During operation of Vesta, after the first thousand kilometers, owners notice a knocking sound in the front suspension. The most common cause of extraneous noise is a worn stabilizer bar link. Let's look at the instructions for replacing it.

You will need : buy a stabilizer bar strut (part number 8450006750). Raise the car on a lift and remove the wheel.

Analogs

: Renault 8200 669 065, SASIC 4005146, SIDEM 5666 or LEMFORDER 28334 01, 26004 01.

Attention! To avoid injury, the struts should only be replaced when the stabilizer bar is in a relaxed state (both front wheels are suspended or evenly loaded with the weight of the vehicle).

Procedure:

- Use a wire brush to clean the stabilizer strut pin nuts from dirt and rust. If the nut is soured, use VD-40;

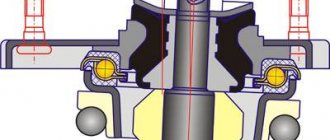

- Unscrew the nut of the upper fastening of the stabilizer link (No. 2) using a “16” spanner, holding the ball joint pin from turning with a “5” hex key;

- Unscrew the lower mounting nuts using a similar tool.

- Remove the stabilizer bar by removing the ball joint pin from the front suspension strut (No. 1) and from the stabilizer bar (No. 4);

To check the anti-roll bar link, you need to pull out the top pin of the ball joint, grab it firmly with your hand and wiggle it up and down. The presence of a knock indicates a faulty part. Installation of the stabilizer link is performed in the reverse order. The process is also shown in the video:

It is worth noting that this part is symmetrical and does not have oriented “top” and “bottom” installation marks. The rack mounting nuts are self-locking and cannot be reused, so they must be replaced with new ones during assembly. The tightening torque of the fastening nuts is 44 Nm.

It is believed that the average service life of anti-roll bar struts is about 50 thousand km. How long did they serve on your Vesta? Read other instructions, for example, on self-diagnosis of the suspension or recommendations on eliminating knocks or squeaks in the Vesta suspension.

A knock in the front axle is the first sign of a malfunction in the vehicle's chassis.

To independently replace the stabilizer struts (bones) on a Lada Vesta, you must:

- Place the vehicle within the perimeter of the repair area and block the rear wheels with wheel chocks.

- Break off the bolts, jack up the side, remove the wheel.

- Using a TORX key set to “16”, unscrew the upper fastening of the “bone”.

- By analogy, unscrew the lower fastening.

- Gently tap the tips and remove the “bone”. If the nut is difficult to remove, use WD-40.

- Clean the eyelets from dirt and deposits.

- Insert a new stabilizer link.

Similarly, we change the stand on the right side.

Replacement resource. Consequences of untimely prevention

Lada Vesta stabilizer struts are replaced under warranty after 50,000 km. In practice, the interval is shorter by 5–10 thousand km. If the machine is actively used on rough terrain, the “update” interval is reduced by a third.

The duration of use largely depends on:

- quality of road surface;

- driving style and manners;

- speed and temperature conditions.

When the first knocks appear in the front-wheel drive area, you need to visit a service station and order diagnostics using digital equipment.

Ignoring the vehicle’s “signals” contributes to a decrease in control efficiency. When cornering, the car rolls on its side, making it difficult to control the vehicle at speeds over 90 km/h. At higher speeds, emergency situations cannot be ruled out.

Front suspension. What might be a concern?

- Wheel bearings.

Wheel bearing noise can be detected by ear even by a less experienced driver. It howls and rustles when moving and, gradually increasing, begins to drown out all other noises in the cabin. To make sure that it is the bearing that is making noise, you need to turn the steering wheel a little when driving at speeds above 60 km/h. If the rumble appears in one steering position and stops in another, it means the bearing has definitely failed. You can also check this by lifting the car wheel and spinning it. If you hear a characteristic rustling sound, it means the bearing needs to be replaced.

- Stabilizer's pole.

Stabilizer links are the most vulnerable part of the suspension. Due to the poor quality of roads, they often fail and begin to produce a slight but constant noise from under the bottom of the car. You can determine if the struts are broken by resting the lever on the subframe and shaking the stabilizer. If during these actions a knock is heard and play is felt, it means that the stabilizer links are out of order.

These parts are usually replaced in pairs, and you can do it yourself. To do this, you need to hang the front wheels of the car, and using a 16 wrench, unscrew the hinge nuts, while holding them with a 5 hex wrench on the back side so that the hinges do not turn.

- Spherical bearing

The sound of a broken ball joint can be difficult to distinguish from other suspension noises. You can check the play of this unit by moving the suspended wheel in a horizontal plane. If the fault cannot be determined, you can insert a pry bar between the subframe and the lever and press on the resulting stop. This is the easiest way to identify a loose ball pore.

At the service center, the ball joint is replaced along with the lever and silent blocks. But these parts also exist for sale as a separate unit.

Replacing a ball is not an easy operation, so you can tackle it yourself only if you have the necessary tools and metalworking skills.

- Shock absorber.

Many drivers complain about the knocking of Lada Vesta shock absorbers, but their design itself eliminates this possibility. The telescopic strut consists of two cylinders that dampen vibrations while moving on uneven roads. When they break down, the car begins to “sit down”, the road holding is poor, all the unevenness and bumps become clearly noticeable, and the steering deteriorates. In this case, the outflow of liquid or gas from one cylinder to another is disrupted, and the shock absorber rod begins to make characteristic sounds that resemble knocking.

Visually, a breakdown of the oil shock absorber can be determined by drips on the casing, in the presence of which the part must be replaced immediately. You can also rock the car, focusing on the hood. Under normal conditions, after the impact ceases, the machine should swing once and stop moving. If this does not happen, the racks do not absorb as expected.

- Upper rack support

The upper mount of the front shock absorber contains a support bearing that can knock and howl when driving. You can identify a malfunction of this unit in the following way: swing the car in a vertical plane and put your hand on the support. If a part malfunctions, rattling and humming will be felt.

Another method requires completely dismantling the rack. This check can be done simultaneously with replacing the front shock absorbers. After removing the steering knuckle, you need to rotate the strut together with the spring in a circle. The crunching and grinding sound in the upper part of the assembly that occurs during this indicates that the support is faulty.

Like shock absorbers, it is advisable to change the upper supports at the station, since the process of dismantling and installing them is quite complicated.

Review of prices of original manufacturers

| Catalog item | Price in rubles |

| LADA Vesta front left / right (8450006750), stabilizer link length 275 mm | From 700 |

| RENAULT Logan suspension mounting bolt (30768) | From 130 |

| Nut RENAULT 7703034221 | From 300 |

| Cushion bracket 8450006747 | From 350 |

| Rod cushion 8450006748 | From 450 |

*prices are current as of 03/06/2019.

How to understand that the calipers are knocking

The brake line begins with a pedal inside the car and ends with a pair of discs and pads. The driver’s force, when he presses the brake, is transmitted through a complex system, the penultimate link of which is the caliper on Vesta.

Spring from the “classic”. Photo source: https://lada-vesta.info/694-stuk-supportov-lada-vesta.html

The part performs important functions:

- Presses the pads against the brake disc when the pedal is depressed.

- Fixes the pads at a distance from the disc when there is no force on the brake.

- Keeps the pads strictly parallel to each other and the disc - when misaligned, the braking surfaces quickly wear out and braking deteriorates.

The calipers on the Lada Vesta must work smoothly and be technically flawless. But at twenty thousand kilometers, when the car is still under warranty, an extraneous sound from the brake system appears from under the bottom. At dealerships, the issue is not resolved, citing the design features of the unit and the permissible noise level.

Drivers themselves have to get rid of the problem. But first you need to find out whether it’s the calipers on Vesta that are really knocking, and not the valves or other engine elements. To find the irritant, expensive diagnostics are not needed.

Analogs of stabilizer struts. Dimensions of components

| Catalog number/dimensions | Price in rubles |

| Toyota Rav4 (48820-42020), length 285 mm | From 2500 |

| Non-original from CTR (CLT50) | From 650 / piece |

| Renault, SASIC, SIDEM, LEMFORDER, length 275 mm | From 400 |

| Alfa/Fiat/Lancia 46413122 | From 370 |

| MONROE: L15600 | From 380 |

| Multipla, Lybra | From 350 |

| Kia Rio (548132K100) | From 370 |

| Stabilizer bracket, bracket (548141G000) | From 250 |

*prices are current as of 03/06/2019.

Front suspension struts ASOMI Comfort PRO (without lowering) for LADA VESTA and LADA VESTA SW

Description of Asomi series

Hydraulic struts and shock absorbers are an excellent option for replacing the stock shock absorbers installed by the manufacturer. The choice of car owners who prefer a quiet and comfortable ride.

Gas-filled shock absorbers and struts are ideal for those who prefer a more active driving style. Original settings of shock absorbers and struts ensure their reliable operation, significantly improve vehicle handling and guarantee comfortable vehicle movement both at low speeds on roads with significant unevenness and at high speeds on roads with good surfaces.

Gas-filled struts and shock absorbers with stiffer damping parameters. They are ideal for lovers of an aggressive driving style. Automotive suspension components of the SPORT series reduce vehicle roll when making sharp turns, ensure its stability and controllability at high speeds, and guarantee safety when driving quickly.

Gas-filled struts and shock absorbers that provide lift (lift) of the front and rear suspension of the car up to 15 mm. This is the choice of those drivers who would like to improve the vehicle’s off-road capability and driving on non-paved roads, as well as increase the vehicle’s carrying capacity.

ASOMI struts for LADA Vesta cars improve the driving performance of the car, significantly increase its handling and guarantee comfort.

ASOMI struts on the Lada Vesta have a reliable two-pipe gas-filled design and original settings. The use of “gas boost” in the reservoir significantly improves the performance of shock absorbers in “transition” modes during rapid changes in the quality and type of road surface, and as a result, ensures effective traction of tires to the road, reducing roll and swaying of the car at high speeds and when making sharp turns. In addition, low pressure gas guarantees comfort and prevents knocking in the initial stages of vehicle movement in the cold season and guarantees comfort when driving over uneven surfaces.

When designing struts and shock absorbers for the Lada Vesta, design solutions were used that took into account the characteristics of vehicle operation on Russian, far from ideal roads, climatic conditions (low temperatures in winter and high temperatures in summer) and consumer preferences. Thus, ASOMI struts and shock absorbers for LADA Vesta have a larger diameter of working cylinders and rods compared to the original struts and shock absorbers. As a result of the increased size of the cylinders and specially selected resistance forces, ASOMI struts and shock absorbers have increased energy intensity, which improves the car's behavior on the road without reducing the smoothness of the ride.

IMPORTANT:

Racks for Lada Vesta TM ASOMI are suitable for installation with standard springs and supports, however, it is necessary to replace the standard compression buffer with a protective casing with a buffer A110.2902.816 (2110-2902816) with a casing 2170-2902814.

Advantages of ASOMI racks:

- high quality and attractive price,

— original characteristics providing increased comfort and high controllability,

— provide effective traction of tires to the road, reducing roll and swaying of the car at high speeds and when making sharp turns,

— prevent knocking and guarantee comfort in the cold season, when driving over uneven surfaces, potholes and holes,

— have a larger diameter of the working cylinders and rod (compared to the original struts), which guarantees an increased service life,

— stability of operation both at low temperatures in winter and at high temperatures in summer,

— 100% check of racks at the stand,

- original protection.

APPLICABILITY:

LADA Vesta

Guarantee period:

12 months (unlimited mileage)

Preparation of the workplace

- TORX wrench, socket set;

- rags;

- additional lighting;

- new “bones”;

- liquid for removing rust and deposits;

- related consumables that need to be replaced.

Sequencing:

- We install the machine on a flat platform. We fix the rear row of wheels with wheel chocks.

- Unscrew the bolts, jack up the left side, and remove the wheel.

- Raise the car with a jack until the pressure on the bone decreases and it becomes easier to rotate.

- Using a key set to “16”, unscrew the upper and lower fastenings. Gently tap with a hammer and remove the tips from the seat. We use WD-40 as needed.

- We clean the eyes, remove dirt, deposits, and rust.

- We press in the ends of the new stabilizer link.

- Tighten the nuts with a torque wrench to a force of 5 Nm.

By analogy, we replace the racks on the right side.

What you need to know about the rear suspension elements of the Lada Vesta

In the rear part, the suspension function is performed by a torsion beam, shock absorbers, springs, silent blocks pressed into the beam.

As the machine is used, parts wear out, backlash is formed, and free play increases. To eliminate the defect, it is necessary to replace the rear suspension elements.

- After removing the wheel, unscrew the upper and lower fastenings of the shock absorber strut assembly with the spring. Next, we unscrew the beam fastening, press out the silent blocks, inspect the mounting socket, and press in new bushings.

- Sometimes sagging rear springs make a metallic knock. Inexperienced motorists mistake this for a knocking sound from the stabilizer bar. To replace the spring, first remove the rear shock absorber and spring assembly.

- Using a crab-shaped puller, we compress several turns of the spring and disassemble the module. We install a new spring and assemble the structure.

- At the same time, we carry out troubleshooting of the brake circuit, pads, disc, and working cylinder. If the actual thickness of the pads is less than 19.0 mm, replace them with new ones. Subsequent operation of the machine is unsafe.

Recommendations for selection

When purchasing consumables, prefer original ones; do not purchase analogues or substitutes, even if they are compatible in size.

Note to the driver. Stabilizer struts from Toyota Rav 4 are compatible with Lada Vesta; many car enthusiasts install them instead of standard ones. However, they are 10 mm longer than the originals. When a wheel falls into a hole at speed, the suspension arm hits the lower mount of the bone. An additional blow occurs.

Before purchasing, consult with service station specialists regarding the compatibility of the part with the make (model) of your car. If you are not sure that you can install spare parts efficiently, use the paid services of workshops.

stabilizer CLT - 50 1PCS

Conclusion

The process of replacing a stabilizer link is within the power of every car enthusiast. You need to be extremely careful not to disrupt the installation technology. Incorrect installation contributes to premature wear of parts and failure of mechanisms.

Tips for caring for Lada Vesta suspension

- We adhere to the manufacturer’s recommendations regarding the scheduled technical inspection interval - every 15,000 km,

- The average service life of the suspension is 60 – 65 thousand km. Mandatory preventive maintenance after 15,000 km,

- Purchase components from official points, representative offices, dealers,

- Order paid car repair services only from those service stations that provide a quality guarantee for the work performed,

- Always check the compatibility of parts according to the catalog numbers specified in the operating instructions,

- After carrying out repair work at the service center, check that the technicians have entered maintenance data into the service book.

Driver, remember that a moderate driving style and original parts increase the service life of Lada Vesta parts by 7 - 10%.

Which stabilizer struts are best to install? Obviously, new ones and with factory catalog numbers. Installing parts from other models is a temporary solution to the problem, not always effective or correct.

Reviews

| № | Positive |

| 1. | Kirill , 33 years old (drive2.ru) Sverdlovsk: the car is three years old, there are no capital investments, except for the costs of scheduled technical inspections. The front end does not make noise, does not knock, I drive carefully, at medium speed. The car “sleeps” in the garage, and I systematically carry out diagnostics. |

| 2. | Anatolyevich , 43 years old (prom.ua), Krasnodar: I have no complaints about the suspension of the Lada Vesta, I use the car actively, every day. In two years, I checked the camber-toe angle once. |

| 3. | Gennady , 36 years old (autotoday.com), Omsk: I didn’t expect such good quality from a domestic manufacturer. Lada Vesta was a great success, I like it, good build. I have no complaints, I’ve been riding for a year and a half with pleasure. |

| 4. | Kirill Ivanovich , 46 years old (rozetka.ua), Rostov-on-Don: the car is three years old, like new condition. I look after the equipment, drive carefully, and regularly visit service stations for diagnostics. |

| 5. | Dmitry Vyacheslavovich , 42 years old, Kursk (avtoflit.com): my positive review of the Lada Vesta car. There is something to compare with, the previous model was Lada Granta, the quality is “weaker”. Well built, it turned out to be a solid car. Finally, a domestic manufacturer has pleased car enthusiasts. |

| 6. | Valentin , 34 years old, Voronezh (autotoday.com): I buy only original consumables; I don’t trust analogues, even high-quality ones. The car is in its fourth year, there are no comments on the suspension or chassis. I consider this a good indicator that I am on the right path. |

| 7. | Fedorovich , 45 years old, Ufa (drive2.ru): I saved on consumables once, but later regretted it. It was hardly 40,000 km, so I replaced it with original ones. The racks are still in service, no complaints. |

| 8. | Mikhalych , 39 years old, Bashkortostan (drive2.ru): during the three years of active operation of the car there were no critical breakdowns, all mechanisms operate as normal. There are no complaints about the suspension, I hope it will last for more than a dozen kilometers. |

| Negative | |

| 9. | Vasilyevich , 48 years old (prom.ua), Saratov: I’m not satisfied with the quality of manufacturing of the factory seeds; they served for 45,000 km, after which they replaced them with foreign analogues. The last ones were already 60,000 and without a hint of repair. |

| 10. | Davidich , 45 years old, Moscow (avtoflit.com): after the second winter, the suspension made itself felt. I drove onto the overpass, checked the hinges and racks - they needed to be replaced with new ones, there was some play. |

| 11. | Ivanych , 33 years old, Voronezh (drive2.ru): the car is in its third year, the front creaked, most likely the bones were worn out. For such a short mileage the resource is small. Comrades advised to buy foreign analogues, the price is 20 - 30% cheaper than the originals. I'll try it and post the results. |

| 12. | Vladimir , 36 years old, Pskov (autotoday.com): after buying a car off the showroom floor, at the second maintenance, I replaced a number of spare parts with foreign analogues. Their quality is an order of magnitude higher than domestic ones, and their service life is longer. Stabilizer struts from Renault Logan and Kia are suitable for Lada Vesta. |

How to increase the service life of racks

Experienced drivers have developed their own procedure for extending the life of car suspension parts.

- Completely eliminate high-speed driving on bumpy roads. The main factor that causes shock absorbers to fail is the presence of shocks to the suspension. This is especially painful at high speeds.

- Maintains correct tire pressure. Car tires also participate in shock absorption, as do damper inserts. It is optimal to monitor the indicators inside the wheels every 500 - 700 kilometers. The bottom line is that the built-in puncture sensors may not work or display data incorrectly.

- Timely prevention and diagnostic procedures. Actions will help prevent serious problems with the chassis of the car. When play forms inside hinges or joints, uncontrolled destruction of parts occurs.

- No overload. The machine is not designed to transport heavy loads. If you consistently overload the suspension, you can quickly kill it.

- Installation of high-quality consumables. Some users are trying to save money by purchasing original parts or high-quality analogues, preferring cheap components. It should be understood that a penny saving on parts can result in an expensive, comprehensive suspension repair.

Video - Replacing the stabilizer link

Three years is a short time for a new car. But today the car is widely known and actively discussed. This is not about its advantages and merits, on the contrary. Drivers complain about problems that arise literally from the first kilometers of operation.

The main problem, so to speak, the stumbling block, was the suspension of the Lada Vesta. Although the management of the automobile plant assured that it was adapted taking into account Russian roads. However, a miracle did not happen and the stabilizer struts on Vesta became consumables, which have to be changed after a run of 5 thousand km.

Today we will look at the principle of operation of racks and find out the role of diagnostics. We will reveal the algorithm of actions when replacing them with our own hands and separately highlight the issue of selecting transverse stability struts. Let's find out which analogues can be used in the repair process.

Detected malfunctions in the suspension

Even during the release of the first batches of Vesta from the assembly line, buyers rightly noticed shortcomings in its work, which were corrected in subsequent batches. The sounds that the rear or front suspension can make are very varied - the design is very complex, consisting of many parts that can fail. However, the most common breakdowns among Lada Vesta owners stand out and are worth disassembling.

Creaking, crunching, knocking from the rear suspension of the Lada Vesta

Rear crunching is a fairly old problem for West. The knock of the rear chassis is corrected according to a special instruction from AvtoVAZ, according to which the design will have to be slightly supplemented. Between the upper support and the rear shock absorber strut you need to place a washer with a length of 130 mm, a distance between the holes of 100 mm (hole radii - 5 mm), a base radius of 34 mm, and finally a radius of the main hole of 25 mm.

The crunch will disappear, but only if the washer matches the dimensions, otherwise a gap will appear between the body and the support, into which dirt gets trapped. The cause of concern due to crunching or knocking may also be:

- worn trunk lid damper;

- stretched handbrake cable (it can be pulled from the passenger compartment);

- trunk lock;

- rear sofa backrest fasteners.

And just in case, check the contents of the trunk itself - there may just be tools rattling around there.

Bumping knocks and noises in the front suspension of Lada Vesta

- The first, most popular reason for calling for service is the thumping (knocking) sound of the front suspension of the Lada Vesta, which comes from the stabilizer. Typically occurs when driving over artificial bumps. Stabilizer bushings, unfortunately, are not suitable for long-term use; even lubricant will not help - the only way to treat them is by replacing them. To solve the problem, you can install polyurethane bushings from Niva Chevrolet, its number is 17-012-680.

- The second reason for knocking can be called play of the ball joint, when a large gap is created between the parts. Problems can be solved by changing the design with levers. A grinding noise can be heard due to wear on the stabilizer struts and can mean that the car is gradually “losing” confidence when cornering.

- The creaking of the front suspension is caused by the hinges of the stabilizer struts. While driving, a knocking noise may occur due to insufficient tightening of the wheel bolts. When such a sound is heard, it is better to contact a service station as quickly as possible to prevent parts from breaking.

- The reason why the suspension on the Lada Vesta rattles and creaks can be heard may be that one of the parts has worn down to a sufficient level and is now knocking against another. To notice damage in time, it is enough to periodically inspect your car. If something is rattling, the part can be identified by shaking the car.

- If crunching or knocking noises in the front suspension are heard infrequently, the cause most likely may be a torn steering rod oil seal. This oil seal is in very close contact with the subframe of the vehicle (the distance between them at rest is 1 cm), and they collide at every bump. The oil seal breaks, and the connection of the rod to the rack hits the subframe.

Principle of operation

The stabilizer is a metal pipe that connects to the front wheels of the vehicle. Fastening is carried out using cylindrical rubber. This is the stabilizer bushing. Its task is to ensure rotation of the stabilizing unit relative to the machine.

The suspension is a familiar analogue of the French Renault car. It works great on the roads of the post-Soviet space. Therefore, no technical changes have occurred in the design of the suspension system.

The operating principle of the Lada Vesta anti-roll bar struts is similar to its French counterpart.

Which stabilizer struts are best installed on Lada Vesta

Do you experience knocking noises in the front suspension area while driving over uneven surfaces? The cause may be the front stabilizer bar struts. Let's figure out which stabilizer struts for Vesta are best to choose.

- 8450006750, produced by Metalloproduktsiya LLC, Togliatti, price about 700 rubles.

- 8450032566, produced by LADA Izhevsk LLC, Izhevsk, price about 1000 rubles.

- Track SL70198

- RTS 97-90474

- TRW JTS144

- NK 5113913

- CTR CLT-50

- BREKNER BK90141

- STEELOX 56-01014A-SX

- Monroe L15600

- RTD 8450006750RTD

- SIDEM 19061

- MIKA 8450006750

- and etc.

- A year after the start of Vesta sales, AvtoVAZ modified the front suspension stabilizer bar. The new design of the stand does not allow the liner to move in its hinges, eliminating extraneous noise.

- The play of the stabilizer struts caused knocking noises in the front suspension of the editorial Vesta “Behind the Wheel” already at 43,000 km.

What front anti-roll bar struts do you recommend installing on Vesta? How long did it take for your factory racks? Leave your feedback in the comments, take part in the survey.

Diagnostics

The first signal of failure of the element in question can be heard after 5 thousand kilometers. We are talking about a characteristic knocking sound when the wheel hits a small obstacle or falls into a hole. The knocking sound may appear, suddenly disappear and resume again.

The quality of our roads cannot be called ideal, so the anthers are the first to suffer and tear. As a result, dirt and dust seeps inside. They are the cause of premature failure of the elements of the stabilizing system. Further, play forms in the ball joint: this is the cause of the noise.

Having discovered an emerging problem and determined the condition of the Lada Vesta stabilizer struts, a set of diagnostic measures will be required.

Today, service centers are armed with enough modern instruments and devices that can determine the technical condition of a vehicle.

After the verdict is made, you can make a decision:

- What components to install: original or analogue.

- Where to carry out the replacement: in a car service or in your garage, on your own.

Why do you still need to replace?

Let's return to the principle of operation of the car's lateral stability unit. When the outer wheel turns, the force of inertia pulls the outer wheel in the direction opposite to the turn, and the inner one tries to break away from the road. Thus, the suspension of the outer wheel is compressed, which forces the stabilizer to rotate upward. This means that the part of the stabilizer closest to the turn attracts the wheel to the road, which, thanks to the force of inertia, tries to break away from the road. The stabilizer lever rotates inside the bushings. There is no point in explaining further why timely repair of failed elements of the stabilization system with high-quality new ones is necessary.

Replacing stabilizer struts on a Lada Vesta with your own hands

If you decide to replace the Lada Vesta stabilizer struts yourself, you need to understand what dimensions the analogs and the original have. Next, prepare the tool and get to work.

We'll talk about analogues and original products (their sizes) a little later, but now let's look at the sequence of actions. Let's find out what tools are needed during the dismantling and installation process, which, by the way, does not take more than 60 minutes.

- New set of stabilizer links.

- Jacks 2 pcs.

- Shoes for wheels or a couple of bricks.

- We stock up on WD-40.

- You will need a wheel wrench.

- Key No. 16: socket.

- Key No. 14 for a new rack.

- Key number 15 for a new rack.

- Torx T-30 for a standard rack.

AvtoVAZ official opinion

To answer thousands of questions from car owners about stabilization problems, AvtoVAZ has the following opinion; These are design features of the model caused by the long working strokes of the struts when driving on uneven roads.

Officially recommended:

- bushing lubrication;

- installation of rubber-metal hinges, [under development].

Point one is reminiscent of servicing the Volga GAZ-21 [fifties]. It recommended lubricating ten lubrication points under the car body, after rain and once a week. True, no one suggested doing interesting things like lubrication of bushings. The most incomprehensible thing is how to smear them. Whether it is worth disassembling the stabilization unit or not is still unknown. Although old cars can still be found on the roads and nothing creaks or breaks for years.

Regarding the short operation of the stabilizer struts: They promise to bring them to normal condition. Now the problem is caused by the liner, which creates play inside the ball joint. Replacement of stabilization struts can be done free of charge at the dealer, it does not cause problems, they know about the problem with the stabilization unit and are ready to make repairs. But in this case, it’s much more profitable to learn how to change yourself. The reason for this is quite obvious. Replacing standard spare parts at a dealer does not imply the installation of spare parts or consumables from other brands of cars. How to change the stabilizer struts yourself in 5 simple steps Replacing the stabilization struts on a Lada Vesta car comes down to a simple algorithm, but there is also preparatory work: It is necessary to hang the front wheels of the car. Firstly, this is required by safety measures [the unit must be unloaded when removed from the vehicle]. Secondly, it’s much more convenient to work this way. Let's get started:

Dismantling sequence

The first step is to remove the wheel: unscrew the mounting bolts. If the nut does not budge (soured), VD-40 is used.

Rust is cleaned off and dirt is removed from the fingers of the stabilizing mechanism. The work is carried out using a metal brush.

The upper fastening nut is dismantled. You will need a ring wrench No. 16. To secure the hinge pin from turning, use a wrench No. 5.

Work with the lower fastening is similar in the sequence of removing the upper arm.

Causes of wear on Lada Vesta suspension

- Saving on maintenance of technical equipment;

- Purchase and installation of low-quality parts;

- Violation of the rules for operating the vehicle by the driver;

- Manufacturing defect;

- Natural wear and tear of components due to prolonged use without intermediate preventive maintenance;

- Rupture of the boot, water entering the metal structure;

- Excessive wear of subframe silent blocks.

Installation of stabilizer struts

Installation of the new kit is carried out in the reverse order.

When tightening, you do not need to exert high physical effort. 44 Nm is enough. If you are installing the original, you need to know the product catalog number: 8450006748.

Sometimes you can only get by by replacing the stabilizer bushings. Stub bushings are suitable in dimensions d/h/w: 40/45/38 mm. hole diameter 22 mm.

Of particular interest are products made from polyurethane in the following dimensions: L/W/H: 39/42/43.5 mm. similar dimensions to Chevrolet Niva.

Also suitable are consumables, which according to the catalog go under No. 2123-2906046. If we talk about KIA, this is the catalog number KSBSJULF-21.5 mm (54813-2K 100). This option uses brackets 54814-G000.

Please note that the installation of other spare parts may change the driving performance of the vehicle. This will affect the stiffness when driving straight and cornering.

For complete clarity, we present the average prices of assembly bushings:

- The stub will cost 450-700 rubles.

- Niva costs from 150 to 300 rubles per pair.

- KIA option 150-600 rubles per unit (piece).

Please note that the part in question is symmetrical. Therefore the installation does not matter. There are no "up" or "down" designations on the stabilizer bushings. This greatly simplifies installation and reduces work time.

In addition, the fastening nuts are disposable. When assembling a new kit, you need to use new fasteners.

What's the matter?

The reason for the dissatisfaction of many Newsmakers is the creaking. It is no secret that the stabilizer bushings of the domestic model very soon begin to creak, and sometimes this happens almost immediately after purchase. There have been cases when the car did not have time to travel even 1,500 km, and some manage to drive without making noise for less than 1,000 km. As for the frequency of squeaking, surveys show that this happens in approximately 60% of cars.

Creaking is typical for many Vestas

This creak can be clearly heard in the video.

It is also worth noting that such a squeak is rarely heard constantly. Usually it appears and then disappears. In this case, the problem is extremely clear - the quality of the material or the manufacturing of the components is not high enough.

In this case, there are two solutions:

- Contacting the dealer;

- Independent work.

In general, both options are working, however, both the first and second have certain disadvantages.

Analogs of stabilizer struts Lada Vesta

Now let's look at the issue that worries many Vesta owners. These are original kits and products from related companies. What analogues are suitable and what are their sizes.

The length of the factory stand is 275 mm. Among the analogues we highlight:

- Racks Toyota Rav 4. Length 285 mm. Article 48820-42020.

- Russian set, costing 520 rubles.

- Products of the CTR company. Article CLT Unit price 600 rub. therefore, the cost of the set is 1200 rubles.

- Instead of the “native” stabilizer bar of the Lada Vesta, you can install an ALFA/FIAT/Lancia analogue

- Renault

- SASIC

- SIDEM

- Lemforder

Of course, other kits are also suitable. But these are the most common. Plus, they are affordable.

What racks should I put on Vesta?

Domestic car enthusiasts are often faced with the purchase of new shock absorbers. The 2022 market has a lot of common offers of varying quality and price segment. In such a situation, choosing a quality product is problematic.

Among the most popular manufacturers are the following.

- AvtoVAZ - factory racks are practically the cheapest on the market. Most drivers prefer to choose the original and not bother with the choice.

- SASIC - brand stands are more expensive, but they also take longer to maintain. If factory analogues last approximately 20,000 kilometers, manufacturer parts can survive 30-35 thousand kilometers.

- LEMFORDER is the most common company among its analogues. The company has been on the market for more than 25 years. During the work, users appreciated the quality of the parts and are happy to pay 1000 - 1200 rubles per piece for shock absorbers.

- Renault - experienced users indicate that replacing the rear struts of the Lada Vesta with an analogue from the specified company allows for better control of the car in corners. Tight elements reliably keep the car from rolling and guarantee stable grip on uneven surfaces. The cost of one unit of goods starts from 1500 rubles.

Diagnostics: how to understand when you need to change struts

The first sign that the strut is out of order is a characteristic knocking sound that appears when you hit a bump or the wheel gets into small holes. It appears after 5 thousand kilometers, not earlier. As a rule, knocking does not appear constantly, but periodically.

Due to the poor quality of roads, the anthers tear quite quickly. Because of this, dust and dirt gets inside, “eating up” the stabilizer elements. Over time, play appears in the hinge joint, which is the cause of extraneous noise.

Replacement Guide

In order to change the stabilizer link, you need a lift or two jacks. Unloading the racks is mandatory, and this is only possible with the car raised.

Carefully! You cannot replace an element if it is in a stressed state. Hanging the front wheels allows you to fulfill this condition.

It will not be possible to replace the stabilizer struts without two stumps or bricks, an inspection hole, a 16-size socket wrench, a 14-size wrench, a 15-size wheel wrench, and WD-40. A key for 14 and 15 is required to install a new pair. Different models may require different keys.

First of all, it is necessary to install wheel chocks under the rear wheels. Next, remove the decorative caps on standard alloy wheels. To do this, you need to use a screwdriver.

After this, the bolts are unscrewed, but everything is done while the car is on the ground. Jacks must be placed according to special marks available on the Vesta thresholds. Using a rolling hydraulic jack will greatly simplify the task.

After removing the front wheel, the part will become visible. The first step is to unscrew the top hinge. Using a VD will greatly simplify the task. Next, take a 60 TORX with a 16 wrench. Using the wrench, you need to remove the nut that secures the strut to the shock absorber. In this case, it is necessary to hold the hinge rod. The presence of corrosion can interfere with this process, so we again use VD.

Next, you need to pull the finger out of the mounting hole. You should start with the bottom hinge. Some difficulties may arise due to the fact that the element is located in a hard-to-reach place. It will be much faster if you do all the work from the pit. To get the entire old part, you need to pull out the hinge pin. A new one is installed in place of the old stabilizer link. Everything is put together in reverse order.

Dimensions and components of racks

At the factory, the car is equipped with racks that have a size of 275 mm. Replacing stabilizer struts on a Lada Vesta is only possible with the correct selection of length. Using a longer or shorter part may cause it to break and cause you to lose control of the vehicle.

Features of racks and their components:

- The liner and body were ultrasonic welded. Thanks to this permanent connection, rotation during operation is excluded.

- The liner is made from quality polymer and features an advanced one-piece design for increased durability.

- The hinge has increased wear resistance.

- The hinge is protected by wear-resistant rubber.

- The ball stud has a TORX hole, making it easy to install.

- A cold-burnt body is used, which is lightweight and durable.

- Reliable fastening.