What is an engine breather and why is it needed?

Everyone knows that the internal combustion engine, the same one that is installed under the hood of your car, does not run on gasoline, diesel or gas, but on their mixture with air.

Moreover, it is air, which costs nothing (unlike fuel, for which we regularly pay a tidy sum at the gas station), that is required many times more. But in addition to the influx of clean air and the removal of exhaust gases through the exhaust pipe, parasitic gases are formed during the operation of the internal combustion engine. A breather is nothing more than a breathing valve that constantly relieves excess pressure that forms inside the engine during operation. The need for this simple, relatively inexpensive part is difficult to overestimate.

Purpose

The task of the breather in a car design is to connect the engine sub-piston space with the atmosphere. Additionally, the breather is installed in the valve cover of the block head.

During operation of the power plant, the movement of components, mechanisms, and lubricant leads to an increase in pressure inside the crankcase and under the cover. In addition, crankcase gases accumulate in the sub-piston space, which also increases the pressure.

Piston rings are not able to ensure complete tightness of the combustion chamber, so some of the working gases break through and enter the sub-piston space.

The operation of the motor is accompanied by temperature changes, which causes condensation to form inside. The accumulation of moisture inside the motor is unacceptable, since it is the main cause of corrosion.

A mixture of working gases that have broken into the crankcase, moisture, and oil particles that are mixed in contact with the lubricant are called crankcase gases. An increase in pressure inside the crankcase is usually accompanied by a deterioration in engine performance, since gases create additional resistance to components and mechanisms.

If gases accumulate in large quantities in the sub-piston space, then they break through leaks and “weak” components - oil seals, dipstick, seals, etc.

Therefore, it is important to equalize pressure and gas removal. And this is done by the breather, which is essentially an air valve. Note that this element is used not only on the engine, it is also used in gearboxes and rear axles.

In addition to maintaining pressure in the cylinder block, many car enthusiasts use the breather to diagnose the engine. It helps determine the degree of wear of the cylinder-piston group and the position of the rings.

When engine components wear out or piston rings become coked, a large amount of gases enters the sub-piston space. And thanks to the breather, this is clearly noticeable by the smokiness of the crankcase gases escaping. If the CPG is in good condition, there is practically no smoke in the crankcase gases.

Design features

Previously, the breather was a regular fitting with a hose attached to it and directed downwards. This design ensured the removal of crankcase gases to the atmosphere. To prevent oil from escaping, an oil separator was installed in front of the breather. This element changed the trajectories of gas movement, while the oil, due to inertia, settled on the walls of the oil separator and flowed into the pan.

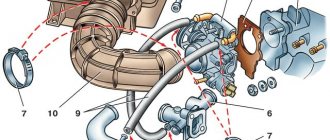

Crankcase ventilation system of VAZ 2111: 1. Engine crankcase. 2. Breather. 3. Hose from the breather to the valve cover pipe. 4. Oil separator under the valve cover. 5. A thin hose from the valve cover to the fitting with the throttle body nozzle. 6. Fitting with a jet on the throttle valve block. 7. Thick hose from the valve cover to the inlet pipe.

In modern cars, to improve environmental friendliness, a whole system for removing these gases is used. Thanks to it, they are not released into the atmosphere, but are fed into the cylinders, where they burn.

This system includes:

- Breather.

- Oil separators.

- Pipes.

It is noteworthy that the crankcase gas exhaust system uses several oil separators - labyrinth, centrifugal, and mesh.

The breather is located in various places in the lower part of the engine block. It can be either a separate element or act as a housing for the probe.

The breather is a very simple element in design, but the performance of the engine depends on it. If you turn it off, then within a few minutes the increased pressure will squeeze out the oil. If the oil comes out through the dipstick, then you just need to restore the lubricant level and wipe the engine compartment. But if the oil presses through the crankshaft oil seals, then replacing them is impossible.

There are no moving parts in the breather, so there is nothing to break in it. But it still requires maintenance. The oil separator is not able to catch all the oil and oil particles remain in the gases. Some of them settle on the inner walls of the breather along with soot and pollutants. Gradually, the diameter of the tubes decreases, which impairs crankcase ventilation. In winter, frozen water is added to the dirt on the walls.

On some cars, the crankcase ventilation system provides for the supply of gas to the valve covers, where they additionally pass through an oil trap mesh before entering the cylinders. The honeycombs of this mesh are also clogged with dirt, so the throughput is reduced. This “results” in the pushing of the camshaft seals

Device

The breather is essentially a valve that bleeds air from the engine. As the pressure increases, it begins to allow a certain amount of gases to pass through it. The greater the pressure, the more air can pass through it. To prevent atmospheric air from entering inside, the valve is capable of flowing only in one direction. But on some cars this process is reciprocal. In such versions, a filter is installed in the valve to prevent dust from getting inside the motor.

Most often, the breather is located next to the oil filler neck. Much less often you can find options with its location on the side of the cylinder block. From the outlet pipe there is a hose connected to the air filter housing. This arrangement is typical for all cars. It may differ only in small nuances due to the characteristics of the body. Sometimes there are 2 pipes, in which case the second hose is connected to the injector.

Design features of crankcase ventilation

The simplest design of the crankcase ventilation system, previously used in internal combustion engines, consisted of a single device - a breather installed in the crankcase.

This breather connected the internal cavity of the cylinder block with the external environment, and crankcase gases simply escaped through it into the atmosphere.

But this scheme had a significant drawback - there were oil particles in the exhaust gases, which also entered the external environment. And this is not only loss of lubrication and the need for periodic refueling, but also air pollution.

In modern cars the ventilation system is closed. It also has a breather, but a pipe is connected to it, allowing gases to be vented into the intake manifold or air filter housing, from where they enter the cylinders and burn. That is, they do not pollute the environment.

Additionally, the system includes elements that ensure oil separation and its return to the crankcase so that it does not enter the cylinders along with the gases.

There are various options for oil separators, and in cars from different manufacturers they may differ in design and operating principle.

It is worth noting that part of the exhaust gases enters the over-valve space and must also be removed. See also: Checking the coolant level for hot or cold

Therefore, the entire engine ventilation system in a modern car consists of a breather, an oil separator and two pipes.

The system may also include a special valve that regulates the pressure of gases entering the intake manifold.

On other machines, the oil separator may be located immediately next to the breather, and a valve is installed behind it.

The configuration of the system may be very different, but this does not change its purpose and operating principle. For example, consider the ventilation design of the VAZ-2110.

At the bottom of the cylinder block of this car there is a breather, into which a pipe is placed, the second end of which is connected to the cylinder head cover through a fitting. At the same time, inside this cover there is an oil separator at the inlet of the pipe.

On its other side there is another fitting to which the air intake tube is connected.

The principle of operation of such ventilation is simple: gases enter the cylinder head cover space through the breather and pass through the oil separator, and the separated oil flows into the valve assembly.

After this, the gases are mixed with those that have broken through into the over-valve space and supplied to the air pipe, and then to the manifold. There is no pressure control valve on this machine.

Where is the breather installed?

Breathers on a car are installed:

- in the engine itself;

- in the gearbox device;

- in the design of the front and rear axles;

Note that the functions of these devices are almost the same regardless of the installation location. It should be added that the valve also has an additional filter that prevents mechanical particles, dirt and moisture from entering the engine along with the outside air.

To put it differently, the breather allows those components to “breathe” from which the working fluid cannot leak out, as well as water and dirt from entering from the outside. During operation of the internal combustion engine, the engine oil in the crankcase heats up, which causes it to expand. The air in the crankcase also expands and pressure is created. If this pressure is not relieved, then the oil will begin to squeeze out through the seals, seals and gaskets of the engine. This statement is also true in relation to other components of the car (axles, transfer case, gearbox).

After stopping the engine and stopping the operation of other components, as well as when it gets into water (important for SUVs), cooling occurs. When cooling, the pressure in the container drops, a pressure difference arises again and outside air tries to break through through the gaskets, etc. To counteract these phenomena and safely equalize pressure on the engine, gearbox, etc. breathers are installed. It turns out that the valve prevents water and dirt from entering the power units when the pressure drops, and also does not allow the gaskets to be squeezed out and the working fluid (lubricant) to leak out when excess pressure occurs.

Breather in gearbox

The gearbox must convert the torque in the engine and also change the traction force. It often happens that the gearbox starts to work poorly due to the fact that the gearbox breather is clogged. To avoid any damage, you should clean not only the breather in the engine, but also all the others that are installed in different parts of the machine.

In the gearbox, the breather is located on the gearbox housing cover. Sand or dirt getting into the breather will cause the wheel mounted on the secondary shaft to jam. As a result, wear of bearings and synchronizers increases. It is necessary to wash the breather during each technical inspection, or even more often. If the valve is clogged, the pressure in the gearbox will increase, which will lead to oil leakage through the seals.

Bridge breathers

There is oil inside each axle that connects the wheels. The internal cavity must contact the external environment, and it does this through the breather. With the help of this valve, an increase in pressure inside the bridge itself is eliminated.

Oil pressure rises when it heats up during forward gear operation. The breather also performs a protective function. It protects the bridge from water entering it when the car overcomes a water barrier. There is also a special hole in the middle of the bridge through which oil drains.

Particular attention should be paid to the rear axle crankcase breather. It is located on the rear axle boat, on the right side, at the top

As a result of this valve being clogged, oil may leak. To get rid of this problem, you need to clean the breathers from dirt. You also need to check the free movement of the breather cap. It should move in all directions.

After cleaning the breather, you should check it again after a short run of 20 km. If traces of oil are detected again, this will indicate a malfunction of the device that needs to be replaced. The rear axle breather must always be in good condition, because it plays an important role in the operation of the entire vehicle.

Engine breather

Some novice drivers are stumped by the question “engine breather and what is it,” because recommendations for the operation and care of a vehicle often mention this important element of the engine.

In addition, the breather often helps diagnose important problems associated with the power unit: the fact is that problems with this element can subsequently cause engine problems, which can then lead to expensive repairs.

That is why the car owner simply needs to know all the aspects and characteristics of the device, as well as have an idea of how to properly prevent disruptions in its operation, because the breather valve, which does not seem like a significant detail at first glance, is of great importance for the proper operation of the power unit.

What is its purpose?

To understand what a breather is, it is recommended to find out what it is for, since this is directly related to its operating principle.

The main task of this device is to reduce pressure in the engine crankcase.

While the car is running, a lot of gases accumulate in the crankcase, which over time create high pressure. If they are not released in time, the engine may stop working, since high pressure will support the pistons, and gas will begin to escape through any other hole. To prevent this from happening, this valve is installed.

Another significant function of the device is to reduce the temperature inside the engine and ventilate it.

Based on the operation of this unit, one can draw conclusions about problems in the operation of the motor.

In normal operating condition, a slightly transparent, barely noticeable smoke can be seen from the unit. There are situations where the engine constantly throws out oil through the breather. This is a common cause of not only valve clogging, but also other technical problems.

The breather valve is an important element that allows communication with the external environment of a closed container. It allows you to equalize the pressure inside the internal combustion engine: if it drops sharply, fresh air will enter through the valve, which will eliminate the difference between the external, atmospheric, and internal pressure created in the crankcase cavity.

The principle of operation of the breather in the engine

Today, a breather valve to reduce pressure is very often installed on SUVs. This is due to the fact that the device is suitable for off-road driving. Breathers prevent oil leakage. Heated engine oil expands, causing engine pressure to increase.

The pressure in engines or in other automotive devices must find a way out. This causes oil to leak out through various gaskets and gaps. To prevent oil leakage, breathers are installed.

All breathers in the car should be checked periodically. Due to the constant movement of oil, debris and dirt remain in it. Breathers must be properly removed and cleaned of contaminants. If it is too dirty, then it must be replaced with a new device. Before installing a new valve, be sure to thoroughly clean the installation area of dirt and debris. This is done to prevent debris from getting into the new device.

Installation location

The breather valve in a car is usually located:

- directly in the engine;

- inside the rear and front axle structures;

- at the checkpoint.

Blow-by gases: Ventilation system operation, oil trap and PCV valve

This is the second version of the article, created together with members of the project team; it corrected gross errors in the operation of the engine crankcase ventilation to remove crankcase gases. So, a crankcase ventilation system is necessary to reduce harmful substances escaping from the engine crankcase into the air. There are certainly gasoline vapors, water vapors and oil vapors in the crankcase - all these are crankcase gases. The accumulation of crankcase gases deteriorates the properties and composition of the engine oil, destroys the metal parts of the engine; in a Honda Civic, in the event of system failures or aggressive operation of the engine, the amount of vapor increases and the engine becomes covered with soot from the inside. The obvious fact of the failure is a decrease in power and an increase in fuel consumption. Visually this can be seen as carbon deposits on the throttle valve, carbon deposits on the intake manifold. Carbon deposits in any of its manifestations are a negative factor affecting engine performance. The diameter of the throttle valve decreases, which means less air will flow into the intake manifold. Carbon deposits on the intake manifold will reduce its volume and, therefore, the return.

Blockage of the channels will accordingly lead to incorrect composition of the mixture and air starvation.

Carbon deposits on the throttle body, intake manifold, and even on the injector rings

Schemes of operation of the crankcase ventilation system

The crankcase ventilation system of the Honda Civic is practically no different from most passenger cars with internal combustion engines. The intake tract is used as the source of air flow. A fresh air flow enters the cylinder head, then into the engine, the flow passes to the bottom of the engine into the crankcase, and takes exhaust gases with it through the breather chamber for recycling into the intake manifold. Such a system is needed to process material that has a negative impact on the environment. That is why this system is looped in the engine and does not go outside after the breather chamber. As you understand, this system, in addition to the ventilation circuit and the intake tract, has two more components, a breather chamber that acts as a receiver of heavy particles and a PCV valve (Positive Crankcase Ventilation) - a forced crankcase ventilation valve. PCV is needed to direct the flow. A few illustrations to help you understand the terms.

Typical crankcase ventilation diagram on a horizontal intake manifold D16Z6

Typical crankcase ventilation diagram on a D14A4 vertical intake manifold

Breather chamber at the rear of the engine near the oil filter

Carbon deposit problem in the system

Where does the soot come from? Let's say the engine is new, and the function of a primitive filter is performed by the breather chamber. In which the oil settles and the gases escape through the PCV valve into the intake again into the engine. Everything is perfect, the heavy parts of the oil are separated, and the gasoline-saturated stream is recycled. But this is ideal. Firstly, over time, the breather chamber becomes extremely dirty and ventilation gets worse. Since nothing is perfect, crankcase gases still contain oil, even after the breather. And the PCV valve begins to become dirty, and eventually it becomes clogged with oil, dirt, etc. As a result, the circulation of gases is disrupted, depending on the position in which the valve is “jammed” there will be certain consequences.

- PCV is always open, additional air leak past the throttle valve through the cylinder head - a leaner mixture, as a result of which the computer adds more fuel, increased consumption, unstable idle

- The PCV is always closed, gases accumulate in the engine, increasing pressure in the crankcase may increase the risk of “squeezing out” the crankshaft seals from oil pressure. Crankcase gases exit through the cylinder head back into the intake tract, carbon deposits settle on the throttle valve, intake manifold, and injectors, eventually reaching the pistons.

Location of the PCV recirculation valve in a Honda engine

Engine and PCV valve operating modes

Solving the soot problem

The solution is simple, you need to clean the PCV valve and breather chamber. But it is suitable for city traffic. If you constantly press the accelerator pedal, then inevitably there will still be contamination of the intake manifold. The solution came from motorsport, where performance is the main thing; in motorcycles, an oil trap was installed more often than in cars. Oil catcher, oil trap, oil sump, oil separator, Oil Catch CanTank are different names for the same product capable of separating oil from crankcase gases. Ideally, you need two of them, one for the intake, the other near the PCV.

Drained oil from the oil trap, all this could become carbon deposits in the engine

Schematic design of a simple oil trap

Oil trap design and operating principle

A jar-container with two fittings and an oil selection filter inside the jar, all in any color scheme. This is a primitive description of a device that costs $40-300. In addition to the cost, first of all you need to describe the principle of operation. Installed in the section of the hose from the cylinder head to the intake tract. Crankcase gases with a mixture of oil vapors are supplied to the inlet fitting; then, once in the can, this gas flow enters the cunning structure of the obstacle. In one case, it is simply a metal wall, similar to how cigarette lighters are made. This is the worst way, although it works. The second case is a foam filter, mesh, or metal sponge. This is a good method for filtration; the oil will settle on the wire and flow down.

Using foam rubber, there will be a problem with the passage of the gases themselves into the intake manifold. Cleaning such an oil trap will also be problematic.

The most normal oil trap system, spiral with a metal filter. The flow hits the wall, the gases quickly find their way out into the intake manifold, and heavy oil droplets flow down and remain inside, in the closed part of the oil trap. All that remains is to drain the accumulated oil in time; there are options when the oil goes back into the engine, thereby the oil does not leave the engine at all.

Crankcase ventilation hose for installing an oil trap

Fuel filter as a cheap replacement

As a half measure, a fuel filter (for example VAZ) can be used. Low cost of 1-2 dollars and availability. But, such filters are designed for gasoline and not for heavy oils. The filter will become clogged very quickly. The result is clogging of the channel, ventilation of crankcase gases, and their circulation and accumulation inside the engine in all its parts. This is especially noticeable at low temperatures. Further, there is a drop in power, with a very high chance of unstable engine operation, for example, the engine begins to stall.

A fuel filter is a half-measure to solve the problem of oil in the intake manifold.

This article is relevant for Honda cars manufactured 1992-2000, such as Civic EJ9, Civic EK3, CIVIC EK2, CIVIC EK4 (partially). The information will be relevant for owners of Honda Integra in DB6, DC1 bodies, with ZC, D15B, D16A engines.

Useful tips: The lapping paste should not get on the valve stem, otherwise it will also rub the guides. Full list of tips The VKontakte community can help you with most questions. It's really more convenient than writing comments below.

Troubleshooting

The first thing you need to pay attention to is the color of the exhaust, blue or black smoke, a sign of burnt valves or problems with rings. Next, you should check the compression in all cylinders. The value on gasoline internal combustion engines should be within 11-13 MPa. Disconnect the pipes from the valve covers, air intake and breather

Assess the degree of contamination. If the pipes are very dirty or clogged with oil deposits, use gasoline to clean them or a special carburetor cleaner. Check the condition of the oil separator. Unscrew the required bolts to get to this unit. Remove the oil separator and assess its condition. If necessary, clean or rinse followed by drying. Inspect and, if necessary, flush the breather valve. There are situations when the valve gets stuck, resulting in exhaust gases entering the crankcase and creating excess pressure. Remove the part and wash it; in most cases, this will resolve the issue of squeezing oil out of the breather.

Helpful advice! To distinguish stuck rings from a burnt-out valve, it is enough to perform several manipulations. After checking the compression in the cylinders, determine the cylinder with the lowest value. Then inspect the spark plug of this cylinder; if the rings are lodged in this cylinder, the spark plug will be covered with a thick oil layer. If the valve is burnt out, the spark plug will appear normal without any major abnormalities.

Why is there smoke coming from the breather?

There can be only one malfunction of the breather: it began to poorly pass accumulated gases, comparing the pressure inside the engine with atmospheric pressure. But the smoke coming from it can say a lot:

- The cylinder oil scraper rings were stuck or worn out. Simple decarbonization using traditional methods or special chemicals will not help here, so you will have to disassemble the engine.

- Likewise, if one/several exhaust valves burn out. A simple compression test will help determine this.

- Oil seals. Just replace them when it's time or they show signs of increased wear.

- The shaft seals, which allowed oil vapors to pass through, were worn out. Change them without hesitation, preferably without shelving them.

- The oil in the engine is old and needs replacing for a long time. No comments: as practice shows, repairing the “heart” of a car is tens of times more expensive than replacing it.

- White smoke on a hot engine - coolant enters the lubrication system. You'll have to look for where exactly the leak is.

- Oil overflow. In an internal combustion engine, it is just as dangerous as underfilling: engine wear/fuel consumption increases significantly, so check its level with a dipstick on a level surface when the engine is well warmed up. Then you will see how well the technicians at the service station (or you yourself) performed its replacement/topping up.

- The oil is of poor quality/not suitable for the car/counterfeit. There is only one way out - replace it. Likewise, if you filled up with fuel at an unknown gas station: just don’t do it again.

- Finally, the breather itself clogged from time to time, not working at 100%. Simple cleaning and preventive maintenance will eliminate this.

An impressive list of different situations. And there is no doubt that if your car’s breather is smoking, you have definitely found your case among them.

Oil is squeezed out through the breather: how to fix the problem

There are situations when oil leaks through the breather on a car. The liquid is squeezed out, and streaks on the unit become noticeable. This sign indicates the need to perform diagnostic procedures on the engine. Let's try to figure out the problem in the garage. If necessary, the technical fluids needed for replacement can be picked up in Tikamis and ordered there if you live in the service area of this company.

When operating a car, crankcase gases accumulate in the crankcase. Without maintaining excess pressure, we use a special ventilation valve. This way we will cover the crankcase from interaction with the atmosphere. This valve is called the breather.

In the installation, gases are mixed with a mist of oil composition, so the particles penetrate into the element in question. As a result, some of the liquid flows out. This means that we can allow minor contamination of the device.

If leaks occur from the breather, the channels immediately become clogged and soot appears. The remaining substance flows into the crankcase, and the system “cokes.” Parts under load are practically not lubricated, the “engine” wears out. By the way, traces of the composition are not always visible from the outside.

Let's find out the causes of this disease. Oil appears due to worn piston rings. Gases flow from the seal into the crankcase, where overpressure is created. If the level is excessive, oil will leak out from the breather. The oil deflector drains may become clogged.

Increase in crankcase pressure

When an engine operates, high pressure arises in its cylinders as a result of the release of energy from the combustion process. Under normal conditions, exhaust gases should be vented away from the engine into the atmosphere. However, if the seals between the cylinder and the sealing rings are broken, some of the gases can pass through and enter the crankcase of the unit, after which excess pressure will be created there. The solution to this problem was the creation of a crankcase ventilation system.

There are times when the system cannot cope with a large influx of exhaust gases and removes them as intended. In this case, the engine begins to actively consume oil, leaks occur through the oil seals and oil seals, and there have been cases when the oil dipstick fell out of the neck due to excess gas forces.

The first simple engines had a hole with a special oil baffle to remove excess gases to prevent overheating. In modern units, excess gases enter the air filter and from there are returned to the engine; some designs simply remove them into the collector.

Why you need to clean the breather

Operating under the conditions described above means that the breather may become clogged. The release of oil through the valve is accompanied by the subsequent accumulation of dust, which clogs the valve passage. As a result, when heating, excess pressure is created or insufficient pressure when cooling, which leads to oil leakage through the oil seals and gaskets of the engine and other units.

To troubleshoot the problem, the breather must be removed for cleaning or replacement. It is recommended to replace the engine or gearbox breather with a new one if it is very dirty. Before installing a new breather, it is necessary to thoroughly clean the installation site. This will avoid its rapid re-contamination.

Important

The breather is an important element that helps the car operate properly, but to prevent breakdowns it is recommended to clean or change it in a timely manner.

A faulty valve can lead to various problems:

- risk of gearbox leakage;

- rapid wear of synchronizers and much more.

Regular cleaning of the valve will help protect the oil from deterioration in its lubricating and protective properties, and therefore will extend the life of the iron horse for a long time.

Preventative work

Some motorists are wondering: why clean the breather? This is done in order to avoid problems with the operation of car components; it is necessary to clean the breather in a timely manner. Such actions will allow you to maintain the permissible pressure level, and as a result, stable and trouble-free operation of the car. It is recommended to carry out cleaning at every technical inspection (MOT), and in some cases even more often. The cleaning process itself looks like this:

- removal of pipes and hose. All pipes and hoses coming from the “breathing valve” are removed; in some models you will also need to remove the air filter housing;

- removing the breather cover;

- cleaning work. Now you can begin cleaning the valve cap and tube.

- installation work. Assembly is carried out in reverse order.

This is how cleaning is done. The procedure is quite simple, and you can do it yourself with your own hands, without the need to visit a service center.