An element of the car, such as the crankcase ventilation system of the VAZ 2114, serves to remove unexhausted gases and re-supply them inside the engine for afterburning, as a result of which the toxicity of the exhaust is sharply reduced. But, during the operation of the car, this system becomes clogged, resulting in problems with the engine. Today we’ll talk about what crankcase ventilation includes and how to clean it with your own hands.

Crankcase ventilation system

Design and principle of operation

As was said at the very beginning, the ventilation system removes crankcase gases from the VAZ 2114 back into the engine, preventing unburned fuel oil mixture from entering the atmosphere. It includes a pair of pipes through which gases are removed, and a filter that traps solid particles and clots.

The whole system functions as follows:

- the fuel mixture entering the engine burns and forms exhaust gases, most of which are discharged from the engine into the exhaust line;

- a small part of the gases leaks through the piston rings and enters the lower pipe of the ventilation system;

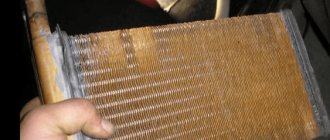

- From the lower pipe, gases enter the filter (made in the form of a multilayer mesh), after which, already purified, they return to the engine, where they burn out.

Signs and causes of oil leaking through the breather

Despite its simplicity, this system is very important, and it is necessary to monitor its performance. One of the most common ventilation problems is oil leaking through the breather.

This can become a serious problem in the future, since oil particles entering the manifold and cylinders will clog the channels, and during combustion, increase the amount of soot, which will then enter the crankcase, coking the oil channels, and impairing the operation of the lubrication system.

Signs of oil rut.

There are not many of them. In a carburetor engine, these may be leaks of lubricant inside the air filter housing and significant traces of oil on the filter element itself.

As for injection engines, the problem manifests itself in the form of deposits on the throttle body and the internal surfaces of the intake manifold.

In this case, there may be a drop in engine power and an increase in fuel consumption.

Reasons for oil ejection through the breather.

But there are many of them, and many of them do not relate to ventilation.

Lubricant may flow through this system due to:

- Severe wear of the piston rings and the cylinder-piston group as a whole. Because of this, a very large amount of gases break into the crankcase, and the ventilation simply does not have time to remove them all. Therefore, increased pressure is formed inside the engine, which squeezes oil into the breather;

- Oil separator drain channel is clogged. In this case, the separated oil has nowhere to go, and it is mixed into the passing gases;

- Air filter dirty. The engine sucks in a large amount of air, and if there is not enough air due to a clogged element, the motor will suck it in along with oil from the ventilation system;

- Increased amount of oil in the system. If there is more lubricant in the engine than normal, then excess lubricant will enter the ventilation;

- Ventilation system valve jamming;

- Timing belt wear or valve burnout. As a result, crankcase gases enter the above-valve space, then they penetrate into the crankcase, significantly increasing the pressure.

How often should cleaning be performed?

If the ventilation system is clogged and its filter is unable to clean the mixture passing through it, then not only unburned gases, but also oil particles and other pollutants will enter the engine. All this will ultimately have a negative impact on both the operation of the engine and its remaining service life.

The frequency with which the crankcase ventilation of the VAZ 2114 should be cleaned directly depends on the condition of the engine. So, if the car just recently came off the assembly line, and its engine has not clocked up 50,000 km, you shouldn’t even think about cleaning it, since the piston rings are still new, and there is practically no leakage of gases through them.

The first cleaning (as recommended by AvtoVAZ itself) should be performed after the car has covered 60,000 km. And all subsequent cleanings should also be performed after every 60,000 km.

Many owners of domestic cars with extensive experience say that 60,000 km is too much, and cleaning should be done at least every 30,000 km - this will help avoid many problems with the engine and extend its life. In this case, the first cleaning should be carried out after the first 60,000 km.

Diagnosing the cause of oil rush

Since there are a large number of reasons for oil leaking through the breather, a comprehensive check of the engine is necessary to determine exactly why the problem arose.

At the same time, to carry it out, you don’t even need to disassemble the power plant, it’s just enough to take measurements of some parameters, as well as visually assess the condition of the ventilation.

For example, let's take the already mentioned VAZ-2110. Let's assume that in the engine of this car, plaque and oil deposits were noticed in the intake manifold, which indicates oil leakage through the breather.

To determine what caused this problem, you will need little - a set of open-end wrenches, a screwdriver, a compression gauge.

We'll start the test by assessing the exhaust gases. To do this, just start the engine and look at their color shade.

If it is gray or black in color, this indicates oil getting into the cylinders due to wear or sticking of the CPG rings or problems with the timing belt. Only this can help determine the cause; read more here - the causes of smoke from the exhaust pipe.

It is also necessary to check the compression in all cylinders. In the normal state of the cylinder-piston group, it should be in the range of 11-13 MPa. The difference between the readings in the cylinders is allowed to be no more than 1 MPa.

If the compression in one cylinder is significantly lower, it can cause oil leakage.

But why exactly this is happening - rings or valves - can be determined by the spark plug that was installed on this cylinder.

Heavy carbon deposits on it will indicate a problem with the CPG.

But if the compression is low, and the spark plug has a normal working appearance without carbon deposits, you should check the valves.

If the compression in all cylinders is normal, we proceed to inspect the elements of the ventilation system.

How to clean

To begin work, you will need to prepare the necessary tools, namely:

The crankcase ventilation of a VAZ 2114 is cleaned as follows:

- Loosen the fastening clamps of both pipes and then remove them.

- Inspect the pipes for cracks or chips - if the latter are present, replace the pipes with new ones of the same diameter.

- If the pipes are in good condition, clean them outside and inside with a damp cloth.

- Disconnect the throttle cable from the sector.

- Remove the pair of mounting bolts securing the throttle body to the receiver.

- Remove the bracket along with the cable.

- Unscrew the two bolts securing the cylinder head, and then remove the washers and rubber bushings located on them.

- Remove the cylinder head cover itself.

- Find the oil separator on the cylinder head cover and unscrew the mounting bolts that hold it.

- Remove the housing cover, and then remove the oil separator itself.

- Thoroughly rinse the filter mesh (oil separator) in gasoline (it is recommended to use highly purified gasoline for this) or kerosene.

- Clean the cylinder head cover from oil and adhering dirt (this is best done using a rag soaked in kerosene).

- Install the oil separator filter back into the cylinder head cover.

- Reassemble in exactly the same order, but in reverse order.

To avoid possible injuries, all work on dismantling the cylinder head cover and cleaning the ventilation system should be carried out only with the engine completely cooled.

It should be noted that when performing operations to clean the ventilation system, it is worth paying attention to the condition of the rubber bushings that fasten the cylinder head, as well as the gasket. If they are worn out or covered with cracks, they should be replaced immediately, without waiting for serious damage.

At the end of today's conversation, it is worth mentioning a situation where cleaning the crankcase ventilation system does not actually help improve engine performance. This happens when the engine is very worn out, and the secondary vapors entering it to burn out actually “choke” all its work.

There can be two ways out of this situation - either carry out a major overhaul of the power unit or remove the ventilation system to the external environment (in this case, unburned gases will not enter the engine, but into the atmosphere). True, at the same time, the environmental friendliness of the car will noticeably decrease, and it will no longer meet the high Euro standards. For this reason, such a decision should be postponed until the last resort.

Easy to fix oil leaks from the gearbox

An attentive driver who cares for the car can quickly detect an oil leak. Measurements are taken of oil droplets on the asphalt surface. The appearance of oil indicates that there is a problem that needs to be solved. Ignoring the problem in the future will cost a lot of time and money.

Oil leaks appear on the surface of the gearbox housing. If you don't look closely, they are hard to notice. As the amount of oil increases, droplets appear.

After parking the car, small black oily puddles form on the asphalt. You need to drive the car onto a viewing hole or lift. It will make it possible to quickly find the location of the leak and fix the problem.

The main easily repairable oil leaks from the gearbox:

Loose nut on transmission oil drain.

A common cause of oil leaks, it can be eliminated in less than 5 minutes. When changing the oil in the gearbox, they were in a hurry and did not act carefully. After a while, a loose nut is discovered. Oil oozes through the drain hole and leaves marks on the road surface.

Vibration increases the leak, as the nut moves away more and allows more oil to pass through. Some unlucky drivers managed to completely pour the oil onto the ground during the day. If you don't notice the problem in time, you can end up with a jammed transmission.

The oil dipstick is not inserted correctly.

Drivers do not pay attention to the correct installation of the oil dipstick in vain. Often causes oil leaks. A skewed dipstick does not close the channel tightly enough. When heated, oil leaks out.

If leaks are found on the gearbox housing, you need to carefully inspect the position of the dipstick. To eliminate the leak, it must be corrected.

Reverse sensor.

It is mounted in the gearbox and causes oil leakage if not tightened sufficiently. The driver’s actions are the same as when the nut on the drain is not tightly tightened. You need to tighten the reverse sensor and all the leaks will stop.

Excessive amount of oil.

Experts say that overfilling the gearbox with oil is much worse than underfilling it. An excess amount of oil fluid creates excess pressure in a confined space.

Lada 2114 1.5 (8 valves) › Logbook › Crankcase ventilation system

Igor' Nenashev, 28 years old I drive Lada Vesta euro69 (before: Lada 2114) Berezovka, Russia

If you follow my blog, you know that I recently changed the oil dipstick. Everything would be fine, but after a short trip, looking under the hood, I discovered that the dipstick was not seated tightly, as if it had been squeezed out of the mounting hole.

Having pulled out the dipstick with the car running, I felt that there was a decent amount of air blowing from there. In principle, as far as I know, it should blow in any case, but there is a limit to everything. Upon closer inspection, the dipstick also turned out to be of poor quality (crooked, rubber too soft). I bought another dipstick in the store (it has stronger rubber and harder metal), it fit tightly and was no longer squeezed out. By the way, the new probe turned out to be a little shorter than the standard and low-quality probe, this one made by AVTOVAZ (so they said in a large store and the marking was appropriate).

Do I need to replace a worn or damaged pipe?

Some motorists believe that you can drive with a cracked pipe, but this position is fundamentally wrong. Firstly, a damaged pipe will not be able to supply clean air to the engine. After all, through the gap, air from under the hood will enter it, which has not been filtered, and therefore carries abrasive particles (which, as mentioned, can quickly damage the engine).

Replacing the pipe

Secondly, driving with a damaged corrugation also leads to faster wear of the air filter; it will have to be changed much more often. That is why a damaged or worn pipe should be immediately replaced with a new one.

Schemes for upgrading the crankcase ventilation system

Schemes for modifying the crankcase ventilation system, as well as a description, are provided by IgorRV.

For LADA cars with manual transmission and AMT (“robot”), scheme No. 1 “Crankcase ventilation scheme with PCV valve for E-GAS and cable throttle” is suitable:

installation of a PCV valve in the crankcase ventilation system of a VAZ installation of a PCV valve in the crankcase ventilation system of a VAZ (cable throttle) installation of a PCV valve in the crankcase ventilation system of a VAZ (E-GAZ)

It is necessary to install a PCV valve (article 94580183, price about 400 rubles) from a foreign car into the small crankcase ventilation circuit. When connecting the PCV valve to a small circuit on an E-GAS, use a new hose (petrol-oil-resistant 8 mm without fabric reinforcement). On a cable choke, connect to the receiver, not to the choke.

As a result, the valve will shut off the circuits in transient modes, which will allow:

- Accept the load without jerking or dropping engine speed (for example, when the compressor is running, heated windows, seats, etc.).

- Reduce vibration load at idle

- Increase traction from the bottom (noted by owners of automatic transmission with VAZ-21126 engine, manual transmission with VAZ-21227, 21126 and 11186 and AMT with VAZ-21127).

- Get a sharper response to the gas pedal and faster shifts (on AMT). Perhaps due to the fact that the valve does not allow the engine to slow down, maintaining a more optimal switching algorithm.

- Reduce oil consumption through ventilation.

The valve replacement period is 40,000 km.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 2 is suitable:

Description of scheme No. 2: The pressure reducing valve is connected in series to a large ventilation circle. Thus, it regulates the flow of crankcase gases at high speeds and during transient processes. This allows:

- Exercise full control over the flow of crankcase gases between the small and large circuits.

- Improve engine operating mode.

- Reduce vibration load.

- Reduce oil release into ventilation.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 3 is suitable:

ventilation diagram with PCV valve, pressure reducing valve and ejection pump

ventilation diagram with PCV valve, pressure reducing valve and ejection pump

Description of scheme No. 3: To improve the operation of the braking system and facilitate the process of holding the car on the brakes in mode “D”, an “Ejection Pump” was used. Due to the flow of crankcase gases from the small circuit, the vacuum in the tube leading to the vacuum booster increases. This happens at low speeds, which is very helpful when driving in traffic jams. Keeping your foot on the brake all the time is not very easy, but this pump makes the task easier.

- Getting rid of vibrations, failures, transmission shocks.

- The engine begins to operate more calmly and softly.

- The force on the brake pedal becomes less.

- The air conditioner turns on almost imperceptibly.

- ejection pump (article 10793 VIKA, price 546 rubles);

- pressure reducing valve (article 1117701500 JP GROUP, 422 rubles);

- PCV valve (article 94580183 GENERAL MOTORS, 400 rubles);

- clamps (about 10 pieces, 600 rubles);

- thin, petrol-resistant 8 mm hose 50 cm (100 rubles);

- standard ventilation pipe.

By the way, there are other ways to modify the crankcase ventilation system. Are you ready for such modernizations? Let us remind you that modification of the ignition system (installation of capacitors in the ignition coils in the harness) is also common among owners of LADA cars.