Phase sensor VAZ 2112

The phase sensor (PPV) is one of the most critical elements that ensures optimal operation of the internal combustion engine. Its main purpose is to analyze the angular position of the camshaft in a certain time period. The information received from it is needed for the operation of the ignition and fuel injection mechanisms. Having this data, the car ensures coordinated operation of the camshaft, taking into account the placement of the cylinders in the engine, which allows the supply of gasoline to a specific cylinder and ignition of the fuel-air mixture.

Symptoms of a problem

If you have the following symptoms, then the phase sensor (df) is most likely faulty.

When starting the engine, the starter spins for 3-4 seconds, then the engine starts and the check engine lights up. In this case, during startup, the computer waits for readings from the phase sensor, does not wait and switches to engine operating mode relying on the ignition system (according to DPKV).

Increased gasoline consumption. (Also read: Reasons for high fuel consumption on VAZ)

Self-diagnosis mode failures.

Reduced engine dynamics. (the reason may also be the mass air flow sensor and low engine compression)

Relay and fuse box at the link.

On these engines, the sensor is located at the end, in the rear cover of the timing belt. Replacing the camshaft sensor on a VAZ 2110, VAZ 2112 is not at all complicated: use a “ten” key to unscrew the two bolts and remove it from the cover.

How to check

1. Set the voltage at voltmeter V1 on the power supply unit “E” to 13.5±0.5V, the voltage at contact “B” of the sensor must be at least 0.9.

2. Bring a steel plate made of soft magnetic material to the end of the sensor, as shown in the figure, placing it in the slot of the housing. The sensor should operate, which is determined by the change in voltage at contact “B” of the sensor. When the sensor is triggered, the voltage at contact “B” should be no more than 0.4V.

3. Remove the steel plate, and the voltage at contact “B” of the sensor should change to a value of at least 0.9

Changing the oil seal

Below is a step-by-step manual for changing the camshaft oil seal for a VAZ 2110 car. The instructions are relevant for 16- and 8-valve engines. If you notice a new knocking noise coming from the camshaft, then, apparently, you need to disassemble it. Most likely, the knocking will go away after replacing the element. The part itself must be purchased in accordance with the manufacturer's specifications.

As for the characteristics themselves, the component must correspond to the dimensions of the part installed in a given car model. If the specifications are not met, you may have to go to the store for a new oil seal in the midst of repairs.

We change it with our own hands

- First of all, you should dismantle the timing belt of the VAZ 2110.

- Then you will need a "17" wrench. Take the tool and begin to unscrew the screw that secures the toothed disk of the timing pulley. You need to make sure that the pulley does not turn. To do this, you will need to pass a “10” head through the hole in it, which must be put on an extension cord. Engage the nut securing the rear cover of the timing belt drive.

- After this, using a screwdriver, pry up the timing pulley disk and dismantle it. At this moment, be careful: under no circumstances should the toothed disk key be lost. Remove it from its installation location.

- Now, using the same screwdriver, pry up the camshaft oil seal that needs to be replaced and remove it.

- Take a new oil seal and lubricate its edge and installation location with engine fluid. If you do not lubricate the element itself with oil, the knocking may not go away. To install the component you will need a small piece of pipe. The oil seal will need to be pressed in carefully. You will also need a hammer for this.

- Carry out all subsequent assembly in reverse order. Don't forget to align the timing belt correctly.

After completing the repair work, start the engine and check if the knocking noise disappears. If there is no knocking noise, then the whole problem was in the camshaft oil seal.

1. Unscrew the camshaft pulley screw.

2. After this, the toothed pulley itself can be dismantled.

3. Using a screwdriver, pry out the element that needs to be replaced.

4. Lubricate the part with oil and press it into the installation location.

Actually, this completes the procedure for replacing and eliminating camshaft knock. We strongly advise you not to carry out this work yourself if you do not have enough skills. Incorrect tightening of the timing belt and incorrect alignment of this element to the markings can subsequently cause the belt to break. If this happens while driving, the VAZ 2110 engine valves may bend. As you understand, subsequent repairs will cost a pretty penny.

Injection engine operation

The normal operation of an internal combustion engine is due to the coordinated action of all components. The fuel combustion process is controlled by an electronic unit. The following systems are used that are responsible for the operation of the injection engine 2115, 2114 models:

- air preparation;

- fuel supply;

- electronic engine control system (ECM);

- ignition;

- gas distribution;

- exhaust;

- cooling;

- engine oil system.

The ECM system for a Priora or VAZ 2115 car is controlled by an electronic control unit (ECU). Stable operation of the unit largely depends on the condition of the sensors. The ECU processes information received from various sources. Based on the analysis, a command is issued to open the injectors.

The camshaft position sensor tells the processor the actual position of the pistons at that moment. The operating principle is based on the Hall effect. When the gear teeth approach the device, an electrical signal appears at the output. In Priora and other cars, the gear is installed on the valve control shaft. It is set on a dowel. One tooth is missing on the camshaft gear.

The depression is placed opposite the sensor. The mark must not be moved. Such positions of the distribution mechanism correspond to the extension of the piston of the first cylinder to top dead center.

When the position of the VAZ 2114 camshaft changes, an alternating magnetic field appears. The sensitive element generates a pulse signal. The ECU counts the number of pulses and issues the necessary commands.

Signs of device failure

A faulty phase sensor will result in signal disruption. The ECM polls the DF for 4-5 minutes. If the signal does not appear within the specified period, the unit switches to double fuel injection mode.

If the phase indicator fails, the controller queries only the crankshaft position sensor. In this case, gasoline is supplied simultaneously to two cylinders. At the same time, fuel consumption increases by approximately 10%.

Failure of the phase sensor leads to a number of other troubles. Repairs need to be made. Signs of engine trouble:

- Increased gasoline consumption.

- Vehicle diagnostic failures.

- Violation of acceleration dynamics of VAZ 2115.

- Difficult start. The engine starts after 4-5 seconds.

- After starting, the Check Engine light comes on.

- Error P0343 or 0340 appears during diagnostics.

Before inspecting the sensor, you should make sure that the remaining parts are in good condition. Failures will occur due to a broken timing belt, loose camshaft gear, or incorrect installation of marks.

Often sensor error 0343 is associated with oxidation of contacts or broken wires. Before discarding the phase indicator, make sure the wiring is intact. Resistance measurements in the circuit are carried out with a multimeter.

It is difficult to determine the malfunction of the phase sensor yourself. It is better to carry out diagnostics at a service station. The sensor is checked on a computer.

If the auto mechanic makes a disappointing diagnosis, then we go to the store. You should know that you can run into low-quality spare parts or fakes. Experts advise purchasing sensors from Bosch or the Kaluga plant.

The phase sensors for 8- and 16-valve engines are different. Therefore, when purchasing, tell the seller your engine type. The best option would be to go to the car market with your original. If after replacement the sensor error occurs again, return it.

Replacing the device

Dismantling the part is not difficult. We find it behind the air filter. The phase sensor housing is secured with a bolt.

First, disconnect the terminals from the battery. In this case, the electronic unit will be de-energized. The control unit memory is reset to zero.

If you don't turn off the on-board network, you won't feel the difference. After replacement, the unit will maintain the same mode as with a faulty phase sensor. Process control returns to normal only after several engine starts.

Tools and materials for removing the sensor are available in the arsenal of every motorist. You need to prepare a key for ten, sealant, alcohol, rags. It is convenient to unscrew the fastening bolt using a socket wrench. Take the sealant from ZOLLEX. It is designed for temperatures up to 350°C.

Replacing the sensor will take 10 minutes. First of all, disconnect the wire block from the phase sensor. To do this, you need to bend the latch with one hand and pull out the wiring with the other. Next, unscrew the only bolt. It's on the back side. We take out the body of the spare part.

Do not apply great force when removing the DF.

Moreover, you should not use impact-type locksmith tools. The plastic housing may crack. Residues will fall inside.

Before installing a new device, you need to clean the seat. Apply a thin layer of sealant to the joining ring. Let stand for a few minutes. We put the camshaft sensor in place. We tighten the bolt.

What needs to be done before replacing the DPKV

When symptoms of a malfunction appear, you need to check several points due to which the control unit is not receiving proper information.

PHASE SENSOR.FULL OPERATION CHECK

HELLO EVERYONE, IN THIS VIDEO I WILL SHOW HOW TO DIAGNOSE A PHASE SENSOR

.THE PROCEDURE IS SIMPLE AND...

Quick check of the phase sensor

How to quickly check the phase sensor

.

- Inspect the DF for external damage.

- Make sure that no moisture gets on the contacts.

- Check contacts for oxidation.

- Make sure that the electrical wiring near the unit is intact.

If nothing was found during a visual inspection, then it is necessary to dismantle the device. How to change the camshaft sensor on a VAZ 2114?

Dismantling any sensor or repairing electrical wiring should always be carried out only with the battery disconnected, otherwise you can complete the repair not only by replacing the burnt circuit, but also by purchasing a new vehicle.

Dismantling on an 8-valve engine is not difficult. Where is the phase sensor located on the VAZ 2114? It is located on the right, on the top of the engine, near the air filter. It is secured with one 10mm wrench bolt. With a few simple movements, the bolt is unscrewed and the sensor is removed. After the unit has been removed, it is necessary to close its structural socket from accidental entry of foreign objects.

Design, functional features and typical malfunctions of the VAZ 2110 phase sensor

Constant modernization in the field of road transport ensures technical improvement of its internal filling. The functioning of modern technology is impossible without the presence of a variety of measuring, signaling, adjustment and monitoring devices capable of converting the value under study into a signal suitable for use.

The phase sensor (DPRV) on the VAZ 2110 is one of the most critical elements that ensures optimal operation of the internal combustion engine. Its main purpose is to analyze the angular position of the camshaft in a certain time period. The information received from it is needed for the operation of the ignition and fuel injection mechanisms. Having this data, the car ensures coordinated operation of the camshaft, taking into account the placement of the cylinders in the engine, which allows the supply of gasoline to a specific cylinder and ignition of the fuel-air mixture.

Kinds

Depending on the engine modification, the VAZ 2110 camshaft sensor has two types of design:

- Slotted. The sensitive element is U-shaped, and the moving element (mark) of the setting disk passes between its halves.

- Tortsevoy. It has the shape of a cylinder, at the end of which there is a sensitive element for reading the proximity of the mark.

For each type of DPRV, the corresponding type of camshaft pulley is used. For a slotted DPRV, a pulley with teeth and one air gap along the entire circumference is used. When the gap passes, the sensor transmits a corresponding signal. For an end-mounted DPRV, a pulley with one mark or one tooth at the end of the pulley is used. The DPRV reacts when it passes a protruding pulley element.

DPRV on VAZ 2110 8 valves or 16 valves have no functional or design differences.

Purpose of the phase sensor

The device is needed to determine the operating cycles of the electric motor. The camshaft cams cause the movement of the shut-off and control valve mechanism, and the DPRV detects the opening of a specific valve. Such a control system is integral, including a sensitive element and a signal transformation mechanism. The work consists of the device recording the cylindrical phases of intake and exhaust.

For carburetor power units it is not necessary, since the spark arrives at the moment of compression and after exhaust gases are released. The crankshaft sensor serves this purpose.

The device is located in the upper part of the block head near the air-cleaning filter. The features of its work are based on the Hall effect. A DPRV, consisting of a magnet and a semiconductor, detects voltage changes under the influence of an electromagnetic field. With a constant magnetic field, the sensor is indifferent. To change the parameters, a metal element must enter the magnetic zone. In a car, such an element is the teeth on the camshaft in the area controlled by the DPRV.

In order for a car to operate smoothly, it requires periodic diagnostics of systems and mechanisms. If faults are identified when diagnosing the phase sensor, it will need to be checked. A voltmeter is required for surface analysis.

The first step will be to measure the voltage in the electrical circuit. For this purpose, without turning off the ignition and disconnecting the connectors, you should check the voltage level at the contacts to the DPRV. If it is not there, then the whole problem consists of faulty wires or insufficient contact when closing due to banal oxidation or opening of contacts. As a result of checking the chain, as a rule, it is necessary to strip the contacts and connect the wiring to the electrical terminals and contacts.

If there is voltage, you need to connect a voltmeter to the device and the negative contact of its power supply; as a result, when turning the camshaft, the voltmeter will show a voltage change in the range of 0...5 Volts. If there are no changes, you will need to buy a new “tens” phase sensor to replace the old one.

Malfunctions and replacement of phase sensor

A malfunction of the DPRV is indicated by the fact that the engine starts only as a result of prolonged rotation by the starter (about 10 times), while the power decreases slightly, the dynamics deteriorate, and the car's takeoff run is accompanied by failures. With such signs, you should not delay repairing the phase sensor, since the cost of replacement is low.

An additional confirmation of the malfunction of this device is increased fuel consumption. If the electric motor detects a defect in it, it removes it from the system and begins to function in emergency mode. As a result, fuel begins to be supplied simultaneously to all cylinders without taking into account their location, based on the readings of the crankshaft sensor.

Sometimes when starting the engine, the “check engine” signal is displayed on the panel and shows an error in the phase sensor. This algorithm is considered the norm. Its purpose is that during the process of starting the engine, while the control system is waiting for a command from the DPRV, in the event of its absence, it can switch to the mode of receiving data from the crankshaft sensor. As a result of this, the electric motor starts and error signal No. P0340 turns on, indicating the need to check the VAZ 2110 phase sensor.

To effectively eliminate an error caused by DPRV, it is not necessary to contact a car service for qualified advice. Most often you can do it yourself; the whole process takes no more than 10 minutes.

Its replacement begins by removing power from the battery, as a result of which the memory of the control unit will be reset. If you neglect this stage, the device will continue to function in the same mode as the faulty one. It will begin to work efficiently only after several starts of the electric motor. The necessary tools are a “10” wrench and sealant for insulation.

The next step in replacing the phase sensor on a VAZ 2110 will be to disconnect the wires and remove them using a key. The new device should be coated with a small layer of sealant and wait about 5 minutes before installation. The final step is to install the device in the seat and connect the wires.

Then you need to connect the battery, start the electric motor and check the “check” light signal. If it is not enabled, this indicates that the installation is correct.

When is it necessary to change the engine camshaft sensor on a VAZ 2110?

The engine camshaft sensor on the VAZ 2110 is located on the right side of the engine, not far from the cylinder head. If this unit fails, further operation of the engine is impossible, but often the sensor simply begins to act up, which leads to:

- Increased fuel consumption;

- Reduced engine power and thrust;

- Increased vibration and noise under the hood;

- Increasing the average operating temperature of the motor;

- Problem starting the power unit.

The presence of several reasons at once indicates a problematic condition of the sensor itself. You can check the serviceability of the engine camshaft control indicator using a multimeter - just measure the current resistance on the external winding of the unit. Alternatively, the verification procedure can also be carried out using a megger.

According to factory standards, the resistance should be between 550 and 750 Ohms. If the resistance is lower or higher than the value, then the sensor should be considered faulty and a new part should be urgently purchased. Remember, neglecting the timely replacement of the camshaft position sensor seriously shortens the service life of the engine and adjacent systems - it is quite possible that a major overhaul may be required in the near future.

Replacing the camshaft sensor on a VAZ 2110 with your own hands: it’s simple!

To replace or dismantle the control device, you will need no more than 15 minutes of free time, as well as a set of wrenches. The procedure is carried out according to an intuitive scenario, therefore it does not require specialized skills and, if necessary, can be performed even in the field. To replace the camshaft sensor on the “ten” you need to:

- Secure the vehicle on a level surface and then remove the battery. If the battery is not removed, then memory dumps of the old unit will remain in the engine ECU, which can cause problematic operation of the power unit during the first time after repair. Resetting the memory of the engine control unit significantly shortens the time required for engine self-diagnosis;

- Next, remove the engine protective cover and find the sensor itself. As a rule, the part is located on the right side of the engine, near the 4th cylinder. On the sensor itself, you need to unscrew all the fasteners and also disconnect the wiring;

- Now it would be a good idea to carry out a number of maintenance activities, namely, clean the wiring contacts from the presence of oxidation sites and remove old sealant residues. If necessary, it is also necessary to replace the power wiring leading to the sensor - often the reason for the sensor’s inoperability lies in problem cables;

Phase sensor malfunctions

A malfunction of the phase sensor , which is also called a camshaft position sensor, leads to the engine starting to operate in pair-parallel fuel supply mode. That is, each injector fires twice as often. Because of this, fuel consumption increases, exhaust toxicity increases, and problems with self-diagnosis arise. A malfunction of the sensor does not cause more serious problems, but if it fails, replacement is not delayed.

Design

On the VAZ 2110, the camshaft position sensor is made in the form of a cylinder and has an end-mounted operating principle. Its structural elements are:

- plastic case;

- semiconductor wafer;

- secondary converter;

- magnet;

- current-carrying elements.

The DPRV connector has three contacts:

- constant power supply;

- transmission of the read signal to the control unit;

- weight.

Engines on which two camshafts are installed, and the gas distribution mechanism consists of sixteen valves, also have one camshaft position sensor of the same design.

What is a phase sensor used for?

To understand possible malfunctions of the phase sensor, it makes sense to briefly dwell on the question of what it is, as well as the principle of its design.

Thus, the main function of the phase sensor (or DF for short) is to determine the position of the gas distribution mechanism at a specific point in time. In turn, this is necessary so that the electronic engine control unit (ECU) gives the command to inject fuel at a certain point in time. In particular, the phase sensor determines the position of the first cylinder. The ignition is also synchronized. The phase sensor works in conjunction with the crankshaft position sensor.

Phase sensors are used on engines with distributed phased injection. They are also used on engines that use a variable valve timing system. In this case, separate sensors are often used for the camshafts that control the intake and exhaust valves.

The operation of modern phase sensors is based on the use of a physical phenomenon known as the Hall effect. It lies in the fact that in a semiconductor wafer through which an electric current flows, when it moves in a magnetic field, a potential difference (voltage) arises. A permanent magnet is placed in the sensor body. In practice, this is implemented in the form of a rectangular plate of semiconductor material, to the four sides of which contacts are connected - two input and two output. Voltage is applied to the first, and a signal is removed from the second. All this happens on the basis of commands coming from the electronic control unit at a specific point in time

There are two types of phase sensors - slot and end. They have different shapes, but work on the same principle. So, on the surface of the camshaft there is a mark (another name is a benchmark), and during its rotation, a magnet included in the sensor design records its passage. A system (secondary converter) is built into the sensor body, converting the received signal into information “understandable” for the electronic control unit. End sensors are designed in such a way that there is a permanent magnet at their end, which “sees” the passage of a benchmark near the sensor. In slot sensors, the use of the letter “P” shape is implied. And the corresponding reference point on the distribution disk passes between the two planes of the housing of the slotted phase position sensor.

In injection gasoline engines, the master disk and the phase sensor are adjusted in such a way that a pulse from the sensor is generated and transmitted to the ECU at the moment the first cylinder passes its top dead center. This ensures synchronization of fuel supply and the moment of spark supply to ignite the air-fuel mixture. Obviously, the phase sensor has a direct impact on the operation of the engine as a whole.

What is he like?

The phase sensor operates on the principle of an elementary Hall sensor. Installed only in the camshaft area on both 8 and 16 valve engines. The device reads data from the engine camshaft using a gear mounted on the shaft with two missing teeth. These two teeth are positioned so that every time the device is hit, the first piston of the engine is at top or bottom dead center. Information signals about the location of the camshaft are sent to the engine control unit, which, in turn, monitors and changes the ignition angle. It began to be used at VAZ factories on the first cars with distributed fuel injection.

It is worth noting that carburetor engines do not have this unit, because their mechanism has a vacuum-mechanical ignition timing system.

The main function of the camshaft position DF or phase sensor is to constantly adjust the ignition angle while the engine is running. Thanks to its use, VAZ family engines began to transmit power more efficiently with reduced fuel consumption. The main indispensable use of the phase sensor remains for two camshaft, 16-valve engines, which without it cannot operate evenly and economically according to the folded factory design.

Signs of a faulty phase sensor

If the phase sensor fails completely or partially, the electronic control unit forcibly switches the engine to paraphase fuel injection mode. This means that the timing of fuel injection is carried out according to the readings of the crankshaft sensor. As a result, each fuel injector injects fuel twice as often. This ensures that a fuel-air mixture is formed in each cylinder. However, it is not formed at the most optimal moment, which leads to a drop in engine power, as well as excessive fuel consumption (albeit small, although this depends on the specific engine model).

Symptoms of a faulty phase sensor are:

- fuel consumption increases;

- the toxicity of exhaust gases increases, the smell of exhaust gases will be felt, especially if the catalyst is knocked out;

- the engine begins to operate unstably, most noticeably at low (idle) speeds;

- the acceleration dynamics of the car, as well as the power of its engine, are reduced;

- the Check Engine warning light is activated on the dashboard, and when scanning errors, their numbers will be associated with the phase sensor, for example, error p0340;

- at the moment the engine starts in 3...4 seconds, the starter spins the engine “idling”, after which the engine starts (this is due to the fact that in the first seconds the electronic control unit does not receive any information from the sensor, after which it automatically switches to emergency mode, based on data coming from the crankshaft position sensor).

In addition to the above symptoms, often when the phase sensor fails, problems arise with the vehicle’s self-diagnosis system. In particular, at the moment of starting, the driver is forced to turn the starter for a little more time than usual (usually 6.10 seconds, depending on the model of the car and the engine installed on it). And at this time, self-diagnosis of the electronic control unit occurs, which leads to the formation of corresponding errors and transfer of the engine to emergency operation mode.

Malfunctions of the phase sensor on a car with HBO

It is noted that when the engine is running on gasoline or diesel fuel, the unpleasant symptoms described above do not appear so acutely, which is why many motorists often use cars with a faulty phase sensor for a long time. However, if your car is equipped with gas equipment from the fourth generation and higher (which uses its own “smart” electronics), then the engine will work intermittently, and the driving comfort of the car will sharply decrease.

In particular, fuel consumption will increase significantly, the air-fuel mixture may be lean or, conversely, enriched, and engine power and dynamics will significantly decrease. All this happens due to a mismatch between the software of the electronic engine control unit and the LPG control unit. Accordingly, when using gas-cylinder equipment, the phase sensor must be changed immediately after its breakdown is detected. Using a machine with a damaged camshaft position sensor is harmful in this case not only to the engine, but also directly to the gas equipment and its control system.

Causes of malfunction

The main reason for the malfunction of the phase sensor is its natural wear, which occurs over time for any part. In particular, due to exposure to high temperatures from the engine and constant vibration in the sensor housing, its contacts are damaged, the permanent magnet may demagnetize, and the housing itself may be damaged.

Another main cause is problems with the sensor wiring. In particular, the power/signal wires may be broken, which is why no supply voltage is supplied to the phase sensor, or a signal does not come from it via the signal wire. It is also possible for the mechanical fastening on the “chip” (the so-called “ear”) to break. Less often, a fuse that is responsible, among other things, for powering the phase sensor may fail (for each specific car it will depend on the complete electrical circuit of the car).

Articles

Instead of the numbers 2112-3706040, the article number 21120-3706040 is found. Both designations are correct. You can also find an article with the numbers -00, -01, -02... This is how the manufacturer is designated: 01 and 03 - “SOATE”, 00 - “Autoelectronics”, etc.

Read more: Priora check engine light is on and jerking

Parts with article number 2112-3706040-04

Recently, flexible lead sensors have been launched. The length of the wires is 15 cm. So far there is nothing like this in retail. But the article numbers remained the same - 2112-3706040-XX.

How to check the phase sensor

Checking the functionality of the internal combustion engine phase sensor is carried out using a diagnostic tool, as well as using an electronic multimeter capable of operating in DC voltage measurement mode. We will discuss an example of a test for phase sensors of a VAZ-2114 car. On models with a 16-valve engine, a sensor model 21120-3706040 is installed, and on 8-valve engines - 21110-3706040.

First of all, before diagnostics, the sensors must be removed from their mounting location. After this, you need to visually inspect the DF housing, as well as its contacts and terminal block. If there is dirt and/or debris on the contacts, it must be removed with alcohol or gasoline.

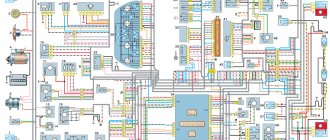

To check the sensor of the 8-valve engine 21110-3706040, it must be connected to a battery and an electronic multimeter according to the diagram shown in the figure.

Next, the verification algorithm will be as follows:

- Set the supply voltage to +13.5±0.5 Volts (you can use a regular car battery for power supply).

- In this case, the voltage between the signal wire and ground must be at least 90% of the supply (that is, 0.9V). If it is lower, and even more so equal or close to zero, then the sensor is faulty.

- Bring a steel plate to the end of the sensor (with which it is directed towards the camshaft reference).

- If the sensor is working properly, then the voltage between the signal wire and ground should be no more than 0.4 Volts. If more, it means the sensor is faulty.

- Remove the steel plate from the end of the sensor, the voltage on the signal wire should again return to the original 90% of the supply voltage.

To check the phase sensor of a 16-valve engine 21120-3706040, it must be connected to a power supply and a multimeter according to the diagram shown in the second figure.

To test the corresponding phase sensor, you will need a metal piece with a width of at least 20 mm, a length of at least 80 mm and a thickness of 0.5 mm. The verification algorithm will be similar, however, with other voltage values:

- Set the supply voltage on the sensor to +13.5±0.5 Volts.

- In this case, if the sensor is working properly, then the voltage between the signal wire and ground should not exceed 0.4 Volts.

- Place a pre-prepared steel piece into the sensor slot where the camshaft reference is placed.

- If the sensor is working properly, then the voltage on the signal wire should be at least 90% of the supply voltage.

- Remove the plate from the sensor, and the voltage should again drop to a value of no more than 0.4 Volts.

In principle, such checks can be performed without removing the sensor from its mounting location. However, to inspect it, it is better to remove it. Often, when checking a sensor, it makes sense to check the integrity of the wires, as well as the quality of the contacts. For example, there are cases when the chip does not hold the contact tightly, which is why the sensor does not receive a signal to the electronic control unit. Also, if possible, it is advisable to “ring” the wires going from the sensor to the ECU and to the relay (power wire).

In addition to checking with a multimeter, you need to check for relevant sensor errors using a diagnostic tool. If such errors are detected for the first time, you can try to reset them using software, or simply by disconnecting the negative terminal of the battery for a few seconds. If the error appears again, additional diagnostics are needed using the above algorithms.

Typical phase sensor errors:

- P0340 - no camshaft position sensor signal;

- P0341 - valve timing does not coincide with the compression/intake strokes of the cylinder-piston group;

- P0342 - the signal level in the electrical circuit of the DPRV is too low (detected when there is a short to ground);

- P0343 - the signal level from the meter exceeds the norm (usually occurs when the wiring is broken);

- P0339 - an intermittent signal is received from the sensor.

Thus, if these errors are detected, it is advisable to perform additional diagnostics as quickly as possible so that the engine operates in optimal operating mode.

CMP Camshaft Position Sensor Error Codes.

| See all advertisements in the archive |

| Common CMP Trouble Codes | Cause of camshaft sensor error |

| P0340 CMP | No signal from camshaft sensor |

| P0341 CMP | Incorrect valve timing |

| P0342 CMP | Camshaft sensor circuit low |

| P0343 CMP | Camshaft sensor circuit high |

| p0344 CMP | Unstable signal from the camshaft sensor (intermittent signal) |