Hi all! It is unlikely that anyone will argue with the fact that proper operation of the braking system is the key to the safety of every driver. Therefore, today we will continue this topic by talking about why the caliper is knocking, what to do in this situation and who is causing the noise.

Surely everyone knows that you should always monitor the degree of wear of the brake discs. We also talked to you about grooving brake drums, and also studied the nuances of grooving brake discs yourself. I don’t encourage you to do this yourself, but you must know the features and tasks of such procedures.

The caliper refers to the braking system of a vehicle. It comes in both front and rear. But in both cases, his treatment is carried out approximately according to the same scheme. And the reasons for the knocking are identical.

Blog - Hello comrade!

Many people are faced with a fairly common problem: caliper rattling. The main symptom is a metallic rattle, which disappears if you lightly press the brake and mainly appears on cobblestones or similar roads and is also clearly audible when you get into holes. The sound itself can be either sonorous or more dull. The main reason is the broken holes for the guides due to untimely maintenance. Although once a year it is necessary to check the presence of grease on the caliper guides, as well as the condition of the rubber boots.

How to eliminate knocking calipers

If the knocking has just appeared recently, an inspection of the calipers may help, that is, lubricating the guides with high-quality lubricant and checking the boots.

It is important to use high-quality lubricant special for guides. It is not recommended to use copper, ceramic or hub grease. These types of lubricants will jam the caliper guides under certain conditions. The optimal lubricant for guides is SLIPKOTE 211 DBC or similar. If the necessary lubricant is not available, as a last resort, use blue lubricant for the hubs, up to 170 degrees; without sudden braking, such lubricant will work normally. In principle, there were no problems with it on the Starex bead; the anthers did not swell.

Is the caliper really knocking?

In fact, there are many elements in the car that can knock. These are the same engine valves and the notorious hydraulic compensators, the knocking of which we recently talked about. But the calipers also knock. Moreover, this phenomenon is quite common.

For some cars, such symptoms are quite common and their appearance is purely a matter of time.

The first step is to determine whether the calipers are actually knocking. Fortunately, there is no need to go to a car service center and spend money on expensive diagnostics. You can do it on your own. The knocking noise is most noticeable when the car is moving at low speed. It is worth intentionally driving through easy obstacles. The easiest option is to drive over a speed bump or drive onto the ground. And as soon as you press the brake, the knocking will disappear.

One of the disadvantages of the defect in question is the fact that it is not covered by warranty defects. Roughly speaking, if the car is under warranty, you will have to repair the calipers at your own expense.

Looking for the root of the problem

So, what causes such a characteristic ringing? The reason lies in insufficient pressure of the pads to the discs. As a result, a gap appears between them. On bumps, the pads vibrate and involuntarily come into contact with the surface of the disc.

This is what causes the haunting sound. What is noteworthy is that from the street it looks more like a ringing sound. And dull blows are felt inside. Sometimes this indicates a problem with the shock absorbers or ball joint. But don’t rush things and sort out the suspension. Perhaps your brake calipers are just rattling.

Knocking of calipers on a Chevrolet Aveo - elimination instructions

Almost every owner of a Chevrolet Aveo, when driving on a rough road, paid attention to the appearance of a rattling sound from the front calipers. Many begin to fight it using various lubricants, however, even if the rattling disappears, it does not last long.

The fact is that the clanging occurs as a result of play between the guides and the movable caliper bracket.

Source of rattling sound

The guides dangle freely in the holes of the movable caliper bracket and ring. The reason for the increased play is the increased temperature gap and wear of the guides.

Caliper mounting guides showing wear

In this regard, we want to talk about three effective ways to eliminate the knocking of calipers on a Chevrolet Aveo.

The first way to eliminate caliper knocking

Considering that this is one of the simplest and cheapest ways to “improve” the front calipers, you will only need to buy two rubber bushings from the torque rods used on classic VAZ models.

Rubber bushings for VAZ jet rods

We will also need a tool to remove the front wheel, a 10mm wrench to remove the calipers (the publication “Replacing Front Brake Pads” described how to remove the calipers) and a sharp knife to cut off the rubber.

Procedure for eliminating caliper knocking

- Jack up the car.

- Remove the front wheel.

- Unscrew the upper caliper guide and lower the movable bracket down.

- Cut off some of the rubber on the bushing (determined experimentally).

- Insert the bushing in the area of the lower guide bolt and place the caliper bracket in place.

The rubber bushing is inserted into the caliper

As a result of installing the bushing, a certain pretension of the calipers will be created, which reduces the rattling of the guides and the movable bracket.

The second way to eliminate caliper knocking

This method is one of the most expensive methods, which eliminates the root cause of rattling.

Taking into account the fact that the clanging sound occurs due to the increased gap between the guides and the movable caliper bracket, it is necessary to remove the guides and brackets and go to a lathe to grind new guides with a reduced temperature gap.

New caliper mounting guides

In this regard, the question arises: How will the front brakes behave if the guides overheat? After all, for some reason the car manufacturer’s engineers didn’t do this.

This video clearly shows the difference between the old guides and the new ones, with a reduced temperature gap and no play in the bracket.

ETsvbmCXSvg[/]

The third way to eliminate caliper knocking

This method seems to me to be the most optimal in terms of its principle and costs. It involves installing a special bracket that creates a certain tension on the caliper and is similar to the first method discussed at the beginning. Similar brackets are widely used on cars of other brands.

So, we buy staples with the number TRW PFK 241,

Brackets for mounting on calipers

We prepare a drill and a metal drill with a diameter of 3 mm, as well as a 10mm wrench for removing the calipers.

Procedure for eliminating rattling calipers

- Jack up the car and remove the front wheel.

- Insert the bracket into the caliper and mark on it the places where you need to drill two holes.

- Remove the caliper and drill the marked holes. In this case, they must be drilled at an angle so that the bent ends of the bracket can fit completely into them.

- Reinstall the caliper.

- Insert the staple.

Install the bracket onto the caliperIf necessary, help with a screwdriver

Bracket installed

- Screw the wheel and go to the other side.

THIS IS INTERESTING: Where is the battery located in the Audi Q5?

That's all! Think, do, enjoy the silence when driving a Chevrolet Aveo!

What, you haven't read it yet? Well, it's in vain

I would be grateful if you use the social buttons!

Source: https://chevy-aveo.ru/remont-hodovoy/stuk-supportov-na-shevrole-aveo/

Plate

Many manufacturers install special anti-squeak plates from the factory. They follow the contours of the block and are up to one millimeter thick. Many people do not see the point in installing these elements. But they have an effect. If the spring is not able to properly press the pads, this pad partially compensates for this gap. If the calipers rattle, what should I do? It is necessary to inspect the brake mechanism and check for the presence of an anti-squeak plate.

Guides

The caliper is constantly subject to quite heavy loads. Therefore, problems with them are not uncommon. And on some Chevrolet models, this is a generic disease that appears after 20,000-30,000 kilometers. There are several ways to fix this problem:

- Replacing guides. This method does not always help. We buy a set of new guides and install it. If everything is in order, then the problem will disappear. But, she will return after some mileage. When the knocking occurs again depends on the characteristics of your vehicle. In some cases, the knocking noise is caused by wear on the guide seats. Dealing with such a malfunction is much more difficult. In this case, special rubber bands are installed on the pins. To do this, you will have to purchase special reinforced guides. But this pleasure is not cheap. Each set contains only 1 elastic band. Accordingly, one wheel will require from 2 to 4 sets. But, you will forget about the knock for quite a long time;

- There is a special lubricant for calipers. In general, this is a preventive measure. But, in some cases it helps to get rid of knocking. To use, pull the guide out of its seat and lubricate it thickly with lubricant. After that, we place part of the lubricant in the socket. We insert the pin into place and secure it. Depending on the degree of wear and the quality of the lubricant itself, one treatment should be enough for 500-10,000 kilometers. This lubricant is usually sold in small bags per guide;

- There is also a rather radical way to solve the problem. This is the addition of a spacer spring. To do this, you will have to drill holes in the caliper and brake cylinder block. After which, the parts are tightened using a spring. Suitable from VAZ drum brake repair kit.

This is interesting: How to add distilled water to a battery: how much liquid should be

What to do if the pads rattle in the caliper immediately after replacement?

In this case, the culprit of the problem is a disk that is too thin. Typically its service life ranges from 120 to 200 thousand kilometers. With significant wear, neither lubricant nor additional plates will help restore the previous gap. There is only one way out of the situation - replacing the brake disc with a new one.

Some produce grooving of this element. But it is worth remembering that such an operation is performed only if the part is sufficiently thick. In our case, this operation can also cause harm.

If the calipers rattle, what should I do? If you install a new disc and pads, the problem should be solved. But if it remains, you can try replacing the clamping bracket.

Possible reasons

To repair a fault, it must be found. Therefore, first we will look at the main causes of caliper knocking:

- Worn pads. Actually, it is not the caliper that is knocking, but the pads;

- The guides were taken out, as a result the caliper moves along them, while it knocks;

- The bolts holding the caliper have come loose.

Each of these problems has its own methods and repair methods. Let's look at them in more detail.

This is interesting: Lada Vesta fuses: where they are, replacement

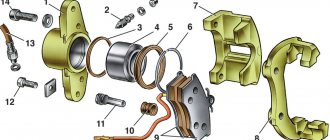

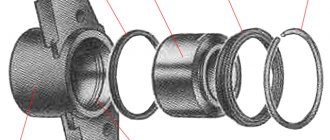

Wear of guides and bushings

When the guides and bushings wear out, a knocking noise appears when braking, as well as on uneven road surfaces. In the most advanced cases, the pads rattle throughout the entire movement. To solve the problem, you need to purchase a special repair kit. It includes 2 boots, 2 guides, 2 bushings and special lubricant.

Instructions for eliminating pad knocking due to the guides are given below.

- Unscrew the two caliper guides.

- Remove the caliper.

- Knock out the bushing.

- Replace the bushing and reassemble everything in reverse order, using the elements from the repair kit.

Build error

If the pads begin to rattle after overhauling the brake system or replacing them, this may indicate an error occurred during installation work. At the same time, one should not exclude the risk of installing low-quality consumables, which cause extraneous sounds.

The most common error during assembly is poor fixation of the inner pad by the petals in the piston. In this case, you need to get it out by disassembling the caliper. Next, you should bend the petals further and mount everything in place.

Drum brake pads

Drum pads knock much less often. In most cases, the problem is due to excessive stretching of the springs of the mechanism. Elimination of chatter is carried out by rebuilding the drum brake. To do this, you must first purchase a special repair kit.

If knocking occurs immediately after replacing the drum pads, this indicates their low quality. The contact of friction material from a collapsing consumable on the drum leads to contamination of its surface, which causes impacts on the pads and their clanking.

Causes of knocking noises

Since you can independently determine the knocking noise from the caliper when testing the suspension on uneven surfaces, you can also safely tackle the problem with your own hands.

There is nothing scary or difficult about this. This happens on a variety of machines, including:

- Toyota Corolla;

- Gazelle;

- Lada Largus;

- Ford Focus;

- VAZ 2110;

- Mercedes Sprinter;

- Renault Logan;

- VAZ 2114;

- Lada Vesta;

- Chevrolet Aveo (every 30 thousand km);

- Hyundai Solaris, etc.

The reason usually lies in one of 3 reasons.

This includes poor fixation of the element, wear on the guides, as well as wear on the brake pads. In the latter case, the pads themselves will actually knock, although the symptoms manifest themselves identically. In any case, you will have to go there and take appropriate measures.

Now we will consider each reason separately.

The pads are worn out

The first thing that should be checked when such symptoms occur is the pads.

There are two simple diagnostic methods that you can do yourself.

- While driving. If you feel that the car brakes worse with the same pressure on the pedal, plus there is a creaking noise when braking, the pads are probably seriously worn out. This also includes such a symptom as beating in the pedal;

- Visual method. You will have to get to the pads by removing the wheel and examine their condition visually. Worn linings indicate a problem. Even if they are not completely erased, it is better to treat the node immediately.

On every car, the pads must be replaced after a certain period. Usually this is 10-15 thousand kilometers.

If the pad is worn out, the driver will observe a sound reminiscent of a knocking sound from the caliper. Under no circumstances should the pads be allowed to wear excessively, otherwise this could result in damage to the brake disc. Also, such pads can squeeze out and cause jamming of the car brake cylinder.

Having dealt with the wear of the pads in the calipers, we move on.

The culprits are the guides

There is a rather important component in the brake system, called caliper guides. When they wear out, it is necessary to take measures to replace the components.

In fact, there may be 2 problems here.

- The guides themselves are worn out. If these elements are worn out, then there is no need to repair or restore anything. You just need to purchase new guides and install them in place of the old ones. Based on the video instructions, this will be quite easy to do;

- The sockets are worn out. The guides have sockets that also wear out over time. Special repair rubber bands will help you here. These rubber bands are put on the pin, thereby the guides stop causing knocking.

What you shouldn’t do is use the so-called collective farm method. It consists of drilling additional holes in the brake system cylinder block, as well as in the caliper itself, after which the elements are tightened. For this, a spacer spring is used.

In some cases, knocking noise due to the guides can be eliminated with lubricant. It is applied in a thick layer, after first removing it from the nest.

Sometimes lubricant helps to get rid of extraneous noise for a long period. For some, the sound appears again after 200-500 kilometers, for others it lasts several thousand kilometers.

Development on the steering knuckle

Front and rear disc brakes squeal their pads very often due to wear on the steering knuckles. As a result of prolonged use, the metal is “eaten” at the point of contact with the supporting plate. Upon visual inspection, small grooves may be found on the knuckle, which are signs of wear.

Initially, an extraneous sound appears on bumps, but subsequently it can accompany the entire period of movement of the car. When contacting a service technician with a question about what to do with a worn steering knuckle, the car owner receives two standard ways to solve the problem:

- Using welding, weld metal onto the worn surface.

- Replace the fist.

Both of these methods are very often unacceptable for car owners, as they are very expensive. There are artisanal ways to solve the problem. One of the cheapest and simplest methods is given below. It only requires plastic clamps.

- Clean the protrusions on the fist.

- Insert the tie into the ledge.

- Tighten the plastic tie. Do similar actions for the remaining protrusions.

- Trim off excess.

Since plastic ties do not have high strength, they need to be updated 1-2 times a year. For a longer lasting solution to the problem, it is recommended to use metal. You can fasten it, for example, as shown in the photo below.

Discs

Failed discs can also cause pads to knock. As a result of intense braking, the metal heats up. When driving through a puddle, water entering leads to deformations. Disc beating occurs. In this case, the knocking of the pads directly depends on the speed of the car. Elimination of runout is possible by boring, but provided that the deformation is not significant and the thickness of the disk is sufficient. Otherwise, it needs to be replaced.

The use of low-quality discs leads to their delamination. This causes damage to the pads and their knocking. The problem can be fixed only by replacing the disks with high-quality ones.

The mount has come loose

This happens, but quite rarely. A common reason is traveling on poor quality roads. Vibration can cause bolts to become loose and unscrewed. Usually, this happens soon after a repair affecting the caliper. In this case, you or the master simply did not tighten the bolts. For prevention, always pull fasteners with a certain torque when assembling.

This will save you from problems. To eliminate this knocking noise, simply tighten the bolts. If one of them is lost, make sure it is not broken off and screw on a new one. The broken bolt will have to be drilled out.

Conclusion

. There are quite a large number of different mechanisms near the wheels. They periodically fail. Therefore, the question of what to do if the calipers are knocking is not uncommon. In many cases, this is a design feature that will be quite problematic to eliminate. But it is still quite possible.