The carburetor is one of the most complex components of the fuel system of any gasoline unit. Its purpose is to prepare the air-fuel mass by saturating gasoline with oxygen in the required proportions with further supply of the finished mixture to the cylinders. Mixing of ingredients is carried out in the required consistency, corresponding to the operating modes of the motor. In this article we will look at the basics of how a carburetor works, analyze its design in detail and describe the main elements.

Carburetor for VAZ 2105 - device

The carburetor plays a vital role in the fuel system of any car or mechanical system. This part is used to combine fuel with air in the correct proportion for natural combustion and operation of the entire mechanism. The VAZ 2105 carburetor is suitable for uninterrupted use in different modes. For each individual mode it is necessary to provide a separate air-fuel mixture.

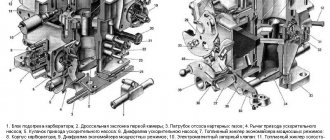

Carburetor models 2105-1107010 and 2107-1107010 from the throttle valve drive side: 1 - air damper; 2 — starting device; 3 — three-arm air damper control lever; 4 — telescopic rod; 5 - microswitch; 6 — throttle valve drive lever; 7 - lever limiting the opening of the throttle valve of the second chamber; 8 — return spring; 9 — pneumatic drive rod; 10 — pneumatic drive of the throttle valve of the second chamber.

With the development of high technologies and mechanical engineering, carburetors are inferior to injection units. They are characterized by greater functionality and improved details. Carburetors still have a number of undeniable advantages. For example, starting the engine the first time in the most severe weather conditions. In addition, thanks to the suction, the heating process of the power apparatus occurs much faster.

Functions of the carburetor on the VAZ 2105

- responsible for starting the engine after idle time;

- regulates the supply of gasoline while the engine is running without connecting to the transmission;

- mixing air and fuel in the correct quantities with further transfer to the power unit;

- guarantees additional fuel supply when the vehicle accelerates.

Structural parts of the carburetor for VAZ 2105

- lid;

- main block;

- throttle body.

In turn, the carburetor cover consists of a semi-automatic starting system, a filter, a float with a valve and an econostat tube.

The main block diagram contains more details:

- air and fuel jets, diffusers, which constitute the main dosing system;

- float chamber;

- pump;

- transition system and idle channels with jets;

- fuel supply channel;

- vacuum drive unit.

At the bottom of the carburetor there are axles with dampers and adjustment screws. The channels of the starting system, idle speed, and crankcase ventilation also end here.

Algorithm for carburetor operation on a VAZ 2105

The principle of operation of the carburetor is quite simple - in the intake manifold, which connects the fuel system with the power unit, a decrease in pressure occurs when the engine is turned on. As a result, a vacuum occurs in the carburetor. The vacuum thereby provokes the simultaneous absorption of air and gasoline. Then these two elements are combined to form a working mixture, which, when ignited, sets the pistons in motion.

Idle system

Prepares a rich hot mixture while the engine is idling. Fuel from the emulsion well enters the idle jet 33 (see Fig. 33) and is mixed with air entering through the air jet 26. Then, in the form of an emulsion, it passes through the emulsion channel and exits through the holes into the throttle space. The emulsion output is regulated by screw 37 for the quantity of the mixture and screw 36 for the quality of the mixture. The outlet hole above the screws ensures that there are no “dips” in engine operation when the throttle valve is opened. To prevent violation of the factory idle speed adjustment, plastic limiting bushings are pressed onto screws 36, 37, allowing the adjusting screws to be turned only half a turn. Blue bushings are installed at the factory, and red bushings are installed at service stations.

Types and modifications of carburetors for the VAZ 2105

The carburetor for the VAZ 2105 and its modifications - Ozone, Solex - are produced at the Dimitrovograd Automotive Component Plant.

- Ozone - among its other parts there is an idle air control. Suitable for classic VAZ models - 2107, 21043, 21074;

- Solex - in comparison with previous options, it is the most versatile. Used in new front- and all-wheel drive versions.

Carburetors are also distinguished depending on the supply of fuel mixture to the cylinders:

- float - consists of a mixing and float chamber;

- needle;

- bubbler - represented by a fuel tank in which there is a board and two pipes.

Following the direction of fuel flow, carburetors can be:

- horizontal;

- vertical - with upward and downward flow.

For the number of cameras:

- single-chamber;

- multi-chamber.

The Zhiguli 2105 uses four-stroke, four-cylinder Ozone. The most commonly used 2105-1107010-20 and 2105-1107010-10 Ozone models.

The difference between them is the cross-sectional size of the following elements:

- additional pipe;

- the main jet, which is located in the primary chamber.

What's the problem with the valves?

The concept of “adjustment” is that a specialist should restore the original clearances of the power unit. The signal for the need for repairs is a sound - tapping when the engine is running. As a rule, with minor changes in the gap, knocking is present only at the beginning, and then under certain loads. But over time, the condition worsens and the knocking becomes constant. You can miss it at first. But over time, when the noise becomes constant, even an inexperienced driver should not miss it.

The problem can be not only an expanded, but also a narrowing of the gap. The balance of the engine is set during assembly so that all the internal combustion power is transferred to the pistons at a certain pressure and speed. The gap (no matter which way it changes) will introduce an imbalance into the operation of the machine, which promises a drop in power under loads necessary for powerful operation.

Adjusting the carburetor VAZ 2105

Adjusting the VAZ 2105 carburetor is a fairly simple task if you have minimal technical knowledge. Otherwise, the best solution would be to contact a professional, since rash intervention can only aggravate the situation, and you will be forced to resort to repairing the 2105 carburetor.

If you are still confident in your capabilities, then such adjustment of the VAZ 2105 carburetor device will significantly improve the functionality of the mechanism, reduce fuel consumption and improve the performance of the power unit. If this procedure is carried out competently and wisely, then it will not harm the 2105 carburetor in any way.

To do this you need to do the following:

- change the crankshaft speed. Screw it until it stops, and then turn it 3 turns in the opposite direction;

- the amount of ozone needs to be adjusted. For this procedure we need a quality screw. It needs to be turned all the way, and then returned back four to five turns. This will increase the fuel fluid level;

- warming up is a necessary and integral part of carburetor tuning;

- the next step will be to adjust the idle speed of the DAAZ 2105 carburetor. To begin with, using the quantity screw, it is important to stabilize the operation of the power unit, while simultaneously turning the quality screw. Such a rotational imbalance will cause unstable engine operation. Now you can begin to gradually unscrew the screw back until the power apparatus is restored;

- In the end, it is important not to forget about adjusting the idle speed. This result can be achieved by using a screw.

After adjusting and tuning the carburetor on the VAZ 2105, it would be appropriate to check its serviceability. Start the car, and then sharply press the gas pedal, releasing it just as sharply. If all steps were performed correctly, the crankshaft will begin to rotate faster. This means that the adjustment of the VAZ carburetor was successful. If you fail to start the car, increase the number of revolutions using the screw.

Features of the timing chain and belt

One of the components of servicing the VAZ-2105 engine, like any other, is replacing the gas distribution mechanism drive. But the difficulty of performing this operation on this car depends on the type of drive used. Replacing a VAZ-2105 timing belt is easier than replacing a chain, but it also needs to be changed more often.

The ease of replacing the belt is one of its most positive qualities. Additionally, the belt is not so noisy, costs much less, and does not stretch very quickly.

The main disadvantage of the belt is the possibility of it breaking. And although the negative consequences of this breakage are structurally reduced by applying special grooves on the pistons, eliminating the possibility of a collision between the open valve and the piston bottom, the fact of the breakage itself remains unpleasant. In addition, the service life of the belt can be significantly reduced due to engine fluids getting into it.

The possibility of a chain break when the engine is running is practically eliminated, given the fact that the VAZ-2105 timing chain is double-row. Another positive quality of the chain is that it has a significantly longer service life than a belt.

But the chain stretches over time, and although there is a mechanism for tensioning it, when stretched, the noise of the engine increases significantly. Also, the chain requires lubrication, so it must be located inside the engine, which makes replacing the VAZ-2105 timing chain more complicated.

Assembly

Reassemble the carburetor in reverse order. In doing so, pay attention to the following:

- the float must rotate freely on its axis without touching the walls of the chamber;

- the needle valve should slide freely in its seat, without distortions or jamming;

- Before assembling the float chamber cover, adjust the fuel level in the float chamber;

- To avoid mixing up the jets during assembly, pay attention to the markings of the jets and when installing them, follow the table. 3;

- after tightening the screws securing the throttle valves, caulk the screws against self-loosening on a special device that does not allow deformation of the valves;

- When assembling the accelerator pump, tighten the screws securing the cover 3 by pressing lever 2 of the pump drive all the way, tighten the cover screws completely and release lever 2.