Welcome! It's time to get into the clutch. Grant norm, engine 186, gearbox 2181, mileage 31t. with kopecks, 3 years like from the assembly line. Having read a lot on the Internet + rattling of the release lever (as I thought) + since the spring it began to twitch when starting off. Gradually, over the past five months, the jerking when starting off has increased. It was not comfortable to touch. I had to step on the gas. I waited until vacation to slowly start replacing the clutch. The plans were to change the basket (most likely) and the release lever. But first you need to take it apart, so to speak, perform an autopsy, and then make a diagnosis. This means that to replace the clutch we need a garage with a pit, a car with a manual transmission, two hands, a little gray matter in the head and the actual tool. Since the repair will take place in privacy, first (the day before) you need to purchase 3 bolts 150 mm long (quite enough), I estimated the diameter and thread by unscrewing one of the top bolts and... two hub nuts (in old ones, the thread will pull when unscrewing). 1 first of all, the very first thing is to pull off the hub nuts and unscrew them (I took a cut-off union nut, like a “30” one (it was rusty) and a 40cm pipe), pull off the wheel bolts, DO NOT UNLOCK IT! 2 You can start either from the top or from the bottom, but it is advisable to start from the top while your hands and gloves are clean. 3, remove the air intake and throttle pipe, take other wires and tubes to the side and tie them up so that they do not interfere with us. 4 unscrew the platform, pull off the power fuse block from it and two tubes (fuel and canister valve) are attached to it at the bottom. 5, unscrew the spark plugs to make it easier to turn the crankshaft by the flywheel in the future. 6 remove the starter (three bolts) + disconnect the harness block and the power wire “+” (but it’s more convenient to remove from below, unscrew one bolt at the top and two at the bottom). Under (behind) the starter there is a key bolt at “13” that secures the ignition coil (don’t forget about it).

6(a) we remove the gearshift cable, the principle of the hinge (the horizontal one was pulled off, on the third attempt after a couple of hours, the vertical one still couldn’t. I removed it together with the axle (having previously unpinned it) from (from) the gearshift mechanism. (There’s a little photo below). The nuance is that the fixation mechanism is located on the cable, behind the bracket (in the photo in the same color, gray L = 4-5 cm), it moves back accordingly, if it doesn’t work by hand, pry it with a screwdriver, otherwise you won’t have any luck. bracket (two bolts). Throw the cables over the steering rack rod, tie it a little. 7 fix the bar with the wires to the thermostat, otherwise it will interfere

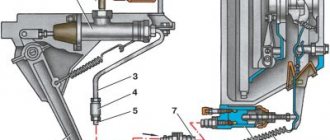

8 unscrew the two upper bolts and one in front near the starter and tighten our long ones (bought bolts), one by one, not all at once. As they say, with feeling, with sense, with arrangement.

9 this nut is better (it’s more convenient to unscrew when the right drive is removed), but it’s possible without removing it, a knob + a long insert.

10 We unscrew the lower flywheel screen (three bolts with a key *10*) last, before removing the box, since this bolt (see below in the photo) is not convenient to unscrew and remove and install the screen itself. Accordingly, when assembling, we put it first and screw it on!

11 remove the wheels (both), put the car on supports. 12 we climb “into the grave” (under the car in a hole), remove the protection. We drain the oil from the box (a five-minute task). It is advisable to first remove the filler and drain plugs so that they “go by hand”. Then, substituting a clean canister (to use the oil in the future), unscrew the drain plug. If you unscrew the filler plug first, the pressure will be higher, we will cheat a little. 13, remove the screen of the right drive (at the CV joint, grenade, whatever). The right one is in the direction of travel, of course. We unscrew the ball (E12 sprocket head (who hasn’t changed it)). We move the rack to the side, pull out the CV joint (outer) from the hub. Most likely you will have to knock it (it sits on the splines) out of the hub a little. When dismantling the right-hand drive, it is advisable to turn the wheels to the right (the hub will interfere less). 14 on the left side you need to remove the lower lever along with the saber (stretch). Personally, it bothers me when you work alone. We remove the left drive in the same way. 15 place a jack (preferably a diamond jack, it is possible to lower the engine lower) under the engine sump). It is advisable to lift it later by moving the jack under the box. 16 unscrew the clutch cable bracket on the left support of the box, then you will have access to the support nuts and two pillow bolts (head on *15* both here and there) fa.d-cd.net/cc36678s-960.jpg (—//— ). 17 remove the rear support (three bolts on the box, two nuts on the body) 18 lower the box so that it goes under the wing. — after lowering, we remove the gear shift mechanism itself (three bolts), prying it a little (it sits on the sealant) and plug the resulting “hole” (no matter how rude it sounds) with a clean rag (rag) to prevent dirt from getting in during the work.

19 After everything that gets in the way has been removed, we extend the box to the full length of the bolts, adjusting with a jack.

I took it off and shortened the basket and disk, everything is fine there. The disk and basket are “Valeo” from the factory. On the basket, a couple of petals were almost out of plane (one of the reasons for the twitching). The disk was alive, the springs did not dangle (did not rattle), by the way, weak springs are the second reason for jerking and they are trying to replace such a disk.

What affects service life

There is no clear answer regarding the frequency of replacing the input shaft bearing. Therefore, the procedure is carried out depending on the current condition. The wear rate of elements is influenced by several factors, including:

- The quality of the bearings used;

- Driving style;

- Conditions under which the vehicle is operated (weather, road quality);

- Frequency of visits to car repair shops or self-diagnosis of the car’s condition, etc.

Checking status

Let us say right away that it will not be possible to replace the bearing without removing the gearbox. Therefore, first of all, we get acquainted with the features of dismantling the gearbox, after which we proceed to further actions.

Make sure the bearing and its components are in good condition. To do this, check the following:

- There should be no cracks or defects on the shutdown plug;

- The bosses, which are used for mounting on the release bearing, should not show signs of severe wear;

- Check the spring bracket under the soldier. The casing contains a stand for fixing the fork. The spring bracket normally does not have any signs of defects or wear;

- The presence of signs of wear on a soldier is a bad sign.

The input shaft is a block consisting of drive gears. Some of them are made on the shaft, the other is pressed with great tension. That’s why we are talking about a non-separable design, where only the front and rear bearings are replaceable. If other components fail, the entire assembly must be replaced.

How to install a new element on the shaft?

A new part can be installed on the input shaft using press-fit technology. The bearing is generously lubricated with engine oil and then pressed in using a small hammer.

It is important that the tool is not only small, but also not heavy. Use a hammer to gently and evenly hit the inner ring of the part.

The shaft is pulled forward. After pressing, it is recommended to make sure that the part is working properly. A serviceable bearing rotates easily and quietly, without noise. After the replacement of the input shaft bearing (including the VAZ) has been completed, the gearbox is installed in its rightful place. All assembly work should be done in reverse order.

Where is the best place to make a purchase?

You can buy a Granta clutch new or old, original or non-original. The choice depends on the financial condition of the car owner and his preferences regarding the manufacturer. Car mechanics recommend installing new original parts, as they are ideal for the car.

But original spare parts are expensive. You can save a little by purchasing an analogue from another company (for example, Valeo or KraftTech). New clutches are sold in the following places:

- Auto parts store.

- Online store.

- Car market.

The first option is preferable due to reliability. In the car market there is a risk of buying a Chinese counterfeit.

Old auto parts have a short service life, but are cheaper than new ones. Motorists with a limited budget should choose such parts. Used clutches are sold on the car market, by advertisement, at a disassembly point.

Replacement

Many people turn to a service station to replace this bearing. It is noteworthy that car services often refuse to perform such work. It’s understandable, because the procedure is painstaking, and you can’t get a lot of money for it.

Dismantling works

To do the job yourself, follow the instructions.

- You can often find advice about the need to completely disassemble the gearbox to replace the bearing. But this is optional. You can do without such complex manipulations.

- In any case, you will have to remove the box, so familiarize yourself with this procedure.

- Before removing the gearbox, remove the negative terminal from the car battery.

- All the chips are removed from the box, the wire from the speedometer is unscrewed.

- Next, the trousers of the vehicle exhaust system are dismantled.

- After this, you can completely remove the gearbox.

- At the next stage, the bell is dismantled. You can try to do without it, but then it will definitely constantly interfere with your work.

- Thoroughly clean the box from accumulated dirt.

- The bearing is secured using retaining rings. To remove them you will need a flathead screwdriver.

- The rings are pryed off and loosened a little, after which there will be no more problems with removal.

- To make it more convenient, arm yourself with tweezers that can be used to remove the ring.

- Using a flat-head screwdriver, pry the bearing by the ring groove, and at the same time move the input shaft slightly forward.

- Insert a pry bar between the gearbox and the bearing. It is unlikely that you will be able to do this without an assistant.

- You will operate the tools, while your friend will hold the pry bar.

- Your main task is to press out the bearing. To do this, precise, strong, but most accurate blows are applied to the input shaft.

- In the process of striking, the shaft must rotate.

- This work will take you about 20 minutes. But if you have a special puller at your disposal, you can speed up the work. Although it is really convenient to work with a puller only if you decide to disassemble the gearbox.

- Before installing a new input shaft bearing, be sure to lubricate the element with regular engine oil.

- Carefully press the component into place using gentle, light blows with a hammer. It is better to use a pipe of diameter or a stand.

- When pressing, apply blows to the inner race, in a circle, as evenly as possible.

- Once the bearing is pressed in, make sure it is seated properly. Scrolling should be calm, without obstacles.

- Reassemble the box in reverse order and install it on the car.

Location at checkpoint

Lubrication issue

Many people do this kind of work on their own, and quite efficiently. But their main mistake is that the bearing does not always need to be replaced. Sometimes just lubricant is enough.

- Check the bearing for dryness. There is no lubricant on it, as well as visible damage, then all extraneous sounds can be caused precisely by a lack of lubricant;

- Treat the element with high-quality lubricant. Plain motor oil is often used;

- Reinstall the old, greased bearing.

Lubrication can be accomplished in two ways.

- Digestion in lithol. It is recommended to use a water bath for this procedure.

- Injection. The method is safer. To perform it, you need to draw lithol into a syringe and pour it into the element. The process is long but effective.

When choosing a lubrication method, it is better to focus on safety rather than the speed of repairs.

The gearbox is a constantly working element of the car, which leads to the inevitable occurrence of malfunctions. Try to detect the failure of the input shaft bearing as early as possible and carry out repair or preventive measures aimed at preventing complications of the situation.

When to change and how to check the clutch - its service life may have come to an end

Good day, dear car enthusiasts! Each of us is always concerned about how long this or that part or car system will last. It `s naturally. Especially considering the quality of some products, the “skills” of workers, etc.

This issue fully concerns the car’s clutch. Very often on motorist forums there is a serious question about when to change the clutch, and how to know when the time has come to replace it. So let’s try to figure out together what the actual service life of the clutch is, and whether it exists at all.

Is there a certain clutch resource?

Whether or not you will be upset when you find out that the manufacturer does not indicate specific figures for clutch service life. If, for example, in the brake system, it is clearly stated that the thickness of the brake disc should be such and such, then why is this not applicable to the clutch?

The fact is that clutch wear depends on many reasons, and first of all, of course, on how the driver changes gears and in what mode the clutch is used.

And while clutch disc thickness cannot be measured the same way brake disc thickness can be measured with a caliper, there are ways to measure it. There are two of them.

- The first way to measure the thickness of the clutch disc is with a special measuring gauge. This method does not require dismantling the clutch; it is performed on a lift. But you are unlikely to use it.

- the second method is simpler to implement and allows you to determine the wear of the clutch disc in order to replace it. Replacing the driven disk is a procedure provided by the manufacturer, because The driven disk is a consumable part. The check is carried out as follows: with the engine running, you need to put it in high gear, accelerate it, and if the car does not stall, this means that the driven disk is worn out and requires replacement. It must be remembered that such a check of the thickness of the clutch disc is not technologically correct, but it is effective and allows you to determine the condition of the disc extremely accurately.

As already mentioned, the life of any clutch is determined by its operating conditions. Without going into technical details of the interaction of clutch parts, you should understand that basically the life of the clutch and the wear rate of the discs depend only on the driver.

A clutch of the same quality and manufacturer can last 5,000 km for one driver, and 100,000 for another. Participation in drag racing, frequent slipping, abrupt starting at high speeds, ingress of foreign liquids and objects, unqualified installation and adjustment clutch - all this reduces the life of the clutch.

Pricing factors

Car repairs are always accompanied by certain financial costs. In addition to purchasing a serviceable part, the car owner will have to pay the technician for the service of installing it. Therefore, today many motorists are trying to save money. To do this, they visit a number of sales locations and analyze the price range.

It is not recommended to take the cheapest spare part: most likely, its quality is low. You need to understand what factors influence cost in addition to quality. The price depends on:

- States.

- Varieties.

- Brenda.

- Originality.

- Places of purchase.

- Delivery prices.

The more famous the manufacturing company, the more its spare parts will be sold at a higher price. The better the condition of the part, the higher its value will be.

According to the control method, the clutch is:

- With hydraulic.

- With mechanical.

- With electric.

- With a combined drive type.

There are spare parts for the switching mode:

- Constantly closed.

- Not permanently closed.

Clutches are classified according to the type of friction:

- Wet (parts operate in an oil bath).

- Dry (elements operate in air).

Depending on the number of driven disks, a car part can be:

Based on the location of the pressure springs, spare parts are distinguished:

- With a peripheral location.

- With central diaphragm spring.

According to the condition, a spare part for a Grant can be:

- New.

- Old, restored.

- Used, unrefurbished.

Various companies produce this part. Therefore, we can highlight the clutch on the Grant:

A non-original device is sold under the following brands:

You can buy a clutch for Granta in different places. For example:

- At the car market.

- In the online store.

- According to the advertisement.

- At the parsing point.

- At an auto parts store.

Replacing the gearbox bearing

First, to carry out the replacement, the gearbox is removed. Next, you will need to completely or partially disassemble the box. To remove the box basket, you must first disconnect the negative wire of the car's electrical system and disconnect the speedometer sensor. In any case, you will have to disconnect the exhaust pipe (“pants”) of the exhaust gas system. Next, the wizard performs the operations described below.

The box is well cleaned of dirt, its body is checked for defects. The bearing on the shaft is secured with additional retaining rings. The master carefully pries out and unclenches the rings using a flat screwdriver. Among the list of special auto repair tools there is also tweezers for removing retaining rings. Next, you need to pry off the bearing with a screwdriver, while the shaft moves forward. A thin pry bar is inserted between the bearing and the box and the mechanic begins the operation of removing the gearbox input shaft bearing. The bearing is pressed in and needs to be knocked out - with precise, careful and, at the same time, strong blows. In this case, the shaft must rotate. This entire operation is performed by a master with the help of an assistant and can take quite a lot of time, usually up to 30 minutes. Also, the workshop can use a special puller for such cases.

Before replacing the old input shaft bearing, it must be carefully prepared. Preparation involves thorough lubrication. To press the bearing in, you can use a pipe of a suitable diameter or special tools. The worker drives the part into its proper place with precise, uniform and neat blows. After the technician makes sure that the bearing is seated properly (the shaft should rotate lightly and smoothly), the box is assembled in the reverse order and installed back on the car.

The bearing does not always need to be changed; sometimes you can simply lubricate it well. A gearbox is a vehicle component that operates constantly. That is, the smear on the bearing “burns” quite intensely. The reason for the “disappearance” of the lubricant, according to many car owners, is also the synthetic oil poured into the gearbox - it is this that “corrodes” and “washes” the lubricant out of the bearing.

There is no need to rush into purchasing this part (as with purchasing any parts). Its price is low, VAZ bearings cost about 300-500 rubles (you can find them cheaper in advertisements) and that is why purchasing can be difficult. Current traders and manufacturers prefer to sell cheap parts as “repair kits”. The most important thing is what was mentioned at the beginning of the article - the only sign of complete destruction of the bearing is jamming and knocking. If a “whistle” is heard, then most likely it will be enough for you to simply lubricate the part.

When the workshop knocks the bearing off the shaft, check it for grease. For lubrication, it is best to use regular good motor oil, for example, litol - a proven and reliable option. Lubricate the old (and new) bearing by syringing, carefully introducing oil into the working areas, or by dipping into lithol heated in a water bath. Lubrication using the first method takes longer, but the result is better.

Useful tips

If there is no oil on the bearing, but there is no damage to its surface, then you don’t have to replace it, but simply lubricate it and install it back. This is done if for some reason the required spare part is not on hand. Lubricate the gearbox input shaft bearing (including VAZ) in two ways. The first option involves boiling the part in lithol. It is best to carry out this operation in a water bath. But there is a safer option - lubrication using the injection method. To do this, lithol is drawn into a syringe and lubricant is filled into the bearing. But you need to take into account that such a process requires more time.

Issues of correct selection and replacement of gearbox bearings

As a rule, routine maintenance activities do not include operations to replace gearbox bearings - this is performed as necessary in the event of wear or destruction of parts. The need to carry out such repairs may be indicated by extraneous noises and even knocks from the gearbox, spontaneous switching on and off of gears, an incorrectly functioning or jammed clutch, and generally deteriorated transmission performance. In all these cases, it is necessary to carry out diagnostics, and if a malfunction is detected, replace the bearings.

Replacement bearings should only be of the types and sizes that were installed on the box by the manufacturer. It is best to select the required bearings using parts catalogs or specialized reference books, which indicate the catalog numbers and types of all bearings for this particular box, as well as acceptable analogues of parts. You can buy bearings separately, but in some cases - for example, to overhaul a box - it makes sense to purchase complete sets of parts for a specific model of the unit.

Replacing bearings in most cases requires dismantling and almost completely disassembling the gearbox (an exception is replacing the input shaft bearing in some gearboxes, for which the unit only needs to be removed from the vehicle, but does not need to be disassembled). This work is quite complex and requires the use of special tools (pullers), so it is better to trust it to specialists. If the box repair is carried out correctly and in accordance with the instructions, the unit will stop causing problems, increasing the controllability and comfort of the car.

Verdict

Substandard behavior of the Granta pedal assembly is a malfunction that should be eliminated as soon as possible. The issue may be either in the drive, which here is a cable drive, or directly in the unit connecting the engine and the gearbox.

Most often, the problem lies in an unraveled cable or its limited mobility in the jacket. This problem can be eliminated by replacing the cable and/or lubricating it with oil, silicone or WD-40. The fork shaft often needs lubrication.

Less commonly, the problem is caused by a deformed or cracked fork. Wear on the leaf spring can radically change the amount of force required to release the pedal. A new clutch can also cause it to feel stiff.

Changing the bearing of the manual transmission input shaft on a VAZ 2107 car

This bearing (PPV) is an important component of the box. If it malfunctions, the speed switch may become jammed (optionally, the release bearing fails completely).

Signs indicating a bearing failure.

In manual transmissions, bearing units act as support bearings. When they fail, the rotation of the shafts becomes difficult, multidirectional beats, extraneous noise and noticeable play occur.

External manifestations of a malfunction include:

- Strong bearing noise that increases when the clutch is disengaged;

- Difficulty switching gears;

- The gearbox spontaneously switches from one gear to another;

- When you press the clutch pedal, you can hear extraneous knocking noises.

Possible causes of PPV failure may be:

- Malfunctions of mating units. Such as clutch, axles, release bearing;

- Lack of lubrication or severe contamination of the internal cavity of the bearing;

- Aggressive driving style;

- Installation of a product of inadequate quality;

- Expiration of service life.

In order to clarify the occurrence of a malfunction associated specifically with the breakdown of the PPV, you can verify this by checking how easily it rotates and conducting a visual inspection (integrity of the races, separator, condition of the raceways).

If the product is externally in good condition, measure its clearances in different directions (axial, axial) to determine the actual play.

Removing the faulty PPV bearing

The work must be performed by driving the car onto a lift or onto a viewing hole. If it is impossible to fulfill this requirement, you should use strong supports (stops) and a jack. However, this is quite dangerous.

Before starting work, stops are installed, neutral gear is set, and the car is put on the handbrake.

The “-” terminal from the battery is disconnected.

After this, you can proceed directly to dismantling, according to the following work algorithm.

- Remove the cardan shaft from the coupling;

- The intake pipe of the manifold (another name, exhaust), which is held on a three-bolt connection, is dismantled.

- Unscrew the working cylinder from the gearbox.

- Disconnect the wires connecting the rear dimensions, then the ground cable.

- The speedometer cable is dismantled, after which the lower housing is removed from the clutch.

- The rocker lever used to change gears is dismantled. Why do you need to remove a special plastic sleeve with a screwdriver?

- The bolts securing the box are unscrewed.

- The back of the box rests on a traverse. To complete dismantling, you need to unscrew a couple of nuts from the studs.

Do not forget to first lay a block between the engine and its protection. Otherwise, after removing the box, it may sag.

We remove the starter and remove the box. Please note that on a VAZ classic, you can dismantle the bearing that we are going to change (PPV) without disassembling the box. However, you still have to remove the clutch bell. Having approached the bearing Open: 6-50706AU Closed: 6-180502K1US9, remove the retaining ring (with round pliers). The bearing assembly is removed. The small fixing (retaining) ring located in the groove of the cage, which secures the bearing to the shaft, is removed. The product to be removed is pressed from the neck.

Bearings Lada Granta

List of bearings used in the Lada Granta car that can be easily replaced

To view information on a specific bearing, simply click on the number.

| Knot | Bearing number | Quantity | Imported analogue |

| Differential box (right and left supports) | 7207 | 2 | 30207 |

| Front wheel bearing | 256707 | 2 | — |

| Gearbox shaft bearing (rear support) | 180305 | 2 | 6305 2RS |

| Gearbox secondary shaft bearing | 464706 | 5 | K32x37x27 |

| Clutch release | 520806 | 1 | — |

| Rear wheel bearing | 256706 (ball - higher rotation speed) 537906 (roller - higher load capacity) | 2 | — |

| Transmission input shaft (front support) | 42205 | NJ205 | |

| Transmission output shaft (front support) | 42305 | NJ305 |

It should be noted that in the vehicle documentation, bearing numbers are often indicated with a lot of additional (and often long-outdated) letter designations, which you can ignore. The same applies to accuracy class 6. Nowadays, quality standards are implemented in such a way that bearings with a declared class 6 from one manufacturer can be an order of magnitude worse than the zero class of another.

AVTOVAZ’s developments do not stand still, and in 2013 the company’s management, together with the design department, decided to switch to a new type of cable-driven gearbox. These gearboxes are installed on Lada Granta and Kalina 2 cars.

Appearance of the gearbox

Recommendations

Comments 20

I forgot to add that the rear bearings in the housing cannot just turn, they are clamped by a plate. There is no tight fit, only clamping with a plate, again, the factory tolerances are violated, everything must be measured during the assembly process, and the plate must be new, and tighten the screws with an impact screwdriver; do not tighten them to the required torque by hand.

Everything that is written here about the checkpoint is all at the level of speculation, and not knowledge of the technical part. Think theoretically, when the car is parked and the engine is at idle, then only the input shaft rotates in the gearbox, and only two bearings work with it. Roller front and ball rear. The ball knocks on very rare occasions, this is if he is really fucked up, mostly he howls. But the roller one makes a knock if it is of poor quality. It would take a long time to explain the nature of the knock; it has to do with the clutch disc and wear on the splines of the shaft and disc, and again the quality of the workmanship. Sometimes the gears on the secondary shaft jangle, they rotate, but the shaft stands still. At the factory they don't bother with quality. If all tolerances are met, the gearbox will work quietly, but for this you need to have several sets of gears and bearings, and select all this, which is impossible at home. The main couple howls as they walk, there’s nothing you can do about it. To reduce the howling, use additives, I poured VMP Auto.

Hi, what kind of thread locker is this? Do you have a number?

there are plates fixing the shafts, SKF bearings come from the factory to the 2181 gearbox

If the bearings start turning again on the outer race, everything will come back again. It's not even a matter of new bearings; the old ones turned out to be no worse than the new ones. The fit in the body of the box itself is simply loose. Therefore, the output was placed on a clamp.

Release bearing Lada Granta

Multithumb found errors on this page: There was a problem loading image https://mars.wb63.ru/upload/iblock/841/841ca9a759e5a47b28a3c3ae5fcc9f9b.jpeg There was a problem loading image https://mars.wb63.ru/upload/ iblock/841/841ca9a759e5a47b28a3c3ae5fcc9f9b.jpeg

Release bearing Gearbox 2181, Clutch release clutch Gearbox 2181 - replacement in Lada Granta

Well, I was struck by the death of the release bearing with a mileage of 23 thousand km, also known as the clutch release clutch of the gearbox 2181. Judging by people's reviews, this bearing does not last more than 30 thousand km. Everything was fine in the evening

The next day in the morning, while squeezing the clutch, I noticed that it was somehow not being pressed correctly, I thought, maybe it seemed, and after 20 - 30 km the clutch disappeared altogether

With the car running, I could not turn on the first and rear, 3,4,5 turned on with difficulty, and after a while they did not turn on. But with the car turned off, all transmissions were switched on. Having opened the hood, I pulled the clutch fork, it dangled as desired in different directions, i.e. was not fixed. Having reached the garage under my own power (25 km), I began to find out the reason. I disassembled and removed everything unnecessary that interfered with removing the box. We unscrewed and separated the box from the engine and supports, hung it by the CV joints (in this position it is problematic to install it later, it is better to read a repair book). The problem became immediately clear - the release bearing had died. Among other release bearings, I chose a roughly similar one - the Priorov one, but it still needed to be installed somehow, and for it to still work. In the 2181 gearbox there is a release fork similar to a fork from a cornfield, based on this I decided to also buy a release bearing spring from a cornfield (or from a VAZ 2101) that secures the bearing to the fork.

on the left - Grantovsky, on the right - Priorovsky bearing

modified Priorov bearing sits on the shaft

The spring is installed in the bearing groove and fixes the fork on the other side, i.e. the fork is clamped by a spring, if something is not clear, then read the manual for replacing the release bearing in the field.

Well, that’s all, actually. I put the box back, assembled everything, and connected it. Works great. Don’t forget to lubricate the shaft where the bearing sits and the splines with a lubricant like lithol, but not too much because if you overdo it, then when the shaft rotates, lubricant can splash onto the clutch disc, and it will slip. After these procedures, the clutch pedal became a little softer, and the gears shifted better. I drove more than 100 km, everything is fine, time will tell how long it will last. Well, everyone decides for themselves to change the original 2181 release bearing every 30tkm or less, or install another one with modifications. The release bearing should last for the entire service life of the clutch, i.e. operating time to failure is at least 800 thousand “off-on” cycles of the clutch, which is equivalent to a car mileage of 100,000 km, and a bearing that falls apart up to 30 thousand km.

Replacing the Lada Granta clutch release fork

The clutch release fork on a Lada Granta is replaced in case of mechanical damage (deformation, cracks on the surface). To carry out repair work, remove the gearbox from the car, prepare a standard set of tools and perform the following sequence of actions:

· Remove the clutch release bearing.

· Remove the protective rubber cover of the clutch fork; to do this, carefully pry it up with a flat-head screwdriver and remove it from behind the collar. If the casing is damaged, the rubber has dried out or lost elasticity, we replace it with a new one.

· From the inside of the clutch housing, using pliers, squeeze the petals of the clamp and from the outside, using a flat-head screwdriver, remove the plastic bushing of the clutch fork axle.

· Lifting the fork slightly, remove its axle from the bushing and remove it together with the lever.

· Remove the spring clip from the fork by squeezing its ends.

· If necessary, replace the worn metal axle bushing.

· Carry out the necessary repairs, after which we carry out the installation in the reverse order.

Reviews

| № | Positive |

| 1. | Vladimir: I have been successfully using the machine for two years now, there are no comments on the work. Investments are minimal, consumables, filters, oils. |

| 2. | Gennady: I attend every scheduled maintenance according to the schedule. The car is in good condition, the technician is carrying out computer diagnostics. Soon the mileage will be 90,000 km, I hope that repairs will occur after 105,000 km. |

| 3. | Vasily: at 60,000 km I replaced the cable, it started to creak, I didn’t lubricate it, I bought a new one. There are no more comments, everything works properly. |

| 4. | Ignat: I have no special complaints about the car. Of course, Lada is not ideal, but for the budget segment it is the best solution. |

| 5. | Dmitry: at 80,000 km I replaced the repair kit for the bushings on the clutch pedal, it started to creak. Additionally, I lubricated the cable. My recommendations to motorists. All work was carried out independently, without the help of service station workers. |

| 6. | Kirill: I replaced the clutch at 95,000 km, I think that this is a very good mileage for a domestic car. The installation process is not complicated, I did the work myself. Special thanks to the store manager for recommending quality spare parts. |

| 7. | Georgy: replaced the release bearing at 105,000 km, mileage as in the instructions. There are no problems with the engine, the car runs like a watch. |

| Negative | |

| 1. | Victor: my bearing fell apart at 50,000 km, it was replaced at a service station. After 10,000 km the cable creaked and was also replaced with a new one. The Granta model is crude, has many flaws, I do not recommend purchasing it. |

| 2. | Vyacheslav: over the past six months it has undergone unscheduled repairs twice. Initially, the basket flew off after a problem with the starter. |

| 3. | Kirill: despite the manufacturer’s warranty, the clutch basket has already flown for 60,000 km. Contacted the service for diagnostics and repairs. The manufacturing quality is low, the actual service life of the parts is lower than stated. |

Symptoms of malfunctions

Signs of failure of this element are strongly related to the installation location. The gearbox input shaft bearing is installed on the input shaft, and behind it there is an oil seal. In various transmission models, the bearing itself can act as an oil seal. So, paired with a release valve, this part experiences almost the entire load from the car engine. To find the problem bearing, you need to dismantle the transmission. Symptoms of failure of this element are similar to how any other bearings become unusable. In case of serious breakdowns, characteristic sounds resembling a howl are heard from the gearbox. This sound can be heard when the clutch is released and the car is stationary. But the input shaft bearing can also whistle while driving. It is very rare to hear characteristic knocking sounds - they indicate complete destruction of the unit.

There are also problems with engaging or not disengaging the clutch. The reasons for this type of gearbox operation lie in this bearing. A malfunction often occurs if a part is jammed. In difficult situations, it may be necessary to replace the input shaft. Often, whistling and humming are heard when there is no lubricant in the bearing. This issue can be resolved by lubricating the part. But first you need to remove it from the gearbox. The transmission will make a howling noise if the bearings are chipped or cracked, or if one or two rollers are destroyed. If characteristic knocking noises are heard, this indicates complete failure of the part. The knock will be made in any gear. If you do not replace a worn or damaged part in time, then the element may become seriously “welded” to the shaft. As a result, you will have to change the input shaft bearing and the shaft itself.

Signs of clutch wear

| Sign | Cause and remedy |

| Incomplete engagement of the clutch (slips) | Replacing discs, cleaning clutches |

| Incomplete shutdown (leading) | Prevention of the clutch mechanism |

| Periodic jerks | Clutch cable wear, clutch replacement |

| Vibration, beating when shifting to higher gears | The flywheel is bent, the gripper teeth are worn out. Replacing the flywheel and related consumables |

| Noise, creaking, grinding noise when activated | Damper spring wear, replacement with a new one, drive lubrication |

| Pedal free play is increased, exceeding 2 -3 mm | Tensioning the cable, replacing with a new one |

| You can hear the smell of burnt friction linings | Dismantling the clutch block, replacing worn elements |

| Increased fuel consumption | Flywheel worn, teeth damaged |

| Reduced acceleration dynamics | Replacing clutches |

Friction clutch device

The manufacturer installs the same clutch on the Lada Granta as on the Lada Kalina. The mechanism consists of a flywheel with a basket attached to it. The task of the latter is to continuously press the disk with linings made of friction material - this is how the torque from the engine is transmitted to the transmission. A cable-type clutch means that when the pedal is pressed, the cable connected to the clutch fork becomes taut, the paddles stop pressing the disc, and torque from the engine is not transmitted to the gearbox.

The clutch on the Grant has one disc; it is frictional with a central spring in the form of a diaphragm. It is located in a special aluminum crankcase and combined with the gearbox in one housing, attached directly to the cylinder block. For clarity, you can see a detailed drawing of the device.

Lada Granta clutch device

- Drive cable.

- Outer braid of the cable.

- The end of the cable braid is lower.

- Dust cover.

- Metal leash.

- Fork bracket.

- Bearing sleeve.

- Release bearing.

- Casing.

- Diaphragm spring.

- Disk (master).

- Flywheel.

- Friction material linings on the disc.

- Disk (slave).

- Damper spring.

- Rotation vibration damper.

- Disc hub (driven).

- Central spring.

- Cable end.

- Automatic cable tensioner housing.

- Sleeve.

- Fastening the cable braid.

- Pan (crankcase).

- Gearbox input shaft.

On the Lada Grant, the clutch does not require additional adjustment during its entire service life - this is what is written in the car’s operating manual.

Finalization

Purpose: install a gasket between the clutch cable and the gearbox fork

Procedure:

- Remove the clutch cable end from the fork.

- Unscrew the cable end, having previously measured the length of the free threads.

- Remove the clutch cable boot.

- Remove the rubber insert from the cable stop (photo No. 1).

- Instead, install a round washer made of porous rubber (diameter 32-35 mm, hole 12-13 mm) (photo 2).

- Cut a piece of rubber measuring 20x70 mm, 2.5-3 mm thick.

- Glue it (for example, with “Moment” glue) to the plastic cable stop (one turn), secure with electrical tape 1.5 turns.

- Insert the cable into the bracket on the gearbox and put on the boot.

- Screw on the tip, leaving a couple of millimeters less free threads on the stud (since the new gasket is thicker than the factory part).

- Place a 2 mm foam rubber spacer between the cable tip and the fork lever.

- Adjust the clutch pedal.

As a result: the effect was noticeable immediately. Now the rattling can only be heard with the windows open. After modifying the clutch cable fastening, the car drove more than 15 thousand km, the gearbox noise was within normal limits. Increased vibrations and noise are noticed only at a temperature of -20 o C, when the rubber gaskets become hard. The author has posted sound files (engine acceleration-braking mode at 1500-2000 rpm in 3rd gear), which shows what the noise was from the gearbox before and after modification. Site users can download the file:

Interesting Facts

Let's look at the interesting facts that we managed to learn about the new Lada Granta gearbox:

- The VAZ-2181 gearbox will not be installed on the Priora, since the designers considered that it would not be cost-effective to redo the entire design of the power units.

- The cost of Lada Grant and Kalina 2 increased by 5000-7000 rubles. with the introduction of a new gearbox into the car.

- According to reviews from car owners, the first copies of cable-driven gearboxes were not entirely successful and had quite a lot of flaws: vibration became audible after 70-80 thousand mileage, howling of the gearbox, increased wear of parts, etc. Based on this, the manufacturer made adjustments to the design and improved the characteristics, but many car owners had a negative impression of the VAZ-2181 cable-driven gearbox.

- The AVTOVAZ plant continues to develop and modernize a new gearbox, which will become the second generation of cable gearboxes. It is planned to install it on the 2nd generation Lada Granta, which is currently under development. The designers promise to take into account the experience gained during the development of the first generation and not allow such an oversight a second time.

Design and differences of a cable-driven gearbox

Unlike a conventional gearbox, the cable-driven gearbox has received some improvements and upgrades.

VAZ-2181 gearbox with cable drive

In order to understand how everything works, let’s compare a standard gearbox labeled VAZ-2180 and the new VAZ-2181:

- To reduce the vibration generated by the traction drive gearbox, cables from the manufacturer Atsumitec were installed.

- To reduce the effort for shifting 1st and 2nd gears, the manufacturer installed multi-cone synchronizers.

- The clutch size has increased to 215 mm.

- Due to changes in the transmission design, the starter had to be positioned along the engine rather than the gearbox.

- To facilitate gear shifting, it was necessary to reduce the bevel angle of the synchronizer teeth from 125 degrees to 100.

- To eliminate oil leaks, the designers moved the gear selection mechanism to the top. But this nuance gave impetus to the development of a new switching scheme and design changes.

- The volume of lubricant poured has decreased from 3.3 liters to 2.2 liters.

- A selector plate is installed, which allows you to change gears more clearly.

- The transition from mineral oil to semi-synthetic oil has been completed.

- To prevent accidental reverse gear, a special lock was developed.

The main elements and components that go into the design of the new gearbox can be seen in the figures below:

Gearbox diagram and decoding of its main elements

- main drive drive gear;

- secondary shaft;

- input shaft;

- fifth gear shift fork;

- third and fourth gear shift fork;

- reverse light switch;

- clutch housing;

- gear shift mechanism;

- central lock.

VAZ-2181 box synchronizer device

1 – first gear gear; 2 – intermediate rings; 3 – blocking ring; 4 – synchronizer clutch; 5 – synchronizer clutch hub; 6 – clamp; 7 – second gear gear.

Gear selection mechanism

1 – gear selector levers; 2 – selector grid pin; 3 – selector grid; 4 – reverse locking mechanism; 5 – central three-dimensional plate.

Full view of a cable-driven gearbox

Thus, the manufacturer decided to improve and modernize the gearbox, which was unreliable and had a lot of problems. Due to the new improved system, vibration in the body and gear knob has been reduced. The gears switched on, started more clearly, and the huge backlashes disappeared.

Why the ECM detects error “P0830”, video explanation

Praise to the author! I am also a terrible car enthusiast, albeit with little experience... I also had right-hand drive ones, but unfortunately, they are not convenient with our traffic. I now have probably the most boring Toyota model. For almost 2 years of owning this car, I had no problems at all, it burned out once a light bulb in the foot, and I changed the brakes and oil according to plan, despite the fact that the car is 8 years old, the mileage is about 150 thousand. It accelerates quickly, drives smoothly, and is maneuverable. spacious trunk and for its size a very comfortable and spacious interior, dad feels completely comfortable in the back seat, and he is a large man. After a night in a windswept parking lot at minus 35, it started up and didn’t even sneeze once. The stove heats perfectly, the air conditioner cools quickly, the consumption is 6-7 liters of 92 in the city. engine 1.5. 106 horses, + with its size it will fit into any hole in the parking lot. In short, the car is just great. )))

I've been meaning to adjust the clutch on my Grant for a long time. I made a printout of your article. Tomorrow I’ll arm myself with the necessary tools and go to the garage to do everything with my own hands step by step, as described in the article.

Open the hood, under the air filter there is a clutch foot. It is equipped with a cable with a plastic screw. Lightly pressing the foot, remove the cable to the side. We adjust the cable screw and put it back on the foot.

When accelerating, the engine roars slightly when the leveler revs up

Clutch needs replacement! It's slipping!

When starting off there is jerking, what could be the problem?

Replacement clutch disc

The clutch cable broke. I went and bought a new one. Changed it. While I was driving, the clutch was soft; accidentally, in 4th gear at 90 km/h, I jumped into 3rd gear instead of 5th. But nothing. An hour later, I noticed that when changing gears, my car seemed to be giving up gas (by the sound), but in fact I don’t know what it is. The clutch pedal has free play, i.e. hanging out. And the pedal is too soft. Can there be different clutch cables on the grant?

Replacing Grant cable gearbox bearings without removal — search on DRIVE2

Replacement of rear bearings of gearbox 2181 - Lada Granta.

Review from the owner of Lada Grant

- with your own hands.

I decided to carry out the repair by removing the box

, because I wanted...

I decided to carry out the repair by removing the box

, since I also wanted to solve the issue of a dry splined primary shaft, and at the same time look at the condition.

Replacing the Grant clutch. — Lada Granta, 1.6 l., 2013.

Granta

normal, engine 186, gearbox

2181, mileage 31t. with kopecks, 3 years like from the assembly line.

10, unscrew the lower flywheel screen (three bolts with a key *10*) last, before removing the box

, so this bolt (see photo below) is not convenient to unscrew and the screen itself.

Preparation for repair

To remove and subsequently replace the clutch, prepare a set of tools consisting of:

- center punch;

- extension cord;

- funnels;

- heads (8, 10, 15, 17, 19 and 30 mm);

- high head (13 mm);

- heads Torx E12 and Torx E14;

- Phillips and flat screwdrivers;

- pliers;

- curved spanners (8 and 13 mm);

- straight spanners (17 and 19 mm);

- two adjustable stops;

- metal brush;

- ratchet wrench;

- caliper;

- stands;

- hammer;

- jack;

- balloon wrench;

- torque wrench;

- centering mandrel.

In addition, you will need to apply certain parts and consumables. So, you will need CV joint-4 lubricant, a guide pin M12×1.25 mm, transmission oil, wood blocks, a technical container, a hose, rags and the clutch itself.