The standard Chevrolet Niva speed sensor is a separate module designed to transmit a signal from the gearbox output shaft to the speedometer. The device is simple - the functionality of the system is limited to only one option. The main advantage of the electronic system is increased accuracy. Such a speedometer has a minimal error, which increases traffic safety and eliminates the appearance of controversial fines for speeding.

This performance means that over a range of 1000 meters, the sensor generates more than 6000 pulses, which allows it to maintain extreme accuracy.

On the Chevy Niva, the sensitive sensor is made entirely of plastic; the contact chip is also quite sensitive. Therefore, care will need to be taken during repairs.

Location of the Chevrolet Niva speed sensor

The standard Chevrolet Niva speed sensor is a separate module designed to transmit a signal from the gearbox output shaft to the speedometer.

The device is simple - the functionality of the system is limited to only one option. The main advantage of the electronic system is increased accuracy. Such a speedometer has a minimal error, which increases traffic safety and eliminates the appearance of controversial fines for speeding.

On the Chevy Niva, the sensitive sensor is made entirely of plastic; the contact chip is also quite sensitive. Therefore, care will need to be taken during repairs.

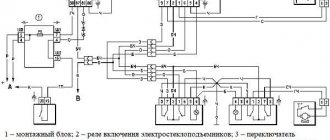

VAZ-2123 diagram until 2009

General diagram of the electrical equipment of the Chevrolet Niva VAZ-2123 produced before 2009.

1 — right headlight; 2 — right fog lamp; 3 — sound signal; 4 — engine compartment lamp; 5 — engine compartment lamp switch; b — VAZ-2123 starter; 7 - battery; 8 - generator; 9 — outside air temperature sensor; 10 — left fog lamp; 11 — left headlight; 12 — power window switch of the right front door; 13 — electric window motor-reducer; 14 - switch for interior lighting in the door lock; 15 — gear motor for door lock; 16 — connection blocks to the right front speaker of the audio system; 17 — heater electric motor; 18 — vehicle speed sensor; 19 — electric motor for windshield washer; 20 — windshield wiper electric motor; 21 - switch for interior lighting in the driver's door lock; 22 — gear motor for locking the driver’s door lock; 23 — brake fluid level sensor; 24 — connection blocks to the left front speaker of the audio system; 25 — power window switch of the right front door; 26 — power window relay; 27 — sound signal relay; 28 — power window switch of the left front door; 29 — fog lamp relay; 30 — connection block to the wiring harness of the engine control system; 31 — diagnostic block; 32 — mounting block; 33 — connection block to the wiring harness of the front seat heating system; 34 — control unit for the door lock system; 35 — instrument cluster; 36 — right side turn signal; 37 — glove box lighting lamp; 38 — switch for the glove compartment lighting lamp; 39 — ignition switch; 40 — brake signal switch; 41 — reverse light switch; 42 — differential lock activation sensor; 43 — control lamp block; 44 — headlight electric corrector regulator; 45 — instrument backlight brightness control; 46 — steering column switch; 47 — left side direction indicator; 48 — heater motor switch; 49 — additional resistor of the heater electric motor; 50 — parking brake sensor; 51 — rear fog light switch; 52 — fog light switch; 53 — switch for heating the glass of the luggage compartment door; 54 — external lighting switch; 55 — alarm switch; 56 — connection block to the right rear speaker of the audio system; 57 — fuel pump with fuel level sensor; 58 — backlight lamps for the heating and ventilation control unit; 59 — cigarette lighter; 60 — cigarette lighter lamp; 61 — control unit for the automobile anti-theft system; 62 — interior lamp; 63 — lamp for individual interior lighting; 64 — connectors for connecting to the head audio reproduction device; 65 — connection blocks to the left rear speaker of the audio system; 66 — right rear light of VAZ2123; 67 — trunk light; 68 — license plate lights; 69 — electric motor for the tailgate glass washer; 70 — tailgate glass wiper relay; 71 — electric motor for the glass cleaner of the luggage compartment door; 72 — heating element for the glass of the luggage compartment door; 73 - additional brake signal; 74 - left rear light.

Connection diagram of the engine control system of a VAZ-2123 car produced before 2009

Scheme for switching on the exterior lighting of a Chevrolet Niva VAZ-2123 produced before 2009

Headlight connection diagram for Chevrolet Niva VAZ-2123 produced before 2009.

Scheme for connecting the electric headlight corrector to electrical equipment. Until 2009 release.

Diagram for switching on direction indicators and hazard warning lights. Until 2009 release.

Wiring diagram for the VAZ-2123 windshield cleaner and washer. Until 2009 release.

Diagram of the electric motor of the heater fan and the heating element of the glass of the tailgate until 2009.

Diagram for switching on the sound signal, before 2009.

Diagram of power windows for doors up to 2009.

Diagram of the door lock system for VAZ-2123 until 2009.

Where is the speed sensor located on a Chevrolet Niva

The DS sits directly on the gearbox housing. It is noteworthy that the location of the device on machines of 2008 and 2022 has not changed. The stability of the structure indicates the correct placement of the device. The module is covered by body panels and the gearbox housing, which makes it inaccessible to obstacles and sharp elements that could damage the sensor.

You can see what the module looks like in the photo.

Operating principle and design features

The standard Shnivy speedometer sensor is a hall sensor enclosed in a plastic housing. The element has a specific design that allows it to read the number of shaft revolutions.

The next stage of the device's operation is signal processing. The computer counts the revolutions of the box for a certain period of time and transmits the data to the speedometer display.

Connection diagram

The Shnivy sensor connector itself is a three-pin connector, where:

- red – plus;

- black – minus;

- blue – signal.

The electrical diagram of the element will tell you how the wiring is connected to the speedometer.

Skipping the details and complexity of the speedometer drive pinout, you should focus on connecting the sensor itself. There are three wires here.

- Cable number 1 is a plus, goes to the brake fluid sensor. To maintain constant nutrition.

- The second wire is connected to the speedometer and is responsible for transmitting the signal.

- The third one is black. The cable is responsible for the minus and is connected to another similar wire, or screwed onto the car body, directly at the installation site.

Causes of breakdowns

There are a number of possible reasons for module failure. The most popular of them are described below.

- Mechanical damage. A similar problem occurs among users who operate the vehicle in off-road conditions. Protruding road surface elements, branches and stones can damage the plastic housing or break wires.

- Moisture ingress. Over time, the insulation of wires and blocks can dry out. The winding cracks and allows water to enter the system, which can cause a short circuit.

- System failure. During power surges, the on-board computer may malfunction. Errors within the module prevent data from being read from the device correctly.

What are the types of DS malfunctions?

If this element malfunctions, it is difficult to determine the speed of the vehicle. Photo: avtomarket.ru

In order to promptly fix a breakdown before it develops into a more expensive repair, every owner must listen to the behavior of the car. At the slightest deviation, it is recommended to replace the DS. The main symptoms of malfunctions include:

- Incorrect speedometer readings;

- Fuel consumption increases;

- The engine does not develop full power;

- At idle, unstable operation can be observed.

In this case, each driver will see a Check engine indicator; if there is an on-board computer, error “24” is displayed.

The first thing you need to do is check the condition of the wires and contacts that could simply break. Most often this happens near the connector, where the wires bend and can fray. If the contacts have oxidized or become dirty, they need to be properly cared for. In the area of the exhaust manifold, the integrity of the wire insulation is monitored. In addition, a malfunction of the DS may be associated with a failure of the speedometer cable, which has simply worn out over the years.

How can you test the DS?

Each car owner should know three possible ways to determine the serviceability of the DC; it is necessary to determine whether it produces 12 V. Since the operating principle is based on the Hall effect, the state of the contacts can only be carried out during rotation, and the voltage readings should be within 0.5 V – 10 V.

- Check with a voltmeter. The speed sensor is removed, it is necessary to determine which terminal is responsible for what. One contact of the voltmeter is connected to the terminal that outputs pulse signals, the second is connected to the ground wire. Rotating the sensor, we look at the voltage readings. The faster it rotates, the higher the indicators should be.

- It is not necessary to remove the DS from the car to determine its operation. To do this, you need to lift it with a jack so that the wheel does not touch the ground. Then connect the sensor contacts to a voltmeter, which will give voltage readings when the wheel rotates. If there is a frequency in Hz and voltage, we diagnose that the DS is working.

- It is necessary to disconnect the impulse wire, which is determined by a special controller. As in the previous version, we lift the wheel to rotate it. The “Signal” wire is connected to the control; if the indicator is “-“, then the DS is working. A wire with a light bulb can replace the control in this procedure.

Troubleshooting

Faults are not always related to the part, i.e. The DS may turn out to be quite functional; only some procedures need to be carried out to restore the previous functionality. Photo: drive2.ru

Dirt, dust deposits and oil smudges may form on the DS during the operation of the car. By cleaning this device, you will ensure preventive maintenance of the product and possibly prevent future breakdowns.

The problem may be in the contacts, their fracture, abrasion, and it is necessary to replace the damaged area.

The problem may turn out to be elementary and be hidden in mechanical damage or defects in the cable, which is easier to replace. Having diagnosed the sensor, everyone is convinced that it is not working properly, then it is worth testing and eliminating the above-mentioned malfunctions.

You can learn about some features of speed sensor repair from this video:

Symptoms of a problem

Simply observing the car's behavior will help you understand that the speedometer sensor is not working. Typically the symptoms of a breakdown are factors.

- The speedometer needle jumps, jerks or does not respond. This is due to the complete failure of the device and the need for its immediate replacement.

- Increased fuel consumption. Part of the system is interfaced with the ECU, therefore, the remaining sensors will also act up.

- The speedometer is reporting incorrect data. If a motorist sees that the actual speed of the car differs significantly from the measured one, this is a sign of a device failure.

- 4. Separately, instability of idle speed should be considered. The device is also responsible for the operation of the motor at idle.

How to identify a malfunction

Failure to display information is the last stage; in such a case, the device cannot be repaired. But how can you determine that a node is approaching the extreme limit of its performance? Possible signs of malfunction:

If the car belongs to the category of modern, highly equipped, then the sensor failure will be indicated by error code No. 24 displayed on the on-board computer, or the Check engine light will come on. In relation to Kalina, if the device breaks down, the electric power steering also refuses to work.

To fix the problem, in this case you just need to clean the contacts and coat them with any special lubricant for electrical wiring, which can be purchased at car dealerships. Their cost is low, so such prevention is affordable for every car owner.

If the sensor has completely failed, then it cannot be repaired, you can only replace it. Replacement is carried out quickly. And the price of the device is low: starting from a couple of hundred, depending on the manufacturer’s brand.

How to check the sensor

Usually, if the speedometer needle readings are incorrect, an error from the 0500 level is displayed on the dashboard. Such a code indicates the presence of problems in the module network and indicates the need for diagnostics. There are also possible ways to check the device.

- Check with a multimeter. Connect the positive terminal of the device to the sensor, and the negative terminal to the car body. If nothing happens when the sensor shaft rotates, it is faulty. In the working position, if you spin the wheel faster, the voltage also increases.

- Using a voltmeter. Raise the car on a jack, connect a voltmeter to the DC and spin the free wheel. In this case, changes should occur on the device proportional to the shaft rotation speed.

How to connect a tachograph?

These devices are required to be installed in long-distance vehicles - regular buses, long-distance trucks, taxis, and so on.

But it is not prohibited to equip any car with such a device at the request of its owner.

This device measures speed, as well as the driver’s physical condition, rest mode, and so on.

The tachograph is connected to the circuit between the speed sensor and the speedometer, due to which the data from the DS enters two devices simultaneously.

When installing this device, you must follow some rules:

- It is not recommended to place the device antenna on surfaces made of metal;

- It is recommended to place the wires in such a way that they are not exposed, since they are quite fragile and can be damaged even by the salt that is sprinkled on the roads in winter;

- If, when installing the tachograph, the speedometer suddenly stops functioning, it may be necessary to connect it in parallel to the DS.

Replacing the speed sensor

Installation does not require deep knowledge of mechanics or specialized, expensive tools. To change the sensor, just follow a simple sequence of steps.

- Drive the car onto an overpass or inspection hole. If such equipment is not available, you can use a jack.

- Disconnect the wiring from the battery and securely secure the machine. In this case, it is recommended to put the gearbox in neutral position.

- Climb under the car and find the DS on the front flange of the transfer case - this is a plastic part connected directly to the device body.

- Using a rag or brush, remove dirt, dust and possible debris from adjacent surfaces that could harm the operation of the new sensor.

- Using a screwdriver, loosen the clamp of the wiring plug and pull it off. In this case, extreme caution should be exercised - the part is quite fragile.

- Use key No. 22 to unscrew the sensor.

- Install the new part in the seat in reverse order.

The replacement process can be seen in more detail in the video.

A standard Chevrolet Niva DS is supplied to the market at a cost of 250 to 350 rubles. The module article number - 51.3843 may differ. The exact value depends on the manufacturer of the part and its compatibility with other vehicles.

Despite the technology of the car, the Shnivy sensor is quite simple to repair and maintain. You can diagnose and calibrate the device without the help of specialists.

Specialization : Graduated from the State Automobile University, worked for 20 years at GAZ-56, now I drive a Zhiguli.

Source

Location.

To remove the DS, you need to place the car on a level surface. After this, it is best to disconnect the battery terminals to avoid errors in the BC.

Disconnect the wire terminals; to do this, press the plastic lock on the block. After this, use a wrench to unscrew the sensor from its seat. If you cannot unscrew it immediately, it is not recommended to use excessive force. You need to treat the threaded connection with WD-40, wait a few minutes and continue dismantling.

If during the inspection it turns out that the camshaft position sensor itself has failed, then it must be replaced. As a rule, these units are non-repairable, since their body is sealed and cannot be disassembled. The sensor is inexpensive, and the replacement procedure is simple, and even a novice car enthusiast can handle it.

The sensor replacement algorithm is as follows:

- With the engine not running, disconnect the negative terminal from the battery.

- Disconnect the “chip” from the camshaft position sensor (as when checking).

- Depending on the vehicle model, it is necessary to remove parts that prevent access to the sensor. For example, on modern cars like the Lada Vesta, it is necessary to remove the bracket for auxiliary units.

- Using a wrench, unscrew one or two mounting bolts, depending on the type of fastening. The size of the wrench can be different, usually for VAZs it is a 10 mm wrench.

- After dismantling the mount, you must similarly remove the sensor from its seat.

- Installing a new sensor is performed in reverse order.

- Connect the negative terminal to the battery.

Error P0340 appears on the self-diagnosis system if the crankshaft rotates. Code P0342 - the camshaft electrical circuit shows a low signal and code P0343, accordingly, shows a high signal. It is necessary to check the wiring - for this purpose it is good to use an oscilloscope or other testing device.

Mechanical specialists, even if the sensor is in good working order, still recommend changing it every 4-5 years - such prevention will protect you from breakdowns and accidents, especially since the part is very cheap despite its importance. After all, the semiconductors inside the sensor react poorly to temperature fluctuations - remember your school physics course. There is a special offer on our website

You can get a free consultation with our corporate lawyer by simply asking your question in the form below

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

Basic functions of the device.

Each car has a speedometer in its design, which displays the speed of movement of the vehicle. But the speedometer is only a display of useful information; the main function of indicating the speed of movement is performed by the sensor. If it malfunctions, further travel becomes a pain, especially on city highways, where it is necessary to maintain the speed of movement.

Therefore, the main function of the device is to read information about the movement of the vehicle. Indirect functions of the device include:

- possibility of rational fuel consumption;

- regulation of traffic according to road markings and signs;

- makes it possible to regulate speed in order to avoid fines.

To control the speed of movement, a special device is installed on the dashboard - a speedometer. But it only displays the information received, and the speed sensor is responsible for collecting data. If it fails, it will create many dangerous situations on the road, since it will become difficult to control the speed limit in the city and on the highway.

But besides this, thanks to the integration of the electronic control unit into the system, the speed sensor allows you to perform the following functions:

- fuel consumption control

- displaying information on the instrument panel

- in cars with an automatic transmission it is included in the complex responsible for engine control

In case of failure, you are allowed to continue the journey, but this will become difficult.

A speedometer is installed in the design of almost every car. But the speedometer is only a general display that displays information. The main function of indicating speed is performed by the sensor itself. If the device is faulty, further movements become very difficult, if possible at all. The part needs to be replaced as quickly as possible.

The main purpose of the device is to read information related to moving around the city. There are other, so-called indirect functions:

- Adjust speed to avoid fines.

- Simplified traffic following road markings and signs.

- Rational fuel consumption. It is also important for cars produced in 2007.

Without this part, driving a car is possible, but it becomes much more difficult.

Replacing the crankshaft position sensor Lada 2123 (VAZ 2123)

After the publication of my article on the topic of oil seals for the Niva, requests began pouring in to write the same regarding bearings and sensors for the 21214 engine, which is installed on Nivas, Niva-Ms, crocodiles and Shnivas. I’ll begin to slowly talk about “trouble-free” sensors, that is, those that you install and forget about for a very long time.

A few general words. Why did this question even arise? Let me give you an example: such garbage as a throttle position sensor (TPS). Since the electronics of our injector are taken entirely from their front-wheel drive counterparts, and their number is very large, a very large number of companies make spare parts for them, and there is no need to talk about the Chinese brothers at all. For some time I even saved up faulty TPS from different manufacturers in a box, after 7 I got lost and threw everything away)) While the factory supplies only two manufacturers.

Another example is the speed sensor. When it’s burned out, it happens that when driving through a puddle, the “check engine” lights up, or the engine simply starts to stall when coasting and nothing lights up. And when you reach the service level, like a wartime exterminator, suddenly the defect disappears. This means that water got inside the case and then also leaked out. So all is well......until the next puddle. One of the most basic sensors is the mass air flow sensor (MAF), so a separate detailed article is devoted to it.

Crankshaft position sensor - DPKV

The task of this sensor is to read the revolutions of the engine crankshaft and whether it is spinning at all. Perhaps the only sensor that I recommend keeping in your car’s first aid kit (so as not to get lost) as a spare. This is the only sensor without which the injector will not start in principle. Without the rest, the engine will sneeze like a sick person, hiccup, fart, blink the check engine... but rattle. Which means it’s bad, but go. Without DC there will not even be signs of life. Therefore, we will consider it, in medical terms, as setting the heart rhythm. I’ll tell you a little secret, if you are leaving somewhere or leaving the car in a bad place, open the hood and slightly disconnect the DC connector. It is difficult to imagine a more effective anti-theft. The main thing is not to forget about it yourself))

Throttle position sensor - TPS.

The function of this sensor is to provide information to the brain about the position of the gas pedal and the degree of throttle opening. The TPS contains electromechanical parts, that is, a potentiometer. This means that after some time it wears out and the sensor dies. In Russia there are about 10 companies producing this sensor

But I want to draw the reader’s attention to the so-called non-contact (inductive) TPS. It is made by one company that used to be a “mailbox”

My experience has shown that the sensor in their “non-contact” design is virtually eternal. This is exactly what is shown in the photo.

Speed sensor - DS.

The brain uses the signal from the speed sensor to control the engine's idle speed. And support for “pickup” speed while the car is coasting. The actuator of this circuit is the idle air regulator, which controls the air supply bypassing the throttle valve. Enough theory, let's get closer to the people. In fakes based on this sensor, ahead of the original by an order of magnitude - the Chinese brothers. 8 out of 10 sensors that I held in my hands in stores and on the market were made in China. They work for three months, after which they announce their retirement as a “check engine”. What is the difference between the original and the pale one? In the photo, I indicated with arrows where the wires entering the connector are filled with varnish. The seam of the body, which consists of two parts, is also filled with varnish. Mao's heirs consider this unnecessary, and that is why the sensor dies after the onset of the first St. Petersburg slush.

Phase sensor - DF

It's also a camshaft sensor. The VAZ phase sensor is designed to determine the angular position of the camshaft. The main function is that when the engine is running, the phase sensor provides a pulse signal to the controller synchronizing fuel injection with the opening of the intake valves. Failure of the phase sensor switches the fuel supply to pairwise-parallel mode, which leads to a slight (up to 10%) increase in fuel consumption. And I’ll also add this “miracle of nature” is a headache and a source of a lot of errors, for example the famous 0301, 0302.... In my humble opinion, this is the same disgusting and abomination as the old-style hydraulic compensators. But what has grown has grown. (How to get rid of it forever, lambda, roll sensor - will be written in the article about chiptuning). The only normal manufacturer of this sensor is Avtovazagregat. The logo is visible in the photo.

Why does the speedometer on a Chevrolet Niva not work?

In addition to the reasons already mentioned, problems may arise with the vehicle's electrical network. It is best not to try to diagnose and fix the problem yourself - this can lead to unpleasant consequences.

But if you have the necessary knowledge, then pay attention to the sensor itself; moisture may get into the connector, which affects the correct operation of this device.

Where is the speed sensor located in the Chevrolet Niva and design features

The gearbox is where the speed sensor is mounted in the case of the Chevrolet Niva. The guidance of electromagnetic pulses inside the device is ensured by the rotation of the gearbox shaft.

The design of the sensor itself is formed by just a few simple elements:

- conductors;

- internal components;

- housing, on a steel or plastic base - connection using it is the safest.

Attached directly to the shaft, with the participation of the gearbox. Inside there is a core of ferromagnets. It is this part that rotates, creating impulses when the car moves. The pulses travel along the conductor to the controller located on the sensor.

Signs, symptoms and causes of faulty sensors in a car.

Good day, dear readers, in this article we will analyze many reasons, but mainly the symptoms of malfunctioning car sensors. Remember that before you go to a service station and panic, you should spend a little time and try to find the cause of the problem yourself and save money.

Signs of a malfunction of the TPS sensor:

— high speeds are possible at idle, this is the most characteristic sign; — a noticeable decrease in engine power and deterioration in throttle response; — when pressing the accelerator there are jerks, dips and twitches; — floating speed at idle; — when changing gears, the engine turns off spontaneously; — overheating is possible; - detonation. (personally, my symptoms were high speeds, inability to brake the engine, jerking, decreased power and, accordingly, increased gas consumption).

The photo shows very worn tracks

The reasons for the malfunction of the TPS sensor can be: - oxidation of the contacts - you can help in this case, you need to take a special WD liquid and clean all the contacts in the block and under the cover with a cotton swab; — worn sensor substrates if their design included sputtering of a resistive layer; - the moving contact fails - some tip of this contact may break, then scoring will form and other tips will also fail; - the throttle valve does not close completely at idle - in this case, you can slightly file the sensor seats and the throttle valve should close.

The emergency sensor rarely fails, but the average car owner will not be able to diagnose its failure, and some do not know where the sensor is located. The sensor is located opposite the throttle valve.

The check error does not always appear.

Signs of a malfunctioning idle air valve:

— unstable engine speed at idle; — spontaneous increase or decrease in engine speed; — stopping the engine when the gear is switched off; — no increased speed when starting a cold engine; — reduction in engine idle speed when the load is turned on (headlights, stove, etc.).

The idle control valve will not be able to function normally in this state.

The check error does not always appear.

The best prevention for the idle air valve is to periodically remove and clean the idle air valve, usually done in the fall and spring. The valve is located near the throttle valve.

Signs of a malfunction of the mass air flow sensor:

Signs of a malfunction of the air flow sensor or absolute pressure in the intake are characterized by: - Up to 70 degrees the car works more or less well, after 70 an unstable idle begins; — Failures during acceleration and adjustments; — The car sometimes stalls at idle when the gas pedal is sharply pressed; — Increased consumption; — Unpleasant exhaust smell; — Popping noises in the muffler during operation and sometimes popping noises in the intake manifold. (incorrect ignition timing due to faulty sensor)

The air flow sensor is very sensitive and it is not recommended to clean it yourself; the more often you change the filter, the longer it will last you.

The check error only appears when the air flow sensor has stopped working completely, and it can give incorrect readings for a long time.

You can check the air flow sensor or mass air flow sensor by having a multimeter or diagnostic scanner on hand.

Signs of a malfunctioning speed sensor:

— the speedometer does not work or gives incorrect readings; — unstable idling; — increased fuel consumption; - the engine stops developing full power. — the fuel gauge needle reacts almost instantly to fluctuations in the fuel level in the tank, because the computer thinks that the car is not moving and “smoothes” the sensor readings less; — the odometer does not show mileage; sensor in the automatic transmission - when changing speed, the automatic transmission resets itself to neutral, or switches spontaneously in an illogical manner; — the car stops responding to the gas pedal and coasts; — in city driving, when picking up speed, the box sharply increases speed and does not accelerate, does not react to other modes 2 and 1. It seems to only drive at speed 1 but does not slow down with the engine.

Causes of breakdowns

If a breakdown occurs, it can be indirectly determined by the following signs:

- If your car has a cruise control system, it stops working. The electronic unit forcibly turns it off to ensure safety.

- Forced disabling of the power steering on the car.

- Reduced power and other dynamic characteristics of the car. This is noticeable in poor overclocking and malfunctions when the load increases. Damage is noticeable when towing loads.

- Reduced idle speed or “floating” indicators. A sharp decrease in performance also occurs in the event of braking. Sometimes the engine itself is forced to shut down while driving.

- Increased fuel consumption due to the choice of a less than optimal operating mode.

- Check Engine Light Activation.

- Some cars face forced restrictions on maximum speed or available revolutions.

- Forced disabling of the anti-lock braking system.

- Spontaneous gear shifting in jerks. Such actions are carried out randomly, since the car itself cannot establish optimal performance for the present moment.

- Lack of normal operation of the speedometer - completely or partially.

The listed symptoms are often characteristic of breakdowns in other components that the car is equipped with. It is recommended to use a special scanner for comprehensive diagnostics of the entire circuit.

The sensor itself rarely fails because it is a reliable device. But its operation may be negatively affected by the following factors:

- The sensor is dirty from the inside. Such problems are especially common with sensors with detachable housings.

- Metal shavings get on the device. Sometimes this reason appears in devices supported by permanent magnets.

- Interference from other devices.

- Problems related to fixation. The scheme must take into account the color of each individual part.

- The integrity of the wiring is broken. For example, if it overheated, or some mechanical damage appeared inside. In this case, the contacts are completely cleaned of traces of corrosion, then a special protective lubricant is used for them.

- Oxidation of contacts. The phenomenon is attributed to natural factors, often arising simply from time to time.

- Overheating that occurs during direct operation. This happens even if the pinout is initially correct.

Like any car part, the sensor is subject to vibration and is susceptible to contamination and oxidation. Therefore, its failure is possible from time to time. To understand the cause of the breakdown and what to do in each specific situation, the following problems should be eliminated:

- broken wiring

- the appearance of oxide on the contacts

- destruction of wire insulation

- mechanical damage to the housing or its internal components

To do this, you can carry out a certain set of measures to check the condition of the sensor. Typically, such work requires a multimeter. The sensor is removed from the seat. A positive probe is connected to the contacts. The negative one is connected to the ground of the vehicle. The multimeter must be set to minimum power measurement mode.

There is a second diagnostic method. This does not require dismantling the sensor. The car is raised with a jack, then a multimeter is connected to the sensor. To appear, you need to rotate the wheel, observing the readings of the device. If the value does not change, the sensor is faulty.

In the Niva Chevrolet, the speedometer needle is driven not by a cable and a magnetic device, as in classic VAZs, but by electronics. The speedometer itself, like the rest of the instruments on the panel, are nothing more than voltmeters or ammeters with different scales.

The speedometer receives an electrical impulse, and the needle is driven by a simple stepper electric motor.

This is for information, because it is useless to poke into the speedometer itself, it is not repairable and if at least one element fails, you have to buy the entire instrument panel on the circuit board.

Causes of malfunctions

Despite its importance for a car, the sensor is not durable, because it can very easily break from excessive mechanical loads. This requires caution not only in its operation, but also during the installation process. However, even without physical damage, it is not difficult to find enough other factors that can cause a breakdown of the device for measuring speed, including:

- Oxidation of contacts, which can occur due to simple wear and tear of the device or its contact with moisture;

- Damage to the integrity of the sensor housing due to mechanical shock or careless installation procedure;

- Violation of wiring insulation, which subsequently leads to a short circuit.

You can check the condition of the sensor using a multimeter in one of two ways. The first time, you will need to turn it off and then remove the device from its location in order to test it. With the second option, it will be enough to jack up the car, connect a multimeter to the sensor and spin one of the wheels. If electromagnetic pulses are detected, one can judge whether the product is working properly.

Device location.

Each vehicle is equipped with only the appropriate equipment, designed for a certain number of shaft rotations and installed in the appropriate seat. The Chevrolet Niva speed sensor is installed on the gearbox.

The sensor itself is a small steel or, more often than not, plastic device that is mounted in the shaft area. Inside the case there is a core that transmits impulses to a special controller responsible for displaying information on the instrument panel.

When carrying out work, it should be taken into account that the device can be quite fragile, so installation should be carried out with care.

Relay and fuse box

The mounting block with fuses and relays is mounted on brackets to the left of the steering column and closed with a lid from below. To access the unit, remove its cover by unscrewing the screws.

Mounting block 2110-3722010-08

Mounting block 2110-3722010-01

Mounting block 2123-3722010 since 2009

| № | Current, A | Purpose | |

| 1 | 5 | License plate light lamps Instrument lighting lamps External lighting warning lamp in the instrument cluster Engine compartment lamp Additional brake signal lamp Left side side light lamps | |

| 2 | 7.5 | Low beam lamp (left headlight) Electrical headlight corrector Motorized corrector | |

| 3 | 7.5 | High beam lamp (left headlight unit) Indicator lamp for turning on the high beam headlights | |

| 4 | 10 | Left fog lamp | |

| 5 | 30 | Power window relay Power windows | |

| 6 | 15 | Before 2009: Door lock control unit From 2009: Cigarette lighter | |

| 7 | 20 | Cigarette lighter (Before 2009) Horn relay Horn light Trunk light (Since 2009) | |

| 8 | 20 | Before 2009: Rear window defroster relay (contacts) Rear window defogger element | |

| 8 | 25 | From 2009: Heated tailgate glass element Heated tailgate glass relay Heated outside rear view mirror elements | |

| 9 | 20 | Tailgate heated glass switch (Since 2009) Windshield wiper relay Windshield wiper motor Windshield washer pump Right steering column switch Glove box light Reversing lamps (Since 2009) Headlight wiper relay (contacts; before 2009) Headlight wiper motors (until 2009) Electric headlight washer motor (until 2009) | |

| 10 | 20 | Before 2009: Reserve Since 2009: Electrical accessories remote control unit (door lock) | |

| 11 | 5 | Tail lamps Instrument lighting control | |

| 12 | 7.5 | Low beam lamp (right headlight) Corrector motor gearbox (right headlight) | |

| 13 | 10 | High beam lamp (right headlight) | |

| 14 | 10 | Right fog lamp | |

| 15 | 20 | External mirror control unit Electric external rear view mirrors External mirror control unit | |

| 16 | 10 | Relay-breaker for direction indicators and hazard warning lights (in hazard warning mode) | |

| 17 | 7.5 | Individual lighting lamp Immobilizer warning lamp Brake lamps Additional brake light Interior lighting lamp | |

| 18 | 25 | Before 2009: Reversing lamps Heater fan Windshield washer motor Rear window defroster relay (coil) Rear window wiper relay Rear window wiper motor Rear window washer motor Door lock control unit | |

| 18 | 25 | From 2009: Heater motor switch Heater motor | |

| 19 | 10 | Relay-interrupter for direction indicators and hazard warning lights (in turn signal mode) Instrument cluster (except for the engine management system fault warning lamp) Differential lock warning lamp Starter relay (Since 2009) | |

| 20 | 7.5 | Fog lamps in the rear lights Anti-theft system control unit (Since 2009) Buzzer (Since 2009) | |

| Relay | |||

| K1 | From 2009: Windshield wiper relay Before 2009: Relay for monitoring the health of lamps (jumpers are installed instead of relays) | ||

| K2 | From 2009: Turn signal and hazard warning light relay Before 2009: Windshield wiper relay | ||

| K3 | From 2009: Low beam headlight relay Before 2009: Turn signal and hazard warning light relay | ||

| K4 | From 2009: High beam relay Before 2009: Low beam relay | ||

| K5 | From 2009: Auxiliary relay (Tailgate defroster relay coil, heater fan, windshield wiper and washer, tailgate wiper and washer) Before 2009: High beam relay | ||

| K6 | From 2009: Heated tailgate glass relay Before 2009: Additional relay (Relieves the ignition switch contacts) | ||

| K7 | Heated tailgate glass relay | ||

| K8 | Reserve | ||

Remote relays on the mounting block before 2009:

- Power window relay

- Fog light relay

- Auto horn relay

- Power exterior mirror relay

Remote relays on the mounting block since 2009:

- Fog light relay

- Power window relay

- Seat heating relay

- Horn relay

- Starter relay 2123

Additional fuse block

Additionally, under the instrument panel on the passenger side there are relay blocks with fuses that protect the elements of the injection system.

- Additional relay (turns on the right electric fan through an additional resistor at low rotation speed);

- Fuse (50A) protecting the power circuits of the additional relay and the right electric fan relay;

- Fuel pump (fuel pump) fuse (15A), protecting the power circuits of the electric fuel pump relay;

- Fuse (15A) protecting the constant power supply circuit of the controller;

- Right electric fan relay;

- Left electric fan relay;

- Electric fuel pump relay;

- Main relay 2123 Niva;

- Fuse (50A) protecting the left electric fan circuits;

- Fuse (15A) protecting power circuits switched on by the main relay;

- Controller

Mounting block connection diagram

The outer number in the designation of the wire tip is the number of the block, and the inner number is the conventional number of the plug. In the diagram K1 is a relay for monitoring the health of the lamps (contact jumpers are shown inside, which are installed instead of the relay); K2 – windshield wiper relay; K3 – relay-interrupter for direction indicators and hazard warning lights; K4 – headlight low beam relay; K5 – headlight high beam relay; K6 – additional relay; K7 – relay for turning on the heated rear window; F1–F20 – VAZ-2123 fuses.

Fuse box diagram from 2022

Replacing a faulty speed sensor in a Sheva Niva

After identifying the problem, further actions depend on the reason for the problems in the work.

The following options are available to correct the current situation:

- Dismantling the device, checking with a multimeter. The signal screen is also easy to disassemble. In case of serious malfunctions, it is easier to replace the device; repairs will be too expensive. The main thing is to dismantle the dashboard in advance to gain access to the interior panel of the car. The fixing nut from the device is also completely removed. After this, disconnecting the sensor itself will not be difficult.

- Additional check on sensor contacts. Contamination or oxidation of contacts remain the causes that car owners encounter most often.

- Examination of the sensor circuit to ensure integrity is maintained. To do this, take a multimeter and test the wires. Problems are usually associated with a short circuit or break in the contacts. It is best to replace damaged wires immediately, as they can operate in high temperatures, causing the connection to deteriorate.

The work is carried out in an inspection pit. Before dismantling, you must disconnect the battery.

The sensor is located on the rear cover of the transfer case. Before removing it, you must disconnect the terminals. They are held in place by a plastic retainer.

Then, using a wrench, the device is unscrewed from the seat.

If the device is firmly “stuck”, it is forbidden to use excessive force; it is better to treat the threads with a lubricant like WD-40.

Before installing a new device, you should carefully examine its condition. On the sensor, the assembly points and contact group must be carefully filled with varnish to prevent the penetration of water. Otherwise, the device may soon fail.

Trouble-shooting

So, the nature of the device malfunction and the reason for its occurrence have been determined. Now you can move on to fixing the problem. As a rule, repair work is quite simple and does not cause difficulties even for inexperienced motorists. But if you have any questions, it is better to contact the service center.

Elimination of minor defects in the operation of DPKV

Quite often, to ensure the normal functioning of the device, it is enough to eliminate only minor defects. Such work will eliminate minor interruptions:

- Renewal of varnish insulation. It was described above that quite often corrosion, improper installation, and mechanical stress can lead to damage to the protective coating.

- Cleansing from dirt and moisture. This can also lead to a short circuit in the winding. Clean and dry the device thoroughly. If moisture accumulates inside, blot it out with a cotton swab.

- Changing the polarity of signal wires.

- Replacement of synchrodisc and other spare parts.

- Elimination of design inconsistencies. As a rule, they are caused by incorrect installation of spare parts.

Self-replacement

If repair work to eliminate minor defects does not produce results, the sensor must be replaced. You can perform the replacement yourself.

Preparatory stage

First you need to prepare the device itself, the working field, and the necessary tools. To replace the DPKV you will need:

- set of flat probes,

- new device,

- calipers,

- wrench.

Clean the work surface from dirt and oil deposits.

Removing the sensor

The space is prepared, now you can move on to the next step - removing the sensor. De-energize the device. Using a previously prepared wrench, remove the bolt that secures the device. Remove the sensor itself.

Rinse and dry the device thoroughly. Excess moisture can be removed with cotton swabs.

The drying temperature should not exceed 85 °C.

Next, measure the distance between the core and the timing disk. Check the results obtained with the data specified in the technical data sheet of the device. This distance must be maintained during installation.

Installation

Install a new device. It is recommended to use old fasteners to properly install the sensor in place. Do not overtighten the bolts to avoid damaging the housing.

Connect the DPKV to the network. Check its functionality.

The following tips will help you correctly install yourself:

- Quite often the crankshaft and camshaft sensors are identical. If one of them malfunctions, try replacing it and checking its functionality again.

- It is better to purchase a new device in a service store rather than on the Internet. Firstly, this way you can check the size of the new and old copies. Secondly, on the Internet you can come across Chinese versions of sensors without electronics.

- If you go on a long trip by car, take a spare sensor with you. This is one of those devices that determines whether the car will start or not. In case of force majeure situations, the sensor can be easily replaced.

Basic elements of the electrical system

The vehicle's on-board network is designed so that all components and assemblies function smoothly, and control is as comfortable as possible. According to international standards, the voltage is 12V to be compatible with most consumers.

The circuit itself is single-wire. In practice, this means that the “negative” terminal is connected to the car body, and each individual device is powered by a “positive” wire. This greatly simplifies the routing of wires along the body and reduces the number of wires required. It also reduces the likelihood of cable damage and, as a result, a short circuit.

Source