If you are not yet a very experienced car enthusiast, and right now you are faced with a task; — remove the steering wheel from your Semerochka, or any other VAZ Classic; Don’t be puzzled - everything is quite simple, but some persistence will still be useful to you.

Why take it off at all?

Here, there are often two options; — either the steering wheel on your car is crooked; or, the signal of your car does not work due to a disconnected terminal in the steering wheel itself.

A simple and faster method for removing the VAZ 2107 steering wheel

How to quickly remove the steering wheel of a VAZ 2107 from a car? From the very beginning, place the steering wheel straight, or rather, so that the wheels are straight, even if the steering wheel is not positioned the way you like. After all, how else will you understand at what angle to place the steering wheel with the wheels turned out? - of course, this is still possible, but you must agree - it is better to spend less than one minute of your time at once, so as not to be left guessing later.

So, the wheels look straight ahead, now pay attention to the front part of the “steering wheel”; namely, look at the very center - where the Lada emblem usually appears. This very part can be picked out with a thin knife or a very thin screwdriver. You pry it up, remove it, and you see the Nut at 24. It is this that attracts the bullets to the shaft.

It is clear that you will not be able to get to this nut through the hole that appears. You will need a head, an adapter tube, and a ratchet. Unscrew the nut, and then tap the steering wheel on the back side, loosening it up and down (this is the operation that may require persistence on your part).

You pulled out the steering wheel, took out the nut in the head, now you can put it straight.

What to do

Drivers had to deal with the fact that occasionally after the start an incomprehensible knocking sound began to appear, but when accelerating and warming up the engine it disappeared. As we have already figured out, most likely the camshaft on the engine has failed.

Now another question. What to do in such a situation?

If it is the camshaft that starts knocking, you should be prepared to spend a considerable amount of money. But this is not a 100% probability, since sometimes hydraulic compensators begin to knock, or knocking noises are made by worn gears and bearings. Not all situations solve the problem by replacing the entire camshaft. If you suspect a knocking noise from this unit, it is better to immediately go for diagnostics. Due diligence can help you find out where the source of the problem is and what needs to be done about it.

It’s definitely not worth delaying diagnostics. If the compensators fail, and the problem was in them, then the chain reaction will lead to the breakdown of the shaft itself. And these are completely different expenses. So it would definitely be a good idea to check the hydraulic compensators.

You can drive a car without hydraulic compensators with a knock from the camshaft for more than 50 thousand km, but then you will probably have to completely change the engine or carry out major repairs.

As you can see, delaying the check is definitely not in your interests.

The second, longer method of removing the VAZ 2107 steering wheel

You will have to remove the VAZ 2107 steering wheel using a more complicated method if you do not have a suitable 24mm wrench (for working through holes); or you have problems with the signal.

But don’t worry, it’s not much more complicated here). You will just need a normal Phillips screwdriver. It is advisable that it is not very long. The fact is that on the back of the steering wheel there are 4 bolts. You unscrew them, and this will make it possible to remove the upper part of the steering wheel. Exactly - the one you click on for the signal.

Removed? Please note that two of the bolts have bushings, but the other two do not. Now, you can connect the signal terminal, or unscrew the nut holding the steering wheel on the shaft.

By the way, when you tighten these 4 bolts back, you should not tighten them with all your might. So you can clamp the signal, and when you turn on the ground, you will hear a loud and constant - BEEEE!

PS – before work, do not forget to remove the terminal from the battery; or any other method available to you, turn off the mass. I’m not an electrician myself, but when I touched one of the cross-shaped bolts with a screwdriver, it sparked (.. Therefore, don’t forget).

As you can see, the procedure for removing the Seven Rosh steering wheel is quite simple, and there are not many operations involved. Somewhere you will need to bend, somewhere you will need to tug at the steering wheel with enthusiasm, but in the end you will succeed).

Knocking in a VAZ engine: what to do, reasons

Any unusual extraneous sound from under the hood must not be ignored. You need to understand that a knock made by the engine may indicate serious malfunctions leading to major repairs or complete irreparability of the cylinder block, cylinder-piston group, or cylinder head. VAZ engines have a similar design, which allows us to consider the causes of knocking and other noises in a comprehensive manner.

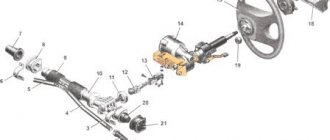

Removing and installing the steering wheel (steering wheel)

Removing and installing the steering wheel can be done for several reasons:

- replacing a conventional steering wheel with a new or sports version

- After adjusting the wheel alignment angles (wheel alignment), you need to set the steering wheel to the correct position

- it is necessary to remove the steering wheel to gain access to replacing other parts, for example, steering column switches

Removing and installing the VAZ “Classic” steering wheel

The procedure for removing the steering wheel:

- Disconnect the negative terminal of the battery so that when working with the steering wheel you do not accidentally turn on the sound signal.

- Use a screwdriver to remove the plug in the center of the steering wheel. (Fig. 1)

- Using a 24mm socket wrench, unscrew the steering wheel mounting nut. (Fig. 2)

- Remove the steering wheel. (Fig. 3)

Tips and tricks for novice drivers

The above list of actions should save you from further squeaks, whistles and squeals from the brake system. However, if only a temporary solution to the problem appears, simply contact the nearest car service center, where they will offer you a full diagnosis of all components of the brake system and identify the malfunction.

- It is necessary to replace old pads with new ones after every 75-100 thousand km of the vehicle.

- Buy brake pads and rotors of the same brand and type as the original ones on the car.

- When driving on wet roads, squealing brakes are not uncommon, so dry the brakes a little first.

- To check the serviceability of the pads, perform about 5-10 gradual braking at low speeds.

- Any set of new spare parts, including the brake system, requires a certain amount of time to break in.

Source

How to easily and safely replace the steering wheel?

The operation of replacing the steering wheel is not particularly difficult, but safety precautions must be observed. The basic steps on how to remove the steering wheel have been described above, but in some cases the following tips may be needed:

Method #1. If the steering wheel sits firmly on the shaft and cannot be removed, then it is necessary to loosen the steering wheel nut as much as possible, but leave it one turn (to protect the teeth, nose and other parts of the face). Then sit in a chair and sharply and evenly hit the steering wheel with your palms from below, upward along the steering axis. After several such impacts, the steering wheel should fly off the shaft.

The main thing is to remember to leave the nut on one turn!

Method #2. To remove the steering wheel, you can use an old Zhiguli jack. The base of the jack needs to be rested against the steering shaft through a wooden spacer, wrap a rope around the steering wheel and throw it over the top of the jack. A piece of cloth (rag) should be placed at the point where the rope comes into contact with the steering wheel so as not to scratch the steering wheel. Next, gradually pull with a jack and remove the steering wheel. Do not forget to completely unscrew the steering wheel fastening nut, since in this case the steering wheel itself will gently “come off” from the shaft.

How to disassemble the steering gear of the “six”

If the driver decides not to change the gearbox on his six, but only to replace the oil seals or bearings inside it, the gearbox will have to be almost completely disassembled. To do this you will need the following:

- a large head is taken as 30;

- bipod extractor;

- flat screwdriver;

- hammer;

- vice.

Sequence of work

It must be said right away that the extractor and vice are the main tools when disassembling the gearbox. It is better not to start disassembling without them, since these tools cannot be replaced with anything.

- There is a fastening nut on the gearshift bipod. Unscrews with a wrench. Next, the gearbox is installed in a vice, a puller is put on the bipod, as shown in the photo, and the rod is smoothly removed from the shaft with the puller.

Video: disassembling the steering gear of a “classic”

How to properly remove the steering wheel on a VAZ-2107

Not every owner of classic cars, for example, VAZ-2107, is satisfied with the design solution of the steering wheel. Many car owners note that the old-style steering wheel is not comfortable due to its large size, and the inability to adjust the steering wheel prevents the driver from taking a comfortable position and even sitting in the driver’s seat. This problem can be eliminated only after the factory element is removed and a steering wheel with a more acceptable design is installed in its place. Therefore, many are interested: how, according to the rules, can you remove the steering wheel on a VAZ-2107 and can you do it yourself? We will deal with these questions in this article. It is also worth noting that you need to remove the steering wheel not only to resolve design issues, but also if the sound signal starts to disappear.

Can the camshaft make a knocking noise?

Many people have encountered crankshaft knocking in their lifetime. But not all drivers know how and when exactly the camshaft knocks.

It's all about the sounds. They are really very similar to each other. This appears the same on different cars:

- for VAZ 2106;

- Niva has 8 valves;

- VAZ 2107;

- VAZ 2109;

- on Priora;

- VAZ 2110;

- VAZ 2114;

- for Daewoo Nexia;

- for Subaru Forester, etc.

But what should a car owner do when he hears a sound, but cannot understand what exactly is knocking? Is it the crankshaft or the camshaft?!

Step-by-step replacement of the steering wheel

You can remove the steering wheel in a VAZ-2107 yourself, but in order for the process to be completed correctly, you need to do it step by step:

- The battery lock must be done first to prevent short circuit. To do this, it will be enough to disconnect the negative terminal from the battery.

- Using a small screwdriver, you need to pry off the Lada logo, which adorns the middle of the steering wheel. This logo is not only a decoration of the steering wheel, but also an original plug that covers the fastening element.

- After the plug is removed, you can see a 24-size nut inside, which must be unscrewed. Before unscrewing, you need to set the steering wheel to a position in which the wheels of the car will “look” directly from the body.

- A size 24 socket must be inserted into the extension so that it is convenient to put the tool on the fixing nut. Next, you need to insert such a device into the so-called knob and try to turn the latch with a sharp counterclockwise movement. In this case, you should hold the steering wheel with your knees so that the structure does not turn when unscrewing the lock. If the nut does not come off the first time, you need to repeat the whole process again, but experts do not recommend completely unscrewing the lock. This is explained by the fact that the steering wheel is quite firmly attached to the shaft, and if it is removed with a sharp jerk, the structure can hit a person hard in the chest.

- Once you feel that the fastener has become loose, you need to start swinging the steering wheel in different directions. You can completely remove the steering wheel from the shaft after you hear a peculiar click. This will indicate that the steering wheel is starting to hit the nut, so the clamp can be completely unscrewed without fear.

Such simple manipulations and a minimum of tools will help VAZ-2107 owners remove the steering wheel without much effort for further replacement of the structure or troubleshooting any problems.

The principle of operation of the car's brake system

All modern brake systems work according to the same type. The work takes place in several stages:

- When you press the brake pedal, the pressure in the hydraulic brake system begins to gradually increase;

- The increased pressure in turn causes pressure in the brake pads;

- The pads, in turn, transfer energy to the wheel housing, which then brakes the car on the road.

Thus, pressure from the driver is transferred to the caliper, which is inextricably linked to the disc. As a result, the force applied to the brakes is directly proportional to the pressure of the disc on the wheels. That is why drivers can control the braking speed with a slight movement of their feet.

At the same time, manufacturers of brake pads and discs have made sure that your vehicle always operates quietly. Let us remind you: when the brake system is activated, the disc is pressed against the base of the wheel, causing vibration. To eliminate noise during contact and prevent strong vibration of the wheel, manufacturers divide the area of the brake pads into several specific segments, each of which has a special cut along the surface. This suppresses the occurrence of squeaking and vibration.

Often, when purchasing brake pads, buyers overlook the fact that there are no slots, which can cause not only squealing from the pads even on a new car model, but also a knocking sound in the front suspension on small bumps. However, you can make slots in the pads with your own hands. To do this, adhere to the following slot parameters:

- the width of the cut should be no more than 2 mm;

- incision depth – 3.5-4 mm.

Tip: if you want to completely dampen wheel vibration when braking, round the new brake pads. To carry out this operation, contact a car service center, where they will lightly file the edges on the pads and install new brakes to replace the old ones.

However, the cause of squeaking in the brake system is rarely due to a lack of slots. We propose to consider the most common problems with brakes and effective methods for eliminating them.

How to return the sound signal yourself

If the steering wheel needed to be removed because the sound signal stopped working, then the removal process is carried out in the same sequence as previously described. Next you will need to do the following:

- Be sure to check the steering play, which should not exceed 5 C, and the copper contact of the horn. The contact is located on the steering column; if traces of oxidation or other types of contaminants are noticed on its surface, they are carefully removed;

- Next, the connecting fasteners on the back of the steering wheel are unscrewed so that the entire panel assembly can be removed, including the contact plate;

- The removed steering wheel with the panel should be placed on a table or workbench to find the failed contact. The latter is most often the main reason why the sound signal disappears;

- if the contact is disconnected, you just need to solder it back to its original place and install the panel with the steering wheel.

At this point, the process can be considered complete, and it’s hard to believe that such work is difficult for car enthusiasts, even with little experience. And with an Internet connection at hand, if necessary, you can watch a training video at any time, which will further simplify the process of replacing the steering wheel and help you find out why the sound signal in the VAZ-2107 began to disappear.

A little about the camshaft

Fortunately for many, the camshaft is not one of the components that are positioned as capricious, often and quickly failing. The resource largely depends on the quality of the part and operating conditions.

The camshaft has a life limit. Uninterrupted operation can last from 50 to 150 thousand kilometers. These are fairly average indicators, since each situation is still individual. Active work is already underway to remove this element from the engine design. Moreover, experts say that in the future the camshaft may completely cease to be part of the engine. It will be replaced by electromagnetic actuators.

It is difficult to say how effective and realistic this will be in the near future. Plus, some skeptics doubt the correctness of the transition from a mechanical part to a computer-controlled actuator.

Replacing the steering wheel on a VAZ 2104, VAZ 2105, VAZ 2106, VAZ 2107

Welcome! The steering wheel is one of the most important parts in a car, imagine what it would be like if the car didn’t have a steering wheel? Naturally, it’s unlikely that you’ll be able to go anywhere with such a car. And that’s not the point, experienced people who have driven different cars know firsthand that if the steering wheel installed in the car is not comfortable, then it is unlikely that you will be able to drive normally in this car. (For example, you can take the VAZ 2101 car; anyone who has driven it with the original steering wheel will understand what’s going on)

Signs of large thermal clearances in car engine valves

Large (larger than normal) thermal gaps in the valve mechanism of a car engine lead to a number of problems in its operation.

Using the example of the 21083 carburetor engine of VAZ 21083, 21093, 21099 cars, we will determine by what signs you can independently determine that the valve clearances are greater than required.

Signs of large thermal clearances in engine valves 21083

— Valves are knocking

Frequent metallic knocking noise under the valve cover while the engine is idling is a sign of problems with the valves. In most cases, valve knocking occurs when the thermal gaps between the end of the valve stem and the pusher are increased. This happens either due to incorrect adjustment of the thermal gap, or from abrasion of the valve ends on engines with high mileage or with bad oil. All (or almost all) valves, or just one or a pair, can knock.

Engine valve mechanism 21083

Sometimes the valve starts to knock if it is bent and hanging in the guide sleeve. In this case, you will have to remove and disassemble the block head to replace it.

Almost always, valve knocking is accompanied by unstable idle speed and a decrease in engine power and throttle response, as the filling and ventilation of the combustion chambers deteriorates due to a decrease in the gap between the plate and the valve seat.

In some cases, the knocking of valves can be mistaken for a metallic, frequent sound from detonation in the combustion chambers of the engine (“fingers” knocking).

— The engine is troubling

If the thermal clearances of the valves are too large, the valve does not open completely, the gap between the valve plate and the seat in the cylinder head decreases, and the filling and ventilation of the combustion chambers deteriorates. A situation is created when there is not much to set on fire (the charge of the fuel mixture entering the combustion chamber is too small), in addition, gases from combustion are poorly removed and disrupt the composition of the mixture. Interruptions in engine operation begin; the cylinders sometimes work, sometimes they don’t. The engine sputters, loses power and throttle response, the idle speed cannot be adjusted by rotating the “quality” and “quantity” screws of the carburetor.

The engine does not pull

Since the filling of the combustion chambers deteriorates, the combustion efficiency of the fuel mixture decreases. Engine power and throttle response decreases. The driver does not feel the former playful pickup when pressing the gas pedal, the engine does not pull.

What to do if you suspect that the valve clearances are increased?

On the 21083 engine, you can independently check and adjust the thermal clearances in the valve mechanism. To do this, you need a pair of flat probes, a set of adjusting washers and two or three keys. See “Checking thermal valve clearances on VAZ 2108, 2109, 21099 engines.”

How to replace the steering wheel, also known as the steering wheel, on a VAZ 2104-VAZ 2107?

Replacing the steering wheel:

Removal: 1) First, position the steering wheel so that the front wheels of the car are directed straight forward.

Note! While working, try not to change the position of the wheels, otherwise by changing it slightly, it will be more difficult to install a new steering wheel!

2) Next, using your hands and a screwdriver, carefully pry up the decorative steering wheel trim and then remove it from the steering wheel of the car.

Note! If you are removing the steering wheel in connection with any work not related to replacing the steering wheel, then use a marker to place two marks on the steering shaft and hub and align them with each other when installing the steering wheel!

3) Now loosen the center nut that secures the steering wheel until it aligns with the tip of the steering shaft.

Note! In fact, the nut can be completely unscrewed, but only when removing the steering wheel can it suddenly come off and cause injury, so at the first stage it is recommended to only loosen it to the maximum possible state!

4) Then, gently rocking the steering wheel from side to side, remove it from the shaft splines.

Note! If that doesn’t work, then use your hands to sharply hit the steering wheel on the back of its rim a couple of times!

5) Next, when the steering wheel has already come off the shaft splines, using an extension with a cap socket, finally unscrew the central nut that secures the steering wheel.

6) Finally, remove the steering wheel from the steering shaft.

Installation: Install the new steering wheel in the reverse order.

Note! After installing the steering wheel, check whether it is positioned correctly, because if the steering wheel is positioned incorrectly, the side turn signals will not turn off clearly!

Replacing the steering wheel cover:

1) First, to remove the cover, use a screwdriver to unscrew the six screws on the back side that secure it.

Note! The two middle screws will have grommets, so remove them after removing the screws!

2) Next, carefully remove the cover and then disconnect the wires from the slip ring terminal.

3) Next, remove the four springs from the cover and, if necessary, replace them with new ones, or transfer them to the new steering wheel cover if they are not there.

Note! Installing the steering wheel cover is carried out in reverse order!

Replacing the steering horn slip ring:

1) To replace, first unscrew the three screws that secure the signal slip ring and then remove it.

Note! Replace the slip ring with a new one, and install the new ring in the reverse order!

Additional video: There is another way to replace the steering wheel on a car. This method is shown in detail in the video below:

Note! Be sure to watch this video until the very end, because at the very end, starting at “3:55 minutes,” very important information will be given that you will need to adhere to when replacing the steering wheel!

Filling oil into the steering gear

As mentioned above, the steering gear housing is sealed. Oil is poured inside, which can significantly reduce friction of parts. Any GL5 or GL4 class oil is suitable for the VAZ gearbox. The viscosity grade should be SAE80-W90. Many owners of the Six use old Soviet TAD17 oil, which also has an acceptable viscosity and is cheaper. To completely fill the gearbox, 0.22 liters of gear oil is required.

How to check the oil level in the steering gear

In order for the steering parts to work as long as possible, the driver must periodically check the oil level in this device and, if necessary, add lubricant.

- The gearbox cover has an oil filler hole closed with a plug. The cover is unscrewed with an 8 mm wrench.

Oil filling sequence

If the driver needs to add oil to the transmission or change the oil completely, he will need an empty plastic bottle, a piece of plastic tubing and a larger medical syringe. It should also be noted here that the operating instructions for the machine state: the oil in the steering mechanism should be changed at intervals of once a year.

- The oil cap on the gearbox cover can be unscrewed. A plastic tube is placed over the syringe. The other end of the tube is inserted into the drain hole of the gearbox, the oil is drawn into a syringe and drained into an empty plastic bottle.

Video: we change the oil in the steering gear of a “classic” ourselves

Therefore, the steering on the 6 is a very important part. Not only the controllability of the car, but also the safety of the driver and passengers depends on its condition. Even a novice car enthusiast can replace the gearbox. This does not require any special skills or knowledge. You just need to know how to use wrenches and follow the recommendations described above exactly.

Introduction

The VAZ-2107, to which thousands of compatriots are accustomed, is inferior in several respects to its foreign counterparts, which is why motorists who want to improve the characteristics of their own car do their own tuning of the VAZ-2107 steering. A thoughtful and correct tuning solution can be considered the installation of a hydraulic booster or electric power steering. Thanks to competent modernization, a unit will appear in the car, through which additional force is created on the wheels when entering a turn. The improvements made will bring domestic cars closer to the class of more expensive foreign cars.

Let's sum it up

As you can see, there are more than enough sources of extraneous noise in the power plant.

Some of them do not cause significant harm even with prolonged use of the car without eliminating them.

Some reasons are more serious, but at least allow you to take the car for repairs.

And the causes of knocking in the engine associated with the crank mechanism and the cylinder-piston group are very serious and are a harbinger of expensive and time-consuming repairs.

By clicking on the link, you will learn about other causes of extraneous noise in a car.

In this situation, it is very important to take action in time. Good luck.

Steering tuning

Tuning the VAZ-2107 steering can begin with a well-founded decision to replace the factory steering wheel with a sportier device with a diameter of 320 mm. Such a unit will give the car owner many advantages: firstly, he will be able to park with greater maneuverability. When upgrading the steering wheel, do not forget about installing a safety glass.

Those motorists who prefer sports tuning (low-number rack) should be prepared to pay twice as much money for the unit than for a simple standard device. However, after installation, the car will be able to turn the wheels in just two steering turns.

The third step to improve the car could be adjusting the camber and toe. Experts who have been working with different VAZ models for many years increase toe-in and negative camber on the front axle. At the same time, it is imperative to pay attention to the toe-in of the rear wheelbase, which should, on the contrary, decrease.

Knock at low speeds

A knocking sound in the engine at low speeds when the engine is not warmed up, if it comes from the top, indicates problems with the hydraulic compensators.

A uniform knocking sound in the upper part, which intensifies significantly when warming up, signals the beginning of destruction of the valve seat.

It is worth considering the possibility of damage to the bearings of attachments.

It is also possible that the valve timing is disrupted due to the timing belt slipping, as a result of which the piston bottoms come into contact with the valves, hence the knocking sound in the engine.

Filling with low octane gasoline can lead to detonation in the engine, which is why knocking occurs.

If you detect extraneous noise while the engine is running cold at low speeds, it is better to immediately try to determine where exactly the noise is coming from.

If the knocking sound in the engine comes from the top, the car can still be driven for a short time.

If sharp noises appear from the lower part of the engine, it is better to immediately stop the power plant and deliver the car to the repair site by tow truck or in tow.

Installing power steering

If a motorist wants to install power steering on a VAZ-2107 with his own hands, which the manufacturer did not consider necessary to install in one of the most budget cars in the whole world, he can take one of two possible paths. Firstly, you can select the optimal steering rack that has power steering and then decide on its further location in the car. True, such an action will require enormous labor and money. Secondly, which is more expedient, you can buy a ready-made kit at an auto parts store that allows you to perform all possible most useful manipulations on the stationary steering rack.

The purchased power steering for a VAZ-2107 will consist of many parts: a pump, a pulley, a steering gear, a hydraulic cylinder, an expansion tank and a hose system.

To install power steering on a VAZ-2107, you need to start with a pump, through which pumping is carried out and a certain pressure is created in the unit. This pump must be placed on the cylinder block, since it will operate due to a belt drive. The next step is to determine where to install the crankshaft pulley. Then the steering gear is replaced. The car owner should check the size of the purchased device in advance, since it will most likely differ from the factory analogue, which may require modification of the installation location of the device.

When installing power steering in your car, you should pay close attention to the hydraulic cylinder, which should be located in the car according to the instructions. Further modernization consists of the location of the expansion tank and the sequential connection of a set of parts with high-pressure hoses. The installed reservoir must be equipped with a special fluid intended directly for the power steering. As a result of the manipulation, it is worth pumping the system.

Turn the steering wheel hard

- Please log in to reply.

#121 alex_slobodka

- Users

- 49 messages

- Registration 16-November 12

- Top

- Complaint

#122 Mountain Master

- From: Sevastopol

- Car: VAZ-21041 1.6i

More than a quarter of a century behind the wheel - Sound pro-audio Now - new Russian.

- Top

- Complaint

#123 alex_slobodka

- Top

- Complaint

#124 Dermart 3

- Top

- Complaint

#125 andron1313

The balls are new, also restored, they were changed a week earlier, everything worked fine, it’s either a trapezoid or a pendulum

- Top

- Complaint

#126 Yurij

- Top

- Complaint

#127 Blade

Hello, the problem is that it’s hard to turn the steering wheel left and right. On diagnostics, the ball ends were normal, but the steering shaft itself, where it enters the gearbox when rocking up and down, has play; should the gearbox be changed or can you get by with a repair kit? Pendulum on bearings

- Top

- Complaint

#128 igor

there is play in the gearbox when rocking up and down

- Top

- Complaint

#129 Bludik777

- Top

- Complaint

#130 Yurij

- Top

- Complaint

#131 Mountain Master

- From: Sevastopol

- Car: VAZ-21041 1.6i

More than a quarter of a century behind the wheel - Sound pro-audio Now - new Russian.

- Top

- Complaint

#132 Vadim Joker

- Top

- Complaint

#133 Metz

Vadim Joker, Hang the front wheels (so that they hang in the air) and turn the steering wheel.. If it turns easily, then the problem is in the supports, camber, and tire pressure.. and maybe in the tires themselves (since it is unknown what you have there and in what condition) If the tires are not evenly worn (if they are worn out from the middle, they will also affect the lightness of the steering) The balder the tires, the harder the steering wheel turns (from my own experience)

If when hanging it is still tight, then only: steering column, gearbox, pendulum, trapezoid. You need to check each unit separately, for example, remove the steering linkage and twist everything separately, thereby checking how easily everything turns, I think that in 90% of cases this way you can determine where it is sticking.

- Top

- Complaint

#134 Vadim Joker

Vadim Joker, Hang the front wheels (so that they hang in the air) and turn the steering wheel.. If it turns easily, then the problem is in the supports, camber, and tire pressure.. and maybe in the tires themselves (since it is unknown what you have there and in what condition) If the tires are not evenly worn (if they are worn out from the middle, they will also affect the lightness of the steering) The balder the tires, the harder the steering wheel turns (from my own experience)

If when hanging it is still tight, then only: steering column, gearbox, pendulum, trapezoid. You need to check each unit separately, for example, remove the steering linkage and twist everything separately, thereby checking how easily everything turns, I think that in 90% of cases this way you can determine where it is sticking.

Thanks for the advice. The steering gearbox is new. They set it so that there was alignment and there were no distortions on the spar. When the wheels are up, the steering wheel turns well. It turns out that the whole problem is in the supports ((((((

- Top

- Complaint

#135 ancistr

- Top

- Complaint

#136 Vadim Joker

- Top

- Complaint

#137 Vadim Joker

- Top

- Complaint

#138 Vadim Joker

- Top

- Complaint

#139 dens321

- Top

- Complaint

#140 andron1313

Installing electric power steering

If a car owner wants to install an electric booster on a VAZ-2107, he should give preference to factory units. Before setting up and upgrading the system, the transmission speed sensor should be adjusted. This will avoid turning the steering wheel too “tight”.

Among other additions, when installing an ESD in your car, the vehicle owner will have to install a new choke cable (you can purchase it as part of the ESD kit for the VAZ-2108), replace the gearbox and install a MUR1100E diode.

Electric power steering on a VAZ-2107, when purchasing a ready-made kit, requires the presence of a speed sensor, various fasteners, a choke cable, an ignition switch, several switches and a casing for the steering column.

When assembling an electric power steering for a VAZ-2107 with your own hands, you need to start with the adapter plate and cardan. After removing the crosspiece, you need to select a cardan of the appropriate length. The welded and assembled crosspiece, or rather its bearings, are equipped with new lubricant. After this, the steering device is installed and the electrical component of the power steering is connected. The red wire should go to the battery, and the brown wire should go to its mounting stud. The blue cable for the ignition switch should go to the orange one. The tachometer wires should go to the dashboard chip, and the connecting elements between the speed sensors should go to the ninth pin of the ECU.

Sound diagnostics

If a problem arises that the engine is knocking, as already said, it is first of all important to determine the nature of the knock, as well as the location of its occurrence.

Some of the reasons can be diagnosed without disassembling the power plant.

Thus, a special device - a technical phonendoscope - will allow you to more accurately determine the location of the noise.

Using it, the engine is listened to and it is determined in which mechanism or system malfunctions have occurred.

You can also use more advanced equipment, for example, a motor tester.

A simple procedure will allow you to determine the destruction of the connecting rod liner.

It is done like this: with the engine running, when a loud knocking noise appears, the high voltage wire is removed from the spark plug one by one on each cylinder.

If the fault lies in the connecting rod bearing, then disconnecting the wire on the cylinder that has the problem will significantly reduce the knocking noise.

If noise occurs, when there is a suspicion of destruction of the bearing of any attachment, you can determine which equipment has problems by disconnecting their drive from the on-board network.

Knock of connecting rod bearings

Typically, the knock of connecting rod bearings is sharper than the knock of the main bearings. It can be heard at idle and with the gearshift lever in neutral. The knocking noise increases with increasing crankshaft speed. To determine which of the four connecting rods turned out to be defective, it is necessary to exclude one of the cylinders from operation in turn, removing the high voltage wire from the spark plug. The reasons that cause knocking of connecting rod bearings are very similar to the previous ones: incorrect ignition timing; low quality oil; large gaps between the journals (now connecting rods) of the crankshaft and the bearings; ovality or taper of the connecting rod journals; non-parallelism of the axes of the upper and lower connecting rod heads. And again you have to go to a service station, since the engine will have to be disassembled.

Crankshaft knock

An extraneous knock that suddenly appears in the engine causes concern for every car enthusiast - experienced or new. First of all, you need to figure out which engine mechanism is making the knocking noise. The most convenient way to determine this is with a stethoscope. The Chernigov Auto Parts Plant (GAZ branch) has developed a special technical stethoscope that allows you to determine by ear the condition of the engine and its components by the noise that occurs. To do this, just attach an acoustic probe to one or another node. Some car enthusiasts successfully diagnose the engine with homemade stethoscopes. An old oiler is soldered to a steel bar. To accurately determine the source of the noise, the end of a steel rod is alternately applied to different parts of the running engine, and an oil can is applied to the ear. Due to the fact that the thin bottom of the oil can is an excellent membrane, even the slightest sound will not be hidden from the ear.

The knock of the crankshaft is metallic and dull. Its frequency increases with increasing crankshaft speed. If the axial clearance of the crankshaft is significantly larger than the norm, the knocking becomes sharp with uneven intervals, especially noticeable during smooth acceleration and deceleration of the rotation speed.

The main causes of crankshaft knocking:

- excessively early ignition. If this is the reason, then it is no big deal. It is necessary to adjust the ignition timing and the knocking should disappear;

- the use of oil whose grade and quality does not correspond to those recommended by the factory. If the defect is not started, i.e. it is detected immediately as soon as the knocking appears, the situation can be corrected by draining the oil, flushing the system with detergent oil and filling the engine with fresh oil, as specified in the instructions;

- insufficient oil pressure. This causes malfunctions of the oil pump, pressure relief valve, and clogging of the lubrication system channels. Considering that to correct defects it is necessary to disassemble the engine (even partially), you should not undertake such work at home.

There are a number of other reasons that can cause crankshaft knocking: increased clearance between the journals and main bearing shells, misalignment and ovality of the main journals, increased clearance between the thrust half-rings and the crankshaft, loosening of the bolts securing the flywheel to the crankshaft. In all cases, engine disassembly is necessary, so the listed repair work should be performed at a service station.