What to do if the power steering hums ? This question is periodically asked by most car owners whose cars have this system installed. What could be the causes and consequences of the breakdown? And is it worth paying attention to this at all?

reasons why the power steering hums . Extraneous sounds indicate an obvious malfunction in the control system. And the sooner you fix it, the more money you will save and will not put yourself at risk of getting into an emergency with a faulty steering system of your car.

Power steering device

Extraneous sound in power steering (main reasons)

There are several reasons why extraneous sounds occur in the hydraulic booster.

Here are some of them:

- Low hydraulic fluid level. Be sure to check the fluid level in the power steering; if the indicator is at the minimum level, you should add oil.

- The liquid does not correspond to the temperature conditions. If a sharp change in temperature is expected in the region, for example the onset of frost, it is worth replacing the liquid with one more suitable for winter.

- Poor quality oil. If there is a smell of burnt rubber in the cabin, you should check the hydraulic fluid for contamination. If, when checking the oil, the color of the liquid does not match the color when filling, this indicates that it urgently needs to be replaced. It is best to change the power steering fluid exactly according to the schedule established when the car was released.

- Airing the power steering system. Air entering a closed system is very dangerous. If foam forms on the surface when opening the reservoir, you should urgently bleed the power steering or replace the fluid.

- Damage to the steering rack. The main sign of a malfunction is a knocking sound from the front wheels or in the steering rack housing. The causes of damage can be different, most often it is wear of the gasket, malfunction of the tie rod boots. If there is the slightest problem with the steering rack, repairs are necessary.

- The power steering drive belt is loose or completely worn out. The lower the belt tension when the engine is running, the more it heats up. In such cases, the drive belt needs to be completely replaced, or the belt should be tensioned according to the manual.

Damage to the power steering pump part. The most complex and expensive breakdown in the power steering system. The causes of failure can be different, for example, faults in pump parts, such as bearings or seals.

Design and operating principle

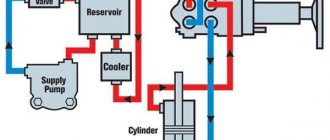

To quickly find the reasons for the buzzing of the power steering, you need to understand its structure and operating principle.

Structurally, the power steering is very simple and includes the following main components:

- Pump;

- Distributor;

- Working cylinder;

- Pipelines (high and low pressure);

There are several design versions of the unit, but on passenger cars power steering is used, in which the distributor and working cylinders are integrated into the steering mechanism.

In this design, the distributor is connected to the steering column shaft, the mechanism body acts as a cylinder, and its piston is mounted on a rack. The working element of the mechanism is a special oil.

The principle of operation of the power steering is as follows: the pump constantly pumps oil, creating pressure in the system, from which it flows through the high pressure line to the distributor.

If the wheels are level while driving, then the working fluid from the distributor through the low-pressure line returns back to the pump, that is, it constantly circulates in a circle.

When the steering wheel is turned, the steering column shaft moves the distributor spool, thereby opening the fluid supply channel into the desired cylinder cavity.

The oil, having filled this cavity, begins to put pressure on the piston, thereby helping the rack to move. When the steering wheel stops rotating, the spool immediately moves to the neutral position and the fluid stops acting on the rack.

A simplified circuit is described above, which is sufficient for a general understanding of the operating features of the amplifier.

READ MORE: Steering control, structure and principle of operation.

The hydraulic booster whistles, hums, vibrates when cold

- The main reason for a hydraulic unit whistling when cold is low-quality or recycled oil. This may be indicated by a strong hum when the power steering operates in winter. Old, recycled oil thickens at low temperatures and makes it harder for the system to pump.

- Air entering the pressure lines. Air leaks can cause severe damage to the entire power steering system, because unaccounted for oxygen changes the properties of the hydraulic fluid, causing the engine itself and all its parts to suffer.

- Poor flushing of the entire hydraulic system. After improper flushing of the system, an air bubble forms at the bottom of the liquid tank, which interferes with the normal operation of the hydraulic booster, resulting in extraneous noise.

- Hydraulic fluid contamination. Even the smallest specks of dust and remaining dirt in the tank can lead to damage not only to the hydraulic unit itself, but also to the steering rack and engine. Check carefully for dirt when changing oil.

- Hydraulic power steering bearing failure. With such a breakdown, the extraneous sound will be constant.

- Chemical elements and salts. In winter, roads are covered with special anti-ice compounds, which in turn corrode oil seals and anthers, which leads to hydraulic failure and the appearance of extraneous sounds during operation.

How to deal with chips in the system?

If your power steering pump whistles for several thousand kilometers, there is a possibility that the oil has carried chips throughout the system. The presence of large particles of pump wear products is dangerous due to clogging of valves, channels and filter elements inside the steering rack. Only a major overhaul will help revive the system, during which the rack is restored or replaced with a new one, be sure to install a new pump, and thoroughly rinse all hoses.

Aluminum shavings can be identified by the characteristic reflections that the particles emit when light rays hit them. To make the test, simply pour a small amount of oil into a transparent container and hold it up to the light.

To prevent costly overhauls, at the first appearance of chips, it is necessary to replace the power steering pump, reservoir with filter element and working fluid.

Extraneous sound when turning sharply

During sharp turns, when the wheels are turned all the way, the load on the hydraulic booster increases many times. As a result, extraneous sound may appear. Which is not necessarily the cause of the breakdown.

- For such subtle differences, you need to thoroughly study the manual when buying a car.

- Manufacturers describe all possible options there, including this one.

- Another reason for the sound when turning the wheels is the blocking of the fluid flow by the bypass valve.

At the same time, the pump begins to heat up. Which can cause serious damage. Do not keep the wheels turned to maximum for more than 5 seconds.

Drive unit

The next reason is the drive of the mechanism. The hydraulic booster is driven by the crankshaft pulley. The nodes are connected by a belt drive.

It should have good tension. Otherwise, the pump pressure will be insufficient. In addition to the hum, you will feel that the steering wheel has begun to turn much more tightly, and in addition there will be increased vibration.

Adjust the position of the tension roller. Typically, a 14mm wrench is used for such work. Also check the condition of the belt itself. Of course, if it breaks, the valves will not bend, as on the timing belt. The pump will simply stop producing pressure. However, you should not drive with a cracked belt. If the element has burrs and small cracks, it needs to be replaced. At the same time, check the condition of other belts (alternator and timing gear) that are located nearby.

Check how the belt bearing rotates: it should not whistle. If so, replace the element with a new one.

Hydraulic noise after fluid change

After replacement, an extraneous sound occurs in the pump part due to the change of power steering fluid. Friction increases between the inside of the stator ring and the rotor plates. Vibration of the plates appears.

To avoid this, you should select hydraulic fluid according to the recommendations in the manual.

Grinding, as well as squeaking (the steering wheel turns both when driving and when standing still)

A grinding/creaking sound that is felt when the steering wheel is turned in different directions. This noise occurs due to wear on the suspension joints or steering joints. Similar to the previous point, here you will need to diagnose the suspension components or steering system, replacing worn parts, if necessary.

However, the most common reason for such a sound is the lack of lubrication in the steering tips (as well as their severe wear).

Sometimes such a squeak can even be accompanied by a crunching sound, regardless of whether the car is moving or standing still. In this case, the culprits are the lower ball joints (sometimes the shock strut bearings). The first option is also accompanied by play in the steering wheel when the car is suspended.

Tips for good power steering performance

By following simple rules, it is very easy to increase the service life of the hydraulic steering system.

- Timely check of the hydraulic fluid level;

- Oil change exactly on schedule;

- Fix the wheels in a level position;

- If there is a problem with the hydraulic system, correct the problem immediately;

- Periodically inspect the steering rack for damage and malfunctions;

- Choose high-quality power steering fluid.

Do not make sharp turns with the wheels turned out, or fix this position for no more than 5 seconds.

By strictly following all the rules for the safe operation of a hydraulic installation, you can maintain its functionality for a long time and save a lot on expensive repairs.

Fixing the problem

Before you begin to correct problems, you must first conduct a complete inspection of the power steering structure, as well as the elements associated with it. It is best to contact specialized workshops for inspection, where experienced technicians will be able to carry out high-quality diagnostics of the vehicle.

If you find minor problems, you can correct the situation yourself. There is an algorithm of actions that allows you to repair the hydraulic booster quickly and efficiently:

- First, the car owner will need to open the expansion tank cap to check the level and condition of the oil inside. If there is not enough fluid, then you should add it to the required level - the Max mark. It will be easy to detect. It is important to check which oil is suitable for your car before adding oil. When the required level is filled, you need to look for a leak. Leaks are usually found near the pump.

- The next step is to check for bubbles and eliminate them. To do this you will need to start the engine. If air bubbles are detected, the steering wheel should be turned to its extreme position. You will need to do this about 5-10 times. Thanks to this simple procedure, it will be possible to expel air from the system and return to normal operation of the power steering. It is worth noting that if after passing the air the sound did not disappear, but only became quieter, then the problem was not in the bubbles, but in a worn-out pump.

- After bleeding the air, the car owner should evaluate the condition of the oil inside the expansion tank. It is noteworthy that manufacturers add dye indicators to the liquid. These can be yellow, red or green shades. This is done in order to determine the presence of foreign inclusions, since serviceable oil has no color and is absolutely transparent. If the oil has acquired a black tint, it is recommended to replace it.

In most cases, these procedures are enough for the noise inside the power steering to stop or disappear completely. If this does not happen, you will have to resort to more serious work - dismantling the hydraulic pump, and possibly other vehicle structures.

Photos of main power steering failures

Knock (steering wheel turns, car turns)

This kind of sound accompanies the car when turning. It is noteworthy that often a small turning angle and a bad road make the car make such a knock more strongly. The reason for this behavior of the car is the wear of the shock absorbers, which no longer dampen road irregularities. In this case, only replacing with new racks will help. As a rule, the axle struts have different degrees of wear, so it is likely that a knocking noise is heard only when the steering wheel is rotated in only one direction.

A knock can occur not only when turning, but also when moving straight along a poor quality road. The maximum load on the racks occurs when the steering wheel is turned, which is why the knocking sound is produced more often. Just in case, check the strut housings - they may contain oil smudges, which indicates an oil leak in the struts.

A car with a decent mileage (the word “decent” means different numbers depending on the model), the shock absorbers can fail (due to various factors). It would be useful to find out how susceptible your car is to this disease either in the official service center or in the appropriate forum dedicated to your car brand. You can also immediately go to a specialist to diagnose the racks.