What is a wheel hub? It refers to a rotating element that has a hole. We are talking about a wheel hub, which resembles a pulley with a toothed wheel. Thanks to the hub, they can be mounted on an axle. By paying tribute to the keyway or spline profile, torque can be transmitted. This is possible thanks to the hole.

Why do you need a wheel bearing plug? It allows the part to rotate on the shaft without interference.

In order to achieve the required strength, a special hub diameter is used. It should reach double the diameter observed in the hole. There should also be no distortions.

The hub bearing allows the central element, which ensures the movement of the car and the safety of the driver and everyone who rides with him, not to fail for a long time. But if the wheel bearing itself wears out, the car will become impossible to drive. Therefore, it is important that the wheel bearing is always in good condition; this requires regular inspection.

Types of bearings

Let's take a look at the hub bearing as it appears on the chassis. We will pay special attention to SNR. This model is one of the most common bearings on the market. The best device is the SNR, which is a rolling bearing. Since it is precisely this that provides the greatest resistance to the movement of the car. Additional details are also used. This is about:

- radial ball bearings,

- roller with radial,

- roller conical shapes, they are also resistant to the radial.

The SNR type wheel bearing has a specific design that is different from other parts. With an independent front suspension and a driven rear axle, it is necessary to install two tapered bearings in front on each side and a single radial bearing in the rear. It is also important to remember that lubrication is needed, otherwise the device will crack, creak, and wear out, which will quickly damage it. But the wheel bearing cannot be repaired; it must be removed and cannot be put back, since many parts will be damaged.

The housing must be filled with lubricant sufficient to last the service life of the bearing. The lubricant cannot be changed, as the seal of the anthers is broken. You can notice that the wheel bearing includes three parts. This is the one that is located inside, there are also rollers on the outside.

Before installing the step bearing, you must carefully apply Litol lubricant and also put on the seals; they are installed separately.

Design and operating principle

Wheel bearings are one of the most heavily loaded parts of a machine. They bear the pressure of the total mass of the car, multidirectional loads that arise during acceleration, braking, and driving over uneven surfaces. Therefore, very serious requirements are put forward for these units, since traffic safety directly depends on them.

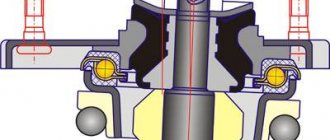

In the design of a car, rolling bearings are used in the hubs. Different types of bearings are used in automobile hubs, although they are structurally identical and consist of several parts:

- clips, they are also rings (outer and inner);

- rolling bodies;

- separator;

The bearing rings act as supporting surfaces for the rolling elements, which are placed between the races. The outer ring of the bearing is installed in the hub hole, and the inner ring is seated on the axle.

To distribute the rolling elements evenly around the circumference of the races, a separator is used. The task of the separator is also to prevent contact of these bodies with each other.

Additionally, in the design of some types of wheel bearings, anthers are used to prevent dust and dirt from entering the unit. Such nodes are considered closed.

Front end

The front wheel hub has great functionality. The main task is to ensure easy control of the car. The SNR model is well suited for this. In order for the control to be reliable, it is necessary to use bearings. They are installed two on each side. Their sizes may be different from each other, but the shape is conical. A thrust washer and nut are used for fastening. It is important to tighten it tightly so that there is no play.

The hub gets dirty easily, since it is in close proximity to the road, and the lubricant is gradually washed out when interacting with water. Therefore, the driver is simply obliged to regularly check the bearings for wear in order to replace them in time. Otherwise, you can lose a wheel on the highway in an accident.

Considering that the size of the wheel parts is different, wear occurs to varying degrees. Regular technical inspection, even if paid, will help protect the lives of both your own and those of passengers and other people who may be road users. The best option is the SNR model, it does not wear out so quickly.

Symptoms of failure

This is where the most interesting thing is - how to determine a malfunction; there are several hundred percent methods.

1) “Dry” crunch . When a wheel bearing fails, a crunching sound appears when driving. These are spherical elements rolling. They broke the clip they were in and are now not evenly distributed. You won’t confuse this sound with anything else; believe me, this sound is perfectly audible in the cabin. This is the very first symptom - as soon as such a sound appears, we immediately go to the service station.

2) Vibration . If the bearing is already well worn, then vibration should appear in both the steering wheel and the body. This suggests that the spherical elements have already worn out the bearing race well, a little more and a “wedge” may occur. We change it urgently.

3) The car is pulled to the side . It is also possible that the part with the faulty element does not work normally - so to speak, it is stuck a little, and therefore the car will pull in one direction or another, as if the wheel alignment .

Using the rear hubs

The rear hub is easier to operate. Although its design is almost the same as the front one. An exception may be the steering knuckle. The rear hub bearing, which is part of the rear suspension, is threaded onto the half shaft, being installed in the provided landing location. At the same time, the design of the rear wheels may differ from one car to another. Here's what the rear wheel hub might look like:

- if the suspension is dependent, then they are used on rollers or radials with balls;

- if the suspension is independent, then you only need to use conical ones, two on each side.

Since the rear wheel hub cannot be repaired, if the possibility of adjustment for pressing against the holder disappears, then if it is worn, it should be replaced. It is easy to buy, it has a specific serial number, which includes all the information about the individuality of the bearing. You should also buy a rear hub oil seal, which also deteriorates over time. But usually it changes along with replacing the hub.

Adjustment work

To carry out adjustment work, you will need a standard set of wrenches, a hammer and a screwdriver. The adjustment on all cars is almost identical and may differ only in some details. The adjustment technology is as follows:

- Loosen the wheel bolts on the hub that needs to be adjusted;

- Using a jack, hang and remove the wheel;

- Using a hammer and screwdriver, knock off the protective cap installed in the center of the hub;

- Using pliers, bend the stopper antennae and pull it out;

- We tighten the hub nut until it stops, and then turn it back ¼ turn;

- Check the ease of rotation of the hub. It should spin easily and without jamming;

- We put everything back together and check the play again.

If the adjustment fails to eliminate the play, or there is wedging and crunching during rotation, the bearing must be replaced.

As already noted, cylindrical bearings are not adjustable, so the appearance of a hum and the detection of play indicates the need for replacement.

How repairs are carried out

To repair an SNR bearing, it is important to remember not to do this. Since this part cannot be repaired. And it's not about size. She fails completely. Since when removed, all the clinging elements are damaged and cannot be restored. Therefore, as soon as you remove it from its place, you can throw it away. The SNR part is not very expensive, which means that replacing it is affordable for everyone. This is better than losing a wheel on the highway and having to repair not the hub, but the entire car. The cap cannot be repaired either, since it is damaged when removed.

If you decide to replace bearing elements, including caps, then you need to be very careful, as removing them requires a lot of effort. Use only proven methods for removal. In particular, use pressing. Just knocking it out with a crowbar will ruin the seats. Also remember that by removing the nuts and bolts and hubcaps (the hubcaps can still be carefully removed if they are not stuck to the nuts), you will need to replace these parts with new ones.

It is also important to remember that you only need to put back original parts of the same model, for example, SNR. Only in this case will the car continue to function properly. Don't try to find a replacement for SNR. She's gone.

List of suppliers

- SNR is the largest French supplier in Europe and rightfully ranks first in product quality;

- SKF is the second-ranked supplier of bearing products, known in the markets for 100 years;

- NSK is also the second largest manufacturer of wheel bearings in the world from Japan;

- FAG is a manufacturer from Germany, absorbed by the INA concern, with high quality products;

- NTN is Japan's largest manufacturer;

- Kouo is the third largest manufacturer in Japan and is part of the Toyota concern;

- Timken is a manufacturer from the USA, the largest in the production of tapered bearings, the quality of which is exceptional.

These companies own many factories around the world, producing products of similar quality that meet the most stringent requirements.

If you need bearings for agricultural machinery, then it is better to pay attention to FKL, a Russian company located in Voronezh. Parts from this company have been supplied to all European countries for 50 years, are known for their high quality, and have no analogues in the world.

How the hub works

The hubs, both front and rear, are the same size, but the individual parts included in them differ in size. As for the caps, they all have the same dimensions, since they cover standard nuts. Each bearing has its own ring into which the axle must be inserted; oil is used during its assembly and installation.

The entire service life of the bearing can be done without additional lubrication. This means that there will be no need to disassemble this system of parts. This means that the cap on each nut will remain in place. But sometimes they still have to be replaced, since the cap can come off due to mechanical damage when driving on the highway.

When installing the bearing, it is necessary to slightly pull it onto the neck onto the inner ring, and then onto the outer ring, where even more effort is required. It is important to follow all safety rules during installation. If everything is done correctly, then there will be no problems during further removal, and the service life can be significantly increased. And the size of individual parts does not play a big role here.

The bearing must be tightened from the inside using a self-locking nut. Its dimensions are indicated on the head. The clamping should be up to twenty kilograms with force. Since it has a side that is crimped along its ellipse, when clamped it becomes tight, acting as a stopper.

In order for the bearing to be protected from dirt, there is another part that is formed due to the conical surface. We are talking about a hinge and a steering knuckle, which, with the centrifugal effect, are capable of reflecting all the dirt flying from the road. This is why caps are also put on the nuts, so that they also do not become littered.

The part in question can be installed on the rear wheels using the outer diameter. At the same time, it gets inside the hub, where it is locked by a ring. Here it is important to use high-quality nuts to tighten everything well, then the bearing will hold tightly.

Is it worth buying the original?

It is often advised to buy original bearings. An original is a part selected by a car manufacturer for sale on markets. These are the parts that are delivered to conveyors. When buying an original bearing, you will be absolutely sure that it will suit you. But there are several questions that need to be addressed here.

The original or a fake?

The original bearings are all the same and if you examine it carefully you will find the engraving. It is located on the edge of the upper or lower part. It should contain several information:

- manufacturer (logo);

- Country of Origin;

- designation digital or alphanumeric details, sizes;

- Additional information is possible;

- The kit must include a hub nut (usually disposable), there may be pins or bolts, seals.

- SKF brand

- Full bearing designation

- Manufacturer country

- Production date code

- Deviation of the average outer diameter ∆Dm [µm] and the position of the maximum eccentricity of the outer ring

- Deviation of the average bore diameter ∆dm [µm] and position of the maximum eccentricity of the inner ring

- Marking of thrust end, stamping

- Serial number (for bearing sets only)

- "V" marking (matched bearing sets only)

If the country of origin is not indicated, it is not an original, but a fake.

Is it worth paying extra for the original?

As a rule, you will find completely similar bearings from different companies on the market. So is it worth paying more for the original if other companies produce the same parts? If you decide to pay attention to any company, then choose well-known, popular manufacturers that supply parts to conveyors. Some people prefer Japanese companies, others prefer European products, for example, they trust only German quality. Our rating of the best manufacturers will help you determine which wheel bearing company is better and who to give preference to. Even if these companies offer products made in China, they will be high-quality products that meet all the requirements. Pay attention not to the country of origin, but rather to the supplier’s brand.

What will happen if you don't change

Many car enthusiasts drive with faulty wheel bearings, and even accelerate at 100 kilometers per hour or more - guys, this is very dangerous, remember this is the connecting element of the wheel, which is responsible for its rotation. If it is broken, it can jam at any moment. And this is a sudden stop of one of the front wheels. Now imagine if your speed is 100 km/h - at that speed you will simply fly off to the side of the road, this is the best case scenario, but you can also fly into oncoming traffic, and then you’re not far from an accident. There have been cases when cars overturned. So guys, the hub bearing is very dangerous, if you don’t want to change it, drive at low speeds, up to 40 km/h, otherwise everything can end very badly.

Signs of wear

At the initial stages, it is almost impossible to determine the malfunction without special equipment. This becomes clear only when there is noise from the wheel. This is precisely the first sign of bearing wear. The hum is very similar to the noise from an airplane. The same noise can occur when the hub nut is tightened too tightly or when it is loosely tightened. The noise is usually different at different speeds. Play in the wheel may also be a sign of a wheel bearing failure.

The easiest way to determine if there is a problem with the hub is to tap the tires with your feet. If there is a certain play or sound when tapping, then this may be the first sign long before the hum.

If the hub has already begun to hum, knock or crackle when driving, then you need to conduct a more detailed inspection of the unit and its subsequent repair. Driving on roads can be dangerous for you and others.

Diagnostics

Checking the viability of a wheel bearing is quite simple; even a person completely uninitiated in mechanics can do this. On the corresponding side, where suspicious sounds are heard, the front end is jacked up so that the wheel hangs in the air; The disk is held by the top and bottom with your hands and swings: you push with one hand, and pull with the other. If the wheel is freely affected, the bearing is no longer suitable for service. Even at first glance, insignificant play indicates that the bearing has begun to crumble; if the slope is simply dangling, then measures need to be taken urgently.

You can pull and pull with confidence: the wheel can withstand much more serious loads than a person can exert without additional equipment. Summarizing all that has been said, the question of whether it is possible to drive if the hub bearing is humming should be answered this way: it is allowed while the hum is still very quiet, at low speed, avoiding the slightest potholes - and preferably in the direction of a car shop or service station. Even risky drivers believe that it is not worth driving more than 200 km with such symptoms if you value your life and are not ready to live with a heavy burden of guilt for someone else’s

Causes of wear

There can be several reasons for wheel bearing wear.

- Lack of lubricants in the bearing.

- Overload of the car, and as a result, overload of the hub unit.

- Aggressive driving style, namely driving through sand or dust to the very bottom of the car. This can lead to the ingress of moisture, dirt and sand, and then deformation of the bearing.

- Overload of the unit during skidding and drifting. When skidding or making sharp turns, the unit is overloaded, and this eventually leads to wear of parts.

This is interesting: How to choose and install a reliable alarm system in your car? Review of the 8 Best Security Systems for 2022

Of course, this does not mean that any overload will immediately have consequences. No, this is all gradual, with use and over time.

In most cases, the rollers in the bearing are destroyed not by the quality of the ride and roads, but by defects from the manufacturer or simply from use. Wheel bearings are specially designed for increased loads and have a large margin of safety.