Disc brakes are an important element of the braking system. While the car is moving, as a result of the friction of the brake discs on the pads, the car slows down. The materials from which disc brakes are made can withstand thermal stress and ambient pressure. For safe and confident operation, you need to choose high quality parts. When buying auto products, take into account their functionality, safety and efficiency.

Types of brake discs

Brake elements are distinguished by their type. Very often the driver makes a decision based selectively on their price. But high cost is not always an indicator of high quality.

1.Ventilated brake discs

They consist of two identical plates of the same diameter. The plates are connected to each other by jumpers with a small gap of approximately one centimeter. This design is needed to use jumpers as fan blades, the purpose of which is to dissipate heat when the engine is running. Ventilated brake elements provide braking performance even under heavy loads and heat. Their purpose is to cool the system while driving. Ventilated brake elements are installed at the front of the vehicle.

Perforated discs

They have many drilled holes on the surface. But the quality of their work is much lower than it seems. This is due to the presence of a special fastening substance in the composition, which disintegrates as a result of vehicle movement and the occurrence of high temperatures during friction. Perforated pads are usually used in old low-budget discs. When the bonding agent decomposes under the influence of hot air, a layer of gas is formed. The gas layer prevents friction between the pad and the disc, which occurs as a result of pressure between the working surfaces during engine operation.

The function of the holes on the pads is to remove this gas layer from the surface, as well as other substances formed during the operation of the brake pads.

Considering this purchase option from a budget point of view, using drilled and budget pads will not be entirely correct than pads and ventilated brake discs.

The disadvantages of perforated pads include:

- slots on the discs reduce the area of friction and heat outflow, which has a negative effect, especially if you use more expensive pads;

- holes lead to the appearance of potholes as a result of constant changes in temperature conditions during vehicle movement. This is due to the fact that when driving, the surface of the parts will heat up significantly more than the holes on it, which disables the car due to constant changes in temperature and on different surfaces.

Due to significant shortcomings, they are practically not used in cars. For cars that move around the city, this type of disc is used to attract attention to your car.

Serrated discs

They perform similar functions to perforated ones. The notches allow the pads to better cling to their edges. But this is rather a disadvantage if the driver bought an economy pad, since its service life can be significantly reduced, and the pad will break prematurely. Notched pads prevail over drilled ones, provided that they are used with expensive brake elements.

The service life of brake discs depends on how you drive them. There are no standards for the amount of mileage after which it is necessary to install new pads. If the driver practices a calm manner of movement, then the pads work properly when the car has driven more than 150,000 kilometers. If the brake pedal is often pressed to the floor, the discs wear out much faster and their critical level of wear is 20 - 30 thousand kilometers. On average, replacing the brake system will require a mileage of 60-120,000 kilometers.

The part must be replaced in other cases:

- as a result of deformation that cannot be repaired;

- the part contains cracks and chips measuring about 0.01 mm;

- visible damage to a part as a result of exposure to high temperatures over a long period.

If the replacement is not made on time, this can lead to depressurization and leakage of brake fluid. The wear of a part is checked by its thickness. To examine it, use a caliper or a regular ruler. The results of the study are compared with normative ones. When measuring a disk, you need to take into account the presence of a shoulder.

Useful tips on TD

We do not recommend “saving” and sharpening old discs:

- often the quality of the groove leaves much to be desired;

- Grooving is permissible only on disks without cracks and deformation, as well as with a certain remaining thickness;

- The cost of turning is on average 50% of the cost of new discs. Machined discs will not last long, while new ones will last much longer;

To avoid becoming the “lucky” owner of a fake, purchase discs only from official representatives or trusted stores that issue a quality certificate upon ordering (on request);

At the same time as new brake discs, be sure to change the pads. Using old ones is strictly prohibited, as the pads are also subject to deformation and can easily ruin your new brake disc.

How to choose a brake disc?

When choosing, you need to consider the following indicators:

- type of pads;

- driving style;

- technical features.

For using average quality brake pads, domestic car brands are best suited. In addition, it is suitable for drivers who drive at low speeds, without particularly accelerating or braking sharply within the city. In this case, it is better to choose non-ventilated pads, without perforations.

If the driver loves speed, periodically making sharp brake presses during high-speed driving, it is better to purchase one with perforations or slots.

Durable material and disc design suitable for driving in extreme conditions.

The best solution would be to use the same brake pads, the same brands and the same class. This choice will provide the car owner with effective operation of this pair. As an example, if you choose expensive options with cheap pads, a situation may arise when either one of the elements or both may break while the car is moving.

You should choose a brake disc based not only on price, but also on its appearance. Considering it from a geometry perspective, it is known that the longer the disk in diameter, the better its heat dissipation function works. There are specific restrictions on diameter and thickness. A thicker part absorbs heat better and its heat transfer is stronger, as well as its ability to withstand high temperatures. For cars like SUVs, ventilated ones are suitable. This is due to the presence of air vents on their surface, which perform the function of brake cooling and improve braking.

Don't forget about the mounting dimensions of the brake element. They are different for different brands of cars. The size of the mounting disks and the location of the mounting holes influence its choice. Summing up the information, there is only one conclusion - the most unreliable are perforated pads, in second place are pads with notches, and ventilated pads take pride of place in the selection of durable and high-quality discs in all respects. Perforated ones should be used when the driver of the car practices moderate driving, without sudden braking, and his car has small dimensions. If, in the driver’s opinion, perforated pads decorate his car more than they play a braking role when the car is moving, then the choice is clear.

Carbon – ceramic disc

The most extreme way to control brake rotor temperature is by choosing to install carbon ceramic rotors. A hot disc heats up the pads to a high temperature, which leads to even more gases, particulate matter and poor braking performance. So why not find another material instead of cast iron?

Ceramic and carbon brake rotors are significantly more resistant to heat and are also less likely to float or warp under heavy use. This means they will live longer. As a bonus, they tend to be much lighter than their iron counterparts. This reduces unsprung weight and improves handling.

But there's a reason their use is still not as common: cost. Carbon brakes are much more expensive to produce. An average set of brake discs can cost 400 thousand rubles! This is hardly suitable for older cars.

In addition, you will need brake pads with a special compound. Guess what? They also cost a lot of money. In general, this option is exclusively for very expensive sports cars.

Have you recently upgraded your brakes? Which drives did you choose and why? Share your opinion in the poll above!

Problems of wrong choice

It is important to draw the attention of every driver to the fact that when choosing a disk, he should not focus only on its price, but also on quality, because the safety of him and his passengers depends on this. If the choice is made incorrectly, this will lead to the following consequences:

- Waste of money and time. The reason is hidden in the wrong choice of pad for a particular type of machine: the wrong choice lies in the incorrect geometric proportions of the part or the wrong selection of mounting fasteners, which in turn leads to additional financial expenses and time for correcting errors.

- Severely worn brake system. This occurs when the pads are of better quality than the brake disc. This leads to malfunctions in the steering part and the appearance of grooves in the discs.

Main parameters of the pads

IntroductionPurpose, design, principle of operation of the brake system of the VAZ 2112

First of all, brake pads are characterized by operating temperature, and if you do not have a racing car, then for moderately fast driving and driving around the city you do not need to buy too expensive ones. Pads that can withstand temperatures of 300 – 350 °C will be enough for you. At the same time, the brakes of sports cars have pads that can withstand up to 900 °C, and their normal operation begins only after heating up to more than 100 degrees. That is, in urban driving conditions such expensive brakes are practically useless, since only when hot they have a coefficient of friction of at least 0.5 units, and at an operating temperature of 150 degrees, only 0.2 units, although the standard indicators of the original pads, which are quite enough for normal use, ranges from 0.3 to 0.5.

Pads designed for sales on the secondary market come with a coefficient of 0.25 - 0.35 units, which is enough to quickly immobilize the car during non-aggressive driving. Therefore, for everyday driving around the city, you do not need to install expensive sports pads (such as Brembo), which will squeak and whistle, which is very annoying, but it is better to choose brake pads from another company from the second or even third category. Although there is one “BUT” when choosing pads, if you rely on the operating temperature and friction coefficient - with the same indicators there may be different degrees of wear.

When you decide to choose brake pads according to the required technical characteristics, then look at the wear indicator, because if they are too soft, then such pads will need to be changed more often, and too hard pads can wear out the brake disc faster, which can even result in vibration when braking .

Brembo

Italian brand for the production of brake systems for cars. The company owns nineteen disc production sites around the world, as well as four research and development laboratories. Wheels of this brand are popular among Russian car owners, especially among those who own a VAZ car. They have a big advantage - good wear resistance and a long service life.

The advantages of the Italian brand "Brembo" are:

- Brembo has patented an invention in the form of a columnar ventilation system for PVT brake discs. Among the advantages of this braking invention is the ability to increase the disc cooling function, which automatically increases the strength of the system by almost half. This, in turn, extends its service life in comparison with disks mounted according to the classical ventilation scheme. Speaking in numbers, this is an additional 80,000 kilometers and even more.

- Discs are painted using a special ultraviolet coloring technology. The use of this technology guarantees that the product is resistant to corrosive phenomena and atmospheric influences, while maintaining its appearance, beautiful metallic glossy shine and performing its functional duties over a long period. Using this technique, it became possible to install the disc without first removing the preservative oil.

- The kit for the brake discs also includes the materials necessary to secure the discs - bolts, so that the driver does not need to waste time searching for them additionally.

Among the reviews on the Internet about the product, most of them are positive. Brake systems from the Italian company are intended primarily for sports cars, as well as for standard vehicles.

Which brake pads are better

Introduction Maintenance and repair of the brake system of the VAZ-2109 car

How to choose good front brake pads

You should not buy pads whose cost is significantly lower than the average price in auto stores; such a tempting price may just indicate that they were produced using cheap friction mixtures that are not capable of ensuring effective operation.

Which brake pads are best to choose is a rather rhetorical question if it concerns the choice of a specific brand of manufacturer, because, as we have already discussed earlier, there are many subtleties in the task of selecting the most optimal option.

Which brand of brake pads is better?

Today, the manufacturer can be recommended solely for advertising purposes, but, nevertheless, there are still some that are worth paying attention to when choosing the best brake pads for your car. The most authoritative of them:. Brake pad test

Brake pad test

Ferodo, Brembo, Textar, Bosch, ATE, Lucas, TRW, Remsa, Jurid, PAGID. Each of these brands has its own advantages and its own consumer niche.

Pads from Ferodo and Brembo are installed on cars with a sporty driving style.

ATE is also installed in the calipers of fast and tuning cars, because, according to the manufacturer, they are able to work well even at temperatures of about 800 degrees.

Lucas and TRW brake pads are manufactured specifically for normal city driving, where operating requirements are more modest.

Remsa is part of the TRW concern and produces not only pads, but also brake discs. Their affordable price does not affect the effectiveness of the characteristics.

One of the leaders in the car market, Bosch, previously supplied its pads as an analogue to Japanese cars, but has now lost its position, and only a couple of German companies use them as a basic option.

Pagid pads are installed on premium cars.

Jurid is an American company that specialized exclusively in brake pads, therefore its spare parts are intended for supply to the assembly production of automobile factories for both passenger cars and trucks, as “originals” (such pads are designated by the index “J”), although they can be found on shelves and the secondary car market with the index “D”. The product of this company can also be presented on the market under the brands FRAMR, BendixR, PrestoneR and some others.

STS, a Russian brand, which can be considered as a more or less good option to install in the caliper of a budget or domestic car.

You cannot skimp on the braking system of your car; it is better to give preference to quality that is suitable for your car. It is better to refrain from purchasing inexpensive brake pads, the cost of which is significantly lower than the average price in auto stores. A low price often indicates that during the production of the pads, cheap components were added to the friction mixture, which will not ensure effective operation.

The topic of choosing “which brake pads are best” is quite controversial and extensive, each car owner always has his own opinion, so if you want to buy the most optimal brake pads for your car, based on its operating conditions, always take an additional interest in pad tests and read reviews.

NiBk

All pads and brake discs are made of high carbon steel. Each of them is coated with an anti-corrosion agent, the main component of which is a titanium-ceramic alloy (designed for sports cars). There are also the usual standard discs with slots on the surface, the main material for the manufacture of which is an organic-based composition without metal alloys. There are also perforated brake discs.

The company's products are suitable for both foreign and domestic car brands. The company's brake systems can also be found on Korean car brands, and among domestic cars they are used on Priora, Kalina, and Grant. The company's products are of high quality, and the price is acceptable for every car enthusiast - within one and a half thousand rubles. Therefore, if you are planning to buy brake elements, then NiBk products are an excellent choice.

Slotted disc

These slots on the disk try to solve the same problem with the removal of gases, only in a different way. Slots or grooves on the surface of the disc allow gases to escape in a timely manner, but this design has other advantages.

The scraping edges of the grooves on the surface of the brake pads can clear dirt from the brake surface, also increasing traction when in contact with the edges of the grooves. The downside is definitely the active wear of the pads. And finally, like the drilled discs, they just look really nice.

Groove designs can vary significantly, with one of the most distinctive grooves being the “J”-shaped hooks (pictured above), which are designed to do the same particulate removal and gas evacuation, but with minimal disc vibration during braking. At the same time, they look even better.

Ferodo

Brake discs from this manufacturer occupy almost 100% of the European market for automotive parts manufacturers. Very often, Ferodo products are used as a replacement, as an analogue of similar products, or as original products. If you use the original, you can be convinced of the excellent quality from Ferodo. In this regard, they are installed mainly on expensive foreign cars, but the cost of the product is affordable, so you can safely buy it for domestic cars.

The company produces only parts for the car brake system - pads, drums, hydraulic parts, etc. They can also be used in domestic vehicles and sports cars. Another direction of the Ferodo company is conducting various scientific research, as a result of which it is studying the developed materials.

Defects and malfunctions

The main defects of brake discs are their thermal deformation, which occurs as a result of a sharp temperature change. For example, when cold water or snow hits the floor of discs that are hot from several consecutive braking, this can lead to their warping and the need for repair. Also, cracks, chips and uneven wear may appear on the working surface of the discs, which is caused by mechanical damage or operation of the car with worn out pads. You can carry out all the necessary repair work to replace such disks yourself, or by contacting a service center, where they will tell you what the minimum thickness is acceptable and carry out the necessary repairs.

ATE

The company develops and produces automotive brake parts. The organization cooperates with well-known car manufacturers, including Audi, Skoda, Ford, Toyota, BMW, VAZ and others. Cooperation with famous brands did not happen just like that, because the products are high quality.

Among ATE's most famous achievements is the release of the famous Powerdisk series. Their main and main advantage is that they are quite resistant to temperature changes that occur during braking - about +800. The main material for their manufacture is alloy cast iron. Experience shows that the company's brake products are best used on racing cars. The company's products are of high quality. The price of the products is acceptable both for car owners of expensive cars and for owners of budget car brands.

Top 10 disc manufacturers

When choosing the best certain products, the “First in Tires” website always focuses on tests conducted by authoritative publications in its field. However, in the case of such a popular and vital product as brake discs, not a single authoritative automotive publication has conducted tests for a very long time. There are results of tests of brake discs 7 years old and older, which were carried out by little-known publications (1, 2). But today there is no point in relying on their results.

Therefore, when choosing the Top 10 best brake discs, the First in Tires website is guided by two criteria - the class of the spare part and the cost. For a correct cost comparison, all wheels were selected for one car.

For example, the top 10 best brake discs for one of the most popular models - Hyundai Solaris - will look like this:

- ATE (“premium” class 2300rub)

- Zimmermann (“premium” class 2300 RUR)

- EBC (“premium” class, 4100 rubles)

- Valeo (“middle” class 1300 RUR)

- Lucas (“middle” class 1300 RUR)

- Bosch (“middle” class 1400 RUR)

- Ferodo (“middle” class 1500r)

- Nibk (“middle” class 1700 RUR)

- Brembo (“middle” class 1800r)

- Textar (“middle” class 1800 RUR)

- Fenox (“economy” class 1100r)

Otto Zimmermann

The Otto Zimmermann brand develops brake systems, including discs, mainly for German car brands. Automotive products from Otto Zimmermann are represented by more than three thousand models. Products are divided into segments for premium cars and budget brands.

For example, wheels that are cheaper in price and quality are intended for Volkswagen and Opel cars, but there are offers for high-end cars - Bugatti and Porsche. The company positions itself in the market as a manufacturer of premium products.

If among the wide variety of automotive products you come across automotive products from the Otto Zimmermann company, then it is definitely worth buying. After all, the brand guarantees high quality, service life, and an affordable price.

Disk price segments

Based on cost, the models on sale are divided into three classes:

- Economy (from less popular manufacturers and with good characteristics)

- Middle class (represented by a wide selection from different manufacturers, characterized by the presence of durable and reliable options)

- Premium (the most expensive from famous brands)

If we talk in detail about which brake discs are better , then, of course, premium ones. They have excellent reliability indicators and are durable. Provided that you have chosen the right design for your car.

Lucas TRW

The company produces automotive brake products. Almost half of the material produced is intended for used cars. There are several models of wheels that the company produces for medium-budget cars in original quality.

Among the offerings on the brake systems market, Lucas TRW products have the original black color with a glossy surface. Almost the entire range of products is designed for use in budget car brands. The price for this range is low, so they are also available to domestic car enthusiasts. The brake elements have excellent thermal conductivity.

Disadvantages include the relatively short lifespan of discs based on reviews from Internet users. But this is a controversial issue, because the service life can be sharply reduced if the driver prefers to drive the car at a fast pace.

Composite or solid?

Disks can be solid or composite. Solid ones are made by casting and are a single piece of metal that is machined to obtain the desired shape. Composite versions are made from a hub and ring. The hub is made of an aluminum-based alloy, the ring is made of cast iron or steel. The components are bolted together.

Which option is better? Composite disks are more in demand due to the following advantages:

- light weight;

- Ease of use;

- resistance to deformation;

- better heat dissipation - the device cools faster;

- a more efficient ventilation system is used, which improves the removal of gases and combustion products.

In addition, composite disks are cheaper to operate. If the ring is worn out, it is enough to replace it - the hubs deteriorate more slowly.

Are there any advantages to solid discs? Nowadays they are only used on older cars. Experts recommend installing such products on the rear brakes of cars with low-power engines. Thanks to this, it is possible to more effectively get rid of wear products.

BOSCH

This company is known all over the world for its wide range of automotive products and various development tests. The products are intended both for the secondary market and for European and Asian cars in their original presentation.

Among the advantages:

- Large selection of wheel models for different cars of the secondary and primary market.

- An excellent combination of quality and price. Most products are designed for buyers with a medium and low budget.

- Availability of purchasing brake parts for everyone.

The BOSCH company has its representative offices all over the world, including in Russia. Among the numerous reviews, there are many where car enthusiasts claim that products manufactured in Russian factories are of low quality. Also, according to them, driving with such discs is only possible within the city at low speeds, because extreme driving has shown the poor quality of the braking system from BOSCH.

The original or a fake

Since the market segment representing automobile brake discs is very specific and at the same time extensive, even a sophisticated car owner may experience difficulties when faced with the need to choose the best product.

The number of brands specializing in the manufacture of parts and brake systems is very large, and their names will not always be well known to you. For example, Brembo, Zimmermann, TRW, NK, Textar, Remsa are the best manufacturers of brake discs, leaders in the segment. But the Delphi or Bosch trademarks are known to everyone, but, as you know, in this case you will have to pay, including for brand awareness. At the same time, names such as JapanParts, Kortex or Kamoka may be unknown even to experienced specialists.

In any case, faced with the need to purchase an AP, many motorists begin their search by filtering the information available on the Internet. Here you also need to have enough experience to be able to distinguish real reviews from customers and experts from custom ones, and among the latter, both positive and outright negative ones are equally common.

By and large, the difference in the quality of discs made by well-known and respected companies and new market players is often small, but here it is worth considering that the products of famous companies are mostly counterfeited. So the advisability of choosing a well-known brand is not always obvious.

And yet, a significant portion of potential buyers, regardless of the type of product, are suspicious of unknown names and prefer products about which no suspicion arises.

So the ability to distinguish an original from a fake is a very valuable quality, and we will try to instill it in you. But before that, you should consider what factors influence the degree of wear and changes in the geometry of the disc surface.

It is known that during braking the discs heat up very much, but as soon as we release the brake pedal, under the influence of the oncoming air flow they cool almost as quickly. Such sudden temperature changes are the main condition for deformation of the disk mirror, especially if it is made of not very high-quality material. As a rule, original products are made from cast iron, which is characterized by excellent friction parameters, high thermal conductivity and relatively low cost. Counterfeits are made from cast iron, which is characterized by low density and therefore less durable. This is one of the main differences between counterfeit discs and original discs. But, unfortunately, this cannot be determined visually - such checks are carried out exclusively in appropriately equipped laboratories.

According to the results of many independent market studies, today the volume of counterfeit brake discs reaches 40%, and this is a very serious indicator. To avoid being one of these forty percent, you should be able to recognize counterfeit products.

Visual differences

Pay attention to the surface of the TD. The original discs have special grooves along the edges, designed to increase the strength of the product, and their manufacturing method involves casting blanks, which are subsequently subjected to final processing by turning. Counterfeits, as a rule, are made only by casting, without undergoing any additional processing.

Another possible sign that makes it possible to distinguish whether this is an original or a fake is the thickness of the TD. On fakes, the disc mirror walls are usually noticeably thinner.

The bulkheads inside the disk of the original are processed very high quality, which is reflected in a smooth transition from the walls to the bulkheads. For fakes, edges are clearly visible, indicating the quality of the casting.

Another proven way to distinguish a counterfeit is to estimate the weight of the product, which in this case will be 15-30% less due to the same material savings. So if you weigh your rims before purchasing and compare them to a reference weight, this information can be very valuable.

However, there is an easier way to save yourself from such risks - buy APs only from official dealers of your favorite brand or service centers. Yes, in this case you will have to overpay a little, but this is a small price to pay for a guarantee of authenticity.

It may well happen that there is neither a large service center nor an official dealer in your city. In this case, the purchase should be made at a car dealership that is trusted by the majority of citizens.

After all, a quality product is always marked with a product code. It can be checked on the manufacturer's website.

For those potential buyers who are frankly poorly versed in the huge variety of brands, the question of which brake discs are better is a priority. We have prepared for them a small selection of the ten best brake disc manufacturers, representing all price segments.

EBC Brakes

This UK company produces expensive brake discs. The entire presented list of parts is divided into the following categories:

- The main purpose is for Japanese cars that can accelerate to high speeds. Among them are such brands as Subaru, Honda, Infiniti. Products in this category are of very high quality, and therefore their prices are also high. In addition to price and quality, the big advantage of Turbgroove products is their high wear resistance. The discs have notches and perforations.

- This company's automotive products are suitable for use in high-end brands of sports cars.

- Designed for mid-segment and premium car enthusiasts.

The discs have a smooth surface, so it is necessary to use brake pads with them. The service life under various situations and conditions of use of the car is significantly longer than that of other brands.

Basic classification of disks

In the broadest sense, brake discs are divided into 2 types.

- Non-ventilated

. They are a homogeneous plate (with or without holes), on which there may be notches that improve ventilation. - Ventilated

. They are made of two plates, separated from one another by cavities. There may also be perforations and notches on the surface.

Perforation also varies:

- Through

. It features efficient cooling and removes a large amount of working gases and combustion products. The disadvantage is a decrease in the strength of the product. - Recessed

. Also called a "blind hole". In this case, the disk is not drilled through, which preserves its strength. The efficiency of removing working gases is not as great as in the previous version, but the reliability is impressive. Cracks will not appear on the disc for a long time.

FREMAX

Brazilian brand of brake components for cars. FREMAX is the main supplier of Mitsubushi brand parts. The company's products are of high quality, which is associated with constant quality control by representatives of the organization at all stages of its production.

In addition, FREMAX works on innovative projects and their implementation, constantly investing in the development and implementation of braking elements. Products are delivered in unique plastic packaging with a valve. The disc is ready for installation, even without the use of degreaser.

Advantages of FREMAX:

- long period of use;

- safety;

- ease of installation;

- wear resistance;

- reliability and service life.

The price is acceptable for any segment of buyers, although the parts are manufactured according to high-quality developments and technologies.

Types of brake pads, their advantages and disadvantages

The quality of workmanship and the type of materials used directly affect the cost of the final product. Based on the type of materials used, pads are divided into: organic, semi-metallic and ceramic.

Organic

They are made from a base that does not contain asbestos, into which metal particles (at least 20%) are mixed at the production stage. It consists of high-strength polymer binders, glass, rubber, carbon and Kevlar (aramid) fibers with the addition of filler materials and high-temperature resins. This combination forms a medium-hard, high-strength matrix with good thermal conductivity and excellent friction characteristics.

One of the main advantages is their noiselessness

Another important advantage is the protection of discs and drums from wear. But due to their fragility, they are subject to rapid wear

Also, they cannot be used on vehicles whose brakes are subject to increased requirements (towing trailers or driving along mountain serpentines).

Semi-metallic

When choosing a manufacturing base, you cannot help but notice this type. The pads are made from a solid polymer matrix with the addition of steel fiber to increase hardness and extend service life. This is the most common material; most of the linings for all types of vehicles (trucks, cars, special equipment) are made from it. This is what makes semi-metallic trims suitable for most vehicles.

Advantages:

- more durable;

- excellent heat transfer;

- higher operating temperatures.

Flaws:

- heavy, which has a negative impact on the vehicle’s fuel economy;

- quite abrasive, which leads to rapid wear of the rotor;

- noisy;

- more expensive compared to organic pads;

- low efficiency at low temperatures.

Ceramic pads

They are one of the leaders in their field. As the name suggests, it is a friction material containing ceramic fibers as part of the binder component. Ceramics differ from others in their consistency and predictability at any temperature. Does not cause noise like the previous option. Another advantage is the fact that the dust that is released when the linings are erased is light in color, which makes it less noticeable on the rims.

Ceramic Automotive Brake Pads

The disadvantages include their price, which is several times higher than that of semi-metallic and organic pads. Currently they are used only on powerful sports cars that require increased demands on brake performance. Ceramic brake pads

Metal-ceramic

Metal-ceramic brake pads are developed based on new technologies. Most are made from copper alloy powder that is mixed with other lubricants, adding control components such as graphite and carbon. The resulting mixture is then formed into the desired shapes and then soldered to a base plate at temperatures above 980 degrees Celsius.

Advantages:

- stable coefficient of friction from cold to warm, which does not require heating;

- do not fade under extreme use;

- Their semi-porous surface allows use in all weather conditions.

Flaws:

- highest price;

- increased rotor wear;

- noisiness.

SCHNEIDER

Products for the braking system of German brands of racing cars. Brake discs are designed for drivers who like to drive at high speeds.

Composed of a ventilation and perforation system, this significantly reduces the impact of temperature changes during movement and their friction, and also removes unnecessary gases that form in the friction area of discs and pads.

A characteristic feature of SCHNEIDER discs is their ribbed structure for an optimal air flow path.

Advantages:

- air flow in one direction;

- the ability to quickly accelerate the car;

- lifetime;

- exposure in an aggressive environment.

The product also has disadvantages:

- discs accelerate wear of brake pads;

- When driving around the city, it is impossible to fully exploit the capabilities of the braking system.

The cost is set at 3,700 rubles.

Premium companies

If you own a luxury car, then you need high-quality and expensive spare parts. When producing premium brake discs, companies use exclusively innovative parts that guarantee reliability, durability and complete safety on the roads. Most often, such spare parts are purchased by owners of cars such as Bentley, Ferrari, Infiniti, Mercedes and others.

ATE

ATE produces modern and innovative auto parts that are suitable for most vehicles. It produces various components for cars that ensure comfortable movement and safety while driving. All products are made from wear-resistant materials that undergo regular strict control.

Every year the brand improves its product more and more and makes large investments in its development. Brake discs are intended primarily for foreign cars; they are overpriced, but fully justify the work and satisfy the wishes of car enthusiasts. With such parts, driving will be safe even at high speed.

Advantages

- Temperature resistance;

- Quality materials;

- Use of innovative equipment;

- Durability;

- Practicality.

Flaws

- Not detected.

Reviews of ATE brake discs show that the premium product is used only by owners of expensive cars.

For a medium-priced car, you can use cheap or mid-priced auto parts that can also cope with their functions.

E.B.C.

The English manufacturer offers a large selection of auto parts, including not only brake discs and pads, but also motorcycle clutches, suspensions, batteries and other parts. EBC produces auto parts only for premium cars, guaranteeing safety and practicality. It widely distributes its products, delivering them not only throughout Europe.

Advantages

- Uninterrupted operation;

- Big choice;

- High practicality, reliability;

- Long-term operation.

Flaws

- Suitable for luxury cars only.

The reviews note that the evaluation of the parts corresponds to their practicality and durability. By purchasing an auto part, you can enjoy its performance and safety for many years.

Zimmermann

Another elite German manufacturer of TDs, which has been manufacturing them since the 60s of the last century. The company's products are used by a number of European automakers and are represented in 70 countries.

Traditional German quality and commitment to the latest technological developments are a distinctive feature of products under the Zimmermann brand. An extensive model range (over five hundred items) and excellent characteristics (in particular, record wear resistance) make these wheels the undisputed leader.

EMU

The English brand is considered one of the most popular among fans of sports and extreme driving. It’s not easy to earn such popularity, but the British managed it to the fullest. It is no coincidence that it is equally well represented in both the primary and secondary markets. Currently, the most famous are three series of discs:

- Turbgroove is preferred by Japanese automakers, as well as fans of a sporty driving style. These products have non-through perforation, are well balanced and reliably protected from cracking;

- Ultimax is a series of wheels designed exclusively for sports cars. Characterized by the presence of notches that effectively cool the discs and remove water and dust, as well as helping to reduce noise levels during braking;

- The Premium series lives up to its name. These are the best brake discs for luxury models. They can be recognized due to the ideal smoothness of the disk mirror.

FREMAX

The Brazilian brand produces some of the best auto parts in the entire world market. The well-known Mitsubishi company cooperates with the company on an ongoing basis. Fremax is the official partner of the most popular racing events in Brazil. The manufacturer produces high-quality parts for car brake systems. Their safety, reliability and durability are due to the company’s enormous contribution to the development of new technologies, as well as complete control of all stages of spare parts manufacturing.

The manufacturer has created special packaging for the brake discs made of durable plastic, so the parts will not be damaged during transportation. Moreover, thanks to the introduction of Ready To Go technology, auto parts do not need to be degreased; they are already ready for installation. Undoubtedly, Fremax brake discs are one of the best options for the braking system of any car. All products from this manufacturer are characterized by safety, reliability and durability.

Cost: 5000 rub./pair.

FREMAX brake discs

Advantages:

- Ready To Go technology;

- Auto parts do not need to be degreased; they are already ready for installation.

Flaws:

- not detected.

How not to run into a fake

At the moment there are many fakes of original products. Counterfeits can also be found for expensive products from well-known world brands and for products in the middle and even economy segments. To minimize the purchase of pirated goods, you need to listen to several tips on this matter:

- Make purchases only in trusted and reliable stores, which primarily value their reputation. It is best to avoid shopping in dubious stores, despite the beautiful advertising.

- Before purchasing a disc, you must carefully inspect its surfaces.

- If the disc is original, it doesn’t matter what the price is set for it, it has markings from the factory. As a rule, it is embossed or engraved on its non-working surface. If it is not there, then it is a fake.

- Expensive wheels have a mark and serial number from the manufacturer. Their originality can be checked in the manufacturer's database using its serial number.

Please note that counterfeit products last significantly less, which can be dangerous for the life of the driver and his passengers while driving.

Brands, companies, positioning and product quality

In Russian auto stores you can find a very large number of brake discs from various manufacturers - for every taste and budget. Some of them position their products as “premium”, others as “economy”. For example:

ATE is a well-known German brand that is part of the Continental concern and produces many different products supplied to the assembly lines of such automobile brands as BMW, Mercedes, Volkswagen, Toyota. Brake discs from ATE are positioned as “premium” products.

EBC is a well-known British brand that produces very high quality brake discs. The products are positioned as “premium”, have a high cost, but are in stable demand in narrow circles due to their high quality.

Otto Zimmermann is perhaps the oldest German brand that produces various products for car brake systems and is a supplier to the conveyors of the Volkswagen group. The products are positioned as “premium”.

Brembo is an Italian brand that at one time became very famous thanks to the production of brake mechanisms for sports cars that took part in many car competitions around the world. Today it produces fairly high-quality products available to a wide range of customers.

Bosch is one of the most famous German brands in Russia, producing a wide variety of products, including spare parts for cars. The discs are positioned as a quality product for reasonable money.

Lucas is another very famous British brand, today part of the TRW group. Produces many types of spare parts, including brake mechanisms. The quality of the products is quite high, and the cost is quite reasonable.

Ferodo is a British brand specializing only in the production of brake discs and mechanisms. The product quality is high, the cost is reasonable. Products are sold mainly in Europe.

Schneider is a German brand that made its name on the production of brake mechanisms for extreme conditions, for which the disks of this company are very fond of participants in various automobile competitions. The quality is high, the cost is quite reasonable.

Valeo is a well-known French brand in Russia that produces many spare parts for cars of various brands, including VAZ. Today the company includes about 70 factories around the world. The quality is up to par, the price is reasonable.

Nibk is one of the youngest brands, which began its activities in Japan in the late 90s and has already managed to win the recognition of car owners in Russia. Supplies brake mechanisms to the production line of many popular small cars, including Rio and Solaris. The product quality is good, the price is reasonable.

Textar is part of a huge concern that produces spare parts and various equipment; it supplies its products to the assembly line of many automobile brands. The quality is good, the price is reasonable.

Fenox is a Belarusian brand that is actively developing the production of spare parts for all kinds of makes and models of cars. The price is low, the quality varies.

Where can I see the VIN code?

It's not difficult to do.

The code can be found:

- on a plate installed on the central pillar in the lower part near the driver's car seat;

- under the hood;

- on the threshold of a car;

- on the windshield;

- under the spare tire;

- in vehicle documents.

Once the code is detected it can be read. How to do it?

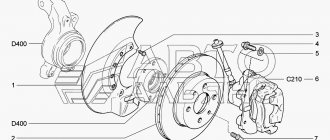

Disc brake device

The design of the disc brake is as follows:

- caliper (bracket);

- brake slave cylinder;

- brake pads;

- brake disk.

The caliper, which is a cast iron or aluminum body (in the form of a bracket), is mounted on the steering knuckle. The design of the caliper allows it to move along guides in a horizontal plane relative to the brake disc (in the case of a mechanism with a floating caliper). The caliper housing contains pistons, which press the brake pads against the disc when braking.

The brake working cylinder is made directly in the caliper body; inside it there is a piston with a sealing collar. To remove accumulated air when bleeding the brakes, a fitting is installed on the housing.

Brake pads, which are metal plates with attached friction linings, are installed in the caliper body on both sides of the brake disc.

The rotating brake disc is mounted on the wheel hub. The brake disc is attached to the hub using bolts.