A knock on the stabilizer bar is a harbinger of the fact that this suspension part will soon need to be replaced, and, consequently, additional expenditure of money. However, few people know and are trying to restore the racks.

Restoring the struts is only possible with a prompt response from the car owner! If there is a knock, quickly remove them and revive them. This reaction will allow the stabilizer struts to serve for at least 100 thousand km. If you drive one or two thousand kilometers, they will have to be changed without any options. But if you “tamper” the rack in time, then it can easily cover another 50 thousand kilometers, about the same as a new one.

Design and purpose of the stabilizer strut

The design of the stabilizer struts is primitive and their typical designs do not differ greatly from each other. The length of the rod, the angle of the hinges and their size, the length of the fingers are different for each car model. Sometimes silent blocks (rubber bushings) are used instead of hinges, and combined designs are also found. There are several types of traction:

- With two hinges (most common);

- With two elastic bushings (silent blocks);

- With one hinge and one bushing.

Let's consider the most popular and complex (compared to other possible) design option - with two hinges. Such “bones” consist of a rod and two hinges in the housings, liners, anthers and a rod. The main working element in the form of a standard hinge (exactly the same design for a ball joint, only larger in size) consists of:

- Ball pins;

- Boot with clamps;

- Polymer liner;

- Nuts;

- Ball housings.

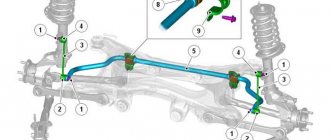

The purpose of the stabilizer bar is the kinematic connection of the anti-roll bar with the shock absorber strut. The stabilizer is fixed to the subframe relatively motionless - the shock absorber strut can rotate both to the right and left (in turns), and up and down (when driving over uneven surfaces). To ensure a movable connection between the stabilizer and the shock absorber strut, the “bones” must have a certain degree of freedom; hinges or rubber bushings serve this purpose. They also fail; we will not consider cases of traction separation - this is not normal and is a manufacturing defect or the consequences of an accident.

Stabilizer link with hinges in section

Almost all modern cars come with a stabilizer, usually the front one. Less often, a rear one is additionally installed. Therefore, it is not difficult to calculate how many stabilizer struts are in the car - two or four .

Types of structures

The repair process differs in some features, depending on the type of fastening used in the car model. There are two types of parts:

- Ball joints are installed on a significant part of modern cars. They break due to insufficient production of lubricant and wear. Restoring such stabilizer elements can be problematic and sometimes impossible.

- Bushings - this type can be found much less frequently, however, there are not many problems during operation.

Let's consider all the stabilizer struts and the intricacies of their own repair.

Signs of failure of stabilizer struts

The main sign of wear on the stabilizer link is a metallic knock when driving over uneven surfaces. It can be confused with the knocking of a ball joint, but if the latter fails, it is usually the same one that “drums” (if the left front ball joint starts to play, the knocking will come from there). In the case of stabilizer struts, the failed right “bone” will also tap when the left wheel passes over an uneven surface , but not as loudly as on the “sick” side.

Stabilizer struts, photo dr1ver.ru

Without a trip to a diagnostic station, the best way to check your stabilizer bars is to drive out onto a gravel road. But on highways and in the city with a good asphalt surface, they may not provide comfort (with the exception of speed bumps). Off-road, if it’s really time to change the struts, they will drum properly.

Stabilizer links can also knock due to loose nuts on the pins. In some machines this is a “sore” - the problem is solved with thread lockers or cotter pins. But if you need to dismantle such a “bone” to repair other suspension components, you may not be able to do without an angle grinder.

An inspection in a pit or on a lift will confirm or refute the failure of the “bones” - in advanced cases, the hinges will knock even if you shake the racks by hand. Ball boots with cracks or tears are also a sign of the imminent death of the stabilizer struts (if they are not knocking yet, they will soon start).

Replacement: when repairs cannot be made

Of course, it will be much cheaper to repair shock absorbers than to replace them, but sometimes you have to do that too. Again, you can carry out diagnostics and determine whether they can still last after repair. If you are not confident in your insight, then diagnostics can be carried out at a car service center. If you change shock absorbers, then this process should also be carried out only in pairs. To replace, you will need the same tools: a rack wrench for classics and ties with springs for front-wheel drive cars.

If replacing a shock absorber strut can be done with your own hands, then replacing the entire shock absorber is most often done at a car service center, because This is an extremely responsible undertaking. Finally, we would like to give a few recommendations for caring for new shock absorbers. The first step is to carry out anti-corrosion treatment on the underbody of the car. This will help cope with adverse weather conditions.

Means for treating cars against corrosion

Again, for our realities this is necessary, because... Bad weather lasts for about six months, and it is rare to notice drains on our roads. Therefore, when you move through continuous puddles, it is simply necessary that the underbody of the car is protected from corrosion

In addition, when repairing shock absorbers, we recommend paying attention to the rear axle gearbox, as well as other elements of the vehicle’s suspension

Reasons for the fragility of stabilizer struts

In some cars, the struts “fly out” after 10,000 - 15,000 km. The main reasons contributing to this are:

- "Soft" metal fingers . Low-quality alloys quickly wear out and begin to play and knock;

- Poor fit of the plastic insert and the “ball” of the finger. If the “fingers” in the new stabilizer link rotate easily by hand, this is a sign of their fragility;

- Poor quality rubber boots . It tends to crack quickly and allow moisture to pass through;

- Weak boot clamps . The Chinese can easily replace metal ones with rubber ones, which are not able to ensure a tight fit of the boot, especially in winter, as a result - hello service;

- Not enough lubrication. We will not mention Chinese spare parts here - this is a problem for most manufacturers; the high price of a part is not a guarantee of quality. A drop of grease is normal (not).

- Difficult operating conditions. Regular driving on gravel roads and roads with potholes is an easy way to ruin the suspension. The “bones” are among the first to suffer.

Anti-roll bar assembly with stabilizer struts

If one of the stabilizer struts fails, it is recommended to replace both at once, because they work in pairs, and if one “dies”, the second one will soon break too.

Why coilover rebuilds and coilover suspension repairs should be done in JTlab

We have been repairing screw suspensions from various manufacturers for many years, such as:

- Ohlins

- TEIN

- CUSCO

- ZEAL

- RSR

- HKS

- XYZ

- DGR

- B.C.

- D2

- JIC

- Bilstein

We always have oil seals in stock, and we also have a wide range of possibilities for finding and delivering rare spare parts for shock absorbers from America, Japan and Europe. A wide selection of equipment for refilling coilovers allows us to repair mono-tube and twin-tube shock absorbers and fill them with gas. After repairing the coil suspension, we retain the shock absorber adjustments. A wide selection of shock absorber oils allows you to select suspension characteristics to suit customer requirements. We produce parts for coilovers, so we can perform even complex repairs or even manufacture a completely new shock absorber.

How to extend the life of stabilizer links

Stabilizer links on bushings can be reinforced with polyurethane silent blocks - there are companies that specialize in the production of suspension parts from this material. But there is no guarantee that you will be able to find a suitable size bushing, plus you will have to wait for delivery if there are no craftsmen in the city. Then you still need to repress it, and this usually requires special equipment.

With rods on hinges, everything is simpler and cheaper - you can extend their life (but they still won’t become eternal) with improvised tools and materials. The method is not complicated, but it requires some skill and patience. The point is to put more grease for the joints under the boot, since there is practically no grease there from the factory (one drop, as a rule). When the “ball” runs dry, its wear accelerates. A minimal amount of moisture or sand under the boot will quickly destroy the plastic liner and the hinges will rattle.

Factory lubrication of the stabilizer link (there is almost none - the finger is bare), photo dr1ver.ru

A generous amount of lubricant protects the working surface from moisture and reduces friction. Any viscous lubricant for joints will do; it is sold in every spare parts store. To get the grease under the boot, you need to bend it, to do this you need to remove one of the retaining rings - which of the two depends on the design and execution of the spare parts, it turned out to be easier for me to remove the large one, since the small one was in the form of an elastic band. You can take it off, but you may not be able to put it back on.

Factory lubrication of the stabilizer link, photo dr1ver.ru

When the boot is moved to the side, it is convenient to add lubricant. Try not to lubricate the boot seat and retaining ring - then it will be difficult to put them in place. We add lubricant without fanaticism - the excess will still be squeezed out when installing the boot in place, which will complicate reassembly.

Stabilizer link lubrication, photo dr1ver.ru

It should look something like the photo above. When assembling, you must not damage the rubber of the boot; with holes in the rubber, the stabilizer link will not last long, no matter how much lubricant there is.

Stabilizer link lubrication, photo dr1ver.ru

After lubricating one joint, we proceed to the next one and then assemble the rack back (this may be more difficult than disassembling). The first experience can be a little nervous, but with a little patience, everything will work out.

The stabilizer link is almost assembled, all that remains is to put the spring ring in place, photo dr1ver.ru

When everything is ready, you can install the rack on the car. After such manipulations, it definitely comes off more than usual. The main thing is not to “sour” your fingers - otherwise you will have to cut off the still “alive” one.

Installed stabilizer link for Rover 75. photo dr1ver.ru

It is not always possible to remove the boot - some manufacturers use special metal rings to secure them (joint to joint), which does not imply dismantling. Or they need to be snacked and exchanged for others that still need to be found. In this case, the game is not worth the candle.

High-level “Kulibins” are installed in the joint housings of grease nipples (grease fittings) to introduce grease and add it periodically. They say that this makes the parts last forever, but we haven't tested it (and don't believe it).

Common coilover failures

We have been rebuilding and repairing coilovers and rebuilding coilover suspensions for many years now; sometimes the owners of coilovers neglect the condition of the suspension so much that they have to change most of the suspension parts. Often, an accident or other incident causes damage to the shock absorber rod, housing or adjusting nuts or upper shock absorber cups. It has also become very fashionable recently to buy used screw racks on car club forums or auctions in Japan, Europe and America. Practice shows that most of these used shock absorbers require at least maintenance, and at most serious repairs even before installation on the car.

We list the main types of screw suspension failures:

- loss of oil due to damage to seals

- loss of gas due to damaged seals

- oil entering the gas chamber due to damaged seals

- water getting into the oil due to damage to the seals

- rod damage due to boot damage

- rod damage due to chrome peeling on the rod mirror

- mechanical damage to the rod from impact

- souring of the shock absorber adjustment mechanism

- souring of the adjusting nuts

This is not a complete list of possible damage to shock absorbers; the level of damage is revealed during primary and secondary diagnostics.

Diagnostics of helical suspension before repair

Before repairing a coilover, a primary diagnosis is first carried out, which can identify most of the breakdowns.

Primary diagnostics are carried out without disassembling the shock absorber and allow you to identify loss of gas or oil, damage to the oil seal and rod mirror, breakdown of the stiffness adjustment mechanism, and also allows you to assess the general condition of the shock absorber.

Secondary diagnostics are carried out with a complete disassembly of the shock absorber and allow us to identify all possible breakdowns and damage, such as the formation of an emulsion, chips getting into the oil, damage to seals, wear of guide bushings and others.

DIY stabilizer struts

“Kulibins” of the maximum level make reinforced stabilizer struts with their own hands, usually using ammunition in the form of a “grinder” and welding. Sometimes two parts of the rack are “seated” on a threaded connection (for subsequent replacement in parts, since usually only one ball out of two is broken). We do not accept interference in the design of the car, especially in parts that affect safety. This not only negatively affects the personal safety of the “craftsman,” but also affects other road users. But let us give a few examples of so-called “collective farms”.

Homemade stabilizer rods for Skoda Octavia

Homemade stabilizer struts Mazda 323

DIY Ford Focus stabilizer bar

The effectiveness of such work has not been scientifically proven and this obviously will not make the stabilizer struts last forever. But no matter what the child amuses himself with.

note

I would like to note that it is recommended to repair car shock absorbers only in pairs (standing on the same axis).

Leaking or play in the shock absorber rod is the most common reason why shock absorbers come to us for repair.

We draw your attention to the fact that with such repairs the characteristics (changes in compression and rebound forces) of the shock absorber do not change

We do not change the factory setting of the bypass piston in an automotive shock absorber (including the bottom valve for twin-tube type shock absorbers).

When working with a monotube shock absorber (these are shock absorbers from motorcycles, ATVs, snowmobiles and sports cars), we pump in the same amount of nitrogen as before the repair. Measurement is carried out before repair.

Or, at the request of the client, we can change the nitrogen pressure up or down.

Of course, there is a slight change in the compression and rebound forces when replacing the fluid in the unit, but this change is so insignificant that it cannot be felt on the car. Only our digital stand can show the difference. We consider this quite acceptable. We use special hydraulic oil of the MOTUL brand, which is intended only for use in shock absorbers.

We want the shock absorbers repaired in our company to please you for a long time with their high-quality and long-lasting performance. and we do everything for this.

Contact us, we will help you!

We are waiting for you in our service!

Which stabilizer links are better?

There is no ready-made recipe for choosing the best stabilizer struts; everything is individual and depends on the model and make of the car. In this case, as in general when repairing a car, the best choice is original parts, they are also called OEM. But car manufacturers rarely have their own factories to produce components; instead, they install products from specialized brands. Therefore, original parts are most often produced by premium brands, but with the logo of the car brand. The advantage of choosing original parts is that they are tested and approved by the company's engineers. The downside is the price - a part with the logo of your car brand can cost several times more than the same one, but with the emblem of the manufacturer (even if both parts were produced by the same company).

Information about who the manufacturer of certain parts in your car can be found in car enthusiast communities. With this information, you can buy the original part, but cheaper.

Stabilizer strut Stellox - there is little lubrication, but expensive brands sometimes have less, photo dr1ver.ru

In general, if you have a choice of which stabilizer struts to install, then parts from the brands Lemforder, Moog, Sasic, TRW . For "Japanese" and "Europeans" GMB . In some cars, the “bones” are consumables, so there is no point in overpaying, and you can supply ordinary Chinese spare parts from the Stellox and Patron . Sometimes they are as good as famous brands. As Metal also work well .

If the car is used mainly outside the city, you can install cheaper racks, if it is mainly off-road, city and bad roads, it is better to choose those that are more expensive, so as not to drive to service stations every 5,000 - 10,000 km.

Replacing the rod, valves, adjusting the stiffness of shock absorbers

The next malfunction is damage to the rod, seals, and valves inside the strut. There is a certain selection of spare parts on the market for repairing dismountable shock absorbers. In addition, an experienced car enthusiast never throws away old spare parts, but tries to repair them. In addition, you can always extract workable parts from them.

- So, let's disassemble the shock absorber.

Don't forget to wear gloves, the job is dusty

Turning work is usually cheaper than the cost of a new shock absorber

Tip: The entire process of disassembling the shock absorber should be photographed. This will avoid problems during assembly.

It is important to ensure the cleanliness of the unit; the ingress of dirt or solid metal particles will quickly damage the restored shock absorber. Get rid of stains, dirt and dust while disassembling

Get rid of stains, dirt and dust while disassembling

All parts must be carefully checked

It is recommended to replace the oil seal

After pumping the oil, the rack needs to be pumped as usual

Video: How to repair car MacPherson struts

https://youtube.com/watch?v=82i8P9E6WKU

If you have basic information about how your shock absorbers work, you can save money on replacing them. Most rack models are repairable, and components are either purchased at reasonable prices or made independently.