The wheel bearing is one of the important elements in a car. If it is absent, the wheels simply will not rotate. This element constantly experiences high loads, so it is made only from high-quality materials. But due to the high mileage of the car, as well as due to improper operation, this part may fail earlier. Experts recommend replacing wheel bearings immediately, otherwise you can get into big trouble. So, let's look at what to do if a wheel bearing hums, what kind of device it has, and the dangers of driving with such a faulty element.

In fact, the buzz is only the first signal. Then the situation can develop quickly and rapidly. Against the background of the humming of the part, drivers begin to hear a crackling sound that comes from the area of the front wheels of the car. And at some point, when the bearing cannot withstand the speed, it shatters into pieces. It's easy to guess what will happen next. First, the wheel will jam, and at the most inopportune moment the car will become uncontrollable and skid. Next, the suspension arm support will break and the axle shaft will become deformed. Repairing the suspension will cost the car owner much more than simply replacing wheel bearings.

For self-diagnosis, you need to be able to “hear” the car. To know how to determine which wheel bearing is humming, you first need to get acquainted with the structure of this element, find out the causes of malfunctions, and also learn how to independently diagnose and replace these parts.

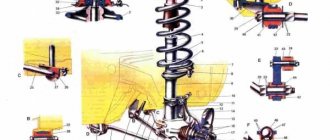

Wheel bearing design

So, a bearing is usually called a mechanism that performs the functions of supporting a support. It can support any axles, shafts or other parts, but in each case the bearing is designed to fix the shafts in space, allowing them to roll or rotate freely. The second function that a bearing performs is to receive mechanical loads and transfer them to other components.

The wheel bearing is a rolling bearing. Its main task is to ensure equal rotation of the wheel around its axis. These mechanisms are divided into single-row and double-row. They can be either open or closed. They are used in the construction of trucks and cars. The front and rear wheel bearings differ in design.

Long runs - high wear

The first and most popular reason is high vehicle mileage. When used for a long time without replacing parts, this leads to severe wear of any unit, and the wheel bearing is no exception to this rule.

And it must be said that high mileage is the root cause of the malfunction. Everything else is secondary. These mechanisms, depending on where and by what company they are manufactured, can operate effectively for 70-120 thousand kilometers. When the time comes to replace the part, the driver will hear a characteristic hum or crunch.

Manifestation of speed noise

Hub noise is not primarily dependent on fast driving. Different levels of wear are reflected in specific ride systems. In practice, the range of 50 - 90 km/h is often used.

- A very worn element expresses itself at low speed.

- This shows the crisis state of friction pairs.

- At what speed absolute disintegration will occur is usually a lottery.

It is important to promptly detect one or another damaged component, as well as replace it.

Violation of installation rules

Another reason can be identified as improper pressing. This reason is secondary. For example, during the repair process, a new bearing can be pressed in incorrectly, say, obliquely. For this reason, after just a few thousand kilometers the new wheel bearing begins to hum, and the car owner must replace it again.

Another reason that can be attributed to improper installation is over-tightening. In most cases, this happens on domestic cars. During the replacement process, the unit was overtightened, as a result of which it overheated, which did not have the best effect on the service life, and then broke. When installing, do not forget about the tightening force.

Determine which hub is noisy

To begin the repair process, it is necessary to determine which side the noise is coming from. The method of monitoring a section along the way is the traditional overload of any axle. Turning to the left creates tension in the left lobe of the car. The mass rests on a specific hub. At maximum wear, this will be reflected by a hum, the element creaks and cracks.

The left-sided line is examined in a mirror manner. When turning left, the car loads the opposite part. The result is similar to the previous one.

Typical symptoms

This is the most interesting thing. In order to determine the failure of a node, there are several ways. At the very initial stage, the behavior of the bearing can be ignored; at this stage, a slight hum, buzzing, and small tapping noises can be heard. Also, one of the first symptoms is a hum when turning (at the very initial stages of a breakdown). This sound is often confused with tire noise. However, over time the sound can be compared to a jet plane. An indirect sign can be considered the complete disappearance of any noise at the moment of turning, but when the car moves in a straight line, everything returns.

When the bearing begins to fail, the driver may hear some crunching noise while driving. The bearing mechanism uses spherical elements - these are the ones that produce these sounds. For the reasons stated above, these parts have broken their cage and are now located unevenly. It is impossible to confuse this sound with something else; it is perfectly audible inside the car. This is the very first signal about the need for replacement, which should not be delayed. The second symptom is vibration. If the unit is already very worn, vibrations will be felt on the body and steering wheel when driving. Vibration informs the car owner that the rim is almost destroyed, and the wheel can jam at any moment. An urgent replacement is needed here. If the car moves to the side, this indicates that the mechanism cannot work normally. During operation, the bearing jams a little.

The hub bearing is humming: is it safe to drive?

Some car owners with faulty bearings not only drive, but also accelerate their cars to 100 km/h or more - this is very dangerous. Do not forget that the wheel bearing is the element that is responsible for the ability to rotate the wheel.

If this unit is broken, it can jam at any moment, and this is very serious. This often results in fatal accidents. A wedge is a sudden stop of one of the front wheels if the front wheel bearing is destroyed.

At a speed of 100 km/h, in the best case scenario, the car will fly off to the side of the road, or it may be thrown into the oncoming lane. Cars also often overturn. It is worth remembering that the wheel bearing is a key component. If the wheel bearing is humming, is it safe to drive? It is possible, but not quickly, up to 40 km/h.

Diagnostic methods

To avoid serious problems, the breakdown should be found and eliminated at the earliest stages.

The easiest way to diagnose is hearing. If the mechanism is in a worn condition, then during operation it makes a sound similar to the sound of a flying airplane or the launch of a projectile, however, the specific option will depend on the type of bearing, size and where it is installed.

What parts can still make noise?

Parts that can make sounds when driving, in addition to the wheel ball bearing:

- Connection of equal speeds;

- Tires;

- Engine gearbox;

- Reduction gear;

- Certain areas of the engine - air conditioning clamping device;

- Lots of other details.

Note! The big noise when moving the car is not the hub, but the gearbox itself. A typical sound also comes from incorrectly installed brake pads.

We diagnose in practice

The process should occur as follows: at low speeds, approximately 50 km/h, the bearing will emit a strong hum, the intensity of which will reach a maximum at speeds from 60 to 65 km/h. Then, when you turn left, the hum will disappear, but if you turn right, it will persist. In this case, most likely the left node is faulty. Here's how to tell which wheel bearing is humming. You just need to listen.

Malfunctions in wheel bearings, as already noted, are accompanied by noise from the wheels, vibrations on the brake pedal, and various extraneous sounds in the suspension mechanisms. Front wheel bearings can make knocking noises from severe play in the bearings, and the noise can be caused by worn out raceways, rollers, and cages.

Symptoms of a bad rear bearing

General signs that are important to pay attention to:

- Clicks and pops. This indicates a worn or damaged outer CV joint. But sometimes this also means excessive play. In most cases this is the result of a bad clamp. And this noise can often be heard when making sharp turns.

- Abnormal lateral pulling force when applying the brake. Sometimes this symptom is considered a sign of a bad equalizer or caliper. But it can also be a sign of worn rotors or brakes. However, excessive play leads to excessive eccentricity, which can cause the brakes to engage. One of the most common causes is warped rotors due to improperly retracted calipers.

- ABS failure. External and internal sensors fail due to movement associated with freewheeling. Therefore, this indicates that there is no clamp. This happens due to mechanical damage.

Diagnostics on a lift or using a jack

There is another way to determine which wheel bearing is humming. In this case, it is necessary to inspect the machine on a lift. A breakdown is detected by how smoothly and evenly the wheel rotates. They also look at the play in the vertical plane. In order to determine the malfunction, grab the lower and upper points of the wheel with your hands and rock it. Only a small amount of play is allowed on the front wheels with the MacPherson type suspension. There should be no play on the rear wheel, as well as on the front wheel, where the suspension is multi-link.

How to check which wheel bearing is humming? Here's what experienced auto mechanics advise. If there is a characteristic noise, but it is not possible to accurately identify the origin, you need to jack up the wheels that are located on the same axis and rotate each of them. If one of the wheels makes more noise than the other when rotating, then very soon the bearings installed on it will fail.

How to replace

The simplest and most expensive option is to buy a complete hub and go to a car service center. For example, on a Priora, a breakdown can be fixed in about an hour. But you can install the hub yourself, or even press the part into place. To do this, in addition to a set of keys and pliers, you will need a pair of pullers: for stoppers and bearings. It would be nice to have a gas canister available to warm up the parts.

Replacing the bearing on the front hub

Place the car on the inspection hole, loosen the wheel bolts, loosen the hub nut and unscrew it with a 30 mm wrench. Place the car on a jack and safety stands. Further (using the example of the VAZ Granta):

- unscrew the caliper and move it to the side;

- remove the brake disc;

- remove the ball joint by unscrewing a couple of bolts;

- pull the CV joint out of the hub;

- release the rack from the lower fastenings (a pair of bolts);

- dismantle the steering knuckle with the hub;

- press it out of your fist;

- Use duckbill pliers to pull out the retaining ring that limits the bearing stroke;

- Place the hub in a vice and use a drift and a light sledgehammer to knock out the middle part of the bearing;

- on the opposite side, pull out the second stopper and press out what is left of the part.

If you have a puller, you can dismantle without a sledgehammer. Lubricate the inner surface of the seat with engine oil and install the stopper on one side. Press in the outer part of the bearing using the old race as a mandrel. Also install the inner part. Reassemble the entire assembly and place it on the machine in reverse order. After completing the work, do not forget to re-adjust the wheel alignment.

About the operation of wheel bearings

The service life of this element will be reduced if the wheel offset is incorrectly selected.

Here the fracture load increases due to the impact of the machine’s weight. In addition, tires with the wrong radius lead to premature wear: in this case, the force that acts on the mechanism during lateral acceleration increases. This factor can often be observed on large SUVs, where the wheels are quite large.

Also, the bearing's service life is reduced if it is installed in a car with faulty shock absorbers: higher shock loads are observed here. A brake system that is damaged will release excess heat into the bearing. Incorrect wheel alignment angles can lead to load redistribution.

The hub bearing is humming: how long can you drive?

Newbie motorists often ask this question. It must be said that the distance depends on the quality of the roads. In some places, the road surface can easily ruin even the chassis of an SUV. Therefore, once again there is no need to take risks, human life is one.

Professional auto mechanics claim that it is still possible to drive, but this is allowed as long as the hum is still barely audible. Driving is allowed only at low speeds. At the same time, you need to go around small holes and potholes. Even drivers who like to take risks are sure that driving more than 200 km with such symptoms is dangerous.

Now you know how to determine which wheel bearing is humming. These tips should help novice motorists who have just gotten behind the wheel of a vehicle.

Coating

The lack of transmission compound can be determined by how loud the bearing is. We emphasize that manual lubrication is possible only for open types.

Closed varieties do not need service; their change is complete. The lubricant is selected according to the type of friction pairs. After work, you should assemble the hub and adjust the gap.