From the point of view of modern environmental requirements, carburetor engines are already outdated. But cars with carburetors feel great on our roads. Yes, they do not correspond to the spirit of the times, but they work conscientiously and will continue to work for a very long time.

That is why the VAZ 2107 carburetor is a very popular unit today. Those who drive a “classic” can service and repair it themselves; there is nothing supernaturally complicated there. On modern foreign cars, stuffed with electronics, do-it-yourself repairs are no longer possible.

Purpose, diagram, structure and principle of operation of the VAZ 2107 carburetor

The “seven” was equipped with various modifications of the DAAZ 2107 carburetor (Dimitrovgrad Automobile Unit Plant). They are all similar in principle and differ only in some design details.

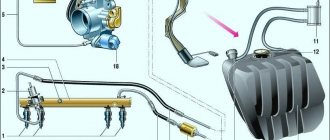

Diagram of the VAZ 2107 carburetor structure: (1 - screw for adjusting the stroke of the accelerator pump intake valve; 2 - carburetor cover; 3 - fuel jet of the transition system of the second chamber; 4 - air jet of the transition system; 5 - air jet of the econostat; 6 - fuel jet of the econostat; 7 — main air jet of the second chamber; 8 — emulsion jet of the econostat; 9 — pneumatic drive of the throttle valve of the second chamber; 10 — small diffuser; 11 — jets; 12 — discharge valve of the accelerator pump; 13 — accelerator pump nozzle; 14 — air damper; 15 - main air jet of the first chamber; 16 - starting device jet; 17 - automatic starting device; 18 - idle air jet; 19 - idle fuel jet; 20 - fuel supply needle valve; 21 - fuel filter; 22 - fuel supply fitting ; 23 — float; 24 — screw for factory adjustment of the idle speed system; 25 — main fuel jet of the first chamber; 26 — adjusting screw for the quality of the working mixture; 27- adjusting screw for the amount of carburetor working mixture 2107-1107010; 28 — throttle valve of the first chamber; 29 — carburetor body; 30 — throttle valve of the second chamber; 31 — throttle body; 32 - emulsion tube; 33 — main fuel jet of the second chamber; 34 — accelerator pump bypass jet; 35 — accelerator pump inlet valve: 36 — accelerator pump drive lever; 37 - carburetor pneumatic valve 2140-1107010-70.)

Purpose.

The purpose of the carburetor is to prepare the gasoline-air mixture in the required proportion and supply it to the engine cylinders. The quality of engine operation, power output, and service life depend on how correctly the ratio between fuel and air is maintained, and how well the dispersion is mixed.

Device and principle of operation. The schematic diagram of the VAZ carburetor is conventionally divided into three structural elements:

- Cover with outlets for hoses;

The structure of the VAZ 2107 carburetor cover: (1 - float axis; 2 - needle valve; 3 - float; 4 - gasket; 5 - trigger diaphragm with rod; 6 - spring; 7 - adjusting screw; 8 - trigger cover; 9 - idle fuel jet; 10 — solenoid shut-off valve; 11 — plug; 12 — carburetor cover; 13 — fuel filter; 14 — air damper; 15 — fuel supply pipe; 16 — air damper axis with lever; 17 — control lever fixation ball air damper; 18 — air damper control lever; 19 — lever axis; 20 — bushing for fastening the air damper drive rod) - The housing in which the float chamber and chambers with diffusers are located;

Structure of the VAZ 2107 carburetor body: (1 - accelerator pump diaphragm; 2 - accelerator pump drive lever; 3 - cover; 4 - accelerator pump drive cam; 5 - power mode economizer cover; 6 - economizer diaphragm; 7 - economizer fuel nozzle; 8 — economizer valve; 9 — check valve of the accelerator pump; 10 — accelerator pump nozzles with a fuel supply valve; 11 — nozzles; 12 — main air jets with emulsion tubes; 13 — main fuel jets; 14 — bracket for fastening the air damper drive rod shell; 15 — adjusting screw of the second chamber; 16 — stopper of the adjusting screw; 17 — stopper cap; 18 — adjusting screw for slightly opening the throttle valve of the first chamber; 19 — axis of the throttle valve of the first chamber with drive levers; 20 — locking lever of the second chamber; 21 — lever spring locks; 22 — throttle axis of the second chamber with a lever; 23 — throttle valve of the first chamber; 24 — throttle valve of the second chamber; 25 — plug for adjusting screw of mixture quality (composition); 26 — return spring of the throttle valve drive lever of the second chamber; 27 — adjusting screw for the quality (composition) of the idle mixture; 28 — carburetor body; 29 — adjusting screw for the amount of idle mixture; 30 - electrical wire of the limit switch of the forced idle economizer; 31 - carburetor heating unit) - The bottom where the throttle valves are located.

Now in more detail about the design and principle of operation:

- Using a fuel pump, gasoline is pumped into the float chamber from the tank to a certain level, which is regulated automatically by opening and closing the needle valve;

- Then fuel is pumped from the float chamber through nozzles into the mixing chambers. In this case, the fuel is already divided into small droplets, which are mixed with the air coming from the air intake with an air filter;

- Econostat is a device for enriching the fuel mixture. It turns on when the engine is running under high load and adds additional fuel to the mixing chambers;

Diagram of the econostat and economizer of the VAZ 2107 carburetor: (1 - throttle valve of the second chamber; 2 - main fuel jet of the second chamber; 3 - fuel channel; 4 - main fuel jet of the first chamber; 5 - throttle valve of the first chamber; 6 - vacuum supply channel; 7 — economizer diaphragm; 8 — ball valve; 9 — economizer fuel jet; 10 — fuel channel; 11 — air damper; 12 — main air jets) - Then the mixture of gasoline and air enters diffusers, where droplets of gasoline are crushed and the resulting mixture is finally mixed;

- The finished mixture enters the fuel (intake) manifold through the throttle valves. The amount of air in the fuel mixture is regulated by an air damper, and the volume of the finished mixture that goes into the fuel manifold is regulated by two throttle valves (one for each chamber);

- At high speeds, the accelerator pump turns on.

Diagram of the VAZ 2107 carburetor accelerator pump (1 - nozzles; 2 - fuel supply ball valve; 3 - pump diaphragm; 4 - pusher; 5 - drive lever; 6 - pump drive cam; 7 - first chamber throttle valve; 8 - check ball valve ; 9 — throttle valve of the second chamber) - A separate idle system is provided, which supplies the minimum required amount of gasoline so that the engine runs smoothly and does not overuse gasoline.

A working carburetor does not need any control. The system itself determines in what mode the engine operates, how much fuel mixture to supply and at what moment. But sometimes it is necessary to carry out maintenance of this unit with tuning and adjustment.

Purpose of the exhaust system

Before combustion in the engine cylinders, gasoline is mixed with air and supplied through the intake manifold into the combustion chamber. There, the mixture is compressed eight times by the pistons and ignited by a spark from the spark plug. As a result of the process, 3 components are formed:

- heat and mechanical energy that rotates the crankshaft;

- gasoline combustion products - carbon dioxide and carbon monoxide, nitrogen oxide and water vapor;

- combustion under high pressure generates sound vibrations - the same exhaust sound.

The smoke at the exit from the duct is cooled to a safe temperature, you can calmly raise your hand - it won’t burn you

The VAZ 2107 exhaust system performs several important functions:

- Emission of combustion products from the chambers and ventilation of the cylinders after the next combustion cycle.

- Reducing the amplitude of sound vibrations, that is, reducing the noise level of a running motor.

- Removal and dissipation of part of the released heat in the atmosphere.

On “sevens” with an injection power system, the exhaust tract solves another important task - it cleans the exhaust from toxic gases CO and NO by afterburning in a catalytic converter.

Adjustment and tuning of the VAZ 2107 carburetor. Calibration data.

If signs of a malfunction appear, it is quite possible (and even necessary) to adjust the carburetor of the VAZ 2107 yourself. Adjustment is necessary when problems begin with the mode and quality of engine operation:

- Difficult engine start, the car does not start for a long time;

- Violation of acceleration dynamics, slow, heavy acceleration;

- When you press the gas pedal, dips, malfunctions and jerks in the engine operation appear, the car noticeably jerks when moving;

- Fuel consumption increases for no apparent reason.

Carburetor calibration table 2107-1107010

Idle speed adjustment (XX)

Correctly set idle speed is a guarantee that the carburetor will not make “dips” at the minimum engine operating mode, but will not waste extra fuel.

Diagram of the idle system and transition systems of the VAZ 2107 carburetor: (1 - electromagnetic shut-off valve; 2 - idle fuel jet; 3 - idle air jet; 4 - fuel jet of the second chamber transition system; 5 - air jet of the second chamber transition system; 6 — outlet of the transition system of the second chamber; 7 — main fuel jets; 8 — slit of the transition system of the first chamber; 9 — mixture quality adjusting screw)

- Start the engine, warm it up to standard operating temperature, then remove the choke;

- At the bottom of the carburetor there is a mixture “quality” screw. It needs to be unscrewed to the maximum (counterclockwise), and the concentration of gasoline in the mixture will be maximum;

- At the bottom of the carburetor, find the “quantity” adjustment screw, which is responsible for the idle speed. Start the engine. Using the “quantity” screw, set the idle speed to 850-900 rpm according to the tachometer;

- Tighten the “quality” screw (according to emergencies) to gradually lean the mixture. As soon as the engine slows down or starts to misfire, turn it in the opposite direction (to increase fuel) about half a turn until the engine begins to operate normally.

Video of idle speed adjustment (xx).

Float adjustment

The float is adjusted to set the normal level of gasoline filling in the float chamber if the carburetor is overfilled or there are other problems with the fuel supply. To do this, you need to remove the carburetor cover on which the float and needle valve are attached.

Diagram of the main metering systems of the VAZ 2107 carburetor: (1 - main air jets with emulsion tubes; 2 - nozzles of the first and second chambers; 3 - fuel filter; 4 - needle valve; 5 - float; 6 - throttle valve of the second chamber; 7 - main fuel jets; 8 - throttle valve of the first chamber)

- You will need templates to adjust the float. They can be cut out of cardboard (make strips 14 and 6.5 mm wide) or use ready-made measurements;

- Place the removed cover on the end so that the float does not press on the needle valve ball, but only lightly touches it;

- The standard gap between the float and the plane of the carburetor cover should be 6.5 mm. In this case, the float itself barely touches the valve ball, as already mentioned. If the distance is greater or less, you need to bend the float tongue;

- The float stroke to the farthest position should be 14 mm. To measure it, you need to move the float and place a second measuring template between it and the lid. If the distance does not meet the standard, you need to bend the tongue of the float bracket.

The video below very simply shows what the fuel level should be in the float chamber and how to adjust the float.

Setting up the starting system and choke

The starting system is the fuel supply mechanism at start. To start the engine “cold” without putting extra stress on the battery and starter, you need to give an enriched mixture.

Starting device of the VAZ 2107 carburetor: (1 - diaphragm; 2 - adjusting screw; 3 - diaphragm rod; 4 - air damper control lever; 4.1 - lower profile of the groove of lever 4 to limit the maximum opening of the air damper; 4.2 - upper profile of the groove, providing mechanical opening the air damper; 4.3 - edge of the lever to ensure the starting clearance of the throttle valve of the first chamber; 5 - air damper; 6 - air damper lever; 7 - air damper return spring; 8 - air damper drive rod; 9 - adjusting screw stopper; 10 - adjusting screw for slightly opening the throttle valve of the first chamber; 11 - throttle valve drive lever; 12 - throttle valve of the first chamber)

To set up, you will need a 5 mm template (this can also be cut out of cardboard. You can often find a recommendation to use a 5 mm drill).

- Remove the carburetor;

- Close the air damper by turning the lever. This is similar to pulling the choke out of the inside of a car;

- Using a prepared measure, check the distance in the first mixing chamber between the wall and the edge of the air damper. It should be exactly 5 mm;

- If the distance does not correspond to the standard, you need to twist the plug above the adjusting screw (on the side of the body) and tighten this screw with a screwdriver to adjust the correct gap.

Below is a short video on how to set up a “cold start” in a carburetor.

Throttle adjustment

This procedure will allow you to correctly set the amount of fuel that enters the manifold. Operating procedure:

- Remove the carburetor;

- Prepare a measure: a small piece of wire 0.7 mm thick;

- Turn the throttle lever until it closes;

- Using a prepared wire, measure the gap between the throttle valve and the wall; it should be exactly 0.7 mm;

- If the gap is greater or less than this indicator, you need to adjust it by bending the drive rod.

Signs of a fuel pump malfunction

An experienced car enthusiast can determine the malfunction of his car by its behavior or by extraneous sounds. This also applies to the fuel pump. If knowledge is not enough, it is worth considering the following characteristic signs indicating problems with the fuel pump:

- the engine does not start;

- the engine stalls almost all the time;

- the power and dynamics of the car decreases.

However, it is worth considering that power may decrease for a number of other reasons: problems with piston rings, valves, etc. If the fuel pump is completely faulty, the engine will not be able to start.

The fuel pump does not pump

There may be several reasons why the device does not supply fuel. Before you start troubleshooting, you need to make sure that there is gasoline in the tank. It happens that the level sensor shows incorrectly and the problem simply comes down to a lack of fuel. You also need to make sure that the filter elements are not clogged, but it is better to replace them, because they are inexpensive. After these steps, you can begin diagnostics.

Due to clogged fuel filters, the pump cannot supply the required amount of fuel to the carburetor.

The causes of problems may be:

- wear due to long mileage;

- diaphragm damage;

- insufficient spring stiffness as a result of stretching;

- valve contamination;

- violation of the tightness of the unit.

If the gas pump on the “seven” does not supply fuel, then there are two ways out of this situation: install a new device or disassemble the old one, carry out diagnostics and replace damaged parts.

On my car, a situation once arose that indicated a lack of fuel for the engine: there was no normal dynamics, the engine periodically stalled and would not start. There was enough gasoline in the tank, the filters were in good condition, but the car did not drive. After lengthy investigations and clarification of the reasons for this phenomenon, the problem was found: the fuel supply hose from the pump to the carburetor was swollen inside, which indicated the poor quality of the product. The internal cross-section has become very small and insufficient to pass the required amount of fuel. After replacing the hose the problem disappeared. In addition, I change fuel filters at least every 5 thousand km. mileage (preferably more often). I have them before and after the fuel pump. As practice shows, even with the installation of two filters, as well as with a mesh in the fuel pump itself and at the carburetor inlet, debris still penetrates into the float chamber. This results in the carburetor having to be cleaned periodically.

Video: VAZ fuel pump does not pump

Stops pumping when hot

One of the problems of classic Zhiguli cars is overheating of the fuel pump, which leads to a disruption in its performance - it simply stops pumping. The problem is caused by the formation of a vapor lock, which blocks the supply of gasoline. There are several ways to solve the problem: water the cooling pump with water or ride with a wet rag on it. These methods are applicable in a critical situation, but not for everyday use. The problem can be eliminated by adjusting the fuel pump using gaskets, replacing the rod, replacing the unit itself, or using higher quality fuel.

Checking the fuel pump

If there are suspicions or characteristic signs of fuel pump problems, the mechanism should be checked. To do this, perform the following steps:

- Loosen the clamp of the hose that supplies gasoline to the carburetor, and then pull the hose off the fitting. Gasoline will leak out of the pipe, so it is better to lower its edge into an empty container.

- We try to manually pump fuel using a lever.

- Gasoline under pressure should flow out of the outlet fitting. If the pump pumps, then it can be considered working. Otherwise, we continue diagnostics.

- Loosen the clamp and remove the hose from the inlet fitting of the fuel pump.

- We clamp the fitting at the inlet with our finger and try to pump it up. If you feel a vacuum (your finger is sucked in), then the pump valves are functioning. If this is not the case, the unit must be repaired or replaced.

How to remove, install, replace a carburetor

For repairs and maintenance, the carburetor must be dismantled. To work, you will need a set of tools (pliers, open-end wrenches, screwdrivers) and a suitable room. Work is carried out on a cold engine. In short, first you need to disconnect everything connected to the carburetor, and only then remove it. The video below clearly shows the procedure for removing a VAZ 2107 carburetor.

Sequencing:

- Loosen the clamp on the corrugated pipe for the warm air intake, remove the pipe;

- Unscrew the air filter housing fasteners and remove it;

- Remove the suction cable: unscrew the bolt and screw that secure its shell, then loosen the cable itself;

- Remove the hose for removing crankcase gases from the fitting;

- Disable the idle economizer control: remove the wires from the microswitches;

- Disconnect the vacuum ignition timing regulator tube (remove it from the fitting);

- Pull the tube off the economizer;

- Remove the return spring;

- Loosen the clamps securing the fuel hoses, remove the hoses;

- Unscrew the 4 carburetor mounting nuts;

- Remove the carburetor from the studs.

Carburetor replacement is needed less frequently than repair. You can find any spare parts for this device on sale. After adjustment, cleaning and repair, the carburetor can be put back.

The carburetor is installed in the reverse order: first it is placed on the studs, then screwed to the body, and then all communications that were removed are connected to it.

Solex

Immediately after the DAAZ, without retreating a step, comes the Solex model. This is one of the heaviest carburetors in terms of installation. Removing this device from the engine is not a problem, but installing it on the 2107 engine requires a lot of work.

The Solex circuit is the same as the others, but its design is somewhat different. To install it on a car, you will need to purchase some additional parts: a throttle cable from a VAZ 2108, a return tee, a longer fuel hose and a return valve from the G8. Design features of the Solex included 2 chambers with increased volume. This enabled the engine to perform better, namely: increase acceleration speed, rated speed and power. Of course, with such an improvement in performance, there was one drawback - increased fuel consumption. Therefore, the Solex was considered more amateur than for everyday use. Just like Ozone, it had modifications 1107010 and 1107010 - 20. It can be installed on both the VAZ 2107 and 2105.

Disassembling and cleaning the unit

Considering that the amount of impurities in our gasoline is simply off scale, cleaning the VAZ 2107 carburetor turns into a necessary procedure. It can be carried out without dismantling and disassembling, or it can be done with complete disassembly of the device.

Cleaning without dismantling, video.

Many car owners periodically treat the carburetor with special cleaning agents (carbocleaners). These aerosols do a good job of removing deposits in gaps, unless, of course, they are perennial “growths.”

- The engine must be turned off and cool before starting work;

- Remove the air filter housing;

- Using a wrench, unscrew the idle speed solenoid valve on the carburetor;

- Use a carb cleaner to treat the carburetor: external surfaces, jet channels (through a thin tube), chambers, air dampers, etc., as far as you can get;

- Leave for 10 minutes for the aerosol to dissolve deposits;

- Run the engine for a couple of minutes. A stream of gasoline will wash away the residue;

- If necessary, repeat the procedure, first waiting until the engine cools down.

If such cleaning does not produce results after twice use, the carburetor will have to be removed and cleaned “like an adult”, with disassembly.

Cleaning with removal, video.

How to remove the carburetor is already clear. Now the sequence of its disassembly:

- Remove the top cover by unscrewing the five mounting screws;

- Unscrew the jets and remove the emulsion tubes;

- Remove the accelerator pump nozzle - unscrew it, pry it off with a screwdriver and remove it;

- Remove the seal located under the valve;

- Remove the diffusers from the chambers using pliers or carefully knock them out with the handle of a screwdriver;

- Unscrew and remove the accelerator pump screw;

- Unscrew the adapter system nozzle holder and remove the nozzle itself;

- Unscrew and remove the idle fuel jet;

- Remove the accelerator pump cover: unscrew the 4 screws in the corners, remove the cover and the pump itself (diaphragm, pusher, spring);

- Remove the return spring from the pneumatic drive lever, then the rod clamp, after which remove the spring from the throttle valve drive lever;

- Remove the pneumatic drive by unscrewing the fasteners;

- Unscrew the 2 screws that secure the lower part of the carburetor to the body, remove the lower part; Remove the economizer and economizer microswitch with bracket;

- Unscrew the screws for adjusting the quantity and quality of the mixture.

This completes the disassembly of the carburetor. After this, you can start cleaning. The parts and body of the carburetor, including the jets, can be washed with kerosene, the seats of the jets and the jets themselves can be blown out with a compressor. It is advisable not to clean the jets with wire; it can damage the holes and then the jet will have to be replaced.

When the layers are washed off the metal, you can inspect it for corrosion, wear and defects. All parts that show signs of wear must be replaced with new ones. The carburetor is assembled in the reverse order, then adjustments are made and you can put it in place.

Acceleration pump.

- Econostat system.

- Maintains fuel at a constant level.

- Idle support.

- Support for warming up and starting the engine.

- Jets (both air and fuel), diffuser, VTS atomizer, well, as well as an emulsion tube (they are located in the main metering chamber).

Before adjusting the carburetor, you need to clean and reassemble it. At the same time, do not forget that it is necessary to repair only those parts in which failure is possible.

Tuning carburetor VAZ 2107, video

There is always room for tuning in a VAZ carburetor. To a certain extent, it really helps to improve the dynamic characteristics of the engine without interfering with the power unit. As a rule, tuning is done for the purpose of:

- reducing fuel consumption;

- improving engine power output;

- improved acceleration characteristics;

- delays in major repairs or engine tuning.

Carburetor modification and tuning, video.

- Replace diffuser No. 1 with a larger one, install fuel and air jets with non-standard ones, with greater capacity, replace the accelerator pump nozzle, remove the springs connecting the throttle valves to the vacuum pump and replace them with wires. All this is done to supply more fuel-air mixture;

- Replace the repair kit - a set of gaskets and consumables that quickly fail. Often, replacing the repair kit allows you to solve the problem with interruptions in the carburetor;

- Install a sports carburetor instead of the standard one. The sports version has better performance, which significantly improves engine dynamics. Of course, the old “Seven” will not turn into a Ferrari, but it will become a little faster. True, fuel consumption will increase, but this is not important for those who like to drive fast;

- Another step is to install a carburetor from another VAZ model with a more powerful engine. The principle is the same as with the tuning “sports” version - more performance, better dynamics;

- For those who understand, install another carburetor. Oddly enough, a pair of standard carburetors gives an increase in power (which is expected) and at the same time saves gasoline. Such tuning can be done by professional craftsmen who have the necessary equipment, but this is a really interesting option for improving the car.

Checking the strainer

It is necessary to pump up the fuel manually, and then fill the float chamber with fuel. The shut-off valve will then close. The next step is to slide the top filter cover and then unscrew the valve. Rinse it thoroughly in solvent and dry with compressed air.

Problems with fuel supply can be detected by such signs as loss or dips in power, “poor response” to pressing the pedal, and engine problems. Such problems may also indicate a faulty strainer.

It is better not to wipe the bottom of the float chamber with a lint cloth or any similar cloth, since the jets may subsequently become clogged with fibers remaining from it.

If you are also interested in replacing the Lada Kalina fuel filter and replacing the fuel pump mesh, information can be found here.

You need to clean the float chamber with a rubber bulb, then dry it with compressed air. You can also use a blower to check the tightness of the shut-off needle, since the pressure force generated during squeezing is the same as the pressure in the fuel pump.

When replacing the carburetor cover, make sure that the position of the floats is vertical. You should feel pressure during installation, then check for air leaks from the carburetor. If air flow is felt, the valve body and needle must be replaced.

Features of the operation of the timing belt in VAZ cars

The timing belt is subjected to serious loads during operation - heat, oil ingress, stretching, wear due to constant contact with pulleys, etc. In winter, when the car is stopped, the belt freezes, loses elasticity and suffers even more when starting the engine. In hot summers, on the contrary, the belt heats up significantly, which leads to its intensive aging. Therefore, the timing belt must be changed regularly, otherwise one day it will start to slip or even break, and this will have the most dire consequences for the engine.

Any damage to the timing belt is accompanied by a mismatch in the operation of the timing belt and timing belt, which at best simply requires a new engine adjustment, and at worst - serious repairs to the piston group, timing belt, cylinder head and other parts. In particular, a timing belt rupture leads to an almost instantaneous stop of the camshaft, which means that the intake and exhaust valves are locked in the position they occupied before the breakdown. However, in this case the pistons continue to move in the cylinders, so when they rise to TDC they bend the valves, and in the worst case, they are simply broken by the valves. As a result, the engine stops and requires expensive repairs.

It should be noted here that not all VAZ engines break down when the timing belt breaks. In the line of VAZ engines there are models (for example, the 1.5-liter in the VAZ-2109), the pistons of which have recesses for the intake and exhaust valves - they are not afraid of camshaft stopping. But for most VAZ car engines, timing belt rupture poses a serious threat.

In the vast majority of cases, rupture or cutting of teeth (which can also cause serious damage to the engine) occurs after the belt has reached the end of its life; a new timing belt cannot simply break. Today, most manufacturers set the service life of the belt within 50-60 thousand km of vehicle mileage. After this period, the timing belt must be replaced, regardless of its condition. That is, even if the belt looks good outwardly and has no visible damage or serious wear, it still needs to be changed no later than after 60 thousand km.

Replacing the timing belt in VAZ cars is accessible to the average car owner and generally does not present any difficulties.

In what cases is it necessary to replace the heater radiator?

The radiator itself is a simple device from a technical point of view. It consists of a system of tubes through which the coolant moves, equipped with thin lamellas. It would seem that there is nothing to break here. However, radiators fail very often. There are only two reasons here:

- leakage due to drying out, corrosion or mechanical damage;

- obstruction resulting from sedimentation of oxidation products on the tubes or “clogging” with various debris or the same products of oxidative processes.

If you can try to combat the latter reason by flushing the radiator with chemical reagents, which does not always help, and not for long, then if a leak occurs, the only correct solution is to replace the radiator with a new one.

You can, of course, try to correct the situation by soldering the leak, but this option is only suitable for copper-brass radiator models. And no one will give you a guarantee that symptoms will not appear in the near future.

Do you need to bother with repairing the heater radiator if it is not that expensive, and you don’t have to go to a service station to replace it?

Payment methods for goods:

- It is possible to send cargo with a thirty percent (30%) advance payment with blocking and removal of blocking upon full payment.

- It is possible to send cargo without prepayment, provided that the buyer pays for the services of the transport company in both directions at the branch of the transport company.

- Sending by PEC by cash on delivery with the condition of prepayment of delivery in both directions (this way we are safe from fraudsters) - in PEC before payment you can inspect the goods received, PEC charges a commission for this service in the amount of: 1.5% for cash and 3% for non-cash calculation

You can make any changes (tuning/additions) to the standard engine configuration BUT the warranty will be 3000 km or 3 months of operation

You can also make any set of attachments (standard and non-standard) if you have some of the equipment - write what to add/exclude from the set, the manager will write a price change.

Engine manufactured in Togliatti with all warranties. For components, assemblies, engines and gearboxes, the warranty is 15 thousand km or 1 year, whichever comes first. The warranty period is 1 year or 15 thousand kilometers due to the inability to control the operating conditions of the listed products, the replacement interval and the quality of fuels and lubricants.

Methods of payment for goods: It is possible to send cargo with a thirty percent (30%) advance payment with blocking and removal of blocking upon full payment. It is possible to send cargo without prepayment, provided that the buyer pays for the services of the transport company in both directions at the branch of the transport company. You can make any changes (tuning/additions) to the standard engine configuration BUT the warranty will be 3000 km or 3 months of operation. You can also make any set of attachments (standard and non-standard) if you have some of the equipment - write what to add/exclude from the package , the manager will write a price change.

Working volume 1.57 l

Power 74.5 hp

Cylinder diameter 79 mm

Piston stroke 80 mm

Number of valves 8

Power injector system

What does the engine package include: Block, crankshaft, pistons, rings, connecting rods, bearings, half rings, oil seals, cylinder head assembly with camshaft, crankshaft pulley, flywheel, oil pump with oil receiver, iron oil pan (aluminum can be installed - check price with manager), valve cover, gas distribution mechanism with a closed cover, spark plugs. Sensors: oil, temperature, phase sensor (if injector), knock sensor, antifreeze drain plug, dipstick, break-in oil (10v40 semi-synthetic Lukoil, recommended after break-in 1000-1500 km, oil change).

Packaging: everything is mounted on a wooden stable pallet, screwed on, the engine itself is made of cardboard on all sides and wrapped with stretch film. The transport company is packed in a wooden box. At the request of the client, we can dismantle any component of the engine or replace it with a non-standard sports or tuned part.

Preparatory activities

If a motorist is interested in adjusting the Solex VAZ-2107 carburetor with his own hands, he must first carry out a number of preparatory steps.

Initially, you need to warm up the power unit to operating condition (temperature 85–90 degrees).

In the next step, you need to squeeze the handle of the air damper drive mechanism all the way; people simply call it “choke.” After this, the damper should be in a position in which the air channel is completely free, i.e., located in the direction of air movement.

If there is a tachometer, the device must be connected to the engine being turned off. Otherwise, if there is no unit, the item should be skipped. The positive side of the device should go to the ignition coil, and the negative side should go to the “ground” of the vehicle (body, engine or battery negative). Before connecting the device, you should read the operating instructions.

The last action should be to start the engine, turn on the high beam optics and the heating device.

Modifications

- VAZ-2105 - 1.3 l. carb. VAZ-2105 engine with 4-speed Checkpoint.

VAZ-21050 - 1.3 l. carb. VAZ-2105 engine with 5-speed Checkpoint.

VAZ-21051 - 1.2 l. VAZ-2101 carburetor engine with 4-speed gearbox.

VAZ-21053 - 1.5 l. carb. engine VAZ-2103 or injection VAZ-2104 with 5-speed. Checkpoint.

VAZ-21054 is a small-scale modification produced for the traffic police, the Ministry of Internal Affairs and the FSB with an additional gas tank and battery.

VAZ-21055 - 1.5 l. diesel VAZ-341 produced by Barnaultransmash, small-scale modification for taxis.

VAZ-21057 (Lada Riva) - an export version of the VAZ-21053 with right-hand drive, produced in 1992-1997 for the UK.

VAZ-21058 is an export version of the VAZ-21050 with right-hand drive, produced in 1982-1994 for the UK.

VAZ-21059 - 1.3 l. rotary engine VAZ-4132 with a power of 140 hp.

Number of gear stages

Final drive ratio

Maximum speed, km/h

165/70R13 175/70R13

Rear window defroster

| Performances | Four-stroke, gasoline, carburetor, four-cylinder | diesel | rotary |

| Body type | |||

| Number of doors | |||

| trunk volume, dm 3 | |||

| Overall dimensions, mm: | |||

| own weight, kg | |||

| Wheelbase, mm | |||

| Front wheel track | |||

| Rear wheel track | |||

| Drive wheels | |||

| Ground clearance to floor pan | |||

| Clearance to rear axle beam | |||

| Clearance to front suspension beam | |||

| Engine | 341- diesel | VAZ 4132 | |

| working volume, cubic cm | |||

| Max. power, kW (at rpm) | |||

| Max. power, l. With. | |||

| Max. torque my., Nm (at rpm) | |||

| supply system | carburetor | carburetor | carburetor |

| Gearbox ratios: | |||

| reverse | |||

| acceleration to 100 km/h, s | |||

| Fuel consumption, l/100 km: | |||

| fuel consumption at 90 km/h | |||

| fuel consumption at 120 km/h | |||

| fuel consumption in the urban cycle | |||

| Fuel tank capacity, l | |||

| Front brakes | disk | ||

| Rear brakes | drums | ||

| Braking distance loaded from 80 km/h | |||

| Parking brake drive | cable | ||

| Clutch drive | hydraulic | ||

| Front suspension | independent | ||

| Rear suspension | five-rod | ||

| Steering | worm - roller | ||

| Smallest turning radius | |||

| The weight of the towed trailer is storm. | |||

| Towed trailer weight without brakes | |||

| Max, roof rack weight | |||

| Maximum lift without acceleration | |||

| Resource until the first cap. repair, km | |||

| Cold start temperature, C | |||

| Dashboard | |||

| Cooling fan | mechanical | mechanical | mechanical |

| aluminum | |||

| Exterior mirrors | |||

| Seat upholstery | |||

| Headlining | |||

| Door trim | unified |

* - as you master it ** - installed on special equipment

In the line of models coming off the assembly line of the Volzhsky Automobile Plant, the VAZ-2105 occupies a special place, primarily due to the fact that this particular car is considered the first-born of the second generation of rear-wheel drive Zhiguli. For its time, the design of the “five” was close enough to fully comply with the trends of European automobile fashion, and for the USSR in the early 80s, according to many experts and car enthusiasts, it was the most stylish car. Despite the fact that the VAZ-2105 was never destined to become the most popular model, the car continues to enjoy well-deserved respect among car enthusiasts. Today in the automobile market, the status of the VAZ-2105 can be determined in accordance with its direct purpose, that is, as a means of transportation, if not the most comfortable, but quite reliable and time-tested.