The VAZ 2108 device, like any other vehicle, involves powering electrical circuits from a battery. To ensure that the battery is always in good condition and does not let you down at the most inopportune moment, a generator is always connected to it.

The battery is especially important when the engine is ignited; while driving, when the car develops sufficient speed, the entire electrical circuit is powered by the generator.

When the question arises about connecting additional powerful electrical appliances to the car, it is very important to match their load with the permissible power of the generator. To do this, it is important to know its technical characteristics. And if the battery lack of charge indicator suddenly lights up, it’s better not to even look under the hood without understanding how the electrical charging circuit, voltage regulator and ignition work.

After reading today's article to the end, you will learn about the connection diagram and dimensions of the VAZ 2108 generator, the main reasons for failure and how to check the voltage in the circuit. If trouble happens to the generator, then don’t worry, we will clearly show you the process of removing and installing it.

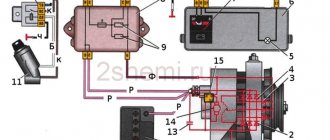

VAZ 2108 generator circuit

The VAZ-2108 generator has a rather massive stator winding, since it uses a large cross-section wire. It is with its help that electricity is generated. The wire is wound evenly over the entire inner surface of the stator into recesses specially provided for this purpose in the magnetic core.

It’s worth talking about the latter separately. The middle part, the generator stator, consists of a series of thin metal plates pressed tightly together. They are often boiled on the outside to prevent separation.

- Alternator. The 37.3701 or 94.3701 series can be installed.

- Negative diode.

- Additional diode.

- Positive diode.

- Alternator warning lamp, also known as battery discharge lamp.

- Instrument cluster.

- Voltmeter.

- Relay and fuse box located in the engine compartment in the compartment between the engine and the vehicle interior.

- Additional resistors built into the fuse mounting block.

- Ignition relay.

- Egnition lock.

- Accumulator battery.

- Capacitor.

- Rotor winding.

- The voltage relay is located in the engine compartment.

Brief overview of the model

We should understand that the electrical circuit for connecting the generator is similar in both domestic cars and foreign cars and includes a standard set of components:

- the generator is a three-phase electrical machine that generates, accordingly, three-phase electric current, converting mechanical energy into electrical energy;

- As a rule, a three-phase diode rectifier connected according to the Larionov circuit is used as a device for converting alternating voltage into direct voltage;

- to protect the battery from overvoltages (the generator voltage directly depends on the engine speed), the circuit uses a voltage regulator;

- the serviceability of the charging circuit can be judged by the indicator light on the instrument panel;

- finally, the ignition key and the electric relay working in tandem with it are necessary to turn on the generator and other electrical appliances in the car (this is why you should not leave the ignition on in the car for a long time, since the charging circuit also consumes current even when the car is just standing still).

The generator rotor is a movable structural element of an electric machine; current is supplied to it through a special collector along which graphite brushes travel. If the charging circuit of the VAZ 2108 generator is faulty, which is confirmed by the corresponding indication on the instrument panel, you should first check the condition of the brushes. The second most likely problem is mechanical failure. We are talking about the rotor shaft bearings and a loose transmission belt.

Voltage regulator

Returning to how the electrical circuit works, we note that the voltage regulator can also let you down. To check this structural element, connect a test lamp or a multimeter set to measure DC voltage up to 20 V to the current-collecting brushes of the regulator, connect the negative terminal of the battery to the ground of the regulator and apply +12V to terminal B (B). If, by analogy, you power the device with a voltage higher than 15 V, the control light will not light up.

If none of the above recommendations help, you should remove the generator itself, check the diode rectifier, as well as the condition of the stator and rotor windings. For this purpose, it will be useful for you to know the technical characteristics of the device on the VAZ 2108 and its possible versions. Read more in the next section of the article.

Technical characteristics of the VAZ 2108 generator

The following generator models are installed on VAZ 2108 cars:

- 3701

- 3701

Technical characteristics of the first:

- The value of the delivered current (at 6000 rpm-1 and a voltage of 13 V) – 55 A — The voltage value – 13.6 – 14.6 V

- Rotor rotation direction – right – Maximum rotor speed – 13000 rpm-1

- Engine/generator gear ratio 1/2.04

Technical characteristics of the second:

- The value of the delivered current (at 6000 rpm-1 and a voltage of 13 V) – 80 A — The voltage value – 13.2 – 14.7 V

- Rotor rotation direction: right

A normally working, serviceable generator of VAZ 2108, 2109, 21099 cars and their modifications produces a voltage in the range of 13.6 V - 14.6 V. This can be visually tracked using a voltmeter on the instrument panel, but it is better to measure the voltage with a voltmeter (multimeter, autotester

Device Description

Before we tell you how to check and repair the 2108 generator yourself, we suggest that you familiarize yourself with basic information about the device. First, let's look at the principle of operation and device. A detailed diagram of the device is shown in the photo.

Principle of operation

The purpose of the unit is to provide electrical appliances and vehicle equipment with energy, and first of all we are talking about the battery. If the mechanism breaks down, the battery stops charging normally, and due to lack of voltage, the battery does not allow the operation of electrical equipment. When the device's charge runs out, the car will simply stall, and it will not be so easy to start it later.

Designation of mechanism components in the diagram

The system is powered by the rotation of the pulley on which the belt is installed. The VAZ generator pulley receives mechanical force from the crankshaft through a belt. The latter can be either wedge or polywedge.

Device components

We will not fully list what components the generator on a VAZ 2108 car or the mechanism on a classic consists of, since the device of different generators is almost identical.

Let's look at the main elements:

- A diode rectifier used to convert alternating current to direct current.

- The generator belt, which transmits power.

- The pulley on which the belt is mounted.

- Brush unit.

- A voltage regulator relay, the purpose of which is to protect the battery from overvoltage.

- A light bulb that is displayed on the dashboard. It is used to notify the driver about malfunctions in the operation of the device (the author of the video is the Engine Repair channel! And interesting!).

Reasons for failure of the VAZ 2108 generator

Experts believe that the main reasons for the failure of the VAZ 2108 generator are:

- voltage regulator failure;

- damage to the diode bridge (aka rectifier);

- wear of current collecting brushes;

- defects in the charging circuit wires;

- damage or operational wear of the pulley;

- wear of slip rings or commutator;

- short circuit of individual turns on the stator winding;

- bearing failure.

Every self-respecting car enthusiast should understand what causes generator malfunctions most often and how they can be dealt with. It is also necessary not to forget that timely prevention helps to avoid serious problems. Towards the end of the article, we will look at some tips that will help you learn how to test the generator yourself. But let's first learn about the internal structure of the node.

Disassembling the device

For disassembly you will need the following tools:

- set of wrenches;

- bearing puller;

- vice.

With their help, the disassembly process will significantly speed up. When starting work, you need to unscrew the hardware securing the rotor shaft with a 19mm wrench. Usually they are secured very tightly, so you will have to put in a lot of effort. In the process of unscrewing the fastener elements, it is important to remember their location, so it is recommended to make a rough sketch on paper. This diagram will help you not get confused when assembling the device.

Place the generator with its back side up and unscrew the 4 fastening elements using an 8 key. This way you can open the front part of the generator housing. There is a bearing located there, which is secured using plates. Unscrew the hardware securing its plates and release the bearing from its seat.

If it does not give in, it is necessary to help it with a wooden strip, the size of which coincides with the dimensions of the bearing. The undisassembled part of the generator will need to be secured in a vice and the back of the housing will need to be pulled to release the element. All that remains is the rotor shaft and another bearing, which are removed using a puller. To do this, you need to place the tool on the bearing and release it from the shaft seat.

Generator parts: 1 – voltage regulator assembled with brush holder for generators produced since 1996; 2 – voltage regulator and brush holder for generators produced before 1996; 3 – terminal block for additional diodes; 4 – insulating bushings; 5 – rectifier block; 6 – contact bolt; 7 – stator; 8 – rotor; 9 – spacer sleeve; 10 – inner bearing mounting washer; 11 – drive side cover; 12 – pulley; 13 – outer bearing mounting washer; 14 – coupling bolt; 15 – front rotor ball bearing; 16 – bushing; 17 – cover from the side of the slip rings; 18 – buffer sleeve; 19 – clamping sleeve; 20 – capacitor

If you have diagnosed bearing wear, you need to write down their markings and purchase new ones. There is no need to go to the spare parts store, taking bearings with you. It is not recommended to listen to advice from sellers about similar bearings that will also work. Buy products that strictly comply with the markings of original parts.

Having dealt with the bearings, you will need to check the diode bridge, which is located inside the back of the device housing. If mechanical damage or oxidation is detected on the surface of the part, you need to dismantle the bridge by unscrewing the 4 fastening elements and replace it with a new one. The cost of all the above-mentioned parts does not exceed 800-1000 rubles. in total, so you can replace everything at once if possible.

How to check the voltage of the VAZ 2108 generator

In order to check the performance of the VAZ 2108 generator, you need to perform the following steps:

- Using a voltmeter, diagnose the voltage at the battery terminals. When the engine is running and the generator unit is operating normally, this parameter should be around 13.8-14.5 volts.

- Try placing your palm on the unit body with the engine running, you need to feel the vibration. If there is vibration, you will notice it immediately. Moreover, it may be due to wear of bearing parts.

- It is also necessary to diagnose the tension of the device strap, while the motor must be turned off. Press the strap with your finger - the deflection should be no more than 1.5 cm

Typical malfunctions and methods for their elimination

To prevent unit failure, it is necessary to ensure its high-quality and timely maintenance. As you can see from the photo of the diagram, the unit consists of many different components, so the likelihood of it breaking due to improper maintenance is quite high.

So, in what cases is a VAZ generator repaired:

- The indicator light on the dashboard does not turn on, although the unit and all equipment are working normally. Most likely, the problem is an open circuit or burnout of the indicator itself. In some cases, the reason is poor contact of the diode with the wiring; in this case, you only need to clean the contacts of the connection connector.

- The indicator on the tidy, as well as the instruments themselves on the control panel do not work. Apparently, the reason for this is the failure of the safety element, which will need to be replaced. Also, the reason may be a break or unsoldering of the wiring.

- The warning light comes on after the engine starts, but it disappears after the driver presses the gas. The essence of the problem lies in the fact that the generator unit is not excited at low engine speeds; in most cases, this is due to the desoldering of the resistor elements in the block. Conduct their diagnostics and, if necessary, solder them again.

- Another malfunction is that the indicator continues to light when the engine is turned on, while the voltmeter needle on the dashboard is in the red zone. In this case, there may be several reasons for the problem. First of all, it could be the strap slipping - you need to check it and, if necessary, tighten it. Also, the reason may be a short circuit or breakdown in the diode elements of the winding; much less often, a malfunction occurs when the voltage regulator fails.

- Another sign is that the indicator does not light up when the engine is running, but the voltmeter needle on the dashboard is in the red zone. In this case, you first need to diagnose the presence of contact between the regulator connector and the brushes. If the contact is normal, then check the brushes (they may freeze), as well as the slip rings; for the latter, the problem of oxidation is relevant. In addition, the cause of the problem may lie in the failure of the voltage regulator; usually we are talking about a break in the wiring between the contact and ground. The same symptoms appear in the event of a short circuit on the positive valves of the rectifier element.

- When the engine is running, the voltmeter needle is located in the red zone - this symptom indicates damage to the voltage regulator. In particular, we are talking about a short circuit that can occur between ground and also contact Ш. The problem can only be solved by replacing the regulator.

- If the unit is significantly louder than usual, there may be several reasons for this. First, you should check the functionality of the bearing elements, as well as the tightness of the pulley nut. In some cases, the loud operation of the unit is due to the creaking of the brushes. The brushes themselves may be of poor quality, but it is possible that the problem is dust getting on the slip rings.

Price issue

The price in this case depends on the manufacturer.

1. KATEK device (price - about 5 thousand rubles)

2. LKD unit (price - approximately 4500 rubles)

3. Startvolt generator (market price - about 7200 rubles)

Interchangeability of the VAZ 2108 and VAZ 2106 generator

The idea of replacing a generator on a classic is as old as the history of the car itself, because everyone who installs more bells and whistles on their own car than a weak Chinese radio, the native 42A G-221 is no longer enough for everyone.

True, even those who neglect the hassle of installing a more powerful generator are annoyed by the weak low beam at idle and poor battery charge. Once, an acquaintance fitted me with a 55A generator on a ball and the idea arose about telling you how to install it in our classic.

Having scoured the Internet to find at least something about installing and connecting it to a car, I didn’t find anything useful, a lot of comments like “Plug it in and forget it” or long discussions of professional electricians, but they spoke in a language that would suit a simple Russian to a person, it’s like a Chinese song, nothing is clear.

In this regard, it was decided to write an understandable article for ordinary people in order to help them do this simple procedure of replacing the generator themselves, without any problems and special skills in working with electricity, but with their hands. It is important to know: There are many alternatives to a standard generator, since with the appropriate skills, means and desire it is possible to install any generator. In the provided article I examine only “economical” VAZ generators from other models, because:

- They are cheaper.

- They are more common.

- They are easier to change - you don’t need to find or make any special fasteners and completely change the electrical system.

Exciting the generator (LADA Samara and similar)

To answer the question briefly, is it possible to provide excitation from a battery , then yes, it is possible, but through a diode.

In details . If the generator excitation suddenly disappears, then you can supply voltage from the battery to input D of the generator during or immediately after starting the engine. Soon, a working generator should switch to self-excitation mode from the voltage it generates. You need to connect through a diode, but not directly, otherwise you risk burning out the generator's additional diodes. And of course, only with the ignition on, otherwise you will drain the battery while parked.

Now in more detail. By itself, simply by rotating the rotor, the generator will not generate voltage. In order for it to start doing this, it needs to be excited - “kicked”, and for this it has an excitation winding that consumes some current. Voltage is supplied to it through contact D of the generator and the voltage regulator. The regulator also turns off the winding when the generated voltage is exceeded, in fact, this is its entire function. There are 2 power modes for the excitation winding. Starting, when the engine starts; and working, when the generator is already running. In the first case, power is supplied to the winding from the battery through a charge control lamp and a diode connected in series with it. In the second case, when the generator begins to generate voltage, the winding is powered through its 3 additional diodes - autonomously.

It happens that the generator does not want to be excited. The very first and simplest possible option here is to check the terminal on contact D of the generator, there may be a bad contact there, everything is very simple: tighten it up, clean it, and be happy. Another option: the charge control lamp has burned out. Naturally, it can be replaced. But if there is no way to change it now, on the road, for example, there are the following options: - “turn on the gas”, and it is likely that the generator will be excited due to residual magnetization; — apply voltage to the excitation winding artificially, i.e. separate wire from the battery. Let's talk about the last method.

How to remove the generator on a VAZ 2108 yourself step by step instructions

In order to remove the VAZ 2108 generator with your own hands, you must perform the following procedure:

- In order to easily remove the VAZ 2108 generator, it is necessary to remove the engine protection.

- During the dismantling process, the VAZ generator must be removed together with the bracket, since its fastening bolt will be impossible to pull out due to the position of the body side member.

- Now disconnect all electrical terminals from the generator

- Then you need to loosen the adjusting nut and the generator mounting nut from below.

- Move the generator forward and remove the loose belt

- Unscrew the bolt and remove the adjusting bar

- We find it at the bottom of the engine compartment (shown in the photo) and unscrew the two bolts securing the bracket.

- Then, carefully pushing down, remove the VAZ 2108 generator

- After repairing or purchasing a new generator, we install it in the reverse order, taking into account the fact that the long bolt securing the bracket should be closer to the generator drive.

- After completing the installation of the VAZ 2108 generator, tension the drive belt

Dismantling the electric generator

Before removing the generator, you will need to turn off the engine, turn the steering column all the way to the right and look under the hood. On the 2108, the device is located in the lower part, to the left of the engine, next to the cooling radiator. Once you have located the generator, be sure to free the battery terminals before starting work. If you suspect brush wear, you should first remove the charging relay, which is located on the back of the generator housing.

It is secured with two bolts. After unscrewing the hardware and disconnecting the contact plug, you need to inspect the condition of the brushes. If their resource is exhausted, you will need to purchase a new charging relay. This is determined by simply measuring the length of the brush; its size must be at least 4 cm. When the brushes are in working condition, it is enough to fasten the relay back. In case of other problems, you will need to completely dismantle the generator itself.

First of all, you need to disconnect the wiring, which is divided into 2 parts. The first one includes two red wires, they are connected to the back of the generator housing and secured with hardware. The second part consists of one red wire, it is connected to the generator terminal using a plug on the same side of the device. Having disconnected both wiring, you need to dismantle the generator in a certain sequence.

First, the hardware that is attached to the belt tensioner bar (on top of the generator) is untwisted. Then the nut securing the same bar to the motor block is unscrewed. After this, you need to unscrew the nut that secures the generator bracket to the engine block. Next, remove the device belt and unscrew the hardware securing the generator to the car body. After completing these steps, you can remove the generator with a slight movement and begin disassembling it.

How to install and connect a VAZ 2108 generator - step-by-step instructions

Installation of a new generator is carried out in the reverse order. Take a close look at the condition of the bottom bolt. If there is damage to the threads, it is better to replace it.

It will be easier for you to repair the generator later. When installing, pay special attention to belt tension. If it is not tensioned enough, your battery will not charge well. But if you tighten the belt too much, the bearing in the front cover will be destroyed. As a result, you will get an unpleasant whistle when the engine is running. And the reason for this is the appearance of play in the bearing.

The installation of the generator on the VAZ 2108 must be carried out in such a way that even the slightest distortion does not occur.

G8 generator repair

First of all, you need to determine the cause of the breakdown. This is done according to the following criteria:

- presence of sounds uncharacteristic of vehicle operation (bearing locking);

- low performance of the device (the VAZ 2108 generator belt is loose, the brushes are worn out);

- unstable output voltage (failure of the diode bridge).

To diagnose a breakdown, you first need to use a voltmeter to measure the voltage level on the battery. To do this, you need to release both terminals and connect the device. If the electric generator is in working condition, the voltage will be in the range of 13.8-14.5 V. After this, you need to start the engine and touch the generator cover with your hand to detect the vibration level.

In case of severe wear of the rotor shaft bearings, the vibration will be quite noticeable. When working properly, it is practically non-existent. Then you need to check the level of belt slack. To do this, turn off the engine and press on the belt with your fingers. It is considered serviceable when the deflection is no more than 1-1.5 cm.

After the initial diagnosis and identification of the problem, it is necessary to dismantle, disassemble and repair the device, and then install it back.