Rate this post

In 2012, AvtoVAZ announced the start of production of a new small car, Lada Largus. The model is actually a version of the first generation Dacia Logan MCV for the domestic market. It is considered a joint project between AvtoVAZ and Renault, based on the B0 platform. In 2022, the car underwent a light facelift, as a result of which the radiator grille was updated, and the Lada nameplate was removed from the rear of the car. There were no serious modifications to the car. The basic idea was retained; the Polish car is quite popular and is in high demand among car enthusiasts. The model is equipped with a 1.6-liter gasoline engine. But we’ll tell you further what gearboxes are installed on the Lada Largus.

Engine 21129 and gearbox 21809, something is wrong...

I would like to immediately make a reservation that this is my second domestic car (about 6 years ago there was a VAZ 2115).

It will be abstract, because I’m not a writer, so please don’t push me or send me to learn the rules of the Russian language.

And so... Immediately after leaving the showroom, I noticed an unclear engagement of 1st and 2nd gears. How this was expressed: you are driving in a traffic jam from the start, i.e. On the spot you turn on the 1st and it either doesn’t stick in, then comes in with some jerks. A couple of times I drove off in a gear that was not engaged and it went into neutral with a grinding noise.

Then, as you gain speed, you switch to 2nd gear and the car twitches 2-3 times and starts moving - my sin was that I forgot how to drive a manual, but no, I’ve already driven almost 2t.km. everything is unchanged.

The second problem is switching from 2nd gear to first; again, first gear almost never engages until the car starts moving at a speed comparable to walking.

And the third thing that worries me is the connection of the 21129 engine with this gearbox. Although maybe the box has nothing to do with it. The engine spins poorly up to 3 thousand revolutions, then it shoots out, pressing you to the seat.

PS There were no such problems on the VAZ2115, the gears were switched on quite tolerably. Here at 3t.km. I plan to go to TO0 and torment the dealer. Kmk, a car at this price should not behave like this. If with the engine you can somehow get used to turning it constantly, then the gearbox irritates me very much, and it’s dangerous.

Experienced Largus guides, please advise what to do? Or maybe someone had this and how they treated it. I enjoy reading your blog.

Good luck to everyone on the roads, as they say - neither nail nor rod

Source

Gearbox JH3, JR5, 21809

Depending on the configuration, the car is equipped with five-speed Renault JH3 and JR5 gearboxes, as well as VAZ-21809 (from 2022), made according to a two-shaft design with synchronizers for all forward gears and combined with a differential and final drive. Transmission fluid is poured into the gearbox at the factory, which is designed for the entire service life of the vehicle. Therefore, there is no need to change the gearbox oil according to maintenance schedules.

Gearbox JH3

The car engine, like all internal combustion engines, develops power and torque in a relatively narrow speed range. As engine speed decreases, power decreases

The power transmission allows you to reduce the number of revolutions of the drive axle in relation to the number of revolutions of the engine crankshaft, increasing traction force. The higher the traction force, the lower the speed.

When driving a car, it becomes necessary to use different speeds and different traction forces. For example, when driving through deep sand, the speed is insignificant, and a fairly large traction force is required to overcome the resistance of the road. Great traction force is also required when starting the car and overcoming steep inclines. On the contrary, when driving on a paved road, little traction is required, but the speed of movement can be high.

To increase or decrease the traction force on the drive axle while maintaining a constant torque on the engine shaft, a gearbox is used in the vehicle's power transmission.

Due to the fact that the engines of different car models have different power, then, of course, the gear ratios of individual gears, and, consequently, the number of teeth of the gears are different. However, the operating principle of the gearboxes is the same, and the disassembly, assembly and repair operations are generally similar.

The basic principle of operation of the gearbox is the same everywhere, the essence of which is the pairwise connection of gears that have a different number of teeth. In this case, the torque transmitted by the gears changes in proportion to the gear ratio, i.e. The ratio of the number of teeth on the driven gear to the number of teeth on the drive gear.

A gearbox is, in principle, a very simple device.

Gearbox control mechanism: 1 – bushing (the gearbox control rod is connected to it); 2 – gearbox lever retainer; 3 – gear shift lever (has a ball bearing that is inserted into the body); 4 – lever handle; 5 – plastic body

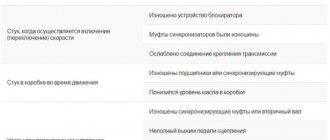

Noise and difficulty shifting gears

The main causes of noise in the gearbox include:

To fix the problem, you should add or replace the oil in the gearbox, replace the bearings and gears with new ones.

Difficulty shifting gears can be caused by the following factors:

The listed faults can easily be eliminated by adjusting the clutch and replacing deformed and worn parts. It also helps to adjust the mechanisms in accordance with the regulations indicated in the car’s operating manual.

All gearboxes for Lada Largus

In 2012, AvtoVAZ announced the start of production of a new small car, Lada Largus. The model is actually a version of the first generation Dacia Logan MCV for the domestic market. It is considered a joint project between AvtoVAZ and Renault, based on the B0 platform. In 2022, the car underwent a light facelift, as a result of which the radiator grille was updated, and the Lada nameplate was removed from the rear of the car. There were no serious modifications to the car. The basic idea was retained; the Polish car is quite popular and is in high demand among car enthusiasts. The model is equipped with a 1.6-liter gasoline engine. But we’ll tell you further what gearboxes are installed on the Lada Largus.

Manual gearboxes Lada Largus

From the very beginning of production, the car was equipped with a manual transmission-5. The transmission ensures optimal transmission of torque from the engine to the drive wheels. Depending on the engine power and torque, the Lada Largus is equipped with either JH 3 540 manual transmission or a similar JR 5 unit . The first type of manual transmission is designed for a 5-seater station wagon with a K7M engine under the hood. There are several versions of the JR5 mechanics:

The operating principle of the above units is almost identical and consists in connecting gears with different numbers of teeth. The main task is to ensure a change in torque in strict proportion to the gear ratio. There are several levels of boost for Lada Largus engines: 84, 87, 102, 105 and 106 horsepower. The different power of the motors is a consequence of the production of several modifications of the same 5-speed manual transmission with a certain number of teeth on the gears and gear ratio.

THREE FROM THE CASTER

Editorial "Largus" tried on three pairs of gears with different gear ratios. In addition to the standard fifth gear of 0.892, we sequentially installed sets of 0.820 and 0.795 (see table). On a 300-kilometer test route, including highways and suburban roads, they compared the difference in fuel consumption and accumulated subjective assessments, which are sometimes even more interesting for the car owner than measurement data. For reliability, the expert assessment was supported by measurements at the Dmitrovsky test site. Test results and comments are presented below, including photographs, tables and diagrams.

0,892. The basic version provides excellent elasticity. Fifth gear can be used from 50 km/h even when fully loaded. You rarely have to shift down - the traction reserve is enough even for quick overtaking. But the noise of the engine operating at high speeds is annoying, even if you are moving no faster than the permitted 90 km/h: on long trips you quickly get tired.

Summary. The basic version is good for those who move mainly around the city, often with a full load

Design of 5-speed manual Lada Largus

Structurally, both manual transmissions on the Lada Largus are similar. They are based on a two-shaft design with synchronizers on all forward gears. This arrangement assumes the presence of two parallel shafts - driving and driven. When the vehicle is moving and the gear is changed from the input shaft gear, torque is transmitted to a specific gear on the driven shaft. This is the work of ordinary and simple mechanics, so the Lada Largus manual transmission does not have any special features. But there are still some differences JH 3 and JR 5 .

JH3 gearbox:

JR5 gearbox:

The main advantage of the car's 5-speed manual transmission is its compactness. The housing of the unit is made of aluminum, inside of which there are shafts with a set of working gears. In order to ensure the best performance of the shafts, they were equipped with synchronization rings. The design also includes: a crankcase, a speed sensor, a control lever, a gear shift mechanism and other parts that are an integral part of a traditional manual transmission.

Spontaneous transmission shutdown

The reasons for spontaneous shutdown of the gearbox are usually:

These faults can only be corrected by replacing them with new parts. Do-it-yourself transmission repair requires high qualifications and a set of special tools. Only a competent specialist can remove and disassemble this part correctly.

If the gearbox malfunctions, it is better to contact a service station, where they will not only repair the unit, but will also give you a guarantee that you can use in the event of a subsequent gearbox breakdown.

JH3 reliability

The JH3 gearbox is considered a reliable unit, therefore it is still relevant in the automotive market. Car owners prefer cars with a structurally simple gearbox, partly because of its accessible and cheap maintenance. The disadvantages of manual transmission boil down to the lack of a high level of driving comfort. The gear shift does not always occur clearly and quickly; sometimes there are jolts and jerking of the vehicle. Structurally, the unit has been fully studied, so even in the event of a serious breakdown, its overhaul will not be difficult. Usually the lever for switching from one speed to another becomes loose ahead of time, which leads to unclear switching.

Often, owners of Lada Largus with JH3 note the noisy operation of the manual transmission and a crunching sound when engaging reverse mode. Early wear of the synchronizers cannot be ruled out. If we close our eyes to some shortcomings, we will get decent mechanics that can go 200-300 thousand km without a single repair. There are known examples of cars that have covered about 500 thousand km on JH3 without a single repair. Much depends on your driving style and quality of service. The oil change must be carried out in accordance with the maintenance regulations.

Motors

Gradually, the “French” were replaced by the VAZ-11189 (8 valves, 87 hp) and VAZ-21129 (16 valves, 106 hp) engines. The cylinder block traces its history back to engine 21083. These engines are more powerful and more economical than French ones, but less reliable. The VAZ-21129 is equipped with hydraulic compensators; on some examples they knock loudly when warming up. Floating speeds and tripping can be caused by various reasons - from sensor glitches and deformation of the throttle valve ring to spark plug failure or clogged injectors. Burnout of valves happens, but is not a system problem. In general, the motors are well adapted to repair and last a long time.

All engines have a weak link - the thermostat, whose failures lead to “underheating” or overheating.

JR5 reliability

It’s difficult to praise the mechanical JR5 in any way, but there’s nothing particularly to reproach either. The unit itself is structurally simple, often hums, and the clarity of gear shifting leaves much to be desired. Over time, it requires overhaul or, in severe cases, replacement due to the destruction of key mechanisms. Often, car owners have to disassemble the box because the 5th speed refuses to turn off. The reason, as a rule, is the wear of the rear gear retaining spring. It can burst at any moment, and one of its fragments usually falls under the 5th speed fork. As a result, while driving, the driver realizes that the 5th speed does not turn off.

A roller bearing with a plastic cage on the secondary shaft is another weak point of the JR5 mechanics. The separator often falls apart even at short mileage, which leads to balls clumping together. At a minimum, the manual transmission starts to hum, but there have been cases when balls got caught between the gears. The deficiency was eliminated after the JR5 modernization. Many problems can be avoided if you follow the manual transmission maintenance regulations and use original oil. It is advisable to change the working material of the box every 50-60 thousand kilometers. Tranself TRJ 75 W -80 is suitable for replacement . After passing 10-15 thousand km, it is necessary to take control measurements of the fluid. In general, the box is old, moderately reliable, but not perfect. With the right approach it will last a long time and can be repaired without problems.

Brakes

Brake pads, Drum pads, Pad wear sensor, Pad repair kit, Pad spacer, Rear pads, Handbrake pads, Front pads, Brake linings, Brake discs, Rear brake discs, Front brake discs, Brake drum, Rear brake drum, Drum bearing, Brake hoses, Brake pipes, Brake caliper, Caliper repair kit, Rear caliper, Caliper guides, Front caliper, Caliper piston, Caliper boot, Caliper bracket, Hydraulic accumulator, Vacuum brake booster, ABS, ABS unit, ABS sensor, Vacuum pump, Brake pedal, Switch Brake Light, Air Brakes, Parking Brake, Handbrake Cable, Brake Cylinder, Master Cylinder, Brake Reservoir, Brake Service Cylinder, Rear Brake Cylinder, Front Brake Cylinder, Brake Cylinder Repair Kit

Source

What is the result?

Mechanical boxes for Lada Largus are moderately reliable, low maintenance, and easy to repair. There shouldn’t be any problems finding a qualified automotive specialist capable of rebuilding a JH3 or JR5, even in a small city. You should not pay attention to the manufacturer’s statement regarding the maintenance-free manual transmission. Experts recommend changing the oil at least every 80 thousand km, ideally after 60 thousand km. If even minor malfunctions occur (knocking, crackling noises made by the gearbox, gears not engaging), you should immediately go to a service station for a comprehensive diagnosis. Timely minor repairs will prevent the development of a serious breakdown and will save the car owner’s time, nerves and money.

Source

Selecting transmission oil

The transmission determines the dynamic and speed characteristics of the vehicle. When the gearbox fails, vehicles lose their driving performance. In some cases, this may be the result of the transmission fluid losing its quality. For Lada, it is necessary to select oil that must match the brand of the automotive system.

Transmission oil is poured into the box, which is designed for the entire operational life of the vehicle. However, a number of car owners decide to replace them at 60,000 km. As a rule, Tranself TRJ 75W-80 is used for the Lada Largus gearbox.

When changing the oil, you should definitely pay attention to whether the fuel has a burning smell; if so, then this fluid needs to be replaced.

Boxes Lada Largus

During its production, three different gearboxes were installed on the Lada Largus:

| 5-speed Renault JH3 | classic mechanics with lever control drive |

| 5-speed Renault JR5 | classic mechanics with cable drive control |

| 5-speed manual transmission VAZ 21809 | AvtoVAZ transmission replaced foreign manual transmission |

Five-seater Largus modifications with an 8-valve K7M engine were equipped with a JH3 gearbox. This is the simplest five-speed manual transmission in the Renault range. Here, the control lever drive and synchronizers are only on forward gears, and the manual transmission clutch is driven by a regular cable, without any hydraulic drive.

The box is reliable and worries only about small things, such as play in the lever or leakage from under the rod. But the manual transmission also has one weak point: the role of the left drive oil seal here is played by the boot of the internal tripod, which tends to wear out quite quickly and leak. And if you don’t notice the leak in time, then you can somehow leave the box completely without oil.

About the domestic VAZ 11189 engine

In April 2022, AvtoVAZ began installing domestic VAZ 11189 engines on Largus. The advantages of this engine are described in one of the issues of “Okay Mechanics”.

| Some measurement results Autoreview | |||

| Options | Cars | ||

| Lada Largus (VAZ engine) | Lada Largus (Renault engine) | ||

| Maximum speed, km/h | 157,1/156,7* | 168,0/167,6 | |

| Acceleration time, s | 0—50 km/h | 4,3/4,8 | 3,9/4,4 |

| 0—100 km/h | 13,9/16,8 | 12,5/14,5 | |

| 0—150 km/h | 61,1/71,6 | 38,9/43,7 | |

| on the way 400 m | 19,3/20,2 | 18,4/19,4 | |

| on the way 1000 m | 36,1/37,8 | 34,1/36,0 | |

| 60-100 km/h (III) | 8,7/10,6 | 9,3/10,6 | |

| 60-100 km/h (IV) | 12,1/15,1 | 12,8/14,1 | |

| 80-120 km/h (V) | 19,3/24,0 | 22,1/23,4 | |

| * Partial load/full load | |||

| Engine characteristics | ||

| Options | VAZ-11189 | Renault K4M |

| Volume, cm 3 | 1596 | 1598 |

| Number of valves | 8 | 16 |

| Maximum power, hp/kW/rpm | 87/64/5100 | 102/75/5750 |

| Maximum torque, Nm/rpm | 140/3800 | 145/3750 |

| Cylinder diameter/piston stroke, mm | 82,0/ 75,6 | 79,5/80,5 |

| Compression ratio | 10,3:1 | 9,8:1 |

| Injection type | distributed, electronically controlled | |

| Octane number of gasoline | at least 92 | not less than 95 |