Print this article Font size 16

Replacing the rear wheel bearing on a VAZ 2110 is not as difficult as it might seem at first glance. This process is not required very often. The service life of an element is usually about 100 thousand kilometers, which is the minimum.

Alas, our roads do not allow us to count on such a long bearing life, so the actual terms turn out to be lower than those stated by the manufacturer.

Signs of need for replacement and diagnosis

In addition to the hum in the area of the front wheel, other signs may indicate the need to replace the bearing on the VAZ 2110. Even inexperienced drivers will notice deviations from the norm while the car is moving. The change in the trajectory of traffic around turns will be clearly visible. Due to the uneven ride, the front of the car will sway from side to side.

To further check the condition of the wheel bearing, release the steering wheel on a level road. If the car skids to one side or the other, the part is worn out and requires replacement. You should not delay such repairs, since if the bearing is destroyed while driving at high speed, you will get an emergency situation and an uncontrolled skid, which can lead to an accident.

Bearings for the secondary shaft of the VAZ 2110, 2111, 2112 gearbox

Front bearing of the secondary shaft of the gearbox

Accepted designations:

- For VAZ - 21080-1701180-01 or 21080-1701180-02 or 21080-1701180-03 or 21080-1701180-04;

- According to the GPZ classification - 6-42305AEUSH1, 6-42305AE1USH1, V26-42305AEMSH1, 6-42305AE1USH1.

Dimensions of the front bearing 21080-1701180-01 (6-42305) of the secondary shaft of the gearbox:

- Outer diameter D - 62 mm;

- Inner diameter d - 25 mm;

- Thickness B - 17 mm.

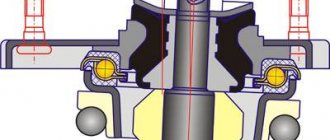

Installation location of the front bearing 21080-1701180-01 (6-42305) of the secondary shaft of the VAZ 2110, 2111, 2112 gearbox:

Rear gearbox secondary shaft bearing

Accepted designations:

- For VAZ - 21080-1701033-00 or 21080-1701033-01 or 21080-1701033-02 or 21080-1701033-03;

Dimensions of the rear bearing 21080-1701033-00 of the secondary shaft of the gearbox:

- Outer diameter D - 62 mm;

- Inner diameter d - 25 mm;

- Thickness B - 17 mm.

Installation location of the rear bearing 21080-1701033-00 of the secondary shaft of the VAZ 2110, 2111, 2112 gearbox:

How to replace the front wheel bearing

Before starting repairs, it is better to put the car in 1st gear and install small supports under the wheels. For more comfortable work, you will need an inspection hole, since it is not easy to get to some of the mechanism’s fastenings. From the tool you need to prepare:

- A puller to remove the bearing itself from the assembly.

- A cut of a pipe of a certain diameter, with the help of which the hub will be knocked out.

- Socket wrenches for 17 and 19.

- 30mm head with a good wrench.

Don't forget to purchase new bearings from the store. It is better to give preference to original spare parts that meet all quality standards.

Methods and options

Let's start the preparatory work. They are necessary in any situation.

- Slightly press out the wheel bolts.

- Using a 30 mm wrench, unscrew the bearing nut. For alloy wheels, you will need to completely remove the front wheel. Press out the wheel bolt to gain access to the caliper

- We press the caliper using a screwdriver and unscrew it from the front knuckle. Using a screwdriver we press the caliper and remove it

- Next, remove the brake disc from the hub.

Further replacement work can take place in several ways. Each of them has its own advantages and disadvantages. Choose the one that is best for you based on the availability of the necessary equipment and tools.

- Replacing the bearing without dismantling the steering knuckle. Its advantage is that we do not need to remove the camber adjustment bolt. But at the same time, the process itself will not be entirely convenient, and you cannot do without a good inspection hole. To knock out the hub and remove the bearing itself, you will also have to put in more effort. This method is often chosen by experienced mechanics to save some time. It requires good practical skills.

- The second method is more convenient and is suitable even for beginners. Unlike the first, the camber adjustment will be disrupted and after replacing the front hub bearing, additional adjustment will be required. We make notches for further camber adjustment

- The third method will take you the most time; it involves completely dismantling the front strut and replacing the bearing using a vice. To do this, you must first unpress the steering tip and remove the bolts securing the mechanism to the body.

We will dwell in more detail on the second method, since it is best suited for novice car enthusiasts:

- remove the steering knuckle by first unscrewing the two bolts on the stand and two bolts securing the lower ball joint; remove the steering knuckle by unscrewing the bolts

- using a pipe of the required diameter, we knock out the hub itself from the bearing; We knock out the bearing with a pipe of the appropriate diameter

- remove the bearing using a vice;

- We clean the seat from dirt and old grease;

- press in the bearing and secure the retaining ring; press in the bearing and install the retaining ring

- We fix the steering knuckle together with the new part on the hub;

- Further assembly is carried out in reverse order.

How to replace (video example)

Despite some difficulties, replacing a wheel bearing can be done without outside help. The main thing is to have a good inspection hole and the necessary tools. If everything is done according to technology, such repairs will take very little time.

How to change the rear wheel bearing on a VAZ. First, let's prepare for repairs

We will prepare the car, as well as the tools according to the list:

- Jack;

- A driver or pipe to increase the torsional moment;

- Wrench 30, better with a head;

- A set of other keys;

- Wheel hub puller with claws (to remove the hub);

- Vise;

- Hammer and chisel;

- Round nose pliers;

- Torque wrench.

Now check out the hub design:

1 – rear axle; 2- hub body; 3- protective casing; 4 – lock pin. ; 5 – bearing; 6 – washer; 7 – nut; 8,9 – protective cap with gasket.

Place the car on a level surface, provide light, and install wheel chocks. Next, we put the first gear, and if desired, the parking brake, now we proceed to operations.

Replacement procedure

Please note that the hub nut is tightened very tightly and is difficult to budge. To make this task easier, you can use a metal pipe as a lever. A chisel and pry bar may also come in handy - it's best to keep them nearby. It is very good if an experienced motorist can help you replace this element yourself for the first time.

This procedure is performed in the following order. First of all, the car should be placed in a garage equipped with an inspection hole. If this is not possible, then you need to find a flat area for repair work. Then use the gearshift lever to engage first gear, and place wheel chocks under the front wheels (ordinary bricks will also do). Having done this, use a balloon wrench to slightly loosen the wheel bolts and lift the side on which the wheel bearing will be changed using a jack.

Then the mounting bolts are unscrewed completely and the wheel is removed from the axle. The guide pins are unscrewed and the brake drum is removed.

If you can’t do this right away, you should take a hammer and, applying a small plank to the drum, tap it around the circumference.

If tapping does not produce results, you can try screwing the pins into place - sometimes the drum comes off after this. If all methods are ineffective, the part must be dismantled using a puller, but there is a serious risk of damage. If this happens, the brake drum will also need to be replaced with a new one.

The hub nut is unscrewed using a socket wrench and (if necessary) a metal pipe.

The hub nut is removed from the axle using a puller

You can try to remove the hub without a puller. To do this, you need to put the removed wheel back in place, and then pull it sharply (but you don’t need to be too zealous, otherwise the car will fall off the jack)

Design features

Fundamental bearing tolerances are designated by the letters lb L. A small letter l is used for the outer race. The letter L is used to mark the small ring. The outer ring of a bearing of the sixth accuracy class is designated l6 (el 6).

The marking of 2110 roller bearings is described by GOST 3189. The marking contains letters and numbers. The designation encodes the basic characteristics of the product.

Failure to maintain alignment changes the motion of the rolling elements. The quality properties of roller bearings are reduced. The axes of the installation locations require mandatory adjustment.

Bearing 2110 is a support for the rotating mechanism. Rolling elements - short or long rollers. The rolling elements are screwed into the cages. The composition includes inner and outer rings.

The spherical roller 2110 improves the technical properties of the bearing. Roller bearings can be used in cases of significant and undistributed radial stresses. The geometry of the inner plane of the outer ring can compensate for the lack of alignment.

The outer plane of the small ring and the outer one from the inside also have running tracks. During activity, rollers move in the raceways. The work is accompanied by constant friction.

Additional design features are present in products with short rollers. They perform poorly at high speeds. Plus it has increased load capacity. Technical flaw - inability to perceive longitudinal load.

How to properly remove a bearing

Assembly dismantling procedure:

- We put the vehicle on the hand parking brake, set the gearbox to first speed, and wedge the vehicle wheels using the shoes.

- Remove the cap from the hub.

- Using a 30mm wrench, unscrew the hub nut.

- Using a wheel wrench, remove the disc with the tire and the brake system caliper, without damaging the hose of the brake system itself.

- We press out the hub.

- Using an open-end wrench set to “19”, unscrew the fastening of the ball joint, dismantle the locking ring and remove the pin with a puller.

- We press out the front wheel bearing of the VAZ 2110.

- We clean the inner surface of the mechanism from the remains of the previous lubricant and metal shavings.

- We visually inspect the surface for possible damage.

- We replace the old VAZ 2110 wheel bearing with a new one, having previously lubricated it.

- Install the retaining ring.

- Next, the brake system caliper is assembled, the wheel is installed, and the hub nut is fixed.

At this stage, we examined the algorithm for dismantling and replacing the front wheel bearing on a VAZ 2110. The average cost of a part ranges from 700 to 850 rubles, depending on the country of manufacture.

Bearing of the input shaft VAZ 2110, 2111, 2112

Transmission input shaft front bearing

Accepted designations:

- For VAZ - 21080-1701031-01 or 21080-1701031-02 or 21080-1701031-03 or 21080-1701031-04;

- According to the GPZ classification - V66-42205AEM1SH1 or 6-42205A1EUSH1 or 6-42205A1E1USH1 or 6-42205A1E1USH1.

Dimensions of the front bearing 21080-1701031-01 of the gearbox input shaft:

- Outer diameter D - 52 mm;

- Inner diameter d - 25 mm;

- Thickness B - 15 mm.

Installation location of the front bearing 21080-1701031-01 of the input shaft of the VAZ 2110, 2111, 2112 gearbox:

Rear gearbox input shaft bearing

Accepted designations:

- For VAZ - 21080-1701033-00 or 21080-1701033-01 or 21080-1701033-02 or 21080-1701033-03;

Dimensions of the rear bearing 21080-1701033-00 of the gearbox input shaft:

- Outer diameter D - 62 mm;

- Inner diameter d - 25 mm;

- Thickness B - 17 mm.

Installation location of the rear bearing 21080-1701033-00 of the input shaft of the VAZ 2110, 2111, 2112 gearbox:

All the details of replacing a wheel bearing on a Daewoo Nexia

- Shoes, stationary jack, puller, repair kit, set of keys and pliers.

- We stop at the inspection hole;

- Use a wheel wrench to remove the mounting bolts on the wheel;

- Having unscrewed the cover, we also tear off the hub nut;

- Let's jack up the car;

- Remove the wheel completely;

- From the engine compartment side, loosen the central rod nut and three auxiliary ones, but do not unscrew completely;

- Remove the hub modularly from the splines;

- Unlock the brake caliper and unscrew the two mounting nuts;

- We move it to the side for convenience and do not remove the brake hoses;

- We completely unscrew the fastening on the glass (top of the stand), remove the complex as a whole;

- We place it on a clean and level platform for further work;

- Using a heel with a diameter of no more than 3.6-3.8 cm, carefully knock out the cage with the bearing;

- If that doesn't work, use a universal puller;

- We clean the bearing location, remove the remains of old grease and metal shavings with a rag;

- If there are no defects, then lubricate the seat and, using the same puller, press the new bearing back in, making sure to lubricate it first;

AutoFlit.ru

Timing belt tensioner bearing

Accepted designations:

- According to VAZ classification - 21080-1006120-00, 21120-1006120-00, 21120-1006120-01, 21120-1006135-00, 21120-1006135-01;

Dimensions of bearing 21080-1006120-00 of the timing belt tensioning mechanism VAZ 2110, 2111, 2112:

For 21080-1006120-00:

- Outer diameter D - 63 mm;

- Inner diameter d - 10.1 mm;

- Thickness B - 27 mm.

Or for 21120-1006120-00, 21120-1006120-01, 21120-1006135-00, 21120-1006135-01:

- Outer diameter D - 63 mm;

- Inner diameter d - 10.1 mm;

- Thickness B - 32.4 mm.

Installation location of bearing 21120-1006120-00 of the timing belt tensioning mechanism VAZ 2110, 2111, 2112:

replacing the wheel bearing of a VAZ 2110

Replacing a VAZ 2110 wheel bearing

It is quite easy for every driver of a "ten" to find out that the VAZ 2110 wheel bearing needs to be replaced. The main symptom is that when accelerating, a hum appears in the wheel area, and a slight vibration occurs in the body. When sharply entering a turn, these signs disappear. You may also notice the hub overheating. Replacing a bearing is quite simple and does not require a special room or expensive tools. Therefore, most car owners will be able to do it themselves.

The VAZ 2110 family is equipped with double-row ball bearings that do not require lubrication or adjustment during operation.

Front and rear wheel bearings are not interchangeable!

To replace the wheel bearing you will need: a body stop, a flat screwdriver, a narrow chisel, a 30 socket, a torque wrench, 17 and 12 ring wrenches, a bearing puller (sold in all auto stores), a universal puller, a needle file and a blowtorch.

Replacing a VAZ 2110 wheel bearing

Place chocks under the rear wheels. Using a flat-head screwdriver, pry up the protective cap of the hub nut and remove it. Using a narrow chisel, unsplit the hub nut, tear it off and loosen it, but do not unscrew it.

Lower the wheel bolts, but do not remove them. Then lift the front of the car completely and place supports under the body. Unscrew the wheel bolts and remove the wheel.

The front part of the car must be lifted completely, otherwise the transverse stabilizer will push the suspension upward and interfere with the removal of the hub.

Removing the caliper

Using a 17 key, unscrew the caliper guide and remove it. Then use a screwdriver to release the brake pads and lift the caliper up. Tie it with wire to the car body, removing the load from the brake hose.

Removing the wheel bearing VAZ 2110

1. Using a 12mm wrench, unscrew the 2 guide pins of the brake disc and knock it down with light blows of a hammer through the adapter.

2. Completely unscrew and remove the hub nut.

3. Pass two M12x1.25x130 bolts through diametrically opposite holes in the brake disc and screw them into the holes of the hub along the entire length of the thread. Then, with a sharp blow of the brake disc on the bolt heads, tear off the hub.

The cylinder head mounting bolts can be used as bolts for an improvised puller.

4. Using a 17mm wrench, unscrew the 2 bolts securing the ball joint and remove the outer joint through the hole in the hub. Then use a hammer to knock the hub out of your fist through a soft metal or durable wood adapter.

To avoid distortion of the hub, rotate it after each blow with a hammer.

5. Remove the retaining ring and press out the bearing using a puller. To do this, rest the puller bolt against the inner ring of the bearing through the washer. As a result, the bearing will remain on the puller.

Release bearing 2110, 2111, 2112

Accepted designations:

- For VAZ - 11110-1601182-00 or 21090-1601182-00;

- According to the GPZ classification - 6-520806KECHS30 or 76-520806К1УL20Ш1.

Dimensions of release bearing 21090-1601182-00:

- Outer diameter D - 55 mm;

- Inner diameter d - 31 mm;

- Thickness B - 19 mm.

Installation location of release bearing 21090-1601182-00 VAZ 2110, 2111, 2112:

| Item number in the picture | Explanation of the position in the picture of the location of the release bearing VAZ 2110, 2111, 2112 | VAZ catalog number |

| 1 | Clutch disc | 21100-1601085-00 |

| 2 | Bolt | 21080-1601207-00 |

| 3 | coupling | 21100-1601180-00 |

| 4 | Release bearing VAZ 2110, 2111, 2112 | 21090-1601182-00 or 11110-1601182-00 |

| 5 | Spring | 21080-1601188-00 |

| 6 | Slave disk | 21100-1601130-00 |

| 7 | Overlay | 21100-1601138-03 |

| 8 | Overlay | 21100-1601138-00 |

| 9 | Rivet | 21080-1601295-00 |

Do-it-yourself replacement of a VAZ 2110 wheel bearing VAZ Repair Zone

Replacing a VAZ 2110 wheel bearing is considered not a pleasant task, as there are some difficulties. You need to have dexterity, cunning, strength and intelligence (computer games come to mind, many will probably understand). You can do all the work with your own hands without much difficulty.

On dozens and similar machines, this procedure will take no more than an hour (subject to good preparation). To be honest, it happened that I was repairing a 12 that just drove for 7 years and the owner didn’t look into it. Everything was complicated there, and along the way we had to change a lot of elements - brake discs, hoses, balls.

Preparation and disassembly

When replacing the wheel bearing of a VAZ 2110, it is necessary to park the car level, and be sure to install stops under the rear wheels. Before lifting the wheel being repaired, be sure to loosen the hub nut and loosen it (you can even unscrew it completely). This is done using a socket or socket wrench set to “30”

It is extremely important that there is a large lever - a considerable amount of force must be applied to rip off the nut

Replacing the rear wheel bearing of a VAZ 2110 is carried out in almost the same way as the front one. The only differences are in the puller used and disassembly in order to get to the hub. That's all, now you need to lift and remove the wheel. Look carefully, what is stopping you? That's right, support! You remove it and hang it under protection so as not to damage it. And don’t even try to “accidentally” press the brake pedal.

Unscrew both bolts securing the ball (if you do not plan to replace it, then there is no point in removing the pin). You also unscrew the two guides from the disk. The disc can now be removed and put aside. Mark the position of the hub on the stand and unscrew the nuts (so as not to disturb the camber angles of the front wheels). That's all, you can try to rip the hub off the grenade. It is better to do this if you put the wheel on a couple of bolts with the back side facing it. You jerk the wheel sharply, trying not to fall.

Removing and installing the bearing

It is worth noting that the VAZ 2110 wheel bearing can only be replaced using a puller. But on my own behalf I will say that it simply does not help me. From the kit - a bolt, a nut and several washers, I use only the bolt - I put it inside the bearing and hit it with a hammer (sharp).

Of course, before doing this, the retaining rings must be pulled out. You can use some of the washers that come with the puller, they are very convenient. But it’s impossible to do everything humanely, so that everything is “by the book.” A hammer saves the day, and this installation did not damage a single bearing (although the manual warns about this consequence).

Replacing the rear wheel bearing of a VAZ 2110 is carried out in a similar way. Removal and replacement can be done with the same tool. I tried to cheat with the installation - I warmed up the bearing and threw the hub in the freezer. This was of little use, only the seal on the bearing began to melt. But this ten has been driving for several years now and has not started buzzing yet.

No matter how much I tried, I couldn’t press the new bearing with a puller - I remembered various mothers, and envied the owners of sixes and all the classics, since their cones (in my opinion) change much faster and easier. The main thing is not to overtighten and lubricate generously. Therefore, I picked up that same bolt, a washer (with a diameter like a bearing), lubricated the outer race and hub, and began to carefully stuff it.

In this case, you don’t need to try to deliver a strong blow, the main thing is sharpness. By applying a lot of force, you will only destroy the bearing (and it falls apart very quickly, however, it is easy to assemble). After pressing, be sure to reinstall the retaining rings and reassemble the entire side of the car. Tighten all threaded connections well, always double-check so that no unpleasant “surprises” happen. I’m telling you this after I rode on three wheels (the left rear one fell off, I changed the wheels from a summer set to a winter one). I rode the drum without even damaging it, but the wheel overtook me.

Differential bearing 2110, 2111, 2112

Accepted designations:

- According to VAZ classification - 21080-2303036-01, 21080-2303036-02 or 21080-2303036-03;

- According to the designation of the GPZ - 6U-7207AK, 6U-7207AK1

Dimensions of bearing 21080-2303036-01 differential VAZ 2110, 2111, 2112:

- Outer diameter D - 72 mm;

- Inner diameter d - 35 mm;

- Thickness B - 18.25 mm.

Installation location of bearing 21080-2303036-01 differential VAZ 2110, 2111, 2112:

| Item number in the picture | Explanation of the position in the figure of the differential VAZ 2110, 2111, 2112 | VAZ catalog number |

| 1 | Main drive driven gear | 21080-2302060-30 |

| 2 | Differential bearing VAZ 2110, 2111, 2112 | 21080-2303036-01 |

| 3 | Adjustment ring | 21080-2303090-00 |

| 4 | Axle shaft seal left | 21100-2301035-00 |

| 5 | Axle shaft seal, right | 21100-2301034-00 |

| 6 | Driven gear bolt | 21100-2403021-00 |

| 7 | Front axle differential | 21080-2303012-00 |

Technical requirements

The landings of large roller bearings are separated from normal and small ones in a larger direction. The seating dimensions of roller bearings 2110 are selected in accordance with GOST GOST 3325-85 (Rolling bearings). Considerable loads require the use of compressed couplings of internal races with the shaft and external ones with the frame.

The type is selected taking into account the following parameters: rotation and operating conditions. TNLA 520-2011 (Rolling bearings) defines basic and additional types of precision. But more high-precision roller bearings are in demand in special cases. Products of accuracy classes from 0 to 6 are considered very popular.

The operation of the 2110 unit in high temperature conditions requires taking into account the uneven tension between the 50 mm caliber inner race and the axle. The value of the fit increases with increasing operating temperature in the roller bearing.

Price of hub and bearing for VAZ 2110

A factory hub produced by AvtoVAZ (21100-3104014-00) costs from 1300 to 1600 rubles. This is the most reliable option.

- Riginal (RG21083103012) — 950 rub.

- VolgaAvtoProm (21080-310301200) — 650 rub.

A proven version of the front wheel bearing is the original AvtoVAZ element (21083103020). Its cost is about 470 rubles.

There are several options for bearing analogues:

- FAG (713691010) - 1330-1500 rub.

- SKF (VKBA 1306) - 1640-2000 rub.

- HOLA (NB721) - 545-680 rub.

- HOFER (HF301046) — 380 rub.

- KRAFT (KT100505) — 590 rub.

- FEBEST (DAC34640037) — 680 rub.

The German company “FAG” and the Swedish “SKF” offer the most reliable front hub bearings for the VAZ 2110. These bearings differ from others in high quality and extend the life of the hub itself. But the worst option, according to car owners, is HOFER.

Radial roller bearing 2110

To improve the properties of the lubricant, anti-slip additives are used. Liquid lubricants are recommended for rotation speeds above 10 meters per second. In general, mineral oils are most often used for liquid oils.

Roller bearing lubrication system

Correct selection of lubrication for radial roller bearings:

- increases service life, reliability

- reduces starting effort

- reduces heat generation, friction

A sign of significant wear is a dull raceway. The appearance of a pink or brown coating on a treadmill bearing is not alarming. Lack of the required amount of lubricant or its incorrect use leads to the formation of a shiny glassy mark on the raceway of the rollers of the rolling bearing.

The greases are suitable for peripheral speeds up to ten meters per second. With correct operation and effectively selected lubrication, the bearing bushing raceway is shiny and smooth. For radial roller bearings, soft greases are used compared to ball bearings.