Removing the bipod

Remove the steering from the car. We wet the connection of the bipod with the shaft in advance with kerosene or WD-40 liquid.

| Using a 30mm wrench, unscrew the bipod fastening nut. |

| Using a special extractor (see Appendices), we press the bipod away from the thrust. |

If you don't have an extractor, you can try knocking it off with a hammer.

| We rest the shaft of the bipod against the block. Using a heavy hammer (sledgehammer), we press on one stop of the bipod, and hit the second with another hammer. |

In some cases, you will have to sacrifice the bipod by cutting it off with a cutting machine.

In modern cars, the front wheels turn through a rack connected to the steering wheel shaft. The VAZ 2107 and other classic Zhiguli models use an outdated system of articulated rods, the so-called trapezoid. The reliability of the mechanism leaves much to be desired: the parts literally wear out within 20-30 thousand km, the maximum service life is 50 thousand km. A positive point: knowing the techniques of construction and disassembly, the owner of the “seven” can save money and replace the elements himself.

Purpose and operation scheme of the trapezoid

The lever system acts as an intermediary between the steering shaft and the steering knuckles of the front hubs. The purpose of the mechanism is to synchronously turn the wheels in one direction or another, obeying the rotation of the steering wheel. The trapezoid is located under the engine at the level of the bottom of the car, attached to the body stiffening elements: the lower side members.

The steering part in question consists of 3 main parts:

- the central link is screwed to two bipods: the pendulum arm and the wheel arch of the worm gear;

- the right link is attached to the swing arm of the pendulum and to the steering knuckle of the right front wheel (in the direction of travel of the car);

- The left link is connected to the gearbox bipod and to the stamp of the left front hub.

The method of connecting swivel brackets to trapezoidal parts is that a conical pin is inserted into the connecting hole in the bipod and secured with a nut. The pendulum and gearbox are rigidly fixed to the side members with long bolts.

The central link is a hollow metal rod with two hinges. The two side rods are prefabricated elements consisting of two ends - long and short. The parts are connected to each other by a threaded clamp secured with two bolts.

How does a trapezoid work:

- The driver turns the steering wheel, turning the transmission shaft and rod. The worm gear transmits fewer revolutions to the bipod, but increases torque (force).

- The bipod begins to turn to the right, dragging the left and central rod with it. The latter transmits force to the right rod through the pendulum bracket.

- All 3 elements move in one direction, causing the front wheels to rotate synchronously.

- The pendulum, attached to the second spar, acts as an additional hinged suspension for the system. In old versions of pendulums, the bipod rotates on a bushing, in new elements - on a rolling bearing.

- Ball pins at the ends of all links allow the trapezoid to move in one horizontal plane regardless of the compression of the front suspension springs.

The increased torque from the worm gear eliminates the need for hydraulic and electric power steering. On the other hand, the driver physically feels problems with the chassis: the ball joint or the end of the stem has to sour, and it becomes much more difficult to turn the steering wheel.

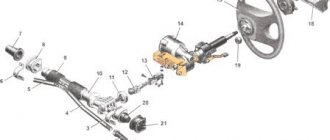

↑ Steering parts

1 – lower part of the facing casing 2 – steering shaft mounting bracket 3 – shaft bearing 4 – coupling bolt 5 – spacer sleeve 6 – upper part of the facing casing 7 – upper shaft 8 – steering wheel 9 – horn switch cover 10 – adjusting sleeve 11 – steering column position adjustment lever 12 – retaining ring

Arrangement of rods and tips

The one-piece central trapezoidal element has the simplest design - an iron rod with two loops at the ends. The pressure pins are inserted into the second holes of the bipod (counting from the end of the lever), screwed in with 22 mm castle nuts and secured with cotter pins.

Note: The center link rod is bent forward slightly to prevent shifting. If you place the part backwards, problems are inevitable - the bend will begin to rub against the gearbox housing, which will make it very difficult to drive the car.

Not all service station mechanics know the correct installation of the central trapezoidal rod. My friend was convinced of this when he came to the service center to change a VAZ 2107 steering rod kit. The inexperienced master installed the middle section with a bend back, so it was not possible to go far - exactly until the first turn.

The side bars consist of the following parts:

- short ball point (external;

- long sock (inside) with zipper;

- connection clamp with 2 bolts and nuts M8 for 13 mm wrench.

The element is removable for adjusting the toe angle of the front wheels. The length of the lever can be changed by turning the threaded clamp and thus adjusting the position of the wheel for straight movement. The threads of the tips and inside the clamp are different - right and left, so when rotating the rod lengthens or shortens.

The design of all articulated ends is the same and includes the following parts (the numbering coincides with the diagram):

- Ball pin with M14 x 1.5 thread for 22mm castle nut. The radius of the ball is 11 mm; a hole for a cotter pin is made in the threaded part.

- The cover is rubber (or silicone), splash-proof, also known as a boot;

- Metal body welded to M16 x 1 threaded rod.

- The support insert is made of composite material, otherwise it is a burglar.

- Spring.

- The lid is pressed into the body.

Some lever manufacturers insert a small attachment called a grease gun into the cap for periodic lubrication.

The short outer ends of the side rods are the same, but the long ones are different. You can identify the part by its bend - on the right side there is a lever bent to the right. The side link ball pins are attached to the first holes of the swingarm and gearbox.

A well-known automotive technician suggests distinguishing between long points as follows: Grasp the loop with your right hand, pointing the ball finger downward, as if you were holding a gun. If the muzzle is bent to the left, you have a left-handed pusher tip.

Video: design of the rod end for VAZ 2101—2107

↑ Steering gear

The steering drive includes two composite steering rods and swing arms 11, welded to the telescopic struts of the front suspension. Each rod, in turn, consists of two parts - internal 12 (long) and external 9 (short) with split tips with internal threads, as well as an adjusting rod 8 (connecting the internal and external rods) with external threads of different directions at its ends and a hexagon in the middle. The length of the tie rod changes when the adjusting rod is rotated.

For a reliable connection, it is necessary to ensure the distance between the ends of the tips and the hexagon: on the inside within 10.8-14.2 mm, on the outside - 10.6-16.3 mm. After the adjustment is completed, the tie rod ends are bolted together. The outer (short) rod 9 is connected to the rotary lever 11 through a ball joint 10, consisting of a liner, a liner spring and a pin. To protect against dirt, the hinge is covered with a rubber protective cover (boot). The hinge forms a non-separable structure with the tip, therefore, if it fails, the tip should be replaced with subsequent adjustment of the wheel toe.

Troubleshooting

While the car is moving, the ball fingers rotate in different planes and gradually wear out the cracks, causing recoil. The following signs indicate critical tip wear (or more):

- obvious dull touch when moving over any uneven surfaces;

- the vibration of the ball pin play is transmitted to the steering wheel;

- on a flat section of the road the car spontaneously moves off the straight road;

- It is difficult to rotate the steering wheel and a creaking sound is heard from below.

If it takes a lot of effort to turn the steering wheel, the worn tip should be replaced immediately. The symptom indicates that the ball pin is stuck inside the housing. If measurements are not taken in time, the loop may jump out of the socket and the machine will become uncontrollable.

A similar story happened to my relative. When there was literally half a kilometer left to the garage, the right steering column on the G7 broke. The driver showed ingenuity: he tied the end of the missing link to the suspension arm, straightened the steering wheel with his hands and continued to drive slowly. When it was necessary to turn, he stopped, got out of the car and manually adjusted the wheel in the desired direction. The 500 m long route was completed in 40 minutes (including entering the garage).

Steering rods of Zhiguli cars become unusable for various reasons:

- Natural wear and tear. Recoil and detonation appear at 20-30 thousand kilometers, depending on conditions and driving style.

- Operation with torn hinge boots. Through the holes, water enters the unit, dust and sand penetrate. Corrosion and abrasion quickly damage the ball pin.

- Lack of lubrication leads to increased friction and accelerated wear. Before installing the part on the vehicle, you should check the presence of lubricant.

- Shaft deflection due to impact with a stone or other obstacle. If successful, the element can be removed and leveled by heating with a torch.

When the wear of all tips reaches a critical limit, the front wheels have large play in the horizontal plane. To drive straight, the driver must fully “take” the car. How to diagnose wear on steering rods and not confuse them with suspension defects:

- Park the car on a picturesque ditch or overpass and apply the “handbrake” to the brakes.

- Go down into the hole and carefully inspect the trapezoid, especially after hitting the bottom.

- Grasp the rod near the tip with your hand and twist it up and down. If you feel freedom of movement, replace the worn element. Repeat the operation on all loops.

The method of traction accumulation in diagnosis is of great importance. It is useless to rotate the lever around its own axis: this is its normal working stroke. If the regulator shows a slight play, it is considered that the loop is working correctly - this is the internal spring working.

Video: how to check the steering linkage of a Zhiguli

Malfunctions of the steering column of VAZ 2107

Given the simple design of the column, there are few options for malfunction. It is important to monitor its condition and promptly eliminate problems when they arise.

There are several main types of faults:

- Column creaking. The cause of the squeak may be wear of the column parts, deformation of the trim panels, or malfunction of the steering switch unit.

- Steering wheel play. There are probably two reasons for this. The first is that the steering wheel fastening nut has been loosened. Fixing this problem is easy. But if this is not done in time, the splines on the shaft will break and the steering wheel may turn, leaving the car uncontrollable. Another reason is wear of the steering gear worm gear. Then it is necessary to adjust the gearbox or repair it.

- Play in the plane of the steering wheel or column axis. This is a dangerous malfunction that appears when the elements of the mounting bracket or spline connections are worn (loose).

Loosening the nuts and bolts of the spline fasteners over time leads to the abrasion of the splines, causing the car to lose control. Therefore, the column play must be eliminated immediately.

Selecting new trapezoid parts

Since production of the VAZ 2107 car has been discontinued, finding original spare parts is becoming increasingly difficult. On the roads of the CIS countries, steering rods quite often become unusable, so the supply of “original” spare parts has long been exhausted. Recently, trapezoid sets have been supplied to the market by several well-known manufacturers:

A special feature of tie rod repair is that worn ends can be replaced one at a time. Few Zhiguli owners put on full sets due to a broken ball pin. As a result, the “seven” trapezoid is often assembled from spare parts from different manufacturers.

The quality of steering rods from these manufacturers is approximately the same, as evidenced by reviews from motorists on the forums. Therefore, choosing a new spare part comes down to the following 3 rules:

- Beware of fakes and do not buy spare parts from dubious outlets.

- Do not buy tie rods from unknown manufacturers at a bargain price.

- Do not confuse the left long tip with the right when changing parts of the trapezoid.

Purpose and necessary checks of the vehicle control system

The transmission of force to the rotary arms from the steering mechanism is carried out using rods, which are part of the so-called trapezoid. This node consists of:

- gearbox;

- long rod;

- pendulum lever;

- two long tips;

- two short tips;

- two clamping devices with tie clamps.

The main malfunctions of the control system in VAZ models. Controllability, comfort and safety of movement depend on the listed parts. Therefore, increased attention should be paid to monitoring their condition and the schedule of periodic inspections should not be violated. Some people prefer to trust service station technicians, but if you look into it, such an operation is quite doable at home. For this purpose, the presence of an inspection hole or overpass will be sufficient. Next we examine:

- condition of rubber boots;

- axial movement of fingers;

- presence of cracks;

- hinges for gaps;

- attaching the pendulum to the body.

Replacing the outer short tip

Since access to the outside of the trapezoid is possible from the wheel side, disassembly can be done without an inspection hole. What tools and materials will be needed:

- 13 and 22 mm keys;

- pliers;

- hammer;

- extractor - “glass” type of perforation;

- a ruler at least 20 cm long or a tape measure;

- wheel pullers - jack, wheel wrench, wheel wedge;

- rags, fabric gloves.

Also, before you begin, prepare a new cotter pin, WD-40 spray lubricant, and a wire brush to remove any dirt from the shaft.

Why is it customary to replace nozzles rather than repair them:

- High-quality factory parts are made non-separable; in a garage it is impossible to remove a worn rattle - the hinge cover is pressed tightly into the body.

- Homemade collapsible rods using a lathe are considered unreliable. The reason is the “lap” profile inside the body; under load, the ball axis can squeeze out the cover and jump out.

Preparatory stage

Before removing the nozzle, perform a number of preparatory steps:

- Secure the car to the platform and unscrew the desired wheel. For maximum access to the tip, turn the steering wheel left or right as far as it will go.

Take this opportunity to check the condition of the boots on the other tips. If you notice cracks, completely disassemble the trapezoid and install new silicone covers.

Disassembly instructions

Dismantling the old part and installing a new drill is carried out in the following order:

- Using a 13mm wrench, loosen the circlip nut closest to the wheel. Do not touch the second nut.

Some car enthusiasts, instead of measuring the length, count the turns when they unscrew the tip. This method is not suitable - the length of the threaded part on parts from different manufacturers may differ by 2-3 mm. I had to personally encounter this problem: after the replacement, the car began to climb to the right and “eat” the edge of the tire. The issue was resolved at a car service: the technician adjusted the wheel alignment angle.

If you can't find the extractor, try removing the pin from the flapper by hitting the pin with a hammer. Method two: Lower the wheel hub onto the block, thread the nut onto the pin threads, and hit it with a hammer through the wood spacer.

Disconnecting is not the best way to unmount a connection. Accidental rivet of the wire is possible, in addition, shocks are transmitted to the hub bearing. It is better to buy an inexpensive puller - it will come in handy with replacement hinges.

Video: how to change the tie rod end

Replacing steering tips on a VAZ-2107 with your own hands: how to do it right

Steering tips on a VAZ-2107 must be replaced if they fail or after a certain mileage. Usually the resource does not exceed 30-40 thousand km. Driving on poor-quality roads makes its own adjustments - inexpensive and non-original elements are destroyed much faster, squeaks and other sounds appear. Therefore, replacement of steering control elements is often required. This is quite easy to do.

Steering gear

On VAZ-2107 cars and other models of the “classic” series, a worm gear is used - it allows you to convert the rotation of the steering wheel into the translational movement of rods. If you suddenly notice that the play on the car has increased, this does not mean that the steering tips on the VAZ-2107 necessarily need to be replaced.

Very often the gearbox elements wear out and the adjusting bolt has to be tightened. To do this you need to perform the following manipulations:

- Place the car on a level surface and have an assistant drive. Without it, it will be difficult to cope with the work.

- Loosen the nut that secures the steering gear adjustment bolt.

- An assistant should rotate the steering wheel left and right by 10-20 degrees, no more. The faster he does this, the easier it will be for you to tighten the bolt.

- Using a wide flathead screwdriver, tighten the bolt until the free play of the steering wheel decreases.

- Hold the bolt with a screwdriver and tighten the nut.

Be sure to check the presence of oil in the gearbox housing: if it is not enough, add more. It is recommended to use TM-4 transmission oil.

Other causes of backlash

But if the play has changed insignificantly, it is recommended to check all other suspension and steering components. The reason that the free play of the steering wheel increases may be:

- Destruction of ball joints on suspension arms.

- Excessive wear of the silent blocks, which are located where the levers are attached to the body.

- Wear of VAZ-2107 steering tips. You can do the replacement very quickly with your own hands; it will be more difficult to adjust the camber and toe angles.

- Wheel bearing failure.

- Destruction of the pendulum arm located on the right side of the car.

Tip malfunctions

Therefore, before sinning on the faulty tips, you need to carefully check the condition of all other suspension elements. Play and extraneous knocking may appear due to the failure of the ball joint, and the tips in this case have nothing to do with it.

Ball joints can make squeaks even when the steering wheel is rotated, so be sure to conduct a full diagnosis before repairing. Sometimes it may only be necessary to replace the boot of the VAZ-2107 steering tip. If the rubber boot is torn or covered with cracks, but the hinge itself is not damaged, it is necessary to disassemble, wash the element and reassemble it with new lubricant.

Tools for repairs

In order to carry out repairs yourself, you will need the following tools:

- A set of wrenches, in particular, socket wrenches and 19mm sockets.

- Jack, shoes, reliable supports.

- Specially designed tip puller. It is possible to replace the steering end of a VAZ-2107 without a puller, but it turns out to be much more difficult.

- Pliers.

- Screwdrivers.

- WD-40 lubricant.

Be sure to have a good hammer and a mounting blade - with their help, it will be much easier to pull out the fingers of the tips of their holes in the steering knuckles.

Removing the tips

All work must be performed with the vehicle parked on a level surface and with wheel chocks under the rear wheels. It is also advisable to turn on first or reverse gear - this eliminates the possibility of rolling away when carrying out repairs. Almost identical manipulations must be performed when replacing the short steering end of the VAZ-2107 and the long rod. The design of the steering linkage has two short rods and one long rod.

The short ones can be adjusted in length - for this there are special crimp clamps into which the elements are screwed. To replace the entire rod assembly you will need to perform the following manipulations:

- Place a jack under the side to be repaired, lift the car and place it on a support.

- Remove the wheel from the side to be repaired.

- Straighten and pull out the cotter pins that are located in the fingers of the tips.

- Apply a generous amount of penetrating lubricant to all threaded connections.

- Using a 19mm wrench, unscrew all the end nuts.

- Install the puller and, by rotating its bolt, remove all the rod pins one by one.

There is nothing complicated, the main thing is to make repairs easier by treating all threaded connections with lubricant. The long rod connecting the pendulum arm to the gearbox bipod is removed in the same way. But its replacement is required extremely rarely.

Assembly of the unit

After removing the old rods, take a tape measure and measure their length. The problem is that you will have to adjust the wheel alignment - you won’t be able to do this yourself, it’s better to go to a service station and do diagnostics on a computer stand. After replacing the steering tips of a VAZ-2107, even if you have achieved the same length with the new elements, it is necessary to carry out diagnostics. Otherwise, when driving, tire wear will occur much faster.

Installation of new tips is carried out in the reverse order. Insert the ball pins into the steering knuckles and holes in the bipod, tighten the nuts and secure their position with cotter pins. It is advisable to purchase new cotter pins, as old ones are usually covered with a layer of dirt and rust.

Complete disassembly of the trapezoid

Removing all rods is practiced in two cases: when replacing complete levers or a set of anthers on hinges. The technology of work is similar to dismantling the outer toe, but is carried out in a different order:

- Carry out the preparatory stage - insert the machine into the hole, clean the hinges, lubricate and remove the cotter pins. There is no need to turn or remove the wheels.

- Using a 22mm wrench, unscrew the nuts securing the two side link ball studs without touching the clamp bolts.

Be sure to position your midsection correctly by leaning forward. After replacing, it is worth driving along a flat section of the road and observing the behavior of the car. If the car is driving sideways, go to a gas station to adjust the camber angles of the front wheels.

Video: replacing steering rods on a VAZ 2107

The operation of replacing tips or rod assemblies can hardly be called complex. Having a puller and a little experience, you can change the parts of the VAZ 2107 trapezoid in 2-3 hours. The main thing is not to confuse the right lever with the left one and install the middle part correctly. There is a reliable way to protect yourself from mistakes: before disassembling, take a photo of the position of the rods with your smartphone camera.

The pendulum on cars is called such a unit with the help of which both wheels rotate when the need arises. This is a type of lever that provides synchronous change in the angle of inclination of both front wheels. When you turn the steering wheel left or right, the wheels change direction accordingly. If there were no pendulum, the wheels would change direction asynchronously, which would lead to a number of unpleasant consequences. In this material we will look at how to replace the VAZ 2107 pendulum, where this part is located and how to determine its malfunction.

Tools you will need for your work

To replace steering rods on a VAZ 2107 with your own hands, you will need:

- jack;

- a special puller, the work can be done without it, but much longer and more difficult;

- a set of keys, including spanners;

- head;

- screwdrivers;

- pliers;

- lubricant;

- hammer.

The work can also be entrusted to car service specialists; as of October 13, 2020, the price is on average 750 rubles. But independent work will allow you to inspect and evaluate the condition of adjacent parts and mechanisms. But you can start installing new parts yourself only if the car owner has clearly understood the issue of how to repair this unit. More on this later in the text.

How to identify a faulty pendulum

The easiest way to determine if the lever is faulty is to listen to the impacts when driving on rough roads. You shouldn’t deliberately drive into a hole or run over a bump, so you can pull over to the side of the road and experiment. But this is not the only way to determine the malfunction of such an important part as the pendulum.

The second way to determine whether the VAZ 2107 pendulum arm is faulty is the presence of large play in the steering wheel. Determining it is quite simple, for which you need to turn the steering wheel in one direction and the other. But the most common case of pendulum failure is the presence of load when turning the steering wheel. But these factors do not always indicate that the swing arm is at fault. Malfunctions with such symptoms may include loosening of the bolts or overtightening of the adjusting nut. Therefore, before replacing the device, make sure that it is damaged. This can be done after disassembling it. The first sign of a part malfunction is the presence of defects in its constituent elements, so to determine the malfunction you will need to disassemble the mechanism.

Location of the pendulum on the VAZ 2107

This product is located on a VAZ 2107 car at the bottom of the engine compartment. You can see the swingarm by opening the hood and looking at the underside of the car from the passenger side. It is more convenient to disassemble or inspect the device from below from an inspection hole or on an overpass.

The bipod, which controls the rotation of the front wheels of the VAZ 2107, starts from the pendulum. The photo below shows a view of the pendulum lever on the VAZ 2107.

Removal and repair of the pendulum

To carry out the work, you will need to stock up on a standard set of tools and a steering rod puller, and then begin the work process:

- Initially, it is necessary to disconnect the two steering rod ball joints from the device.

- Using two “17” wrenches, you need to unscrew the fastenings of the pendulum arm. After unscrewing the bolts and nuts, pay attention to the position of the washers. When reassembling, these washers must be reinstalled in the same place. The photo below shows the location of bolted connections and washers.

- After removing the bolts, you can disassemble the product.

After removal of the product, it is replaced or repaired. Installing a new pendulum is the opposite of removing it. It is recommended to replace the pendulum only if it cannot be repaired. In frequent cases, the product can be repaired, which many motorists do on their own.

Repair of the mechanism is carried out in the following procedures:

- Secure the disassembled part in a vice.

- Using pliers, remove the cotter pin and unscrew the nut.

- Remove the washer located under the nut.

- Now you need to disassemble another washer, whose diameter is larger than the previous one. You can use a screwdriver for this.

- Remove the plastic bushing along with the O-ring.

- Now you can remove the bracket from the axis of the product.

- The second O-ring and the second bushing are removed.

- After this, the condition of the removed parts and the body of the device itself is inspected. It is recommended that after disassembling the unit, install new bushings from the repair kit. They're inexpensive, but once replaced, you won't have to remove the swingarm again any time soon. If there is the slightest defect in the case, the product must be replaced.

The product is assembled in the reverse order of removal, but initially all parts must be lubricated with Litol-24. This completes the replacement of such an important device on the VAZ 2107. After assembly, check the steering play. Pendulum arms with rolling bearings are also sold on the market today. There are several reviews about the reliability of this option. Everyone is told that a pendulum on bearings makes it easier to rotate the steering wheel, works several times longer than the factory one, but cannot be repaired. In the end, the choice is yours.

How to replace the steering gearbox on a VAZ 2104, VAZ 2105, VAZ 2107?

1) First of all, you will need to put the car on a viewing hole, or if you are not afraid, you can lift the front part of it with a jack and slip not very thick planks under the front wheels, and later lower the car onto them, in this regard, it will become even more above, but the work will not be very comfortable because, as they say, it’s up to you to decide what to choose.

Of course, if you put planks under the front wheels, we will tell you a couple of practical tips, and specifically, do not under any circumstances place bricks under the car so that it stands on them, since bricks (It seems that they are not strong) sometimes cannot stand loads in connection with this, they burst (In the best case) or break (In the worst case) and the car falls to the ground, in addition, it is recommended to slip something under the rear wheels so that the car will stop in place, and also for greater safety, raise the handbrake near the car and set it to speed so that it stands rigidly and does not roll anywhere!

Repair of the VAZ 2107 steering gear part 1

Replacing the steering gear

and shaft on my

VAZ

2104. It cannot be said that the old gearbox was already completely dead,...

Replacing rods on VAZ 2101-VAZ 2107

Note! Together, the rods are called “Trapezoid” for short, so in some cases it is more profitable to completely replace the trapezoid than just one part. Sometimes, replacing a trapezoid is cheaper than replacing the parts separately.

Our instructions show the replacement using the example of one side rod; the rest are replaced in the same way.

Removal

1) First remove the wheel from the side where you are going to replace it. (Found difficulties? – read the article: “Replacing a wheel on a VAZ”)

2) Next, using pliers, unclip the ball joint pin nut.

3) After the cotter pin is removed, use a 22mm wrench to unscrew the pin securing nut.

4) Now, taking a special puller in your hands, install it as shown in the photo below, and after installation, start tightening the nut present on the puller. The finger should come out of the fist lever.

Note! If you don't have a puller, take a hammer and give it a few sharp blows to the fist lever and continue hitting until the finger indicated by the red arrow comes out of the lever ear! (You need to hit the lever along its axis).

If you have difficulty removing the pin, try applying some penetrating lubricant like WD-40, it should help and make it easier to remove the part.

5) Then do exactly the same procedure for pressing out the pin, but now press out the inner joint pin, indicated by the red arrow.

6) After all operations are completed, remove the steering rod from the machine.

Installation

Installation of a new rod is carried out in the reverse order of removal.

Note! The new part must be installed exactly the same length as the old one, otherwise the wheel alignment will be disrupted!

It is recommended to adjust the wheel alignment of the car after installing new spare parts! (read details in the instructions: “Adjusting wheel toe”)

Replacement

Well, now let's proceed directly to the replacement procedure. The work cannot be called difficult, but without a certain set of tools you will not be able to achieve the desired result.

When there is no special puller

Therefore, you should have:

- Reliable jack;

- Balloon wrench;

- Pliers;

- Socket wrenches or open-end wrenches (the first option is better);

- Puller for tie rod ends;

- The Almighty WD40 Rust Remover;

- Hammer;

- Brush for working on metal.

Replacement process Is everything ready? Begin.

- Place the car on an overpass or inspection hole, install anti-roll bars under the wheels, engage the handbrake and gear. Safety comes first.

- Using a wheel wrench or a suitable socket with a long wrench, unscrew the wheel bolts, but do not completely unscrew them.

- Properly position the jack and lift the vehicle, lifting the wheels off the ground. To increase reliability and stability, it is better to place something like bricks, a stump or other similar support under the car. Having one jack is not enough; it is very dangerous.

- Now you can completely unscrew the bolts and remove the wheels.

- Turn the steering wheel to the side all the way, which will provide you with fairly comfortable access to the place of work.

- Using a metal brush, clean the threads of the tip, and then be sure to treat the area with a rust killer - WD40. Both threads should be processed - the thread where the tip is screwed into the rod and the thread on the finger.

- Wait a while for the product to react. After this, take pliers or pliers, with which you need to unpin the tie rod end connection.

- Using a spanner wrench, unscrew the fastening nuts of the damaged, failed tip. If problems arise when unscrewing, the fasteners do not want to come off, treat with a wedge again, wait and try again. Take a larger lever, which will make the task easier.

- After removing the nut, you need to remove the tip pin from the stand. This is where a tie rod end puller will come in handy. You can buy it or borrow it from friends. But many people don’t have such a puller. Therefore, craftsmen found a way out of this situation.

- To remove it you will need a hammer, physical strength and a pry bar.

- Screw the nut onto the tie rod end pin so that the pin does not stick out.

- Use the pry bar to rest against the protrusion of the stand and begin to pry the rod upwards.

- With precise straight blows using a hammer, begin to knock the tip up. The blows are applied at the junction.

- With this artisanal method of dismantling, the most important thing is your accuracy when striking. Hit as accurately as possible so as not to damage other suspension components of your VAZ 2109.

- When the finger is finally removed, you can proceed to further steps.

- Unscrew the lever from the steering rod. But before that, be sure to measure the screw-in distance of the tip. This way you can more accurately install the new element at the toe angles.

- Measuring the distance is often done by eye, relying on marks from the old tip. Apply a mark or simply use a ruler or tape measure.

- Unscrew your damaged end from the rod. Here you can already do everything manually.

Not difficult, but long In the process of replacing tie rod ends, many people relax after dismantling the old elements. In fact, reassembly is an equally important stage of repair, on which the overall result largely depends.

Maintenance and testing of the VAZ 2107 steering system

Features of the control system of the “seven” Having become a classic over many years, the seventh model of the “Zhiguli” continues to rack up kilometers and delight owners with its reliability and ease of operation. Finding any part for repair will not be difficult even for a complete “teapot”. And the technology for restoration work at home has been perfected by generations of car enthusiasts. If you ask experienced drivers where they started, every third person will say: with a Zhiguli. Yes, there will be unflattering reviews, but at the same time nostalgia will be noticeable in the eyes - everyone will remember some significant event associated with the “seven”. However, let’s not get distracted and consider the experience of servicing and repairing the control system, namely replacing steering rods on a VAZ 2107

.