Like any modern car, the Lada Priora is equipped with dozens of various sensors, the functioning of which determines the condition of the main vehicle systems. Diagnostics of the machine for errors allows you to detect all sensor faults in order to eliminate breakdowns. Now you will learn how Priora error codes are deciphered and how to independently diagnose the on-board computer (hereinafter referred to as BC).

Instrument panel of Lada Priora: general information on symbols

Domestic cars such as the Lada 2170 are extremely in demand among domestic consumers due to their low cost and budget maintenance.

Among the benefits, one can also highlight its disadvantages - the Priora’s tidy is not the most reliable element of the car, which necessitates frequent intervention in the electrical part of the car. The dashboards of cars from different years of manufacture are almost identical. The symbols on the board of the 2013 version differ little from their 1st and 2nd generation counterparts. Here are signs indicating identical faults and corresponding to similar indicators.

Priora dashboard indicators with interpretation

A separate category of indicators is mainly responsible for indicating the status of on-board systems and mechanisms. Such symbols do not indicate serious damage, they simply notify the driver.

The description and full explanation of the indicators looks like this.

| Visual Identification | Decoding |

| Fuel level indicator | Indicates the remaining gasoline in the fuel tank. When the supply is exhausted, the following sign lights up. |

| This indicator indicates that there are less than 10 liters of fuel left in the gas tank and the car needs to be refueled urgently. Initially, the red symbol of the gas station flashes, but when the fuel reaches 5-6 liters, it lights up constantly. | |

| On VAZ models, it indicates a low battery or a strong drop in voltage in the network. It usually appears after prolonged attempts to start the car in the cold. To fix it, just replace or charge the battery. | |

| The key against the background of the red car indicates that the immobilizer is turned on. This option is not available on 2008 models. Depending on the configuration, a green key may flash on the car’s dashboard. If the lamp blinks, the system is faulty. | |

| Standard turn signal activation indicators. The indicator lights light up for left or right turns respectively. If the indicator lights blink simultaneously, the hazard warning system is on (the red triangle lights up in parallel). | |

| A similar indicator lights up when the car is parked with the handbrake. It may also indicate a serious malfunction of the engine. | |

| The ABS system is not working correctly or the wheel is punctured. The system is present in cars optionally and is not directly related to the brake system. | |

| The red watering can is marked accordingly. The light indicates a critical drop in engine oil pressure. If the indicator goes out after the car warms up and the speed of the power plant is equalized, everything is in order. | |

| The green symbol indicates the activation of the side lights. | |

| The car's headlights are in long range mode. Lights up only when the mode is activated. | |

| Antifreeze temperature dial indicator | The indicator is installed on all machines without exception and displays the actual antifreeze temperature. |

Purpose of the temperature sensor on the pointer

The engine temperature gauge on the Priora is connected to a sensor that is built into the cooling system. It is this element that transmits information about the coolant temperature, which is displayed in a format understandable to the driver. Many people underestimate the purpose of such a device, and if it malfunctions, they are in no hurry to repair it.

And although the temperature gauge sensor does not affect the operation of the engine, it is a very important element that must always be in good working order and display correct information on the dashboard. Using this device, engine warming is controlled, which is necessary for the following purposes:

- Prevent the possibility of engine overheating, which can happen for various reasons: a malfunction of the cooling fan and insufficient amount of antifreeze in the system.

- For controlled warming of the engine to operating temperature, which is especially important in winter. It is strictly contraindicated to drive at high speeds when the engine is not warmed up to operating temperature.

When the engine heating meter on a Priora is faulty, this will not affect the operation of the engine in any way. Such a malfunction can only lead to the fact that if the engine temperature rises, the driver will not be able to react in a timely manner, which can cause serious consequences.

What do the icons on the Priora dashboard mean?

There is a separate group of icons indicating the presence of breakdowns and malfunctions within the vehicle’s on-board systems. The emblems are displayed in the space surrounding the main instruments. The following is a transcript of the signs with photo accompaniment.

| Icon | Decoding |

| If the car with the key is flashing, this indicates a malfunction or lack of response from the immobilizer. To fix the problem you need to check the block. | |

| An exclamation mark surrounded by brackets blinks on the dashboard, indicating a malfunction in the brake system or ABS. A similar indicator located slightly higher may indicate an incorrectly pumped brake system. | |

| The electric power steering is faulty or defects have been detected in the operation of the mechanism. Mostly installed on cars after 2011 model year. | |

| Failure in the wiring or units responsible for controlling the airbags. If the icon lights up after starting the engine, the specified element may not work under shock load. | |

| Seat belts are not fastened. Can also be red. At the same time, it is accompanied by a sound signal. | |

| The passenger airbag is not activated or is faulty. Usually lights up when the engine starts. | |

| If the indicator blinks constantly, this indicates a battery failure or critical discharge. | |

| An urgent check of all engine systems is necessary - a critical malfunction has been detected. |

The reasons why these icons may light up always require driver intervention. Ignoring machine signals can cause serious damage.

Depending on the year of manufacture and configuration, the interpretation of the instrument panel indicators may differ. The exact definition can be found in the vehicle's service manual.

Priora car on-board computer: functions

In fact, the device only transmits the data owned by the electronic control unit. Therefore, all bookmakers for Priora broadcast the same data. Everything interacts: ECU, voice, oscilloscope. The display shows the following data as standard:

- navigation, router;

- watch with date display;

- average fuel consumption per hour/per point in time;

- total/daily mileage;

- remaining fuel (+ how many kilometers you can still travel);

- voltmeter;

- engine operating time;

- ambient/antifreeze temperature;

- precise speed (digital speedometer), average speed;

- acceleration to 100 km/h (time);

- digital odometer.

Additionally, he can report on maintenance based on mileage - changing oil, filters, spark plugs, belts. In addition to counting the mileage to these checkpoints, it displays information from all sensors when the driver enters a certain tab. There is one thoughtful function - it can warn that the lights are not turned off after turning off the ignition.

How to enable autotesting on Priora

Self-diagnosis of the VAZ Priora dashboard is necessary to be able to detect hidden problems or defects in on-board systems. To complete the procedure, you will need to perform a certain sequence of actions.

- Get into the car and insert the key into the ignition lock.

- Press and hold the daily mileage reset button.

- At the same time, turn on the car's ignition.

- If everything is done correctly, the instrument arrows will make several full revolutions and return back. All indicators will also flash.

The problem will be identified if any signal does not respond to manipulation.

How to fix the problem

There are several possible ways to resolve this issue. If one solution does not suit you, move on to the next one. We will also look at what to do if none of the options for eliminating error 4 helps.

Method No. 1 (Software update)

Trying to find out what the essence of the problem might be, many initially undertake to analyze the correct operation of the receiver and its unique ID (as a rule, it is already present on the access card, and if there is no smart card, it is integrated into the system itself). Here it becomes clear that the receiver is not able to recognize its own ID number, which, in turn, makes subsequent decoding of the channel impossible. Accordingly, if error number 4 appears, then you should understand the features of ID recovery.

- If error 4 appears on tricolor TV, you need to go to channel 333. This channel is specially designed for performing service actions. It is after the transition to it that the procedure for updating the standard software is carried out.

- Then check for updates. The receiver will do this on its own. When a new software version is detected, it will prompt the user to confirm the installation. After completing this action, error 4 tricolor should disappear.

What to do next? After the receiver accepts consent, it will initially carry out the installation from the satellite, and then, after reaching the 50% mark on the progress scale, it will begin installing the downloaded files into the device’s memory. This will continue until the progress bar is filled to 100 percent.

Note! If you are connected to a satellite and you have approved the installation of the updated version, do not turn off the receiver under any circumstances! Otherwise, you will not be able to completely fix the problem. In some cases, the receiver no longer displays channels due to insufficient files in the software package or due to their corruption

After all the necessary files have been downloaded and installed, the receiver will reboot itself for the updated files to take effect. After a reboot, the system should completely resolve the problem.

In the case of some models, installation of a software update for the module is additionally required. Remember that its update occurs immediately after the main firmware is loaded into the system. The module updates much faster. Mandatory installation of these files is not always required - much depends on the behavior of the system after the main firmware update is completed. If error 4 disappears, we don’t touch anything else. When saving it, we try to additionally update the module.

Important! Sometimes a software update may not help, since there is a USB flash drive in the slot. Remove it and reboot the receiver, it should help

Method number 2 (Reset settings)

Sometimes eliminating the fourth error requires resetting the receiver to factory settings and searching for channels again. This is done very simply:

- Press the "Menu" button on your receiver's remote control.

- Select "Settings".

- Then scroll to the very end to the “About the receiver” section, “Reset settings”.

After you reset to standard settings, search for Tricolor TV channels again, and in order to watch channels with a broadcast shift relative to Moscow of +2 (+3) hours, select the “Ural” region.

Method number 3 (Contact support)

If the previous two methods of solving the problem did not help you, then you can contact Tricolor technical support. But before you call, collect the following information:

- ID number of the smart card;

- The number of your agreement with the Tricolor company;

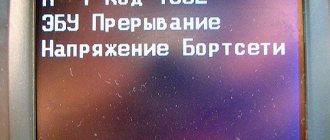

Error codes on the Priora dashboard

When entering self-test mode, combinations of numbers and letters may appear on the display indicating the part of the circuit where a malfunction is detected.

Usually, after entering the service mode, one or more numbers appear on the device:

- 2 – a critical overvoltage was detected in the on-board network, caused by a short circuit or breakdown of the unit;

- 3 – an error has been detected in the fuel level sensor, a circuit break is possible;

- 4 – there is overheating of the cooling system, or the corresponding sensor is broken;

- 5 – the thermometer that determines the temperature outside is broken or there is an open circuit in versions before 2012, mounted optionally;

- 6 – the engine has boiled, you need to wait for cooling or check the serviceability of the sensors;

- 7 – the oil pressure in the crankcase of the power plant is too low, the sump may leak or the lubricant level has dropped significantly;

- 8 – breakdown of the brake line or units of the corresponding system;

- 9 – the battery is discharged or the element is faulty; it can also appear after the car has been idle for a long time in the cold;

- E – the firmware has failed or there is a critical error in the EEPROM data packet.

Main power fuse block

When you set the clock to the actual time for the very first time, and use your knowledge to figure out how to set everything yourself, then from now on you will be able to quickly set the clock in absolutely any situation when it goes wrong, and sometimes this happens at the most inopportune moment. You can also verify the serviceability of the installed LEDs using a multimeter in tester mode, bringing the probes to the LED according to the polarity of the red probe plus.

When do you need dashboard repair or replacement?

The Priora tidy does not have a large number of parts that are subject to frequent breakdowns. Typically, repair of the indicator unit comes down to replacing light bulbs and individual elements of the device. Users resort to replacing the board only when there is a malfunction of the contact group, connectors, or the board is damaged.

In case of serious damage (major short circuit leading to burnout of the main structural elements), repair may not be cost-effective. The cost of labor and materials often exceeds the price of a new module.

Possible malfunctions and ways to eliminate them

When operating a vehicle, individual components of the instrument panel may fail. Among the most common breakdowns are factors.

- Burnt out contact of one of the indicator lamps. Usually resolved by replacing the light bulb.

- Failure of the contact group can be eliminated by completely replacing the module - resoldering the part is not economically profitable.

- Malfunction of arrow indicators. It can be fixed by replacing the block.

Troubleshooting

After finding out the reason why the Priora or Kalina does not drive, it is necessary to correct the situation. If the coding indicates a break in the power supply to a structural element, you need to completely check the entire line and the device itself. It is better to do this by replacing parts with known good ones (new ones). It is also taken into account that standard connectors may become loose or fail over time. In such a situation, the computer will show errors even with a 100% working network. To detect such “surprises”, it is necessary to check all terminals and connections for oxidation, broken contacts or loosening - the elements must fit tightly in the sockets, without play.

Note! If you are unsure of your own abilities, the motorist is strongly recommended to seek help from a specialized workshop or a qualified technician.

If you have the necessary equipment, you can determine whether 8 or 16 valves are broken in a Lada Priora car yourself. Due to the simple design of the machine, repairs do not require the user to have in-depth knowledge of mechanics, electronics or other sciences.

Source

How to dismantle and install the Priora dashboard

To dismantle the module, you will need to prepare two screwdrivers – a Phillips and a flathead one. A complete replacement of the Priora tidy looks like this.

- Disconnect the wires from the battery.

- Pull the steering column all the way down and remove the steering wheel from the pin.

- You will also need to remove the cover covering the fuse box.

- Unscrew the 4 bolts holding the instrument panel and remove it.

- Loosen the two mounting bolts of the trim panel and remove it.

- Disconnect the wiring harnesses from the contact groups and completely remove the board from the machine.

Installation is performed in reverse order.

Specialization : Graduated from the State Automobile University, worked for 20 years at GAZ-56, now I drive a Zhiguli.

Source

Prior error codes on the dashboard

Using the built-in controller, drivers can identify the main error codes for Priors 8 and 16 valves on their own.

The procedure is carried out using a built-in computer or a connected device. Almost all modern cars are equipped with a system of various sensors that monitor the condition of automotive components. The bottom line is that the functionality of many working units directly depends on the correct functioning of the existing sensors. On the other hand, turning off some indicators may not affect the operation and movement of the car, and malfunctions are detected much later, when the negative consequences of deactivating the sensors appear. Symptoms of the indicators turning off include unstable engine operation, excessive fuel consumption, and excessive wear of parts.

How is self-diagnosis performed?

We have sorted out the main errors on the Priora, now it’s worth finding out how self-diagnosis is performed. The VAZ 2170 with 16 valves has a special controller with which diagnostics are performed. If you have an on-board computer installed, then diagnostics are performed on it. There is also special equipment that allows for a more in-depth check of Priora 16 class systems.

Self-diagnosis using BC

The owner can identify the main error codes of Priora 8 and 16 valves using the built-in controller and on-board computer (BC), without resorting to the services of car service diagnosticians. To do this, you must activate the vehicle testing option. The arrows on the instrument panel move to the maximum possible position. Further manipulations are performed in the following sequence:

- The ignition is turned off and the daily mileage reset button is activated. Then the ignition is turned on again with the button held down;

- After this, all the icons on the instrument panel should light up, and the arrows of the control devices should begin to move from zero to maximum values. This behavior indicates the normal functioning of all sensors;

- On the right steering wheel switch there is a key for selecting BC functions. After pressing it, information about the software category will appear on the display;

- You should press this button again, combinations of problems will be displayed on the monitor. If necessary, error information is also reset here. To do this, hold down the mileage reset button for a few seconds.

Practical guide

The car is equipped with an on-board computer, information from which is displayed on a liquid crystal display located on the instrument panel. The on-board computer control buttons are located on the right steering column switch.

Right steering column switch : 1 — RESET button; 2 — key for switching display modes (the upper part of the key is switching back, the lower part of the key is switching forward)

Code meanings for self-diagnosis

Using the on-board computer, the driver can determine the following faults:

- Code “ 2

” – excessive voltage in the on-board network. To eliminate it, you need to check the main electrical circuits; - The number “ 3

” indicates a malfunction of the fuel control indicator; - «4

» – problems with the refrigerant temperature sensor; - The number “ 5

” means incorrect operation of the environmental indicator; - Code “ 6

” means engine overheating; - «7

» – critical lubricant pressure; - The number “ 8

” indicates a malfunction in the brake system; - «9

» – signals that the battery is low; - The " E

" symbol indicates a problem with the packet data.

It is worth noting that if the BC options switch key is inactive for more than 10 seconds, the instrument panel will return to normal operation.

Voltmeter on Priora instead of a button

driving time hour, min, is defined as the time during which the engine has been running since the last reset 0 00-99 59 resolution 1 minute; To reset, you must hold the Reset key for 3 seconds. The instrument cluster with an on-board computer is designed for installation on the following cars: Lada Priora VAZ 2170, VAZ 2171, VAZ 2172, Lada Kalina VAZ 1118, VAZ 1119, VAZ 1117, VAZ 2110, VAZ 2111, VAZ 2112 with a new panel.

Checking with a plug-in tester

More accurate and comprehensive diagnostics can be performed using a connected computer or a special tester. However, the data displayed on the screen is alphanumeric. The letters have the following meaning:

- P

– errors in the operation of the electronic systems of the power unit; - C

– problems with the functioning of the chassis; - B

– electronic malfunctions in the cabin; - U

– joint system errors.

In addition, the number 0 means OBD code 2, numbers 1 and 2 indicate the enterprise code, and 3 is the backup password.

Basic ignition system

(the letter P precedes the digital designation):

- 0300

– no spark in the cylinders of 16 valves; - 0326

– defect or short circuit in the knock indicator circuit; - 0337

– difference of the crankshaft controller to ground; - 0343

– high level in the headlight sensor circuit 0342 – a similar low indicator; - 0422

– signaling device malfunction; - 0444, 0445

– failure of the adsorber valve; - 0480, 0481

– problems with the fan assembly.

Fuel-air system

(the letter P is located before the numbers):

- 0030

– open circuit between the oxygen indicator and the exhaust gas converter; - 0116

– problems with thermal control of the cooling fluid; - 0102

– error in the air flow control circuit; - 0201, 0202, 0203, 0204

– break in the injector wiring; - 0217

– overheating of the power unit; - 0172

– excess amount of air,

0171

– gasoline, in the fuel mixture; - 0230

– malfunction of the electric fuel pump; - 0266 0269, 0270, 0272, 0274

– problems with injector drivers.

In principle, diagnostics using BC makes it possible to identify the main faults. Basic error codes for Priora 8 and 16 valves using a plug-in tester provide significantly more information. To understand it, you should study the decoding of indicators, which is not so difficult.

Like any modern foreign car, the Lada Priora has many different sensors installed. The condition of important vehicle systems depends on their correct operation. The problem is that if some sensors fail, the Priora can continue to move. Faults of this kind can lead to increased fuel consumption, unstable engine operation, and increased wear of parts, but the car will drive, and you will only find out about the fault when it means you have to make expensive repairs.

In order not to go into the engine compartment with a multimeter, the Priora has a controller that allows you to check faults using a special tester, a plug-in or built-in on-board computer. In order to diagnose the systems, just press 2 buttons and look at the error codes.

Voltmeter selection

Of the domestic automobile voltmeters on the market, you can only find devices from UAZ and VAZ 2107. Both of them are poorly suited for installation in a Priora. The first one has a rough appearance and is more suitable for installation on a tank than in the interior of a modern car. The second does not have an external housing, and its dimensions do not allow the device to be neatly placed on the Priora panel. Therefore, it is better to find special tuned devices or use a digital car voltmeter made in China, inserting it into a button or instead of the dial of a Priora watch. Such devices are distinguished by good accuracy, low price and attractive appearance of the digital panel.

- Specifications

- Controls

- Dashboard

- On-board computer

- Lighting engineering

- Interior heater

- Air conditioner

- Circuit breakers

- Replacing lamps

- Passport details

The LCD of the on-board computer is located on the dashboard and contains three lines:

- the top line displays the total/daily mileage counter;

- The middle line displays the functions of the on-board computer, the display of which is carried out sequentially, at the choice of the driver:

- The bottom line displays the icon for the selected mode.

New Lada: Lada Priora Sedan 2022 - buy a Lada Priora sedan in St. Petersburg, prices for a new Lada car from the official KarsAuto dealer. To switch between the bottom line display modes, use the keys on the steering column wiper switch: the keys (position 2) located at the end of the switch switch the functions " around the ring forward and backward; the “Reset” key (position 1), located at the bottom of the switch, resets the values to “zero”.

The top line readings (total/daily mileage) are switched by a button located on the right side of the dashboard (under the fuel gauge). If the daily mileage counter is displayed, then to reset it, you must press and hold the button for 3 seconds.

The procedure for setting the clock on the Lada Priora:

- To switch from the current time indication mode to the installation mode, you must press and hold the “Reset” key for more than 3 seconds, while the hours and minutes will begin to flicker;

- The minutes are set by pressing the “ring forward shift” key located at the end of the steering column wiper switch;

- The clock is set by pressing the “ring back shift” key located at the end of the steering column wiper switch;

- When you press the key once, the minutes/hours value increases by “1”; to change the values faster, you need to press and hold the key;

- When setting the minutes, the seconds counter is reset to zero (setting the hour counter does not affect the seconds counter);

- To return from the installation mode to the indication mode, you must briefly press the “Reset” key or, in the clock setting mode, do not press any key for 1 minute.

Detailed information about the displayed functions (their ranges) of the Lada-Priora on-board computer:

- current time (hour, min) - 0:00-23:59 (resolution 1 minute);

- outside air temperature (°C) - -40°C.. 70°C; (resolution 1°C);

- driving time (hour, min), defined as the time during which the engine has been running since the last reset - 0:00-99:59 (resolution 1 minute; to reset, you must hold the “Reset” key for 3 seconds)

- average fuel consumption (l/100km) - 0.0-19.9 (resolution 0.1l/100km; after zeroing, the first 500 meters of the distance traveled are not indicated);

- instantaneous fuel consumption (l/100km) - 0.0-19.9 (not displayed if the speed is less than 1 km/h);

- approximate remaining power reserve (km) - 999-30 (resolution 5 km);

- average car speed (km/h) - 0-250 (resolution 1 km/h; after zeroing, the first 500 meters are not displayed);

- amount of fuel consumed (l) - 0-9999 (resolution 1 l; to reset, you must hold the “Reset” key for 3 seconds).

Diagnostics using the built-in BC

To view the error codes, you need to find the daily mileage reset button on the dashboard, press it and, holding it, turn the ignition key. The self-diagnosis mode will turn on. All arrows on the instruments should move from minimum to maximum values and back, and all positions on the LCD display should light up. You need to look: if any position does not light up or the arrow on any device does not move, then you should check the corresponding sensors, their networks or display for malfunctions.

Priora on-board computer

In the same mode, press any button for switching modes of the built-in BC 2 times, after which digital codes may appear on the liquid crystal display:

- 2 - very strong voltage in the BS;

- 3 - errors in the fuel level sensor system in the gas tank;

- 4 - error in the coolant temperature sensor system;

- 5 - error in the air temperature sensor system outside the car;

- 6 — motor overheating;

- 7 — emergency low oil pressure;

- 8 - malfunctions in the brake system;

- 9 - battery is low;

- E - error in the data packet stored in the EEPROM.

Many drivers ask how to reset error codes on a Lada Priora. Perhaps their built-in BC is faulty, since a working on-board computer automatically exits the diagnostic mode after 30 seconds if you do not press any control buttons.

Speedometer adjustment with stop

The procedure for adjusting the speedometer is quite simple; even a novice car enthusiast can do it. To achieve a positive result, you will need a small set of available materials, including a marker, a pencil, thin scissors or, better yet, tweezers, and most importantly, perseverance and desire.

Today, two types of speedometers are known: both with a stop and without, each of which has its own adjustment principle. At the very beginning of work, you should determine the type of speedometer installed in your car; to do this, you need to move the needle beyond the 220 km/h mark; if you can’t move it further, you can conclude that the device has a stop.

Now you can proceed to the procedure for adjusting the speedometer. To do this, holding the instrument arrow in position all the way, you need to make a mark on the glass of the dashboard with a marker (we do not recommend putting marks on the scale, since then it will be impossible to wipe them off).

After this, remove the arrow and snap the dashboard glass into place. Rotate the shaft by first removing the nail on the latch.

After this procedure, you should return the speedometer needle to its place, but do not install it tightly. Remember: everything should be done easily, without effort. The arrow should rotate freely, as soon as it reaches the mark made with a marker, try to fix it as tightly as possible. Make sure that it matches the mark; if it does not, the procedure should be repeated again. Having achieved the result, you can snap the nail, lowering the arrow.

Checking using a connected computer or tester

Driver Information Panel

Checking system malfunctions using connected devices gives more accurate results, but at the same time requires deciphering special codes. For example, the monitor displays code p0441 or p0130 or error p0422. Oh, these car manufacturers, in human language they could write “replace the oxygen sensor” instead of P0130 or “check the canister valve” instead of P0441. But nothing can be done, the Lada Priora is also intended for export, so it is easier to write p0441 in the program than to give explanations in Russian, Kazakh, Arabic, Armenian and 10 other languages. And then attach special tables that indicate the meaning of certain codes. Just look at them and everything will become clear. But these tables are not included with the operating instructions. Either way, you can check them out below.

All fault codes for Lada Priora car systems consist of 5 characters. Here is a breakdown of Prior's errors.

The Latin letter comes first:

- P - error in the electronic systems of the motor;

- C - error in the electronic systems of the chassis;

- B - error in interior electronics;

- U is an error in the joint operation of different systems.

- 0 - OBD-2 code;

- 1 - enterprise code;

- 2 - enterprise code;

- 3 - reserve code.

The system indicates an error

The next digit indicates the system in which the malfunction was found:

- 0 — exhaust;

- 1, 2 — fuel and air supply system;

- 3 - ignition;

- 4 - additional control;

- 5 — idle system;

- 6 - ESC;

- 7, 8 - transmission.

The last 2 digits indicate the serial number of the fault.

Decoding errors

Each error code consists of five characters. The last two characters indicate the serial number of the specific error.

The first character changes based on the fault system in the car:

- P – malfunctions in the operation of the power plant or defects in the operation of the gearbox.

- U – disruption of interaction between system units.

- B – electric lifts, airbag and other defects in body systems.

- C – faults associated with the EUR.

- 3 – reserve;

- 1 and 2 – manufacturer codes;

- 0 – general code for on-board diagnostics.

The third character indicates the nature of the malfunction:

- 1 and 2 – inform about the appearance of defects in the operation of the fuel system or malfunctions during the air supply;

- 3 – breakdown in the ignition system;

- 4 – additional control;

- 5 – incorrectly operating components in idle mode;

- 6 – electronic unit, as well as its circuits;

- 7, 8 – gearbox malfunction.

Deciphering faults in the fuel and air systems

- P0030 - the oxygen sensor heater wire to the exhaust gas converter has broken;

- P0031 - the same electrical wire has shorted to ground;

- P0032 - the same wire has shorted to the on-board network (BS);

- P0036 - the wiring of the oxygen sensor heater is broken, after the converter;

- P0037 - the same wiring has shorted to ground;

- P0038 - it has shorted to BS;

- P0102 - weak signal in the mass air flow sensor network;

- P0103 - very strong signal in the network of this device;

- P0112 - weak signal in the air temperature sensor network;

- P0113 - very strong signal in the network of the same device;

- P0116 - antifreeze temperature sensor signal is out of operating range;

- P0117 - poor signal from the antifreeze temperature sensor network;

- P0118 - very strong signal from the antifreeze temperature sensor;

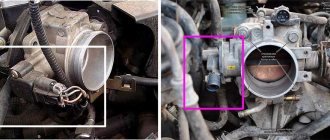

P0122 - poor signal in the throttle position sensor circuit;

- P0123 - very strong signal in the same circuit;

- P0130 - the oxygen sensor before the converter does not work;

- P0131 - weak outgoing signal on the network of this device;

- P0132 - signal too strong on the same network;

- P0133 - slow response to changes in mixture quality in the network of the same device;

- P0134 - oxygen sensor circuit inactive;

- P0136 - the oxygen sensor after the converter is broken;

- P0137 - poor signal in the circuit of this device;

- P0138 - signal too strong in the same circuit;

- P0140 - the same sensor circuit is inactive;

- P0141 - the oxygen sensor heater after the converter is broken;

- P0171 - there is a lot of air in the fuel mixture;

- P0172 - there is a lot of gasoline in the fuel mixture;

- P0201 - injector wire No. 1 is broken;

- P0202 - injector wire No. 2 is broken;

- P0203 - injector wire No. 3 is broken;

- P0204 - injector wire No. 4 is broken;

- P0217 - engine overheated;

- P0230 - failure in the electric fuel pump relay network;

Here we are looking for an electrical problem that has arisen.P0261 - the injector circuit of cylinder No. 1 has shorted to ground;

- P0263 - injector driver No. 1 does not work;

- P0264 - the injector circuit of cylinder No. 2 has shorted to ground;

- P0266 - injector driver No. 2 does not work;

- P0267 - injector circuit No. 3 has shorted to ground;

- P0269 - injector driver No. 3 does not work;

- P0270 - injector circuit No. 4 has shorted to ground;

- P0262 - the injector circuit of cylinder No. 1 is shorted to the BS;

- P0265 - injector circuit No. 2 is shorted to BS;

- P0268 - injector circuit No. 3 is shorted to BS;

- P0271 - injector circuit No. 4 is shorted to BS;

- P0272 - injector driver No. 4 does not work.

Malfunctions of auxiliary systems and ignition

P0301 - no spark in cylinder No. 1;

Camshaft sensor location

P0337 - crankshaft sensor shorted to ground;