The breathing valve, or breather, is designed to allow the car to communicate with the atmosphere. Its task is to release gases and equalize pressure in the internal and external planes. When the car's mechanisms are not working, it is this that allows air to penetrate into the cabin. And it performs these functions despite its location - on one of the axles, engine or gearbox. But it saves the corresponding mechanisms from malfunctions.

Engine breather

The breather valve prevents oil leakage from the crankcase. The breather releases air and gases that form the cylinders of the head unit. This happens due to the intake of air from the atmosphere after the driver stops and turns off the ignition. The breather also prevents dirt from getting inside the engine, which is why they are widely used on SUVs.

Like other mechanisms, breathers are prone to clog and accumulate dirt, as well as malfunction. Devices need to be checked periodically and measures taken for timely replacement. Operation of damaged or clogged engine breathers leads to deterioration in operating efficiency and excess pressure in the internal plane. The oil from the crankcase is just waiting for this, preparing its escape. And this absolutely cannot be allowed.

Preventative work

Some motorists are wondering: why clean the breather? This is done in order to avoid problems with the operation of car components; it is necessary to clean the breather in a timely manner. Such actions will allow you to maintain the permissible pressure level, and as a result, stable and trouble-free operation of the car. It is recommended to carry out cleaning at every technical inspection (MOT), and in some cases even more often. The cleaning process itself looks like this:

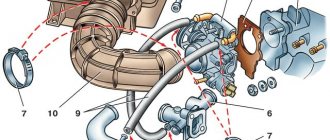

- removal of pipes and hose. All pipes and hoses coming from the “breathing valve” are removed; in some models you will also need to remove the air filter housing;

- removing the breather cover;

- cleaning work. Now you can begin cleaning the valve cap and tube.

- installation work. Assembly is carried out in reverse order.

This is how cleaning is done. The procedure is quite simple, and you can do it yourself with your own hands, without the need to visit a service center.

Breather at the checkpoint

All types of gearboxes must be protected from contamination. A dirty mechanism slows down its operation and makes it impossible to smoothly shift certain gears. The breather is installed on the crankcase cover.

A faulty transmission breather will not be able to withstand the increase in pressure inside the housing. This will lead to destruction of the bearings. During each inspection, clean the breathers and replace them if necessary.

Breather: what is it, how does it work and does it need to be maintained?

A breather is a valve for communication with the atmosphere, an indispensable element of all more or less large hollow components of equipment in which lubricant and air are present.

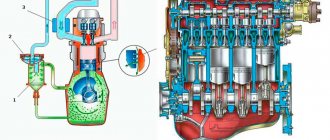

As shafts and gears rotate inside a sealed assembly, their friction heats the oil and the air above it. Accordingly, both liquid and gas increase in volume. After all, the oil is never poured to the top - there is always an “air cushion” above it. Emptiness, in other words. This empty space allows the oil to rise in level when heated, but not leak out. The assembly heated up from the movement - the oil expanded, and some of the air escaped into the atmosphere. The car stopped, the unit cooled down - the oil decreased in volume, and the vacuum pulled the missing air inside. Therefore, the pressure inside is always atmospheric, zero, to put it simply.

To ensure equal pressures inside and outside, in principle, a simple hole in the upper part of the unit - the gearbox housing or axle gearbox - is sufficient. However, you can’t just make a hole: through it, abrasive sand dust can get inside, to the oil and gears - when driving on dusty roads, and moisture - when washing or driving in the rain. And when parking on a significant slope, the oil itself can leak out. Although a breather in the form of a simple hole covered with a breathable felt plug can be found, for example, in small-volume units that operate not with liquid, but with grease - for example, in the gearboxes of large and powerful grinders or circular saws. But in cars where this valve is primarily found in gearboxes, transfer cases on all-wheel drive vehicles, as well as in axle gearboxes, the breather is somewhat more complicated.

In a car, it is a small threaded fitting with a through hole, screwed into the body of a particular automotive component or mechanism. From above, this fitting is closed with a movable (capable of moving and rotating slightly vertically when pressed) cap-cup. And under the cap, the end of the fitting is closed with a rubber disk - a kind of “tablet”, which is pressed against the fitting by a spring. Actually, this disk is the valve element of the breather.

The design is very elementary, but there are several important nuances in its operation that not everyone knows... Let's look at how it works, as they say, “in the basic version”!

In a good way, inside the unit housing, where there is a breather, there should always be atmospheric pressure - the absence of both excess pressure and vacuum. But in fact, if you start unscrewing the breather or even just vigorously move its cap up and down and left and right, achieving a shift in the “pill”, you can hear a quiet “zilch”. Moreover, “zilch” can be a consequence of both slight excess pressure and slight vacuum. But both are the norm, not a malfunction!

The car drove off. Gears and shafts rotate, friction heats them, and they heat oil. It expands, heats and compresses the air layer above it. The air pressure inside the gearbox or axle increases. But the calibrated spring in the breather is extremely weak and presses the rubber “tablet” with a negligible force of 10-12 grams. As soon as the pressure reaches some insignificant value, barely above atmospheric pressure, it is released into the atmosphere, lifting the “tablet”, overcoming the resistance of a frail spring.

The car stopped. The units began to cool down. The temperature and oil level decrease, as does the air pressure inside. Gradually, a vacuum forms inside the bridge, as the spring presses a rubber tablet against the end of the breather fitting, sealing the bridge... However, eventually the pressure inside, albeit with some delay, will become atmospheric. Why?

Let us remember that the spring is very, very weak. And the rubber “tablet” is not a precision valve with a perfectly ground seat and disc. The breather is not intended for long-term retention of vacuum - this is built into its design, it is necessary! It passes atmospheric air into the unit at approximately the same speed as the vacuum there grows synchronously with the cooling of the oil. So, although a vacuum does occur inside, it is insignificant and short-lived.

Well, the third situation. Actually, it is here that the “pill” and the spring will play their role, because in the first two (systematic heating while driving and slow cooling in the parking lot) it was quite possible to do without them - the breather would work successfully, being just a “hole” connecting the crankcases units with atmosphere...

And this situation is a sudden cooling when axle gearboxes, transfer cases and gearboxes are flooded when suddenly falling into a deep puddle or deliberately crossing fords. In this case, the vacuum inside the units arises quickly and reaches noticeable values - for example, a rear axle heated to 90 degrees can fall into a deep ravine of melt water with a temperature near zero... Here a vacuum jump is added to the force of the spring, which suctions the “tablet” even more strongly to the end of the fitting, preventing water, which can easily overflow through the breather level, from being sucked inside the gearbox or gearbox. The breather is self-sealing and quite reliable.

With a short (albeit very sharp) cooling of the unit, the breather quite successfully protects its internal volume from the penetration of water from the outside, but what happens if you have to stay in water up to the hub (or even deeper) for a long time? Say, when the assault on a ford took too long or the SUV got stuck in a swamp? In this case, it is very likely that water will be sucked into the oil through the rubber seals - the oil seals of the axle shafts or CV joints. The oil seal seals have a profile that provides some self-sealing, but not from water from the outside, but from oil from the inside. The oil seal as a whole is sealed in both directions due to the constant pressure from the ring spring, but in the “outward” direction its elasticity is still noticeably higher than vice versa, due to the shape of the profile. And if a new original seal can successfully resist the vacuum sucking in water from the outside, then a well-worn and/or not very high-quality oil seal is unlikely. Although they can hold transmission oil perfectly in both cases!

For this reason, most owners of SUVs (especially new ones) do not trust (and quite rightly) breathers in their standard version. They cut off the cap from them, throw out the spring and the “tablet”, put thin hoses on the remaining fitting and lead them out from the front into the engine compartment, and from the back into the cavity in the wing inside the trunk or into the cavity of the canopy. In general, in a clean, dry place and higher... In this case, the valve in the breather is no longer needed, and it continues to successfully fulfill its role of connecting with the atmosphere. But owners of road cars do not need this procedure at all.

However, if you are not the owner of an SUV, then the breather can cause trouble for you too. When it becomes clogged or simply turns out to be a product from a low-quality manufacturer. The fact is that, for all its simplicity, this part requires very high precision and repeatability in manufacturing! The spring must be strictly calibrated in terms of compression force, the tablet must be made of very high-quality rubber that does not allow deformation and sticking due to oil and temperature. Distortions and jamming of the cap are strictly unacceptable, etc.

Defects and negligence in the design of the breather cause its rapid contamination or sticking (which leads to squeezing out oil through the seals when heated) and vice versa - easy passage of water inside (which leads to the formation of an emulsion from the oil). Even if the breather is initially of high quality and not “left-handed”, then, despite its complete, at first glance, autonomy and self-sufficiency, it requires periodic “maintenance”, expressed in simply moving and turning the cap by hand. This allows you to prevent it from becoming overgrown with dirt inside and the “tablet” turning sour.

Although sometimes low quality control of the manufacturer (this mainly concerns the domestic automobile industry) forces car owners to interfere with modifications to a conditionally serviceable unit... For example, there are frequent cases of oil emissions through the breather at the gearbox of front-wheel drive VAZs of old models. Since garage practice (and even, it seems, some official letters from AvtoVAZ) recommended pouring oil into the box a little more than the nominal volume, the air cushion above the oil level turned out to be insufficient to compensate for thermal expansion - lubricant began to ooze through the breather and flow along the body of the box... Drivers in such a situation, they carried it higher on a short hose, as is customary with jeepers.

Or take the rear axle breathers on VAZ classics, Volgas and IZHs of the troubled 90s, when everything was done with your feet - the quality of components was so terrible that at factories they deliberately removed both the spring and the “pill” from the breathers, pushing the cap back on and making from the breather, therefore, a simple “hole” - as long as it somehow works and does not press the oil out... And if the owners of such cars did not drive along stream beds and did not park on the mountains, then they did not experience any special problems from such a simplification, and often they didn’t even know about it...