Many owners of domestic cars are thinking about modifying their “iron horses”. Considering that more modern models are equipped with injectors, it is possible to install a 16-valve power unit on them. The Niva-Chevrolet with an engine from the Priora, as well as classic VAZ models with a similar modified engine, are widely popular.

Features of installation of the power unit

Installing a Priora engine on a Niva-Chevrolet or VAZ 2107 will take one or two days from a specialist. But first you should devote a lot of time and money to preparatory work. First you need to buy the engine itself. If you purchased a used motor, you need to rebuild it, which will further extend its service life.

Another advantage of disassembling and inspecting the unit is the ease of installation of the transition elements and cylinder block, especially if the parts for the Chevrolet Niva with the Priora engine were made by hand. It is better to carry out manipulations with a screwed oil pan, which will also require modification.

Pros of disassembling a cornfield

The advantage of carrying out manipulations with disassembling parts will allow you to monitor the general condition of the car and avoid sudden breakdowns. This is especially important when some components are created independently. For example, when changing the pan, it is necessary to pay special attention to the safety of the oil. Moreover, all the necessary fastenings are created independently, which, with the right approach, ensures an ideal combination of car elements.

Start of preparatory work

Preparations for installation should begin by dismantling the flywheel of the new power unit. Its teeth will be incorrectly positioned in relation to the starter gear. It is necessary to purchase a suitable crown and place it on the flywheel.

It must be taken into account that the Chevrolet Niva with the Priora engine is modified only in the engine part. The gearbox remains unchanged, so care should be taken to ensure reliable and correct joining of these two blocks. It is optimal to carry out this operation using a special adapter plate. You can buy a ready-made element or make it to order. An alternative to connecting the gearbox and engine would be to fix the engine cylinder block directly to the gearbox. In this case, only three mounting bolts will be involved. Many car enthusiasts who have tested this in practice claim that the clutch is quite reliable.

Advantages of the Priora engine

Based on all the characteristics and descriptions of the engine, we can say that it will be a reliable and efficient component of the vehicle, which will improve and increase its service life. It is worth noting that domestic manufacturers have been using the most modern techniques and developments for a long time, which allows them to create high-quality car components. That is why drivers have been making decisions to replace engines in their fields for a long time. Such a replacement increases the performance of the vehicle, and the costs relative to the purchase of a new car are not large.

"Niva-Chevrolet" with an engine from "Priora": the main stage of preparatory work

The updated engine will be slightly moved towards the cabin. To install it correctly, it is necessary to cut out a part of the metal partition separating the engine unit and the interior of the car. It is recommended to carry out the manipulation carefully so as not to cut out the excess part, since the element being processed ensures the rigidity of the body. Alternatively, you can use a grinder saw if you have the appropriate experience.

A support bearing will need to be installed at the end of the crankshaft of the newly installed motor. VAZ-2107 and 21213 Niva with an engine from Priora require element adjustment. Any turner will help you cope with this problem; the work will not take much time. Adapters with holes should be prepared for the motor mounting pads.

Installing the 2108 engine on a classic

First, we need to free the engine compartment of our car from everything unnecessary, namely from the old engine; from it we only need the starter and the mounting brackets for the engine mounts. After this, we can move on to our new heart, and first we will have to disassemble it a little and remove the crankshaft from it in order to press the support bearing of the input shaft 2101 into it as much as the original one sticks out, it must be cut off and the bearing pressed in its place. A turner will help you with this for a small price.

This drawing can also help you with this. After that we put our crankshaft back. At the same time, you can immediately grab the flywheel to sharpen it under the classic crown for pressing. The turning work is done, now we need to rearrange the brackets from our old motor; there are special holes on the side of the figure-eight block. Then you will need to slightly knead the engine shield, just as in the case of a 16 valve engine. We put a flywheel on the engine with a crown already pressed onto it, and attach a classic clutch basket to it.

Engine cooling system.

You should start with the rear thermostat, as you probably already understood that you will have to make the entire cooling system yourself. It needs to be made at a maximum angle to the side so that it does not rest against the engine shield. This is roughly what it will look like, this one is made from an old eight-point thermostat, if you want you can make a metal one, it’s up to you.

After this, you can put the motor in its place, having first replaced the old pillows with new ones; I recommend using pillows from the Niva. To ensure that your oil pan does not touch the lower beam, I recommend placing a thick washer on each pad; with this you can win a few precious mm. When the motor is in place, you can continue with the cooling system; you will need to make pipes like this. This is how they will look on the car. The thermostat is a classic one. With the cooling system, I think I have more or less clarified the picture for you, of course it will not be possible to describe everything, but I told you the main thing.

The final stage of preparatory work

If the car being modified was equipped with a carburetor system, you should install a remote electric fuel pump, a gas pedal drive with a cable, and a fuel filter. A Volga injection element with an injector is quite suitable. You will also need to install a special adapter for the clutch block.

If the car is equipped with a fuel injection system, then installing and connecting the control electronics will not pose any special problems. When installing a VAZ-2112 or Priora engine on a Niva, you will have to spend a lot of time on preparation. However, the subsequent effect and the new “heart” of the iron horse are worth all the effort.

Installation of the power unit

Having completed all the preparatory work, you can begin installing the motor. For a professional repairman, this process rarely takes more than one day. Personal participation will require more time and effort.

The greatest amount of work will have to be done with the modification of the cooling and exhaust systems. An old manifold from a VAZ of early production will not fit the “Prior” engine, as well as connecting pipes and some elements of the cooling system. It is difficult to purchase the parts in question ready-made, but they can be made to order or using gas welding.

Installation overview

When all the preparatory work is completed, you can install the engine from the Priora into the engine compartment of the Lada Niva. The entire process, if you have the necessary tools and equipment, will take specialists no more than one day; performing such a procedure on your own is more difficult and longer.

Connecting the unit to the gearbox will not cause any problems; assembly and modification of the exhaust and cooling systems will take more time. An old exhaust manifold from a VAZ 2107 or Niva will not fit on a Priora engine. The easiest way is to make it using the same gas welding machine or order this part; it is difficult to purchase a finished product.

The same applies to the engine cooling system. Since it is impossible to connect the cylinder block, thermostat and radiator with old pipes, car enthusiasts make pipes themselves or with the help of craftsmen at their own discretion.

Therefore, the entire process of fitting these products is carried out locally, when the cylinder block is already on the cushions. Some craftsmen, after installing a unit from Priora to a classic, transfer the filler neck for engine oil, because it rests against the partition and it is very inconvenient to install the valve cover, as well as pouring oil into the engine.

If your VAZ 2107 car was equipped with a fuel injection system, then further assembly and connection of electronic control systems will not be very difficult. Various nuances may arise that will need to be addressed during the installation process. If the fuel was supplied using a carburetor, then you will need to tinker with the electronics, install a cable drive for the gas pedal, a remote fuel pump and filter, and organize a return fuel line.

You will have to deal with all these nuances when installing the Priora engine on a VAZ 2106; in many issues you will need advice or help from specialists. Nevertheless, the modern powerful engine from the VAZ 2170 will definitely breathe new life into your legendary classic Zhiguli model.

Return to contents

Engine advantages

The engine with 16 valves turned out to be very successful. Many owners install it not only on VAZ “classics”, but also on new models (“Niva-Chevrolet”, 2109, 2114). On such cars, installation of the power unit is greatly facilitated due to the combination and identity of most of the elements.

The VAZ-2107 with an engine from Priora has the following advantages:

- high engine performance in terms of torque, power and fuel consumption;

- the product is created using modern technologies;

- the versatility of many elements and components, compatible with other VAZ engines, allows you to install the unit on different car models;

- the design of the power unit from Priora does not imply constant adjustment of valves and tightening of the timing chain;

- The motor is considered one of the best among domestic units.

A Chevrolet Niva with an engine from a Priora, the price of which depends mainly on the general condition, turns out to be more economical without losing maneuverability and power. The unit will cost from 35 to 100 thousand rubles.

Design

Dimensions and features of the Chevrolet Niva trunk

Speaking about changes in design, first of all it should be noted that the model was released in a new body, the width and length of which have increased significantly. The new car body guarantees maximum reliability, since only high-quality equipment was used in its production. However, the main function of the body has remained unchanged - it is still the load-bearing part of the car.

In general, the car has become more voluminous and angular, but it does not look rude, but quite harmonious. The changes affected the headlights, which acquired a round shape, and the rear bumper, which was equipped with a special platform for loading. The wheels are now equipped with 16-inch rims, and direction indicators are located on the front fenders.

Colors

The manufacturer also provides a wide range of color shades to suit every taste. In particular, you can purchase the model in the following colors:

- silver;

- grey-green;

- bright red;

- gray-green with a dark tint;

- quartz;

- light brown metallic;

- metallic blue with a dark tint;

- black metallic with a blue tint.

Technical characteristics of the latest modifications of the Priora engine

The common model of the engine in question is released under the index 21126. The unit has a displacement of 1.6 liters and a power of 98 horsepower. In 2013, a new modification was released, which is equipped with the VAZ-2107.

For greater clarity, below is a table with technical indicators of the Priora power unit (21127).

| Year of issue | 2013 |

| Material of manufacture | Cast iron |

| Cylinder arrangement | Inline/4 |

| Number of valves | 16 |

| Piston stroke (cm) | 7,56 |

| Cylinder diameter (cm)/compression ratio | 8,2/11 |

| Working volume (cc. cm) | 1596 |

| Power (hp) | 106 |

| Torque (Nm) | 148 |

| Fuel consumption per 100 km, combined cycle (l) | 7 |

New items equipped with the engine in question

Soon, VAZ developers plan to put into mass production the updated Niva, which will be equipped with an engine from the Priora. The new power unit will make it possible to significantly reduce fuel consumption, while increasing the vehicle’s speed performance.

The plant is actively working to adapt the engine to the Niva. The car can be produced in two variations: with a unit with a capacity of 98 horsepower or a modified analogue that pulls 106 horses and has a torque of 148 Nm. In addition to the updated engine, the car in question will receive a new steering rack, subframe, improved seats, heating, and air conditioning will be installed.

"Chevrolet Niva"

"Niva-Chevrolet" with an engine from "Priora" has the following technical characteristics of the power unit, presented in the table.

| Motor location | Longitudinal (front) |

| Volume/power (cc/hp) | 80/1700 |

| Injection system | Distributed |

| Cylinder block | Inline/4 |

| Piston stroke/compression ratio | 80 mm/9.3 |

| Turbocharging | Absent |

| Number of valves | 16 |

| Type of fuel | Gasoline AI-95 |

| Cylinder diameter (cm) | 8,2 |

| timing belt | HE IS WITH |

The car reaches a maximum speed of 150 km/h, acceleration time to hundreds is 17 seconds. The fuel tank holds 58 liters, while consuming 9.6 l/100 km in mixed driving mode.

Motor device

Briefly about how the VAZ 2123 Chevrolet Niva engine works.

Cylinders

They were combined with the upper part of the crankcase. Like most VAZ engines, this power unit has cylinders operating in a 1-3-4-2 pattern. The lower part of the cylinder block is connected on five supports to the crankshaft.

1 — tension roller of the air conditioning compressor drive belt; 2 — air conditioning compressor drive belt; 3 — air conditioning compressor clutch; 4 — thermostat; 5 — throttle assembly; 6 — outlet pipe of the cooling jacket; 7 — coolant pump pulley; 8 - phase sensor; 9 — tension roller for the auxiliary drive belt; 10 — cylinder head; 11 - generator; 12 — power steering pump pulley; 13 — support roller for the auxiliary drive belt; 14 — cylinder block; 15 — auxiliary drive belt; 16 — crankshaft position sensor; 17 — auxiliary drive pulley; 18 — air conditioning compressor drive pulley; 19 — oil pan; power unit support; an exhaust manifold; receiver; cylinder head cover;

Crankshaft

Five-legged. Cast from cast iron. If necessary, the journals can be reground with a diameter reduction of 0.25; 0.50; 0.75 and 1 mm.

Also interesting: Buy Niva Lynx in Vladimir - prices for the new Lada “Bronto” (Niva Pickup)

Exhaust valves

Welded in two parts. One is an alloy of chromium, nickel and molybdenum, and the other is made of multi-component steel. The operating temperature of the exhaust valves is 700-900 degrees, since during engine operation they are heated by processed gases. In order for them to withstand such temperatures, a special heat-resistant alloy is applied to them.

Intake valves

Their rods are treated with nitrogen and hardened under the influence of high frequency current. This is enough to withstand operating temperatures of 350-500 degrees.

Pistons

The VAZ 2123 engine has pistons cast from an aluminum alloy. A layer of tin is applied to them to make the process of breaking in the car faster. The piston stroke is 80 mm, and it itself has a diameter of 82 mm. The compression ratio is at 9.3 atmospheres.

Camshaft

Cast from cast iron and installed in a removable aluminum housing. Its rotation is carried out by a single-row roller chain.

Chain

It is stretched by a spring-hydraulic tensioner. Its size has increased significantly. Until the engine starts, the tension is carried out by a spring, and during its operation it is provided by oil pressure.

Attached to the block itself with 11 bolts. Centering is performed using the power of two bushings.

Crankcase ventilation system

Closed, and crankcase gases are discharged through the oil separator into the intake pipe. From there they are transferred to cylinders and burned.

Owner reviews

The best recommendations can be given by the direct owners of the model in question, who have tested the car in various weather and road conditions. If you take a Chevrolet Niva with an engine from a Priora, reviews from owners indicate that the car has changed for the better. Special benefits include the following:

- the power unit has a solid reserve before major overhaul;

- fuel consumption has decreased, quite noticeably;

- high speed characteristics and power;

- reliability of the unit;

- high performance characteristics of the motor.

It’s not difficult to create a Niva-Chevrolet with an engine from a Priora. Some modifications to the cooling system and the seat for the unit will be required. All manipulations can be completed in just a couple of days.

The disadvantages of the device in question include one point that was noticed by some owners and specialists. If the timing belt breaks, the pistons inevitably interact with the valves, causing the latter to bend. To avoid this, you can purchase special pistons with recesses for the valves.

Oil pump work

Next, do the following to remove chamfers on the edges of the teeth:

- We compress, that is, remove, the drive gears.

- We trim one of the gears by 0.75 mm on each side.

- We cut the second gear to 11.5 mm (after trimming).

- We repeat the operation with the remaining gears (driven).

Also interesting: Generator Niva Chevrolet - voltage, repair and maintenance

Let's start working on the body. To do this we do the following:

- We release the driven gear axis from the housing.

- We form a longer axis from the drive roller.

- We insert the resulting axle into the body.

- We press the narrow gear onto the second drive shaft.

- Press on the wide gear.

- We fix the wide driven gear in the housing.

- We install a narrow gear into the housing.

Peculiarities

The Niva-Chevrolet with the Priora engine has some features compared to similar classic VAZ models. Firstly, installation of the power unit is simplified, since the location of the motor is identical. Secondly, variations were produced with almost the same engine as the Priora. In addition, a new production version of the domestic SUV is being developed, to which the engine from Priora, considered one of the best among our manufacturers, is adapted.

Modified options

Since it is not always possible to supply an engine of a certain foreign car, it is worth considering imported production options that require a little modification:

- The first candidate will again be the French engine from Peugeot XUD 11 series. Since the power of this unit is higher than that of the previous model, some changes will need to be made to the design of the Niva - replacing the gearbox. An acceptable option is a gearbox from Fiat Polonez. In addition, a good solution would be to replace the front supports of the power plant fasteners, pan and exhaust system. It is also worth replacing the drive elements with similar parts from the Chevrolet Niva.

Nuances when installing an engine from Priora to Niva

Of course, standard units and body elements with suspension are not designed for the installation of the 21126th engine. But with minor modifications, everything can be done in the best possible way.

Let's consider the main nuances that may arise during the installation of the Priora power unit:

- The gearbox is also installed and mounted on 3 bolts (the engine itself, of course, is mounted longitudinally - unlike the classic front-wheel drive)

- It is necessary to replace the clutch from Priora and the flywheel, but keep the classic crown from Niva

- The pallet is slightly modified, since it will rest against the front beam. Many resort to the help of an angle grinder in this case, as well as welding

- The cooling system is being modified for a prioro engine

- The exhaust system is bought for a classic engine on the 21126th engine - there are already many ready-made options

Of course, in addition to the above points, certain problems may arise after installing the motor. For example, inaccessibility in the timing mechanism - in this case, when replacing the belt, you often have to drain the coolant. Due to the alteration of the sump, another negative point appears - now there is less oil in it than it should have been from the factory - this can lead to negative consequences under critical loads on the engine.

The clutch, according to reviews of many owners with already converted engines from Priora, is somewhat worse than on the same Chevrolet Niva, so its service life is reduced, and accordingly, you have to bother with replacement more often. But, as they say, everyone understands perfectly well what they are getting into when installing an engine of greater power and with non-standard mounts.

If you want to see what usually results from such tuning, the video review below will be a visual aid.

Such tuning takes a lot of effort and time, but this stopped few people in such cases!

Features of installing unit 21126 on other models

Recently, models 2114 with a Priora 16V engine have become not uncommon. Car enthusiasts who are striving to improve their “iron horse” appreciated all the advantages of this power unit and began installing it on their VAZ 2114. Such a rearrangement can actually be carried out without any major changes, since the model is more compatible with the Priora than the classic. The mounting flanges of the block and gearbox are quite compatible, and the equipment connections are identical. Nuances arise when assembling the clutch; there is some incompatibility. It is recommended to replace the flywheel together with the crown and install a clutch from a VAZ 2108.

On the VAZ 2114 there are two types of starters: BATE and a gear-type unit KATEK. With the latter, the problem is easily solved - you will need to replace the coupling and head. You will have to say goodbye to a BATE type unit and buy a new one; there is nothing you can do about it.

The fuel line will also need to be replaced, the ideal option is to purchase one ready for the VAZ 2112, its ramp is compatible with the Priorov 16V engine. All further operations must be performed the same as in the case of the classic: it will be necessary to modify the exhaust gas and engine cooling systems.

The first modification is quite simple: the exhaust “Spider 4-2-1” is available for sale, but in the cooling system it will be necessary to manufacture and install pipes to the radiator. The fan also needs to be changed, since its blades will touch the receiver. There is a comprehensive solution to the problem: take a radiator with a set of pipes from a VAZ 2112.

In 2015, a new version of the Lada 4×4 SUV will appear on the market, reports the Russian Automobile portal.” The new product will receive a 1.6 four-cylinder engine from the Priora family, derated from 98 to 90 horsepower, and a modernized steering system. Now the 4x4 model is equipped with an 81-horsepower 1.7 unit.

The new engine in the VAZ SUV will be located longitudinally and will be able to work together with the currently used gearbox – a five-speed manual. In addition, the unit will be adapted to run on gasoline with an octane rating of 92. In this case, a flat “shelf” of torque will be achieved already at around 1400 rpm.

The modernized Lada will have a new subframe and steering rack, which will be borrowed from either Renault Logan or 4x4 produced in Egypt. The oil pan and universal joints in the transmission will also be replaced. The latter will give way to CV joints.

Today there are a couple of prototypes of the new 4x4 version. Both of them are at the disposal of the scientific and technical department. However, Russian Automobile reports that the shareholders and partners of the domestic automaker - the Renault-Nissan alliance and the General Motors concern - may block the implementation of the project for the sake of Renault Duster and Chevrolet Niva. The publication also notes that the new president of AvtoVAZ, Swede Bo Andresson, may block the release of the model to please shareholders.

AvtoVAZ previously announced changes planned for the Lada 4×4. In 2013, the company changed the process of painting the body of an SUV; in 2014, the interior of the model will be finalized, and in 2015, modifications to the front suspension, braking system and transmission are planned.

Niva engine characteristics

Years of manufacture – (1994 – present day) Cylinder block material – cast iron Power system – carburetor (21213) / injector (21214) Type – in-line Number of cylinders – 4 Valves per cylinder – 2 Piston stroke – 80mm Cylinder diameter – 82mm Compression ratio – 9 .4 Niva engine capacity 21213 – 1690 cm3. Engine power Niva 21213 – 81 hp. /5200 rpm Torque - 125 Nm / 3000 rpm Fuel - AI93 Fuel consumption - city 11.5l. | track 8.3 l. | mixed 10.5 l/100 km Oil consumption - 700 g per 1000 km Niva engine weight - 117 kg Overall dimensions of the Niva 21213 engine (LxWxH), mm - Oil in the Niva 21213 engine: 5W-30 5W-40 10W-40 15W-40 How much oil in the Niva 21213/21214 engine: 3.75 l. When replacing, fill in about 3.5 liters.

Full technical specifications of the Chevrolet Niva - summary table

| Parameter | Chevrolet Niva 1.7 80 hp |

| Engine | |

| Engine code | 2123 |

| engine's type | petrol |

| Injection type | distributed |

| Supercharging | No |

| Number of cylinders | 4 |

| Cylinder arrangement | in-line |

| Number of valves per cylinder | 2 |

| Volume, cubic cm. | 1690 |

| Power, hp (at rpm) | 80 (5000) |

| Torque, N*m (at rpm) | 127.5 (4000) |

| Transmission | |

| Drive unit | full |

| Transmission | 5 manual transmission |

| Suspension | |

| Front suspension type | independent multi-link |

| Rear suspension type | dependent |

| Brake system | |

| Front brakes | disk |

| Rear brakes | drums |

| Steering | |

| Amplifier type | hydraulic |

| Tires | |

| Tire size | 205/75 R15 / 205/70 R15 / 215/65 R16 |

| Disk size | 6.0Jx15 / 6.0Jx15 / 6.5Jx16 |

| Fuel | |

| Fuel type | AI-95 |

| Environmental class | Euro-5 (Euro-4*) |

| Tank volume, l | 58 |

| Fuel consumption | |

| Urban cycle, l/100 km | 13.2 (14.1) |

| Extra-urban cycle, l/100 km | 8.4 (8.8) |

| Combined cycle, l/100 km | 10.2 (10.8) |

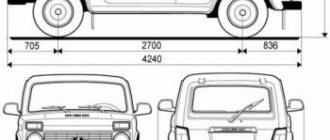

| dimensions | |

| Number of seats | 5 |

| Number of doors | 4 |

| Length, mm | 4048 |

| Width, mm | 1770 |

| Height, mm | 1652 |

| Wheelbase, mm | 2450 |

| Front wheel track, mm | 1466 |

| Rear wheel track, mm | 1456 |

| Front overhang, mm | 721 |

| Rear overhang, mm | 748 |

| Trunk volume (min/max), l | 320/650 |

| Ground clearance (clearance), mm | 200 |

| Geometric parameters | |

| Entry angle, degrees | 37 |

| Departure angle, degrees | 35 |

| Weight | |

| Curb (min/max), kg | 1410 |

| Full, kg | 1860 |

| Maximum trailer weight (equipped with brakes), kg | 1200 |

| Maximum trailer weight (not equipped with brakes), kg | 600 |

| Dynamic characteristics | |

| Maximum speed, km/h | 140 |

| Acceleration time to 100 km/h, s | 19.0 |

* – engine data before modernization in 2020 is indicated in brackets.

| Parameter | Chevrolet Niva 1.7 80 hp | Chevrolet Niva 1.8 122 hp |

| Engine | ||

| Engine code | 2123 | Z18XE |

| engine's type | petrol | |

| Injection type | distributed | |

| Supercharging | No | |

| Number of cylinders | 4 | |

| Cylinder arrangement | in-line | |

| Number of valves per cylinder | 2 | 4 |

| Volume, cubic cm. | 1690 | 1797 |

| Power, hp (at rpm) | 80 (5000) | 122 (5600) |

| Torque, N*m (at rpm) | 128 (4000) | 167 (3800) |

| Transmission | ||

| Drive unit | full | |

| Transmission | 5 manual transmission | |

| Suspension | ||

| Front suspension type | independent multi-link | |

| Rear suspension type | dependent | |

| Brake system | ||

| Front brakes | disk | |

| Rear brakes | drums | |

| Steering | ||

| Amplifier type | hydraulic | |

| Tires | ||

| Tire size | 205/70 R15 | |

| Disk size | 6.0Jx15 | |

| Fuel | ||

| Fuel type | AI-92 | |

| Environmental class | n/a | |

| Tank volume, l | 58 | |

| Fuel consumption | ||

| Urban cycle, l/100 km | 14.2 | 12.8 |

| Extra-urban cycle, l/100 km | 8.9 | 8.5 |

| Combined cycle, l/100 km | 10.9 | 10.1 |

| dimensions | ||

| Number of seats | 5 | |

| Number of doors | 4 | |

| Length, mm | 4048 | |

| Width, mm | 1770 | |

| Height, mm | 1652 | |

| Wheelbase, mm | 2450 | |

| Front wheel track, mm | 1450 | |

| Rear wheel track, mm | 1440 | |

| Trunk volume (min/max), l | 320/650 | |

| Ground clearance (clearance), mm | 200 | |

| Weight | ||

| Curb (min/max), kg | 1400 | 1520 |

| Full, kg | 1850 | 1870 |

| Maximum trailer weight (equipped with brakes), kg | n/a | n/a |

| Maximum trailer weight (not equipped with brakes), kg | n/a | n/a |

| Dynamic characteristics | ||

| Maximum speed, km/h | 140 | 165 |

| Acceleration time to 100 km/h, s | 19.0 | 12.0 |

Malfunctions and repairs of the VAZ 21213 / 21214 Niva engine

Engine VAZ 21213 1.7 l. carburetor/injection (21214) in-line 4-cylinder with overhead camshaft, Niva timing belt has a chain drive. Based on the 214 engine, the VAZ 2123 engine is produced for the Chevy Niva; the differences in adapting the block for installing a pulley in the engine compartment and mounting attachments are technically almost identical. The main differences between the VAZ 21213 engine and the 2106 are the cylinder diameter is 82 mm, the cylinder head, the Niva 21213 engine block from the 2106 is smaller in height. Among the advantages of the 213 engine, it is worth noting the presence of a chain tensioner (no need to tighten it) and hydraulic compensators (no need to adjust the valves). Disadvantages of the Niva engine - noisy, consumes oil, prone to overheating and vibrations, low resource. The motor has all the problems of the classic series, the 21213 Niva engine still heats up, troits, knocks, etc., what the problems are, for each case, are described in detail HERE, in the problems and malfunctions section.

VAZ 2123 engine - features

The VAZ 2123 engine for the Chevrolet Niva has received many changes that have a better effect on its functional characteristics.

Unlike its predecessor models, it has a different generator location. He is now on top.

1 — oil pan; 2 — main bearing cover; 3 — connecting rod cover; 4 - crankshaft; 5 — connecting rod; 6 - piston; 7 — piston rings; 8 - valve; 9 — valve guide; 10 — valve springs; 11 - plate; 12 - camshaft; 13 — cylinder head cover; 14 — valve lever; 15 - hydraulic support; 16 — cylinder head; 17 — spark plug; 18 — cylinder head gasket; 19 — generator bracket; 20 — cylinder block; 21 — oil pump gear retainer; 22 — oil pump gear; 23 — oil filter bracket; 24 — oil pan gasket; 25 - oil pump

The new cylinder block is based on the old one, but despite this it has its own marking. The main change affected the way the oil filter is mounted. In older models it was screwed directly into the block, but now a special bracket is used for connection. It performs another function - it is a support for mounting the power steering pump.

The flywheel received an increased diameter, as a result of which its working surface became 215 mm.

A new pump has been installed, inside of which a roller bearing is located. Unlike the old ball bearing, the new type of bearing has an increased service life.

Also interesting: Construction and repair of the VAZ 2121 Niva transfer case

The water pump, power steering pump and generator are driven by a pulley mounted on the crankshaft. The system includes tension and support rollers. The pulleys themselves are made according to a special design, adjusted to the belt profile.

1 — tension roller of the air conditioning compressor drive belt; 2 — air conditioning compressor drive belt; 3 — air conditioning compressor clutch; 4 — thermostat; 5 — throttle assembly; 6 — outlet pipe of the cooling jacket; 7 — coolant pump pulley; 8 - phase sensor; 9 — tension roller for the auxiliary drive belt; 10 — cylinder head; 11 - generator; 12 — power steering pump pulley; 13 — support roller for the auxiliary drive belt; 14 — cylinder block; 15 — auxiliary drive belt; 16 — crankshaft position sensor; 17 — auxiliary drive pulley; 18 — air conditioning compressor drive pulley; 19 — oil pan; power unit support; an exhaust manifold; receiver; cylinder head cover;

Changes also affected the design of the engine compartment. The front axle gearbox is no longer attached to the engine. This required changes to the internal engine compartment.

A new air intake system is installed in the VAZ 2123 engine. The volume of its body has increased significantly due to the increased size of the air filter, which can now be changed less frequently.

The engine is also controlled by new controllers. Depending on the modifications, BOSCH or JANUARY controllers can be installed.

Tuning the Niva 21213 and 21214 engine

Chip tuning of Chevrolet Niva or 21214 engine

There is no point in writing about this for a long time because the Niva chip is useless, the atmospheric engine cannot be stirred up with a chip, and all the rave reviews are nothing more than an attempt to justify a waste of money, let’s move on.

How to cheaply increase the power of a VAZ 21213 engine

The question on the agenda: how to increase the power of a Niva engine without any special tricks? The first stage is to increase the piston stroke to 84 mm using a crankshaft from a VAZ 2130, 82 mm pistons with a piston pin offset of 2 mm and we already have 1.8 liters. The second stage is to bore the cylinders for an 84 mm piston, thus assembling the 1.9 engine for the field. To fully boost the VAZ 21213 engine, you need to add a more efficient carburetor, bore the cylinder head channels (how to do this is described HERE), the intake diameter is 33 mm and the exhaust diameter is 31 mm, it is advisable to use light connecting rods, in the end we will get about 100 hp. The third stage - we build a 2 liter motor. We buy on the market a tuning crankshaft with an 88mm stroke and 84mm pistons with a pin offset of 4mm. A complete modification of the VAZ 21213 engine will be completed after installing a Nuzhdin camshaft (or an analogue) with a lift of 11.2, a light flywheel, light connecting rods and a modified carburetor, all of which will give a total of about 110 hp.

Niva engine boring options

— piston of standard diameter, increased stroke 1.8 liters. 82x84

85 hp Maximum torque

135 Nm at 3000 rpm - larger diameter piston, increased stroke 1.9 liters. 84x84 - larger diameter piston, increased stroke 2.0 liters. 84x88

16 valve engine for Niva

From time to time on forums they raise the issue of installing a 2112 engine in a Niva; this is a rather difficult and pointless task, due to the fact that 16V engines love speed and are not well suited for an SUV. If you want speed, sell your car and buy a Priora. The Niva is not suitable for high speeds and its tuning should be aimed, first of all, at increasing traction at the bottom.

Turbine for Niva

The pros and cons are described HERE in the “Turbo Classic” section.

Compressor for Niva

We use kit kits based on the PK-23-1 supercharger or analogues with a pressure of 0.5 bar, injectors from the 406 Volga engine, the piston remains factory, the output is more than 100 hp. The resource will be reduced, but not critically. It is not recommended to install more efficient superchargers; the factory piston will not hold up and the engine will require significant and expensive changes.

Work order

First, all attachments are dismantled - the receiver, exhaust manifold, etc. After this, the engine is installed on standard mounts and connected to the gearbox. To avoid problems with changing the fuel pump and when laying a new fuel line, you need to purchase a standard ramp.

In addition to the ramp, you will need longer fuel injectors. The ramp does not connect to the engine immediately. You must first install the receiver. This process is quite labor-intensive - you need to tighten all the cushions and raise the car with a jack. After this, you can push the receiver through and insert the ramp with injectors. The ramp is screwed after the nozzles are installed on the wells. After this, the receiver sits in place and is secured

When performing work, care must be taken to ensure that the rubber seals on the receiver are not damaged. Next, all elements of attachments are installed in their standard places.

Now you can do the electrical wiring. First you need to disassemble the ignition. Since the car does not have four ignition coils, a standard one is installed, and only high-voltage wires are needed from the Priora. It will be necessary to increase the wiring by about 40 cm, since its length may not be sufficient. The same applies to the phase sensor.

Next you need to deal with the exhaust. It is necessary to dismantle the old exhaust manifold with the catalyst, and in its place a 4-2-1 “spider” system with holes for the DC is installed. The corrugation is also placed there. The exhaust pipe is completely replaced, and the standard can is modified.

It is not necessary to change the thermostat - you can leave the standard one, but it will need to be configured correctly. If the cooling fan is in contact with the receiver, you can replace it with a Niva fan, which has two impellers on the outside. The hoses on the radiator need to be replaced. The generator is mounted on standard mountings; its belt does not need to be changed.

In order for the engine to operate normally, the injectors must be flashed and calibrated. The decorative engine grille can be left in place, you just have to make cuts on its front side. The entire structure can be significantly strengthened by installing a brace with a fourth mount for the power unit - this will not cost much at all.

Good afternoon, I haven’t written for a long time: (because I didn’t have time... I assembled my Priora’s engine a long time ago, and even managed to break it in;) I drove 2000 km on it. Well, now about the most important thing... how and from what we assembled the new heart :) Action plan: 1. I decided that I was making a motor for myself, which means I will sharpen the block + After boring, do honing. I didn’t think for a long time and turned to Auto VAZ at Chekistov :) where the mechanic guy kindly and clearly explained everything that first buy the pistons, and then I’ll make everything the right size for you. 2. An hour later I was already at the 50th Anniversary of October in the Ladya store. It was this store that became my favorite in Tyumen:) the sellers understand what they are selling + an adequate price tag for spare parts and their availability. Of course, there is also a defect there, which I changed without problems after 2 weeks :) the timing belt roller made noise... I bought: STK pistons VAZ 21126 - 82.5 (Splitless with anti-friction coating) for a 75.6 mm crankshaft in a 197.1 mm block, for connecting rods 133.3 mm and pins d18 mm) rings 1.2 mm/1.5 mm/2.0 mm

STK plug-inless with a displacer To compensate for the compression ratio, the pistons have a displacer, and according to the manufacturer, the compression ratio with these pistons remains unchanged.

Piston ring set d82.50 mm “PRIMA” 1.2 mm, 1.5 mm, 2 mm

3. In the evening we already started assembling the beast... I won’t describe everything there are too many little details :) I’ll highlight only the most important things...