12/04/2018 Replacing the crankshaft oil seal: everyone will have to go through this Are you tired of the Internet yet? Of course not, we understand that today this powerful source of information is almost the only source of knowledge... However, everyone is tired of this chaos in advice and instructions! On one resource they say that you first need to remove the cylinder head, and on another they say that there is no point in this, and so on. There are many opinions and everyone wants to push their own methodology.

We are convinced that despite the diversity of opinions, there is one correct solution that should be used. That is why we decided to write this article, which contains certified methods of licensed mechanics who worked at reputable official service stations.

We'll consider:

- replacement and purpose of crankshaft seals in most engines;

- replacing crankshaft seals on the popular Opel Astra;

- replacing oil seals on Renault Logan;

- replacement of oil seals on one of the most popular cars in the CIS countries - VAZ 2107.

Go.

Instructions for replacing crankshaft oil seals on most engines

If oil oozes from under the crankshaft, this always indicates one thing - the special seal has begun to wear out. An oil leak can cause a lot of problems for the car owner, but there is only one solution to this problem - the crankshaft seals should be replaced. At a service station, the cost of work is far from low, especially if the rear oil seal is leaking. Let's see how to perform the replacement operation yourself. This will help you save significantly and improve the car owner’s repair skills.

Purpose of the oil seal

For efficient engine operation, constant lubrication is required. To solve this problem, engineers introduced a lubrication system into the power unit, in which oil circulates under pressure. Lubricant is supplied to various components and parts inside the motor. The oil literally sprays out under pressure. Sometimes lubrication is carried out by gravity. Most often, engines operate on a hybrid system: part is distributed under pressure, part by gravity.

The main task is to reduce friction as much as possible, remove wear products, and protect the insides of the precious engine from damage and overheating. In this case, you need to select the crankshaft. It comes out of the power unit housing, and to prevent oil from leaking out, the hole in which the crankshaft rotates must be sealed.

Crankshaft and oil seal

The crankshaft oil seal is used as a seal. Another name for it is the root seal. There are two such seals:

- front: located on the crankshaft pulley side;

- rear: flywheel side.

What it looks like and where it is installed

These sealing elements are made of silicone or fluorine rubber. These materials were not chosen by chance - they are resistant to high temperatures, as well as to the effects of lubricating fluids. This completely avoids the risk of damage to the part due to overheating. Overheating is no joke; at high speeds, the temperatures in the engine can be simply incredible, which is why some parts increase in size. In fact, the part is a ring. The size is equal to the diameter of the engine crankshaft.

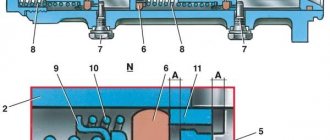

The seal is installed on the engine block where the crankshaft comes out. On different cars and powertrain models, the crankshaft exit location may be different. So, on classic rear-wheel drive VAZs, where the engine is located longitudinally and the timing chain drive is chain driven, the oil seal is installed in the crankshaft shield behind the support bearing. On front-wheel drive cars, the engine is located transversely, and the gas distribution mechanism is most often belt driven. The oil seal in such engines is installed in the cylinder block due to the fact that there are no crankshaft shields on such internal combustion engines.

That is why the advice on which nut to unscrew first is basically meaningless, since it depends on the type of motor.

Malfunctions

Even taking into account the fact that the crankshaft seal can withstand high temperatures, the material is wear-resistant and has a limited service life. It is at rest, but the crankshaft, which is “in conjunction” with it, constantly rotates and “rubs” the seal.

To understand when it is necessary to replace the crankshaft oil seal, it should be borne in mind that high-quality original parts last no more than 200 thousand kilometers. It must be said that an element may fail a little earlier for a number of reasons.

Oil seeps through the oil seal

Among the reasons are untimely oil and filter changes, as well as engine overheating. Oil that has not been changed for a long time contains dirt, dust, and wear products of engine parts. The seal is in constant contact with the oil. Dirty oil causes scratches and burrs to form on the surface of the seal. Then, over time, the scratches increase, and the edge of the oil seal at the point of contact with the crankshaft begins to leak lubricant.

Removing the oil seal

As for overheating, the oil seal is designed to operate at high temperatures, but it also has a limit. Due to severe overheating, the product is deformed, elasticity is lost, and it can no longer provide sufficient tightness. In this case, an oil leak will inevitably form. In this case, an urgent replacement of the crankshaft oil seal is necessary, otherwise all the oil will leak out.

Replacement and subtleties

Obviously, the main reason for replacement is an engine oil leak. In this case, the leakage can be either intense or insignificant. In both the first and second cases, it is better to replace the worn part. It is not recommended to operate a car with a “sweating” oil seal. Firstly, it greatly affects oil consumption, and secondly, it is unsafe.

The oil seal is ready for installation

As we have already noted, there are two types of seals in the engine: rear and front. If you are replacing the front crankshaft oil seal, it is also advisable to replace the rear one. However, if there is a choice, then remember - the front one is especially important. The fact is that it is located near the timing belt - if oil gets on the belt, then there is a serious risk of the belt slipping a tooth or several. Also, the belt material may lose its characteristics and breakage is possible.

Interesting isn't it? It turns out that such a “childish” problem as oil leakage from the oil seal can lead to the belt slipping, and therefore to the wedge.

The rear oil seal is installed at the junction of the engine and gearbox. If oil leaks here, this will lead to a decrease in the lubricant level, as well as dirt in the lower part of the engine. Oil can get on the clutch and it will slip. And again, an amazing fact - problems with the oil seal can lead to failures in the gear and clutch system.

Procedure for replacing the front oil seal

Let's see how to replace the front crankshaft oil seal. Remember - the procedure is labor-intensive. It won't be easy or simple.

Removing the oil seal in a Volvo car

The first step is to dismantle the pulleys. Then remove the protective cover, under which the timing belt is located. Next, remove the belt. After this, it is customary to remove the crankshaft timing pulley. Finally, the front oil seal is removed and a new part is installed in its place.

Rear oil seal

To replace the rear crankshaft oil seal, you must remove the gearbox, then remove the clutch. Next, dismantle the damaged seal and clean the seat. After this, a new seal is installed. Then all the nodes are assembled in the reverse order. It would seem that everything is simple? However, you need to be very, very careful when assembling/disassembling.

What is a crankshaft oil seal and how does it work?

During operation, all engine parts are fairly well washed with engine oil.

Oil lubricates moving parts and reduces friction, extending the life of the mechanism. But what about the parts that come out? A striking example is the crankshaft, part of which is connected to the flywheel. After all, when such a part is brought out, oil can flow through the hole for the rotating shaft. To prevent this from happening, to seal the hole under the shaft, the designers provided a part made of sealed material - the crankshaft oil seal. It is made of silicone or fluorine rubber and is an o-ring with a diameter equal to the diameter of the crankshaft (in the case of the rear oil seal, approximately 99 millimeters). These materials are heat-resistant, which allows the oil seal to be protected from the harmful thermal effects that occur during friction.

Special inscriptions are made on the outside of the seal. Basically, they talk about the direction of rotation of the crankshaft. This information allows you to correctly install the oil seal when replacing it.

Replacing oil seals on an Opel Astra

Let's see how to replace the crankshaft oil seal on an Opel Astra. In general terms, the procedure is clear, but there are subtleties and features. You can diagnose a rear oil seal leak by looking at an oily clutch disc. To replace, you need to remove the gearbox, clutch, and note the position of the flywheel relative to the crankshaft. After this, you need to unscrew the flywheel mounting bolts - there are only five of them. To prevent the flywheel from turning, hold it with a screwdriver. Next, unscrew and unscrew the sixth flywheel bolt and remove it.

Flywheel mounting bolt

Then dismantle the exhaust pipe, drain the oil from the engine, and remove the oil level sensor block. After this, remove the bolts that secure the engine crankcase to the clutch. They also unscrew the crankcase bolts that are screwed to the cylinder block and remove the oil pan. Then unscrew the screws holding the crankshaft position sensor (crankshaft position sensor) and remove it. Next, unscrew the main bearing cover bolts, remove the cover, and remove the rear oil seal from its cage.

A little oil is applied to the edge of the new oil seal (to make it easier to enter), and installation is carried out using a special mandrel. Then all dismantled elements are installed in the reverse order. On Opel, replacing the front crankshaft oil seal is carried out according to the same scheme.

Replacing oil seals on rear-wheel drive cars

Below we will look in more detail at replacing oil seals for VAZ cars, but now we consider it necessary to say a few words. To replace it, you need to disassemble many elements. So, in the case of the VAZ-2107, you will need to remove the front cover. To do this, you will need to remove the generator belt, the cooling casing along with the fan, and unscrew the crankshaft pulley bolt. Then you need to remove the pulley itself. Then unscrew the pan lid. It is removed along with the gasket. When the front cover is removed, replacing the VAZ crankshaft oil seals is not difficult.

The new part is installed in place of the old one in the cover. The working edge should be directed inwards. The part is pressed into place with a hammer. Then everything is put back together in reverse order.

Installed oil seal

To get to the rear oil seal, you need to disassemble even more - the procedure will require enormous effort and a lot of time. Here it is also necessary to remove the gearbox, driveshaft, flywheel, starter, as well as all elements that may interfere with removing the gearbox. After this, dismantle the clutch. Only then can you gain access to the oil seal. Replacing the crankshaft oil seal with your own hands in this case is a very long and difficult process, so you need to be patient. Don’t try to speed up the procedure or somehow circumvent it.

Consequences

Now, let’s take a look at the consequences that can arise when oil regularly leaks from under the crankshaft oil seal. The timing belt is located next to the front oil seal: if engine fluid gets on it, the belt may break faster during operation.

Installation of the front SCV

The clutch mechanism is located next to the rear oil seal, and if consumables get on it, the system will lose its friction characteristics. One way or another, in both the first and second cases, fluid leaks and engine contamination are inevitable,

There was a leak from under the front oil seal

It should be noted that a leak from under the oil pump gasket can also be confused with a leaking oil seal. These elements are located next to each other and the motor fluid in both cases will flow from one side. It is also worth adding that in this case the crankcase will be dirty, since any dirt that remains there will stick to the lubricant.

A broken timing belt is the worst outcome if the crankshaft oil seal leaks. Moreover, on many engine models, cases where engine valves were bent were recorded. In this case, the motorist will need:

- replace the timing belt;

- replace the cylinder head gasket;

- replace the valves, and grind them in;

- grind the engine cylinder head, since in 98% of cases it will be uneven and, accordingly, will not fit tightly to the engine, which will negatively affect the reliability of the power unit.

In addition, if the vehicle is regularly used, the pistons may be damaged by a leaking oil seal, since these are the elements that rub against the valves and can be damaged by them. Experienced car enthusiasts know that minor defects and irregularities on the piston surfaces will not in any way affect the operation of the power unit as a whole.

Installation of a new SCV

But in practice, there have been cases when the piston was simply pierced by the valve itself: in this case, the car owner will have to fork out for expensive repairs, almost a major one. After all, you will have to replace:

- directly failed piston;

- broken shaft valve;

- all liners around the circle will also need to be replaced;

- and change the crankcase gasket.

So, let’s summarize the total costs that a driver may experience in the event of a leak of engine fluid from under the oil seal:

- replacing the timing belt;

- changing valves, grinding them in;

- grinding the surface of the cylinder head;

- replacing the head gasket;

- adding lubricant to the engine, as well as antifreeze to the cooling system;

- It is also advisable to replace the cylinder head mounting screws;

- replacing the piston (if it fails);

- it may also be necessary to replace the piston rings;

- replacing the pan gasket.

This is what a new front SCV looks like.

A motorist who operates his vehicle with a leaking oil seal may face such consequences.

Rear oil seal leaking

Now let’s look at the consequences that the owner of a car with a leaking rear oil seal may face. As in the case of the front oil seal, the car owner will not have such catastrophic problems, but a leak in itself is already a significant problem. To solve it you will have to:

- dismantle the gearbox;

- remove the clutch mechanism along with the disc;

- remove the flywheel.

All this is needed in order to simply get to the oil seal. As for the consequences, if the rear element leaks, motor fluid can flood the clutch mechanism, as a result of which the device will lose its frictional characteristics. In this case, the vehicle:

- will significantly lose power;

- fuel consumption will increase (the driver gives gas, and the car also drives, respectively, gasoline consumption increases);

- you will have to add a lot of lubricant to the engine (all of it, of course, will not leak out, but you will have to add enough).

Fluid leak through rear SCV

Step-by-step instructions for replacing the rear crankshaft oil seal

Just when the rear crankshaft oil seal leaks, then all the troubles begin: the engine begins to get dirty in oil at a rapid pace, and all the dust from the road then very actively sticks to it. One has only to look at such a motor and already there is a desire to pull it out and throw it away. Moreover, the oil will also corrode rubber parts and drip onto the clutch disc, after which it risks losing its frictional properties. Everything starts to creak, slip, rub against each other... In general, because of the small seal, the whole car seems to have gone crazy.

All the oil, of course, most likely will not leak out (however, do not be sure of this), but such a nuisance can add serious problems to you. If there is a leak from the rear oil seal, it must be replaced. There is no other solution to the problems and there simply cannot be.

As we have already noted, this oil seal was invented to neutralize lubricant leaks from the engine through the hole from which the crankshaft emerges. The rear crankshaft oil seal for most car models measures approximately 99 millimeters.

After dismantling the oil seal

Manufacturers apply special marks and inscriptions on the outside of the oil seal. They can be used to determine which direction the crankshaft rotates. Using this information, errors are eliminated during the process of replacing the rear crankshaft oil seals.

This sealing element is installed in the area of the cylinder block where the crankshaft comes out. In ordinary cars, where the engine is located longitudinally and the gas distribution process is carried out using a chain drive, the oil seal is installed in front of the support bearing in the crankshaft shield. In the case of front-wheel drive cars, where the engine is located transversely and a belt is used in the gas distribution mechanism, the element is located in the cylinder block, since there is no shield in the engine design.

Inside the engine crankcase, the lubricant is under a certain pressure. Due to this pressure, the seal is constantly pressed against the parts that it is supposed to seal. This way the engine is reliably protected from oil leaks.

Even with the slightest, slightest displacement of the part, the lubricant will flow. But how can you determine when it’s time to install a new seal? The first sign is oil leaks in the place where the power unit crankcase connects to the gearbox.

If lubricant leaks, it can get into the clutch housing, settle in a thick layer on the walls and stain the clutch disc. All this will lead to clutch slipping. Oil consumption will also increase significantly.

The most surprising thing is that even new oil seals can leak and the reason will not be due to poor installation. In stores you can buy a fake rear crankshaft oil seal for a VAZ. Its cost is low, and car enthusiasts do not notice that they are buying a fake. Poor quality of a part will definitely affect how it performs in the future.

An example of an incorrect oil seal installation

Another reason is a violation of installation rules. Often the seal is placed in a convenient position and carefully hammered into place with a hammer. But manufacturers do not recommend using a hammer or applying significant force when installing the part.

Leakage of poor-quality oil seal

If certain changes occur in the operation, as a result of which the gas pressure in the crankcase increases, then these gases are undoubtedly capable of squeezing out the oil seal. As a result, the contact with the crankshaft will not be tight enough, and the lubricant will leak out through the resulting gap.

Is it possible to confuse the oil seal with something else? Yes, you can. Very often, many experienced motorists confuse an oil filter leak with an oil seal leak. Sometimes a completely normal part is replaced with a new one, and it was just necessary to replace the oil filter.

You should not purchase these sealing parts in dubious stores or markets. There is no need to buy cheap products from unknown brands. This way, you can not only purchase an oil seal, the replacement of which will cause certain problems, but also get more serious malfunctions. Imagine that after buying a cheap oil seal and saving $5, oil will get on the timing belt and damage the entire cylinder block at a cost of $1000, if not more! Saving on oil seals is a real absurdity.

The most popular are the following manufacturers:

- Viuctor Reinz;

- Elring;

- Goetze.

They make quality products. Products of these brands are found not only in car stores, but also at numerous showdowns.

Causes of crankshaft oil seal wear

How do you know when it's time to change the oil seal?

A high-quality oil seal made by a trusted manufacturer can seal the block for 150 thousand kilometers. However, there are a number of specific reasons why there is a risk of the part failing much earlier.

1. The oil and oil filter were not replaced in a timely manner. This is explained by the fact that when used oil is used, dust and dirt penetrate into the oil seal installation site, which scratch the surface that requires sealing. Thus, small scratches that appear during operation damage the edge of the oil seal during rotation and cause it to fail prematurely. Scratches can also occur due to poor quality repairs.

2. Motor overheating. When the engine overheats, the crankshaft heats up to temperatures for which its seal is not designed. Thus, the seal melts and loses its hermetic properties.

To determine the need for replacement, pay attention to where the crankshaft exits the block. If traces of oil leakage are found there and the oil level drops noticeably, then this is a clear sign that the crankshaft oil seal needs to be replaced.

Attention! Do not attempt to repair a damaged seal in any way. This item is consumable and can only be replaced!

Consequences of oil seal leakage

We in no way want to scare anyone, but we consider it necessary to draw the attention of motorists to this problem.

Above, we briefly examined what a leak in the crankshaft rear oil seal can lead to. Now let's look at it in more detail. Most likely, there will not be any catastrophic consequences, but lubricant leaks themselves are a significant problem.

Oil seal leakage

To solve the problem, you will have to dismantle the gearbox, remove the clutch - disc and basket, and remove the flywheel. All this is necessary to get to the crankshaft and its oil seal.

This problem is determined very simply and easily. Even beginners can diagnose it. If there are drops of fresh oil hanging between the clutch housing and the power unit, then it’s time to change the oil seal.

Level overflow

Typically the distance between Min. And Max. The dipstick is 1 liter of engine oil and 1 cm is 300 ml. The latter value or even more is unlikely to pose a danger to the engine.

Yes, the pressure will increase slightly, but this is not necessary, because when developing engines, a safety margin is always provided. And some people deliberately fill the oil above the maximum mark when driving on roads with steep ascents and descents, so that the oil receiver does not trap air.

But if there has been a significant overflow, for example two or more times, the upper oil level will reach the crankshaft, foam will appear, the pressure will increase, and the oil seal will be compressed.

The same thing can happen if the cylinder head gasket breaks or if coolant gets into the lubrication system. The oil turns gray-brown and its level in the base rises, which means you already know what can happen.

The process of replacing the oil seal on a VAZ

To replace it you will have to work hard, since the required part is hidden behind the clutch mechanism. And it is in such a famous vehicle as the VAZ 2107 that this nuance is most clearly observed. To carry out this event, it is better to ask someone to help. Seriously, you can do it alone, but you will waste more nerves than you can imagine. It is better if the assistant has experience in such work.

We begin to unscrew the flywheel

First of all, unscrew the engine flywheel and remove the clutch. The rear oil seal is located in a bolted housing. There are eight of them. Unscrew the bolts and the body will be in your hands. The oil seal can be removed and a new part pressed into the body instead.

The size of the rear crankshaft oil seal is quite large, and the shape is simple, so there should be no problems when pressing in and out.

Replacement using the example of Renault Logan

Using the Renault Logan car as an example, let's see how to change the rear oil seal. The first step is to remove the transmission or gearbox mechanism. The car is hung on a lift. Next, you should remove the battery. Then unscrew the bolt holding the gearbox rocker. After this, remove the bolt holding the clutch cylinder. Then remove all the bolts holding the gearbox.

Next, remove the wheels, unscrew the CV joint nuts, disconnect the ball joints from the steering knuckles, drain the oil from the gearbox and dismantle the axle shafts. A support is placed under the engine pan and the upper transmission mounts are removed, and then the entire gearbox housing.

Yes, to replace the oil seal you need to disassemble the floor of the car. But, alas, there is no other way to cope.

Flywheel removed

Remove the flywheel, basket and driven disk. In this case, it is necessary to remember the position of the flywheel relative to the crankshaft. After this, unscrew the flywheel bolts and remove the Renault Logan crankshaft rear oil seal. The oil seal is replaced with a new one in the reverse order. This completes the procedure. After a successful replacement, you can put everything back together.

Rear drive

All of the above instructions are relevant for front-wheel drive car models. As for rear-wheel drive vehicles, not only the gearbox is removed here. The first step is to remove the driveshaft, then the clutch slave cylinder. Next, unscrew the bolts holding the gearbox. They also unscrew the drawstring. After this, you can safely remove the box and change the rear crankshaft oil seal of a Ford or other rear-wheel drive vehicles.

Attention! Oil seals are made from materials of varying degrees of density. This is done so that they are selected according to the type of oil. If you install oil seals for mineral oils, and the engine is filled with synthetic oil, the seals may dissolve.

Installation of the oil seal (try it on the crankshaft)

Before installation, the oil seal is tried on the crankshaft. The surfaces of the seal housing and the crankshaft are lubricated with oil. After installation, check the status. If no leaks are observed, then everything turned out well. Experts also advise changing both engine seals at once - both the rear and the front.

Here's how to replace crankshaft seals. On front-wheel drive cars, this task can be accomplished even by beginners. As for rear-wheel drive with a longitudinal engine, the procedure requires enormous costs and time. The price for replacing crankshaft oil seals at a service station is affordable (from two thousand rubles), so you can entrust the car to specialists.

What to do in such cases?

As mentioned above, one of the likely problems may be incorrect installation of the element. In particular, if the inner side of the rubber band is bent, then liquid can flow through it. Thus, the element only needs to be changed, despite the fact that it is relatively new.

Replacing the rear oil seal

- Dismantle the gearbox (use the operating manual for your vehicle to do this).

- Then take a screwdriver or any other object with a sharp tip, a regular knife will do. Remove the failed oil seal. Be careful with the work surface when doing this.

- Clean the surface of the crankshaft. Please note that this can only be done with a rag. Some “craftsmen” clean the crankshaft with sandpaper. Under no circumstances should this be done, as this will cause the crankshaft to fail faster.

- Install a new oil seal in place of the old one.

- Install the gearbox.

Remove your gearbox

Remove the rear SCV

Install a new SCV

Replacing the front oil seal

- Remove the pulley block according to the vehicle's operating instructions.

- Next, you will need to remove the timing belt cover.

- Having done this, remove the rubber belt itself.

- After this, remove the drive toothed pulley.

- Only after this you will see the oil seal: it needs to be replaced. Do not forget about the correct installation of the element.

- After replacing it, reassemble everything in reverse order.

Remove the timing case

Remove the timing belt

Install the front SCV

Operating high-quality motor oil

Using a quality lubricant is the first thing you need to do after you have removed a failed oil seal. You will also need to flush the car’s internal combustion engine itself:

- Locate the engine oil drain plug underneath the vehicle.

- Drain the used engine fluid into a container.

- Screw in the drain plug, open the hood and unscrew the filler cap.

- Fill the engine with flushing fluid.

- Screw on the filler cap and start the engine: you should drive it for at least 10 kilometers. The more, the better, since flushing must completely pass through the entire system and clean its components as much as possible from deposits and carbon deposits.

- After this, drain the used flush and fill with new engine oil. Don't forget to change the filter.

If the problem of consumables leaking from under the crankshaft oil seal was precisely due to the use of low-quality oil, then replacing it should eliminate the problem.