Angular velocity joints (CV joints) transmit torque from the engine to the drive wheels. Thanks to their special design, this is achieved regardless of the location of the wheels on the same axle. In shape, these elements resemble a grenade, which is why among motorists this is what they are called.

Each wheel is connected to one inner and outer joint. The first of them is installed in the gearbox. Its purpose is to transfer the motor energy to the external joint, which rotates the corresponding wheel through the hub.

External and internal grenade (CV joint): differences and features

So, before checking the CV joints, it is necessary to separately take into account a number of features. First, the hinges can be internal or external. So, they rarely fail at the same time. In fact, the outer CV joint breaks more often. However, it cannot be ruled out that the problem is not, for example, the left internal grenade or the right internal hinge.

At the same time, to an inexperienced car enthusiast, both internal and external CV joints may seem the same. In fact, they differ in terms of design, experience different loads, have different operating modes, and the very signs of their malfunctions are somewhat different from each other. Let's figure it out.

- The design of the outer and inner CV joints is somewhat different due to the different operating modes of these hinges. The outer CV joint is connected to the hub, and its main task is the need to transmit torque at any angle of rotation or inclination of the wheel.

- In turn, it is important for the inner joint to compensate for the misalignment of the transmission and the drive shaft, thereby partially relieving the outer CV joint. At the same time, the internal joint ensures complete “integrity” of the shaft, provided there is a large suspension travel. In other words, it is the inner CV joint that allows the drive shaft to become slightly longer or shorter under certain conditions.

- If you compare the hinges visually, the body of the inner CV joint is larger than the outer one. Due to this, the inner race of the CV joint can move along with the shaft and balls inside the housing along the tracks. Also, the inner hinge can be rotated at an angle, although less than the outer hinge. If we consider the outer CV joint, it is rigidly fixed to the shaft and is more responsible for the ability to turn. On some cars, the outer grenade is so firmly attached to the shaft that it must be cut off to remove it.

Let’s also add that a special lubricant for the CV joint is placed in the joint cavity. This lubricant protects the element from moisture and shock loads. Please note that the CV joint cannot be filled with lubricant of unsuitable properties and type. In this case, the constant velocity joint will quickly fail.

Also note that front-wheel drive cars have a transverse engine, that is, the gearbox is shifted to the left. The result is that the left drive shaft will be shorter than the right one. So, the longer right shaft is not always solid. There are options when it is made of two parts, which are connected using a suspension support (suspended bearing).

The fact that on some cars a tripod is used as an internal joint, rather than the usual type of CV joint discussed in the article, deserves special attention. In any case, the operating principle of the tripod is still similar and there are no fundamental differences.

Types of CV joints

These mechanisms differ in installation location and design.

- Domestic

- External

Each wheel gets a pair of hinges: the inner one connects the gearbox to the axle shaft, the outer one connects the axle shaft to the wheel, or rather its hub. It is this design that ensures uniform transmission of torque when cornering. The grooves on the internal joints are straight, which allows them to dampen the amplitude of vibrations from vibrations of the suspension and the car itself. The outer joints are equipped with grooves located along the radius, which reduces stress during even the tightest turns.

Having a large working angle, the outer CV joint provides the ability to rotate up to 70%, and the inner one – by 20%. Ball joints are usually installed on the outside, and tripod joints on the inside.

In fact, a grenade (CV joint) is a bearing, and also consists of two rounded planes, in the internal space of which metal balls move along grooves. The grenade is affected by several force factors at once: friction force, torque and the constantly changing position of the axles under the influence of turning the steering wheel or overcoming uneven road surfaces. As a result, the grooves gradually wear out and the gaps between the planes increase; the driver begins to hear a crackling sound when driving. There comes a time when these noises are heard not only when turning, sharply accelerating or falling into a hole, but also when driving smoothly in a straight line. If you don't take action, breakdowns cannot be avoided.

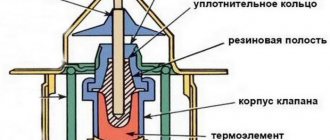

Internal CV joint device

The internal constant velocity joint is designed to transmit torque from the transmission to the outer CV joint. It differs from the external one in size (increasingly) and cost, although it consists of the same parts:

- Bowl-shaped housings with a driven shaft.

- The inner race is a spherical fist with a drive shaft.

- A separator in the form of a ring with holes to hold the balls.

- Metal balls.

The roller type of hinge is characterized by the presence of a support, which, using three rollers, moves along tracks cut into the inside of the body. The balls or rollers are located in the grooves of the housing and are held by a cage, which is connected to the drive shaft by a splined joint. When the angle of the drive and driven shafts changes, the balls move along the grooves, continuously transmitting force.

Is it possible to diagnose grenade malfunctions yourself?

Since the grenade is a simple hinge, it can easily fail. The principle of its operation is very similar to the operation of a bearing - two surfaces, between which balls made of durable metal are located. The difference is that grooves are cut out on the surfaces, due to which you can change the position of the drive axle shaft relative to the driven one. If you take a used CV joint, you can rotate the two axle shafts with your hands without much effort and see how the unit works. You won’t be able to turn them on the new one, since there are no gaps and you need to make a lot of effort to turn them.

Several forces act on the hinge at once. Firstly, when driving, torque is transmitted from the gearbox to the wheel. Secondly, the relative position of the axle shafts is constantly changing, as you rotate the steering wheel while driving or drive over an uneven surface. And there is always friction in the mechanism, which destroys it. In some place, a development may appear, as a result of which the gap between the surfaces increases and extraneous crackling and noise become audible.

Service life and maintenance

A grenade in a car is a consumable item. It will have to be changed quite often. Fortunately, the cost of the unit and repairs is usually not the highest.

How much a factory part costs depends on three factors:

- Driving manners;

- Machine models;

- Timely service.

The first factor is critical. Grenades are especially afraid of the trigger falling down when the steering wheel is turned to the extreme position. At such moments the node experiences maximum load.

If you mostly move calmly, then you can look for a resource for your car on thematic forums. There are cars in which a standard product can cost more than one hundred thousand.

Timely maintenance means periodic inspection of the boots, their timely replacement and filling with lubricant. If a crack appears in the rubber, the death of the CV joint will occur in just a couple of weeks. And in rainy weather this can happen even faster. This is due to water, which, when it gets into the assembly, leads to corrosion and leaching of the protective lubricant.

Surely you will be interested to know that in addition to grenades, absolutely all ordinary cars have a TV! Be sure to read our article on this so you can be a knowledgeable car owner.

A torn boot is a typical malfunction.

Boots, by the way, are quite inexpensive. The lubricant is also cheap and is called tritely - “CV joint”. When purchasing, do not forget to check that the anthers come with clamps for tightening them.

Advice on how to extend the life of a grenade:

- Do not press the pedal to the floor when turning, especially when starting off

- Change boots and lubricant in a timely manner

The lifespan of external and internal grenades is very different. The first is subject to great effort, since it is forced to turn at significant angles, and therefore makes itself felt more often.

The internal part may well not be bothered for the entire service life of the car.

How to repair a CV joint

Damage to the internal parts of the hinge most often leads to a complete replacement of the mechanism. However, this only happens with significant wear. In most cases, it is recommended to simply replace the CV joint grease and boot. This is often enough to get rid of the annoying sound and make it easier for the parts to interact.

Therefore, if knocking or clicking sounds appear on one of the four CV joints (we will assume that you have already found out which one), you must perform the following steps:

New inner CV joint

- Drive the car into the inspection pit in order to check the integrity of the boots and the presence of lubricant splashes from under them on nearby surfaces.

- If traces of grease are visible on the boot or other parts, it is necessary to remove the CV joint. Next, disassemble it, remove the boot, wash the internal parts and surfaces, change the lubricant and boot.

- If during the inspection process you find significant play and/or damage to the working surfaces of the parts, you can try to polish them. However, as practice shows, this procedure is ineffective, since you cannot eliminate significant waste with anything. Therefore, the best recommendation would be to completely replace the CV joint .

You can replace the lubricant and boot yourself, as the procedure is simple. The main thing is, when disassembling, do not forget to wash all internal parts and surfaces with gasoline, thinner or other cleaning liquid. And only then apply new lubricant. However, if you are dismantling and replacing the lubricant for the first time, then it is better to have a more experienced car owner or technician with you. Or have him perform the procedure and show you its algorithm. In the future, you can easily cope with such work.

Conclusion

Constant velocity joints are reliable and durable mechanisms. However, during operation, it is necessary to constantly monitor their condition in order to determine in time which CV joint is crunching or making other unpleasant sounds. After all, this indicates a malfunction in its operation. Hinge failure at the initial stage is not critical . You can drive hundreds or even a thousand kilometers with a crunch. However, you should remember that the sooner you repair or replace the CV joint, the cheaper it will cost you. In addition, do not forget about safety. Do not bring the condition of the hinge to a critical state , as this threatens you with a serious emergency situation, especially at high speed. We hope that the above information helped you figure out what to do when the CV joint crunches and accurately determine which one is faulty.

Front-wheel drive cars are loved by motorists all over the world for a reason. Most often, they use MacPherson-type suspension - a very simple and reliable design that will serve faithfully for many years and will not require significant maintenance costs. Depending on the condition of the roads and the aggressiveness of driving, however, some components will have to be periodically changed, for example, ball or bearings on the hubs. And silent blocks and levers fail much less often. This is what most car owners like - the car should be driven and not need to be repaired.

But there are also vulnerabilities in front-wheel drive cars, an example is the constant velocity joint, which is popularly nicknamed the “grenade” because of its visual similarity; you can also find the abbreviation – CV joint. For their production, only high-strength alloys are used, various coatings are applied to the working surfaces, and the original lubricant must ensure the operation of the unit for a very long time. But in practice, it turns out that nothing lasts forever; grenades also break, even on completely new cars that have just left the assembly line. Therefore, if there is a suspicion of a malfunction, an early check of the CV joint is necessary.

Sounds and symptoms of breakdown

There are several signs of a hinge failure:

- Anther rupture. It is enough to go to a service station, where the faulty element will be replaced, and the need to repair the CV joint itself will disappear.

- The sound of a grenade. The sound is very reminiscent of the friction of brake pads worn down to metal.

- Jerks. When the car starts moving, the driver may feel slight shocks. This behavior indicates broken grenade grooves.

- Clicks. They appear at the moment of movement, and their number varies from 2 to 5. When moving, the unpleasant sound disappears, but the next time you try to move, it appears again. This also indicates a malfunction of the grenade.

- Crunch. If the sound appears directly when moving, then this is an alarming signal. The CV joint is not only worn out, it is about to seize. Driving with such damage is dangerous, so it is best to call a tow truck and send the car to a workshop.

If at least one of the listed symptoms of a malfunction appears, then it is better to send the car for diagnostics. Experienced drivers can inspect the joint themselves and identify the source of the problem.

How to determine a CV joint failure

1. Light jerks when starting off, accompanied by a slight knock.

2. Having raised the car on a lift or driven into the inspection hole, take the axle shaft by hand and move it in different directions. With such actions, having defects and wear in the mechanism, you will feel significant play in the working areas of the CV joint.

It is also worth noting an important point that the design of a front-wheel drive car requires the presence of 4 CV joints. Two internal ones, which are located at the car’s gearbox, and two external ones, which are located on the wheel hubs. And here we will consider the question of which of the above-mentioned units has failed, internal or external.

Two CV joints of one axle shaft are one single mechanism, but due to the fact that the outer one is subject to greater load due to sharper and wider angles of rotation of the hub. To determine the malfunction of the outer CV joint, you need to perform a very simple manipulation. To do this, you need to turn the steering wheel in any direction to the maximum and start driving away. When the maximum angle between the CV joints is reached during such a turn, the faulty hinge, if it is faulty and has wear, will begin to emit a characteristic crunch.

How to check CV joint play video

If we figured out the external CV joint, then how to diagnose the internal one?! Here everything is a little simpler: the internal joints make themselves felt during straight-line movements, in particular, when switching from reverse to first gear when the bearing balls have to suddenly change their location in the cage.

All of the above methods for independently determining diseases of the CV joints of your car with almost a 90% probability will help you recognize this problem and its presence. And yet, the highest quality and 100% method will be diagnostics at a service station, where specialists will point out all the defects and even give you the opportunity to go under your car by lifting it without a lift and examining it more thoroughly.

>

Inner CV joint: signs of failure are difficult to see

Structurally, there are two grenades per drive wheel, that is, two CV joints - internal and external. The outer one transmits force to the wheel hub from the axle shaft, and the inner CV joint rotates the shaft from the gearbox.

Even though CV joints are one mechanism, the outer CV joint fails earlier because it bears more load and is also smaller. To understand that the outer CV joint has worn out, you need to turn the steering wheel all the way to one side and drive off. At this moment, there will be a maximum angle between the axle shafts and the CV joint will crunch if it is faulty.

But the internal CV joint is checked differently; it begins to make sounds while moving in a straight line. And if you drive into a hole at the same time, the crunch will be very clear. In addition, the first signs of a CV joint failure on a Priora or any other VAZ can be clearly seen if you lift the car on a lift. You can also engage first gear on the lift and press the gas so that the wheels begin to rotate.

When the car is in a suspended state, the internal grenade will be strongly bent and the sound of a worn CV joint will be clearly audible. This is how signs of a malfunction in the CV joint of a VAZ 2114 or VAZ 2115 are revealed. After detecting these signs, you can safely go and buy new grenades and prepare for replacement.

Next in the video there are signs of wear on the inner CV joint - a crunching sound appeared in the wheel:

How to identify a breakdown on a VAZ and other cars and understand that the CV joint needs to be changed

You can find out which hinge has become unusable and started to crunch using a universal method. To do this you need to proceed as follows:

- Align the car wheels.

- Apply the handbrake, neutral gear.

- Jack up one of the front drive wheels.

- Engage first gear, release the clutch pedal and move off.

- The next step is to slowly apply the brakes. If the internal “grenade” malfunctions, characteristic knocking sounds will appear on the right or left. The problematic external hinge will manifest itself as a crunching sound. For more accurate diagnostics, during the described procedures, you can turn the steering wheel first to the left and then to the right.

Safety rules cannot be neglected here. It is important not to forget about the hand brake and use a wheel chock. The jack can be lowered only after the wheel stops rotating.

How to check the outer CV joint

Diagnostics must begin with these elements. There are two main methods to focus on here.

Firstly, on a flat area with the steering wheel turned all the way, it is recommended to drive in a circle. It is better to lower the side windows. This is necessary in order to hear better:

- When turning left, knocking noises may appear on the right side, indicating a malfunction.

- On the contrary, when moving to the right, crunching and other sounds may appear from the opposite side.

- In addition, steering wheel vibration may also occur.

How to check the inner CV joint

In this case, it is more difficult to determine the breakdown, since it does not appear so clearly. When accelerating or driving fast, a humming or other noise may appear against the background of vibrations and jerking of the car.

If the car is driving slowly on an uneven road with a lot of potholes, then if there are problems with the internal joint, you can hear its crunching.

You can specifically drive through holes with your left and right wheels to more accurately diagnose the location of the problem.

Why does the CV joint crunch?

Video of replacing the outer left CV joint

Experienced drivers are able to determine the location of a car breakdown by ear. Such skills are acquired over time, but the crunch of a CV joint cannot be confused with anything.

In order to understand the nature of this characteristic noise, you should remember how the CV joint is designed. The task of the CV joint is the transmission of rotation from one axle shaft to another, provided that the angle between them continuously changes.

This property is due to the need not only to rotate the drive wheel, but also to give it the ability to turn and move up and down on a spring.

The CV joint consists of the following main elements:

- outer body in the form of a bowl with six semicircular grooves inside and a semi-axis outside;

- the inner race is in the form of a spherical fist and also has six grooves and a splined connection for the axle shaft;

- Between the inner walls of the bowl and the holder there are 6 balls in the separator.

All elements are made so precisely that they have no play when assembled. The cage transmits force through the balls to the body and rotates it, and moving the balls along the grooves makes it possible to change the angle between the axle shafts.

Over time, a hole forms at the point where the balls come into contact with other elements and a backlash appears. The free movement of the balls (rolling) generates a sound that is very similar to crunching.

Considering that CV joints are installed two on each wheel, when alarming symptoms appear, it becomes difficult to find out which CV joint is crunching: inner or outer, right or left.

Consequences of a CV joint crunch

Is it possible to drive with a CV joint crunching? It all depends on the degree of wear and tear. At the initial stage of the breakdown, you can drive, but it is not advisable , since the operation of the unit leads to even greater damage. Therefore, the sooner you try to repair the hinge, the, firstly, it will cost you less (perhaps everything will cost you by replacing the lubricant), and secondly, you will not put the life and health of you and your passengers in the car at risk.

So, the consequences of a CV joint crunching can be:

- Jamming . That is, the CV joint will stop rotating. This is especially dangerous at speed, as you risk losing control of the car, which can be fatal. You can try to wedge the hinge, but the best solution is to replace it.

- Clip break . If we talk specifically about an external grenade, then when it comes to the wedge, the clip simply breaks, the balls scatter, and then the consequences are unpredictable.

- Shaft or axle shaft rupture . In this case, the gearbox will turn only the designated parts, but for obvious reasons the torque will not be transmitted to the drive wheel. This is the most extreme case, and further movement of the car is possible only with a tow truck or tow truck. Naturally, the only correct solution in this case will be to replace the CV joint. And you will be lucky if you only have to change the hinge itself. After all, there is a risk that other parts nearby will be damaged during this accident.

Debugg

The detection of even small defects in the boot indicates that the joint is filled with dirt and lack of lubrication. The CV joint cannot be operated in this condition, so it is necessary to remove the boot and fill the hinges with new lubricant.

Before applying fresh lubricant, the part is disassembled, thoroughly cleaned, and dirt is completely removed. Then the mechanism parts are washed with gasoline, dried and new lubricant is applied. For the internal hinge, 100–110 grams of lubricant are used; for the external hinge, 70–80 grams are sufficient. The CV joint is installed on the wheel and covered with a boot.

Experts recommend installing new, original boots after lubricating the hinge, since old parts lose elasticity and may crack after a short period of time. Non-original anthers do not fit perfectly at the mounting points, so a new portion of dust and water will quickly fill into the gaps.

You can fix the problem yourself

An important condition for the successful operation of CV joints is the choice of high-quality lubricant. Experts advise giving preference to compositions based on molybdenum disulfide, which minimize friction in the components and effectively protect them from corrosion, and also have a minimal destructive effect on the boot.

It is important! It is contraindicated to use graphite lubricant for CV joints. It cannot protect the part from increased loads, and therefore leads to accelerated wear.

What happens if you don't change the CV joint?

It is possible to operate a car with problems in the CV joint if a slight crunch is heard when turning: it is enough to replace the damaged boots and renew the lubrication of the part. When driving a car with a slightly damaged joint, you must reduce your speed when turning.

If vibration is observed when accelerating and a crunching sound is heard even when driving straight, the CV joint must be replaced urgently. A faulty CV joint can fail completely, causing the wheel to suddenly seize. If this happens at high speed, you can expect the most dire consequences.

It is important! On some vehicle models, significant wear or breakage of the tripod CV joint causes the bearing needles to be thrown into the gearbox housing, from where they are lifted along with the oil and ground by the gears. Repairing such an engine costs almost the same as buying a new car.

Video: what can happen if you don’t change the CV joint boot in time

The CV joint is one of the main chassis parts of a front- and all-wheel drive vehicle, and driving comfort and safety depend on its condition. If there are signs of a joint failure, do not delay diagnostics and repairs - otherwise it is unlikely that it will be possible to “cure” the drive.

Causes of CV joint failure

The experience of service stations shows that CV joint malfunctions occur even in new cars with low mileage. There are several causes and symptoms of failure:

- Lack of lubrication. As a result of friction, metal without lubrication begins to wear off.

- Incorrect CV joint installation.

- Damage to the boot. Through the holes, water and abrasive particles enter the mechanism, which accelerate the wear of the balls and grooves.

- Aggressive driving or towing heavy trailers. High load on the unit, resulting from fast driving on a bad road, accelerates wear of the joints.

- Low quality parts. Defective or counterfeit parts do not last long.

- Mechanical damage. As a result of an accident or a wheel falling into a deep hole, parts may be destroyed.

- Ball joint play. Loose wheels increase the load on parts.

- Natural wear and tear.

What is needed to replace the CV joint?

Are you planning to change the “grenade” (it doesn’t matter - external or internal) yourself? Stock up on the following tools:

- hammer, screwdriver, pliers, jack;

- a set of keys and sockets;

- bench vice;

- with a mount or a long enough pipe.

You will also need new cuffs, boots, a hub nut with a stopper and a lubricant. These consumables are usually provided with the new grenade.

Checking the internal grenade

When checking the internal hinge while moving, it is also necessary to create the worst operating conditions for it, that is, maximum angles. Nothing depends on turning the steering wheel, so you will need to tilt the car as much as possible, moving in an arc at high speed under full traction.

A crunch from the inside of the car relative to the trajectory will mean wear of the internal joint on this particular drive. The opposite side, on the contrary, will reduce the angle of the fracture, so a crunch there can only appear from a node that is in a completely critical condition.

A test on a lift can be constructed in approximately the same way, loading the drive with brakes, and changing the angles of the suspension arms using hydraulic supports. At the same time, it’s quite easy to assess the presence of gaps and the condition of the covers. Long torn boots with dirt and rust inside will mean that the hinge must definitely be replaced.

How to replace a grant

The first question: “should I change it myself or at a service center?”

In principle, for most budget cars (VAZ, Chevrolet, Hyundai, etc.), if you have experience in repairing the vehicle's chassis and tools, replacing the hinge is not that difficult. You can even do without a hole. But you will have to sweat.

Typically, it is precisely these spare parts that make up a kit for replacing a grenade in a store: boot, lubricant, grenade, boot clamps, retaining ring for the axle shaft

For expensive cars, without experience and tools, for cars under warranty or insurance - definitely the way to service.

The second thing that car enthusiasts often encounter is the locksmith’s phrase “if one grenade crackles, then both need to be changed at once.” Moreover, some insist on replacing the external-internal pair. Others persuade you, when one of the outer ones cracks, to replace the second one and leave the inner ones.

The motivation is simple: if one part is broken, then the second one will soon fit. You decide. And although we have already said more than once that the consumables are inexpensive, but with a mass replacement, the repair will cost a pretty penny.

But no one can know when the working joints “crack”. And practice shows that they can travel for more than one thousand kilometers.

Therefore, answering the question “do both grants need to be changed?” We think it's not worth it. Let the details finish in due time and save your budget. Moreover, before the “explosion”, the grenade itself will warn you in advance with light clicking sounds.

Video about replacing a grenade on a VAZ 2108, 2109, 21099

How to install CV joint

Hinge installation must be carried out by qualified personnel. You need to purchase only original devices from well-known manufacturers.

However, it wouldn't hurt us to know how it's done

- The drive is removed from the machine

- The boot is removed from the outer grenade by removing the clamps with pliers

- The grease is wiped off and the retaining ring is removed.

- A short clamp is attached to the shaft

- A new boot is pulled onto the shaft (lubricant is already in the boot)

- A retaining ring is placed on the shaft spline

- The hinge is installed on the shaft, moving until it is secured with a locking ring.

- A long clamp is placed on the boot

- A screwdriver is inserted between the boot and the shaft, a small gap is opened to release excess air from the boot.

- The boot is fixed by fastening a small clamp on its narrow part

- The drive is installed back on the machine.

A systematic (every 5-7 thousand kilometers) inspection of the entire CV joint structure and regular changes of boot lubricant will help you avoid large financial losses and sudden troubles on the roads.

Replacing the outer CV joint

An experienced car owner with practical skills will not encounter any problems when taking on the task of replacing the outer CV joint. The list of tools necessary to carry out the “operation” has already been presented above. In addition to tools and supplies, there are a few other things worth doing. Before removing the wheel, drain a little oil from the gearbox - this will make it easier to work with. You will also need a pry bar - it will serve as a lever when removing the drive shaft.

Let's assume that the problem is on the right. Replacing the right CV joint begins with removing the wheel. We unscrew the hub nut, remove the brake disc, caliper, ball joint and steering tip. We take a pry bar or crowbar and remove the splined drive shaft. Using light blows of a hammer (a support, such as a wooden block, will come in handy), we knock out the outer hinge. Next we perform the following steps:

- It is necessary to remove the hub nut and tear off the wheel bolts. We put stops under the rear wheels.

- We jack up the car, hang it up and then remove the wheel.

- Remove the bolts holding the steering knuckle to the ball joint.

- Turn the steering wheel all the way. Pulling back the steering knuckle, we pull out the outer half of the hub along with the old CV joint. If the grenade does not budge, hit it lightly with a hammer.

- We remove the old boot and clamps and throw them in the trash.

- We remove the CV joint with hammer blows, rotating it along the axle shaft.

- We fix the installed new hinges in the hub together with the boot.

Replacing the left CV joint is carried out in the same way. When returning parts to their place, the above procedures should be done in reverse order. When knocking down a CV joint with a hammer, hit it clearly - some models are equipped with an ABS ring, which does not like strong blows to it. Don't forget to add gearbox oil. When installing the wheels back, be extremely careful to avoid falling apart.

Device

Installation of internal and external CV joints

The drive system consists of the following joints:

- two internal ones, which are installed directly in the gearbox, drive the axle shaft (one on each side);

- two external ones are located on the hubs and serve to transmit torque to the wheels.

It may seem that they have the same service life. But in reality, everything is not quite like that, the internal ones work longer, while the external ones fail much more often. The reason for this is that the loads that arise when the car moves on the wheel hub are too high, as well as the fact that the outer CV joint rotates at a much larger angle than the inner one. External differences can also be noted - the size of internal grenades is much larger than external ones.

How to extend the life of grenades

It’s very simple, follow three basic rules and your car’s drive will last a very long time:

- Never leave your place! With a sharp start, the torque is significantly higher than when driving. Due to heavy loads, grenades quickly become unusable;

- Do not accelerate with the steering wheel turned. When the hinge is rotated at a large angle relative to the axis, the load on its elements increases greatly, which contributes to faster wear of the CV joint;

- Check the condition of the anthers on the grenades (if dirt, sand and other foreign bodies get in, the grenade mechanisms quickly wear out).

How to restore the performance of a CV joint with your own hands

The performance of spherical angular velocities is disrupted for various reasons. Some of them are quite simple, so fixing the problem in such cases is quite simple.

Here are several important points where malfunctions may occur:

- The rubber boot broke. This problem can be easily identified by oily spots on the inside of the tire. Rupture occurs due to excessive mechanical stress, extreme hypothermia, and abrasion. Frequent off-road driving contributes to this condition.

- Critical wear of the support bearing. The consequences of this may be the need to replace not only the worn element, but also the entire internal “grenade”.

- Production of rolling balls, tracks or joint cages. This situation often occurs due to rupture of the anthers, sand and dirt getting into the lubricant.

When the first signs of problems appear, you can try to solve the problem on your own. To do this you need to proceed as follows:

- Place the car on an overpass or inspection pit to check the integrity of the rubber boots and traces of lubricant on adjacent surfaces.

- If ruptures or oily stains are detected, it is necessary to remove the angular velocity joint, disassemble it, thoroughly wash all internal parts, completely replace the lubricant and rubber boot.

- You can try to sand damaged work surfaces. On the other hand, in case of severe damage, it is best to completely replace the CV joint.

When performing work, it is better to enlist the support of a more experienced motorist or car mechanic. This will prevent possible errors.