 mm groove was machined under the ring. 5. Not only, but this is enough)))

Tuning for SUVs

Grooving Niva fists under Iveco. The price includes:

- Grinding YOUR fists

- Distance rings (2 pieces)

- Retaining rings (4 pcs)

- Bearings

- Pressing bearings

Reinforced, non-adjustable hubs

For Niva 4x4 you can find on sale reinforced, non-adjustable hubs with double-row bearings from the Iveco Daily truck. According to the manufacturer, this modernized unit has the following advantages over Nivovsky:

- there is no need to adjust (the bearing tightening is precisely set during its production);

- no need for regular lubrication;

- eliminates rotation of bearings on the hub;

- eliminates wear of bearing seats on the steering knuckle and hub;

- a ball bearing reduces friction in the hub assembly;

- The service life of the hub is increased due to thickening (see photo).

Instructions for installing steering knuckles with non-adjustable bearings are included. To download files you need to log in to the website. There is at least one drawback of such a modified Niva hub - high cost.