Fuel system safety valve

It goes without saying that vehicle fuel systems are quite complex devices, which it is better not to approach without specific knowledge. On the other hand, knowledge of hardware and some experience is already considered as an opportunity to independently repair this or that defect. For example, if a fuel system check valve requires attention.

Design

Any check valve (OC) is nothing more than an element that ensures the movement of fuel in one direction. It can block the flow of unused fuel back into the fuel tank.

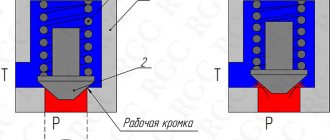

Its design, as a rule, implies the presence of a calibrated saddle made of soft metal. The valve allows gasoline or diesel fuel to pass in one direction, but when the engine stops, the valve automatically closes and the movement of liquid stops.

Fuel system valve and pipe

Despite the simplicity of the design of the bypass valve, its malfunction or its banal absence in the system can lead to great difficulties. For example, the normal functioning of the motor is impossible, and starting it becomes more difficult.

There is no need to confuse the OK with a pressure reducing valve. The latter is responsible for pressure stability, although it operates in conjunction with a check valve.

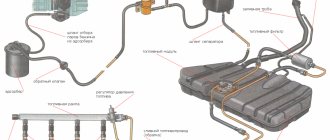

Read more about pressure reducing valve. It is responsible for equalizing the pressure in the section of the fuel rail where the fuel liquid enters the injectors. If it were not for this valve, the injectors would receive fuel under different pressures or without it, as a result of which they would not be able to transfer gasoline further into the chamber.

Pressure reducing valve or pressure regulator

The regulator stops supplying fuel to the injectors when the engine stops and the ignition is turned off. The shut-off mechanism simply operates, cutting off part of the fuel line. Gasoline remains only in the area between the fuel pump and the ramp, if OK. If not, there will be no fuel in the system; it will leak back into the tank.

Malfunctions

The very first sure indication that a VAZ fuel injector pump is faulty is the following symptom: the engine “jerks” during operation, especially at medium and high speeds. This indicates that the fuel pressure is insufficient.

You can read about the reasons why a car jerks when driving in this material: https://vazweb.ru/desyatka/pitanie/dergaetsya-pri-dvizhenii.html

But this is precisely what the fuel pump is responsible for. But sometimes the reason should be sought in the injectors, as well as the RTD.

Location

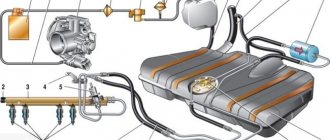

The OK can be installed in different places: in the fuel pump housing, on the ramp, or simply between the tank and the injectors. The exact location depends on the specific car model.

For example, on most diesel cars the OK is placed between the low-pressure pumping device and the injection pump. Here, in addition to its main functions, it is responsible for the stability of the pressure at the injection pump inlet. Examples: KAMAZ, Tatra, Man trucks, etc.

Article on the topic: Warming up the engine in winter, whether it is necessary to heat it, how much to heat it and why

Where is the fuel system check valve located?

But in KamAZ vehicles intended for operation in arctic conditions, in Magirus truck systems, a check valve is installed in front of the heating system.

On VAZs with injectors equipped with 16-valve engines, the OK is installed either in the fuel pump or on the ramp. But in carburetor VAZs of the old type, on the “classics”, it is not there. But the function is provided. The role of OK is played by the fuel pump itself, installed on the BC.

Caring owners of old cars, including the Mazda 323 and Opel Cadet, modernize the fuel systems themselves by installing check valves closer to the carburetor or injector. This makes it easier to start the engine, because fuel is no longer drained back into the tank, even at the lowest temperatures or depressurization of any connections.

Types of valves

Modern injection pumps use several valves. One of the main ones is injection. Let's consider its functions and tasks.

It is customary to distinguish discharge valves by type: cylindrical, combined, mushroom, etc.

| Mushroom discharge valve | |

| Most widespread | Diesel systems |

| Valve with suction belt | It is pressed against the socket by a spring and its lifting depends on the limiter |

| Operating principle | During the injection process, fuel presses from below on the valve mushroom, as a result of which it rises and opens access to the injector. When the supply stops, the spring lowers the valve down and then presses it tightly against the seat. When the suction belt enters the guide, the volume of the discharge line increases and the pressure in the system decreases. |

| Cylindrical valves | |

| Form | Cup |

| Weight | The mass of cylindrical valves is less than that of mushroom valves. They allow for a noticeable reduction in the volume of the fitting. |

| Plate valves | |

| Device | They are simple in design, have low mass, and therefore have low inertia. |

| Operating principle | As the pressure increases, both plates rise. When the lower plate rests against the protrusion of the nut, the upper one continues to move upward and allows fuel to access the fitting. |

| Combination valves | |

| Purpose | Combination valves are used to eliminate vibrations in the fuel injection line. |

| Operating principle | The valve consists of two plasti, one of which is loaded with a spring. During the pumping process, plate 1 moves upward and rests against the body with its protrusions. Fuel passes through the hole in the bottom plate, flows around the top plate and enters the fuel injection line. After the fuel pressure is cut off, the upper plate is pressed against the lower plate, decoupling the fuel line and the high-pressure pump. |

| Double valves | |

| Scope of application | Double valves are installed in critical heavy diesel engines. |

| Purpose | The presence of two sequentially located valves ensures greater reliability of the fuel system, as it creates greater tightness of the unit. In addition, if one of them fails due to jamming or solid contaminants getting under the cone, the other continues to independently perform the functions of isolating the pipeline and the pump. |

Problems

Why does OK fail? This happens quite often, since the market today has become more defective as a percentage. Chinese counterfeits at low and medium prices attract the attention of motorists who do not suspect a trick. It is worth installing such a part, and after a while problems arise.

How to check the fuel system check valve

If the part is of high quality, then the malfunction occurs for a natural reason - due to wear. As a rule, either the spring or the membrane deteriorates. It is extremely rare for the valve to fail completely, which is a credit to it.

Another common cause of failure that we have seen lately is low quality fuel. Gasoline or diesel fuel mixed with water is harmful to many parts of the fuel system.

Typical symptoms of an OK malfunction look like this:

- the speed changes unexpectedly in idle mode;

- the engine starts only after pressing the gas pedal, although previously it started only by twisting the starter;

- at low speeds the engine operates extremely unstable;

- Liquid leaks from the supply and return fuel pipes, although the sealing of the hoses is beyond doubt.

OK has a mechanical design. On the one hand, it seems to be good and can be easily fixed if you understand the mechanics. In fact, the element is non-separable, and it is impossible to diagnose its functionality using electronic devices, sensors, for example.

Ways to check functionality OK

Various methods are used to determine the serviceability of the valve. One of them is based on checking the pressure level. It is measured by a pressure gauge connected to that part of the system that supplies the engine with gasoline. The normal pressure level should be 3 kg/cm2 (passenger cars). Also, the level should not drop sharply when the engine is stopped. Otherwise, this also indicates a malfunction of the return valve.

Article on the topic: Which oil is better to fill in a VAZ engine

Pressure gauge

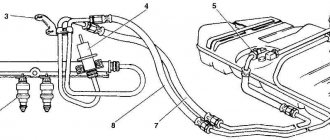

Some experts advise checking OK by squeezing the return hose. In this case, if everything is in order with the valve, the pressure level should increase. The method is suitable for those machines in which the “return” is made of a rubber hose. However, many cars are equipped with metal pipes or the “return” is too short, it is impossible to compress it.

There is another diagnostic method, without a pressure gauge, suitable for engines that are unstable and have difficulty picking up speed. Again, the return line is pinched. At the same time, you need to monitor the operation of the internal combustion engine. If the engine speed increases and all cylinders are functioning normally, the OK is most likely faulty.

Obviously, nothing good can be expected from a damaged valve. A drop in engine speed, unstable cylinder operation, difficult starting, airing - all this will come sooner or later if the valve does not work.

Clamp the return line

It will be interesting to consider the reason for the airing of the system, which opens our eyes to the principle of operation of the OK. After stopping the engine, a certain amount of fuel liquid must remain in the chamber, awaiting the next start. If there is no valve or it is damaged, gasoline/diesel goes back into the tank, and air takes its place. Until the system is ventilated and the pressure is brought back to normal, the engine will not start.

Article: 2108-1156010

Order code: 001030

In stock Available for order – >10 pcs. Data updated: 05/30/2021 at 02:30

Order code

001030 Articles 2108-1156010 Manufacturer DAAZ Catalog group: ..Engine power system Engine Width, m: 0.055 Height, m: 0.035 Length, m: 0.055 Weight, kg: 0.013

Product reviews

Where is it used?

Reviews

There are no reviews for this product yet.

Write a review

Articles about the product

- “Crystal” vases: “Classic”. Do you remember how it all began? April 16, 2013 Today, the next article in the series “Crystal VAZs or typical breakdowns of domestic cars” is dedicated to the “classics”: VAZ-2101, 2103, 2104, 2104, 2105, 2106 and 2107. These cars have been driving along our roads for decades and, despite all the shortcomings that we will talk about, their popularity is still high.

- “Crystal” VAZs: Niva

April 2, 2013 The series of articles “Crystal” VAZs or typical breakdowns of domestic cars” introduces motorists to typical malfunctions that arise when operating AvtoVAZ cars. This article is dedicated to the favorite of hunters and fishermen - “Niva”. - “Crystal” VAZs: “Eight”, Kalina, Priora

March 26, 2013 A series of articles ““Crystal” VAZs, or typical breakdowns of domestic cars” talks about typical problems and malfunctions of cars produced by the Volzhsky Automobile Plant. Today we will talk about the front-wheel drive Samara family, as well as its modern analogues.

- VAZ-2108 fuel check valve DAAZ Article: 2108-1156010 Order code: 001030 90 ₽ or place an order by calling 8 800 6006 966

Availability of goods in warehouses and stores, as well as the price of the goods is indicated on

30.05.2021 02:30

.

Prices and availability of goods in all stores and warehouses are updated once an hour.

If there is a sufficient quantity of goods in the store you need, you can buy it without pre-ordering. Internet price

– valid when ordering on the website or through a call center operator by phone

8-800-600-69-66

. Subject to sufficient quantity of goods at the time of order.

Price in stores

– retail price of goods in store sales areas without pre-order.

The period for moving goods from a remote warehouse to the warehouse of an online store.

The parts data presented on this page is for informational purposes only.

5a33dc6c087cffd2f71020d1d0ef3165

Add to cart

Available to order:

Order quantity:

Product successfully added to cart

!

Installing additional OK

It is recommended as an option for upgrading a system in which the original valve no longer holds (or does not exist at all). You just need to try to choose a high-quality valve, and the cross-sectional dimensions must be suitable. For example, some models of VAZ valves are not suitable for foreign cars. You can install them, but they don't last long. As soon as you accelerate sharply or climb a mountain, the valve slips and the car begins to choke.

It would be better to buy OK from parsing. Find the fuel pump of a specific car model, check the valve, if it works, take it. It does not matter whether the pump itself is running or not. The main thing is to hold the valve.

Fuel system check valve Nexia

All that remains is to embed the valve into the line, in any convenient place. For example, between the fuel pump and the filter. Then check on a hill or when accelerating to see if the car is choking.

Engine timing chain marks 405

When installing marks on the engine of a Gazelle car, experienced mechanics do not recommend turning the crankshaft counterclockwise. Timing timing marks are set according to the engine operating manual.

For example, the marks on the camshaft sprockets should be horizontal. They go in opposite directions from each other. The alignment of the timing marks along the upper plane of the cylinder head is maintained.

The marks are set so that the valves in the engine open and close in accordance with the phases that engineers have laid down in the ZMZ 405 motor. If there is a slight inaccuracy in setting the marks, this will lead to the fact that the valves may not open or close in time. Such behavior is fraught with destruction of the cylinder head and major overhaul of the entire engine.

Checking the fuel pump of a carburetor car (mechanical)

Mechanical fuel pump - diagram

To check the operation of the fuel pump, you should:

- Remove the fuel hose from the carburetor inlet fitting.

- Immerse the hose in a specially prepared transparent bottle. By actively using the pumping lever manually, we notice how strong and dense the fuel is supplied. Air impurities should not be visually noticeable.

Delayed jet output is not a sign of a breakdown, especially if the car has been parked for a long time. As a rule, diaphragms eight and nine are the main cause of malfunction.

Be that as it may, you need to inspect both the strainer and the inlet/outlet valve.

Even if the gaskets are replaced, fuel may leak. In this case, the problem lies in the tightness of the fuel pump housing due to deformation during repairs.

Mechanical fuel pumps of foreign cars are often a non-separable structure, so they cannot be repaired!

Let's summarize:

The causes of fuel pump problems, both electrical and mechanical, are varied, and the need to find/fix a breakdown may take you by surprise along the way. By following the above recommendations, you will be able to independently carry out the entire necessary set of measures to diagnose this device. And you should start with the power supply (if it is an electric fuel pump) and the operation of the diaphragm when checking a mechanical fuel pump. Very often, the unstable operation of a fuel pump is not due to its breakdown, but to related parts - a filter, check valve or injectors.