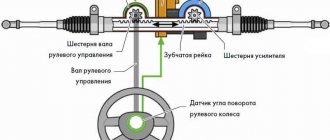

Electric power steering (EUR or EMURU) 11186-3450008: 1 - steering shaft, 2 - electric motor, 3 - electronic control unit, 4 - torque sensor, 5 - rotor position sensor

In electromechanical power steering, the necessary compensation force is created by an electric motor. In general, the EUR consists of the following main components:

– steering shaft with torsion bar drive;

– electronic control unit (ECU);

– torque sensor;

– rotor position sensor.

The EUR is installed on the steering shaft, the parts of which are connected to each other by a torsion shaft with a torque sensor installed on it. When the steering wheel rotates, the torsion shaft twists, which is recorded by the torque sensor. Next, information from this sensor goes to the ECU, which calculates the required compensation force (taking into account the readings of the vehicle speed sensor) supplied to the steering shaft by the electric motor included in the ESD. In general, the EUR can be located both on the steering column and on the steering rack. In the latter case, the load on the steering shaft and its joints is reduced.

The advantages of the ESD relative to the power steering are the simplicity of the design and the compactness of the mechanism. In this case, the power steering is activated only when the steering wheel is rotated, while the power steering pump works constantly, creating additional load on the engine and, accordingly, increasing fuel consumption. The ESD is also flexible in configuration, allowing you to change the steering feel by changing the control program. The advantages of power steering include “honest” feedback and resistance to high loads, which allows it to be used on SUVs, trucks and other heavy equipment, while electric steering is usually installed on passenger cars.

In the LADA KALINA car, the electric power amplifier is located on the steering column. The brushless electric motor included in the EUR is connected to the steering shaft through a gearbox. The EUR electric motor is powered from the vehicle's on-board network. The ESD remains operational when the on-board network voltage changes in the range of 10.8 – 15 V. The nominal supply voltage of the ESD is 13.5 V; for a load torque of 35 Nm, the maximum current consumption does not exceed 50 A.

Rice. 2. Electrical connection diagram for electric power steering 11186-3450008

Table 1. Purpose of electrical amplifier connector pins

| Block | Contact | Address |

| X1 | 1 | + 12 V from battery |

| 2 | "Minus" from the battery | |

| X2 | 1 | + 12 V from terminal “15” of the ignition switch |

| 2 | Tachometer signal input | |

| 3 | Speed sensor signal input | |

| 4 | Output to EUR status indicator | |

| 5 | “K-line” output to the diagnostic block | |

| 6 | Output “L-line” (not used) | |

| 7 | Common wire (“ground”) | |

| 8 | Technological output (not involved) | |

| HZ | A1 | Motor phase A |

| A2 | Motor phase A | |

| IN 1 | Motor phase B | |

| AT 2 | Motor phase B | |

| C1 | Phase C of the electric motor | |

| C2 | Phase C of the electric motor | |

| X4 | 1 | Common wire 1 torque sensor |

| 2 | Common wire 2 torque sensors | |

| 3 | Torque sensor power supply | |

| 4 | Torque sensor output 1 | |

| 5 | Torque sensor output 2 | |

| 6 | 250 kHz frequency signal input | |

| X5 | 1 | Common wire of the rotor position sensor |

| 2 | Rotor position sensor phase A output | |

| 3 | Phase B output of the rotor position sensor | |

| 4 | Phase C output of the rotor position sensor | |

| 5 | Supply voltage +5 V rotor position sensor |

The maximum compensating torque on the steering shaft can reach 30 Nm; the EUR provides such a torque when the vehicle is stationary; with increasing speed, the compensating torque decreases proportionally. The initial data for the electric motor control system is information about the torque on the steering shaft, the position of the rotor and the vehicle speed, obtained from the corresponding sensors.

For EUR 11186-3450008 there are 4 operating modes: “Self-testing”, “Readiness”, “Compensation”, “Failure”. To indicate the status of the EUR, there is a status indicator on the vehicle dashboard (Fig. 3).

Rice. 3. Location of the power steering status indicator

When you turn on the car’s ignition, the EUR goes into the “Self-test” mode, which checks the serviceability of the system. If malfunctions are detected during the self-testing process (negative self-test result), the ESD switches to the “Failure” mode, and a malfunction code is entered into the memory of the ESD control unit (see Table 2).

Table 2. Electric power steering ECU error codes

| Code | Code Description |

| S1000 | No errors found |

| S1011 | Car engine speed signal circuit, no signal |

| S1012 | Vehicle speed sensor signal circuit, no signal |

| S1013 | The vehicle's on-board voltage is below the minimum threshold |

| S1014 | Voltage at the ignition switch is below the minimum threshold |

| S1021 | Torque sensor main terminal voltage |

| S1022 | Torque sensor control pin voltage |

| S1023 | Incorrect signal from the main and/or control output of the torque sensor |

| S1024 | Torque sensor, no signal |

| S1031 | Steering shaft position sensor, main signal circuit malfunction or out of range |

| S1032 | Steering shaft position sensor, control signal circuit malfunction or out of range |

| S1033 | Steering shaft position sensor, no power |

| S1041 | Engine rotor position sensor, phase A circuit malfunction or out of range |

| S1042 | Engine rotor position sensor, phase B circuit malfunction or out of range |

| S1043 | Engine rotor position sensor, phase C circuit malfunction or out of range |

| S1044 | Rotor Position Sensor Sequence Incorrect |

| S1045 | Motor rotor position sensor, no power |

| S1050 | Short circuit to ground in power circuits |

| S1051 | Motor, excess current through phase winding A |

| S1052 | Motor, current overcurrent through phase winding B |

| S1053 | Motor, excess current through phase winding C |

| S1054 | Motor, broken phase windings |

| S1055 | Motor, open phase winding A |

| S1056 | Motor, open phase winding B |

| S1057 | Motor, open phase winding C |

| S1058 | Motor, phase winding short circuit |

| S1059 | Motor phase A winding short circuit |

| S1060 | Motor phase B winding short circuit |

| S1061 | Motor phase winding short circuit |

| S1070 | Fault not recognized |

| S1071 | Control unit, electronic unit RAM error |

| S1072 | Control unit, electronic unit ROM error |

| S1073 | Control unit, electronic unit EEPROM error |

| S1074 | Electronic unit relay |

| S1075 | Control unit, radiator temperature rise |

| S1076 | The supply voltage of the ECU elements is below the minimum threshold |

| S1077 | The voltage on the power capacitors is below the minimum threshold |

| S1078 | Charge time for power capacitors |

| S1079 | The current of one of the phase windings is above the maximum threshold |

| S1080 | Breakdown of at least one of the upper power transistors |

How to determine the malfunction?

Despite the fact that repairing the EUR requires contacting a car service, you can detect the first symptoms of a malfunction yourself

.

Viburnums on the front panel have a special yellow indicator, which, in the event of a breakdown of the electric amplifier, lights up and reports an error in the system. If it lights up, it means you have another reason to visit the nearest auto repair shop. But it’s immediately worth noting that the yellow indicator does not indicate a critical malfunction, but only signals the occurrence of a problem that allows you to drive the car, but without the participation of the ESD.

If the electric power steering has completely failed, it is better to stop immediately and pull out its fuses.

. In Kalina they are located on the left side of the steering wheel. Theoretically, in case of malfunctions, the EUR should turn off on its own. However, it doesn’t happen once at a time. Therefore, to be sure, it is still worth taking care of the fuses.

Diagnostics using third-party devices

For a more detailed check of the vehicle's performance, scanners and computers are used. They are connected to the diagnostic electrical connector (socket) located on the standard panel. Malfunctions are issued in the form of a standard set of alphanumeric codes, consisting of one letter and four numeric designations. The letter indicates specific nodes in which the malfunction occurred.

B - detects problems with electronics inside the cabin;

C - indicates defects in the chassis design;

P - errors in the engine control module or transmission;

U - loss of communication between electronic modules.

The letter designation is followed by four characters:

- the first character indicates a standard code established by engineers at the Automobile Association;

- the second character records personal codes set by manufacturers;

- the third character indicates which system the malfunction occurred in:

1-2 - in the fuel and air system;

- in the ignition system;

- in a secondary emission control system;

- in the speed control controls or when the load is off (XX);

- on-board computer system and wiring;

7-8 - errors in the operation of the gearbox;

9.0 - reserve;

the fourth and fifth symbols are considered together to more accurately locate the point of failure.

Possible malfunctions and their causes

The main problem that causes breakdown of the electric power steering is a malfunction of the speed sensor.

The EUR installed on Kalina does not work with a constant force applied to the steering rack. The amplifier begins to operate at full strength only when the car is moving at low speed or is at rest. When accelerating, the power steering forces on the steering rack decrease. That is, the lower the speed, the more the power steering starts to work.

The naturally described malfunction can only be detected when the car is standing still or moving at low speed

.

This failure can only be corrected by completely replacing the speed sensor. Moreover, here it is not necessary to go to the service. You can replace everything yourself.

The second malfunction may be hidden in the EUR itself. Basically, it consists of self-disabling the electric power steering due to the fact that it has not passed self-test. That is, the device turns off automatically so as not to interfere with the driver when driving the car.

This kind of malfunction guarantees a trip to the service station and will require you to spend a lot of money.

How to tighten the electric power steering rack?

The appearance of a knocking sound in the operation of the electric power steering is associated with the need to tighten the steering rack.

How to do it right:

- First you need to disconnect the battery; to do this, disconnect the terminals from it. Unscrew the battery mount; to do this, you need to unscrew two more nuts located at the edges. After this, the battery is removed and put aside.

- Then you need to lift the plastic stand, there are four more screws under it, they can also be unscrewed.

- Having done this, it is necessary to move this stand forward until the platform is disconnected from the air filter housing retainer pad. After this, the trim can be moved back, this will provide freer access to the rail itself.

- At the next stage, you will need to crawl your hand under the rail. Directly below it, as shown in the photo, there is a rubberized cap; it will need to be removed, this will allow the key to access the adjusting nut.

- To perform adjustment work, you will need a special wrench to tighten the rack; without it, the adjustment procedure will not be possible. Using this wrench, you need to crawl under the car rail to install the tool in the required hole.

- When adjusting, be careful not to overtighten the rack. If its tightening is very strong, then when cornering the rack will bite, and this, in turn, may affect the safety of movement. The angle of adjustment is always different, it depends on how much the nut is loose, but usually when performing such work the nut is tightened by approximately 30 degrees. This should be enough to get everything right. After the adjustment is completed, it will be necessary to check that this task was performed correctly. That is, you will need to make sure that the steering wheel turns normally to any position all the way and there is no knocking. If the knock remains, then the adjustment continues.

Photo gallery “Adjusting the steering rack”

1. Slide the stand and detach it.

2. In this place under the rail there is an adjusting washer.

3. Adjustment is made with a special key.

4. Location of the adjusting nut.

Additional reasons

Troubles in the operation of the electric power steering can be caused by:

- voltage drop due to possible circuit breaks due to wiring faults;

- exceeding the internal combustion engine speed;

- lack of speed sensor information.

In general, it is clear that there are not so many reasons why the ESD fails. Some of them are critical, some are not. But in any case, you need to take care of promptly eliminating the problem.

Today it is difficult to find reliable electrical circuits for an amplifier from a domestic car. Such information is mainly available only in services, and no one will share it with you. Therefore, repair of the electric power steering on Kalina is possible only within the walls of the service station

, since amateurism can be expensive. Here it is better not to take risks, not to be stingy, but to trust competent specialists.

About qualified electric amplifier replacement

If there is a need to replace the mechanism when the ESD does not work, we recommend contacting experienced technicians. When the car is under warranty, the most rational measure would be to contact the dealer network to resolve the problem.

There are situations that do not allow you to resort to these two methods of eliminating an amplifier malfunction. Then the only solution will be to manually replace the mechanism that has become unusable.

Let us immediately make a reservation that the replacement process if the EUR does not work is characterized by sufficient complexity. To carry it out successfully, you will need experience and the possession of special tools. Unqualified replacement actions can aggravate the scale of the breakdown, which will entail a significant waste of money on more expensive repairs in service conditions.

Before the actual replacement procedure, we recommend that you carefully study the entire list of features and actions if the ESD does not work. Here you will need to delve into the connection diagram of the unit, which will avoid damage to the electrical components of the mechanism.

To remove the amplifier, partial disassembly of the front panel of the Lada Kalina is necessary. After this, the device itself must be disconnected from the entire list of supply wires. Sometimes owners repair the electric power steering, avoiding the need to replace it with a new unit. As a rule, after a complex of restoration work, standard devices work no worse than their new counterparts.

A common malfunction is the occurrence of a knock that clearly comes to the driver from under the panel or the amplifier turns off. This phenomenon may be accompanied by a characteristic squeak that occurs during rotational actions with the LADA Kalina steering wheel. This situation is usually solved by using a special lubricant. If such an action does not bring the expected result, then a more detailed diagnosis of the amplification mechanism will be required.

To install the electric power steering in the seat of the Lada Kalina, you will need to be attentive and patient. All cable connectors must be tightly seated, and the device itself must be firmly secured. Only after this can you proceed to the reassembly of the previously dismantled front panel components.

Electric power steering Kalina significantly simplifies the car's movement and makes its operation enjoyable. Lada Kalina appeared on the modern automobile market not so long ago, but has already become widely known and has gained enormous popularity among the population.

This fact is due to the practicality of this machine and its convenience. In addition, the cost of such a brand sets it apart from other cars. This effect was achieved thanks to the presence of many additional parts included in the design of the machine, which not only simplify the use of the machine, but also make this process more comfortable.

Reasons for shutdown

The main reason lies in the electric power steering

.

When ignited, the system performs a self-diagnosis and if the mechanism does not pass it, a signal is turned on indicating a malfunction. The color of the signal indicates the degree of danger. The light turns red, the problem needs to be fixed urgently. If the color is yellow, the vehicle can be operated, but safety precautions should be taken. Lada Kalina - Car Owners Blog: EUR does not work. reasons why steering

on Kalina work

- speed sensor malfunction;

- torque sensor malfunction;

- speed exceeds 60 km/h;

- engine speed is less than 400 per minute;

- failure in the control unit;

- poorly soldered contacts;

- insufficient tension.

Components of the EUR

Modern car models are radically different from their predecessors. Changes can be seen in everything. However, one of the most significant achievements has been easier vehicle control. If previously you had to put a lot of effort into turning the steering wheel, now everything is much simpler. Moreover, you can turn the steering wheel with almost one hand when the car is turned off. All this thanks to the installed EUR. But sometimes it happens that the power steering on the Priora does not work.

With the help of this device, the force required to rotate the steering wheel is reduced significantly. In other words, you can safely operate it with one hand without unnecessary stress.

On older models of VAZ cars, a different system was installed - hydraulic boosting, but starting with Kalina, manufacturers switched to electric power steering, which pleasantly pleased buyers. The shortcomings that the EUR has are completely eliminated in the new model. If it breaks down, the device can be repaired much easier. But there are also disadvantages.

The EUR has the following three main components:

- mechanical;

- electric;

- ECU with peripherals.

The mechanics include the steering control parts and the parts that connect the entire mechanism. This also includes fittings that act as fasteners.

The “electrical component” category includes the amplifier motor - the weakest part, which is most often subject to breakdowns. There are also connectors for sensors and ECUs.

We determine the operating condition of the EUR by the light on the device

Every time you get into a car and turn the ignition key, you should pay attention to the panel - an icon in the form of a steering wheel and an exclamation mark. When the ignition is turned on, it lights up and if the entire system is in working order, then after a few minutes it automatically goes out

If it continues to glow, it is a clear sign of failure.

In this case, diagnostics should be carried out using computer technology.

It is important to obtain fault codes and decipher them. Sometimes only codes are provided

It is worth remembering a simple rule - all faults associated with the electric power steering are given by numerical combinations starting with the letter “C”

Please note - the value “C 1013” indicates a low voltage, which is not enough for the full and safe operation of the electric amplifier

There may be more than one reason for this malfunction. The most common is the breakdown of a pair of wires (or one). They may not function due to weakening or burning. They are very easy to find by color - red and black. The second problem is the large fuse on the device. It can be easily replaced or repaired. And the third is the lack of network in the car. It is almost impossible to fix this problem on your own; contact a specialist.

We find out the operating condition of the electric booster using the steering wheel

A common reason for checking is that the light indicating the EUR is not on.

It is important to pay attention to the technical condition after a major overhaul. This is done easily: without starting the car, turn the steering wheel. Then start the engine and do the same action

If the applied force was the same, this means the following - the EUR does not work in Priority

Then start the engine and do the same action. If the applied force was the same, this means the following - the EUR does not work in Priority.

The cause of the malfunction may be the operation of one of three components. Mechanical problems indicate that the shaft, connections or fittings are not working properly. If this is the problem, the wheels simply do not obey the steering wheel turns. If the problem is not mechanical, the work will be larger and more complex. If the servomotor or amplifier breaks down, you can forget about repairs. It’s better to buy a new EUR and install it yourself - it will be faster, cheaper, more practical and reliable. And the last option that could cause a breakdown is a faulty wire. These are very important components that transmit signals from external sensors. This case can also be easily repaired at home; it is enough to initially purchase electrical wiring and carry out installation.

Software shutdown

- The electric power steering

turns off after 60 km/h.

Therefore, keep this point in mind; it is set in the system unit and is not a breakdown. The Priora's electric power steering - Also, the EUR does not work at low engine speeds. If the value is less than 400 rpm, it is not active.

This is software planned inactivity. It is needed to give information to the steering wheel at high speed and reduce wear of the mechanism.

How to check the EUR yourself

To understand what is broken in the amplifier, you need to diagnose it. Not every car owner has a diagnostic scanner; some people like to repair the car themselves. In this case, you can determine the malfunction of the electric amplifier yourself using a paper clip. This option is suitable for Kalina and Priora cars.

"Paperclip" method

We disassemble the protective cover of the steering column and get to the amplifier control unit. We find a black block with six wires. It is necessary to close contacts 7 and 6 between each other - “ground” and “K-line”. If you look at the block from the side of the wires, then the countdown goes from right to left, from top to bottom. You need a brown wire - contact number 7 and an empty socket, not used - number 6 in a row.

Turn off the ignition, insert a paper clip into the contacts, make sure that it does not short-circuit the other wires. Turn on the ignition and count the number of flashes of the warning light on the dashboard. One long signal, and then several short ones, these are the ones that need to be counted. Let's look at the decoding of fault codes for Kalina's electric booster :

In practice, this method may not always show real breakdowns. In this method, the control unit checks itself, and it needs to be checked under load. There were cases when it generated false errors, and the fault was hidden in the electric power steering ECU.

Electrical booster malfunctions

In the event that it is impossible to immediately check the cause of failure of the electric power steering on Kalina, you need to remove the fuse from the block. Why doesn't the electric power steering work? This is necessary to prevent sudden activation of the mechanism, which leads to emergency situations.

A direct indicator of a malfunction of the speed sensor in the electric power steering

Kalina, is a non-working speedometer, as well as an exclamation mark on the dashboard that lights up. It may not work for several reasons. Check the appearance of the sensor; if it is covered with dirt, simply clean it. See if any metal shavings have become magnetized and remove those as well.

If this does not help, then the sensor is probably faulty. Such sensors are now inexpensive and can be found in many auto parts stores. We do the same for the torque sensor. But where is the speed sensor? It is usually located in the gearbox housing, see photo on the left.

Another cause of malfunction electric power steering is the generator. The control unit requires a voltage of 13.6 V to operate; if you have less, change the voltage regulator (chocolate) on it.

Diagnostics

To check the amplifier in a car, you need to remove the plastic trim on the steering column; to do this, unscrew the bolts securing it from the bottom.

Then you will need to get to the 8-pin plug, its pinout is as follows:

- The blue contact is connected to the ignition switch, this is 12 volt power;

- the red-brown contact is the connection cable to the tachometer;

- the gray contact goes to the car speed controller;

- white and pink wire - amplifier control indicator;

- black-yellow contact is a diagnostic line;

- the next contact is empty, the wire is not connected to it;

- brown contact is ground;

- empty.

More accurate results will be obtained by checking the amplifier using a scanner. But since such equipment can usually only be found at service stations, you can try to check the operation of the system with a paper clip.

To check you need to do the following:

- First the ignition is turned off.

- Then, using a paper clip, you need to close contacts numbered 6 and 7 of this plug, while the plug itself does not need to be removed.

- Next, the ignition must be turned on.

- After completing these steps, the EUR failure indicator located in the dashboard will begin to blink; by the number of blinks, you can determine whether the system is broken (the author of the video is Gosha Vakhromeev).

- one long signal and one short signal - the electric amplifier is working;

- one long and two short - no engine speed signal;

- one long and three short - the torque controller is out of order or there is no power supply;

- one long and four short blinks—problems in the operation of the electric power steering motor;

- one long and five short - the steering shaft position controller has failed;

- one long and six short - the motor rotor position controller has failed;

- one long and seven short - problems with the electrical network - the voltage is either too high or very low;

- one long and eight short - the control module of the electric amplifier has failed;

- one long and nine short - the speed controller is broken.

Error codes

c1044 - incorrect sequence of the rotor position sensor (RPS)

c1621 - incorrect voltage 5V

c1622 - speed signal circuit failure

c1011 - car engine speed signal circuit, no signal - the signal from the idle sensor (or the standard tachometer through a voltage limiter) is divided by 4 and applied to the tachometer input,

c1022 - error, voltage of the main output of the torque sensor - it is possible that the shaft cover has rubbed the insulation and the middle, green wire shorts to ground

Fuse box

The weak link of the electric power steering

on Kalina, is the fuse box, if something doesn’t

work , it’s worth checking them. To get to them, you need to open the dashboard, to the left of the steering wheel .

To do this, pull the top part towards you and the latch will open. Check if it works

fuse, if it fails, replace it. The one responsible for the operation of the electric power steering of the Lada Kalina Universal does not work. It is very easy to check, check the integrity of the thread inside the fuse. Changing a 50 amp relay to a 30 amp one will also help.

Newer versions of Kalina are equipped with electric amplifiers from Hyundai, which has a positive effect on its reliability. However, there are still thousands of cars with the domestic version, which malfunctions and breaks down from time to time. Now it will be easier for you to repair your electric power steering

on Kalina with your own hands. The main thing to remember is that not every amplifier shutdown is a breakdown. And you can find the problem yourself and fix it, but somewhere you will have to go to a service center.

Dismantling and disassembling the electric amplifier

Before removing the amplifier, you need to remove all the steering column switches. Remove the steering rack cover and dismantle the devices, remembering to disconnect the connectors from the power supply.

How to remove the EUR with your own hands:

- After removing the switches, you will need to dismantle the lower cross member of the dashboard. To do this, you need to press the fasteners that secure the connector with wires, and then disconnect the wiring from the control module. Once these steps are completed, you can disconnect the connector from the switches.

- The system bracket is secured with nuts; you will need to unscrew them with a wrench.

- After this, the steering rack will need to be carefully lowered down. To do this, you will need to find the bolt that secures the driveshaft to the booster shaft. This bolt must be unscrewed, but when unscrewing, you will need to fix the nut, this will prevent it from turning. When the bolt is removed, the fastening will need to be loosened, after which the intermediate shaft will be carefully removed. At this stage, we recommend marking the position of the shaft and gears; you can use a marker for this. This step is very important because doing it will prevent possible installation problems in the future. If the marks on the shafts do not match, this may cause problems with the amplifier. When dismantling, be careful not to damage the wiring, as this will also lead to the inoperability of the ESD.

- When the unit is dismantled, it will need to be disassembled and the failed elements replaced. Further editing is done in reverse order (the author of the video is Murzik Bely).

Video - Lada Kalina steering wheel malfunction

Summarize. It is possible and necessary to repair the Lada Kalina EUR with your own hands. This will save the driver’s budget and greatly improve his qualifications as an auto mechanic. Therefore, if you do not want to pay a large amount of money to the car service employees, you can repair the EUR yourself.

Car. Thanks to it, the system creates additional force to turn the wheel. In other words, the electric power steering helps to “turn” the steering wheel in the right direction. In fact, this mechanism performs the same functions as a hydraulic booster. Only the latter is more outdated in design and less reliable, which is why it is practically not used on modern cars. In today's article we will look at how the Kalina electric power steering works and what parts it consists of.

This element assumes the presence of the following devices:

- electric motor;

- mechanical transmission;

- control systems.

Operating principle

It's worth not always working. It only comes into effect when the steering wheel is turned, that is, when the steering wheel is turned. In this case, the engine of this electric amplifier produces the required torque, depending on the torque on All these forces are measured by a special sensor, which transmits information to the amplifier ECU. in turn, calculates the required power for the engine. How much it will be involved depends on the angle of rotation.

There is another sensor. It measures the steering angle of the wheel. It sends the received data, like the torque sensor, to the amplifier ECU, and it decides how much power the electric motor needs to create in order for the wheel to turn at the right moment.

But that is not all. The Kalina electric power steering has at its disposal a third sensor that measures the engine speed to receive feedback to the ECU. It is needed so that the control unit receives correct information about how fast the motor is spinning and whether it is spinning too fast.

How is the rack connected to the amplifier motor?

After the control unit has processed all the information, it sends a signal to the engine. The latter, in turn, transmits its force to the rack through a worm gear and drive gear. The rack itself can move in two ways: from the amplifier motor, which is controlled by the unit, and directly from the steering wheel, which is activated by the driver.

Thus, the Kalina electric power steering, unlike the hydraulic one, takes into account a number of factors, after which the electronics “decide” how and when the power steering motor needs to act. Moreover, the data depends not only on the readings of the three sensors, but also on the speed of the car.