The drives of the steered wheels of a car are a combination of two constant velocity joints (CV joints) connected by a shaft with splined ends. Strictly speaking, a similar design is found in the rear drive axle with a gearbox in a separate housing, but diagnostics are much more often required by the front drive, which operates in more severe conditions in terms of torque transmission angles.

The process of determining which of the four CV joints working there is worn out or has begun to deteriorate is usually difficult and requires adherence to a precise methodology in order to avoid wasted time and money.

External and internal grenade (CV joint): differences and features

So, before checking the CV joints, it is necessary to separately take into account a number of features. First, the hinges can be internal or external. So, they rarely fail at the same time. In fact, the outer CV joint breaks more often. However, it cannot be ruled out that the problem is not, for example, the left internal grenade or the right internal hinge.

At the same time, to an inexperienced car enthusiast, both internal and external CV joints may seem the same. In fact, they differ in terms of design, experience different loads, have different operating modes, and the very signs of their malfunctions are somewhat different from each other. Let's figure it out.

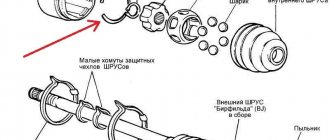

- The design of the outer and inner CV joints is somewhat different due to the different operating modes of these hinges. The outer CV joint is connected to the hub, and its main task is the need to transmit torque at any angle of rotation or inclination of the wheel.

- In turn, it is important for the inner joint to compensate for the misalignment of the transmission and the drive shaft, thereby partially relieving the outer CV joint. At the same time, the internal joint ensures complete “integrity” of the shaft, provided there is a large suspension travel. In other words, it is the inner CV joint that allows the drive shaft to become slightly longer or shorter under certain conditions.

- If you compare the hinges visually, the body of the inner CV joint is larger than the outer one. Due to this, the inner race of the CV joint can move along with the shaft and balls inside the housing along the tracks. Also, the inner hinge can be rotated at an angle, although less than the outer hinge. If we consider the outer CV joint, it is rigidly fixed to the shaft and is more responsible for the ability to turn. On some cars, the outer grenade is so firmly attached to the shaft that it must be cut off to remove it.

Let’s also add that a special lubricant for the CV joint is placed in the joint cavity. This lubricant protects the element from moisture and shock loads. Please note that the CV joint cannot be filled with lubricant of unsuitable properties and type. In this case, the constant velocity joint will quickly fail.

Also note that front-wheel drive cars have a transverse engine, that is, the gearbox is shifted to the left. The result is that the left drive shaft will be shorter than the right one. So, the longer right shaft is not always solid. There are options when it is made of two parts, which are connected using a suspension support (suspended bearing).

The fact that on some cars a tripod is used as an internal joint, rather than the usual type of CV joint discussed in the article, deserves special attention. In any case, the operating principle of the tripod is still similar and there are no fundamental differences.

History of appearance

At the end of the 17th century, the famous scientist Hooke proposed using a cardan joint for rotation between shafts. At the same time, gimbals first began to be used in Ancient Greece. A hinge similar to the one that was invented several centuries ago is still used in automotive technology to this day. Its main disadvantage is the uneven transmission of rotation when angles arise between the shafts. The larger the angle, the stronger the vibration. In practice, a hinge is not always used to connect rotating shafts. Instead, springs and couplings are used.

The universal joint of the English scientist is present in most cars today. At a small angle of rotation, the imperfections of the hinge are invisible. Negative aspects began to appear with the advent of cars with steering wheel drive.

According to another version, CV joints were invented by the scientist Alfred Rzepp. This happened in 1927. After this, the part began to be called the “Rzepp hinge,” but over time the word “grenade” began to be used.

Internal CV joint device

The internal constant velocity joint is designed to transmit torque from the transmission to the outer CV joint. It differs from the external one in size (increasingly) and cost, although it consists of the same parts:

- Bowl-shaped housings with a driven shaft.

- The inner race is a spherical fist with a drive shaft.

- A separator in the form of a ring with holes to hold the balls.

- Metal balls.

The roller type of hinge is characterized by the presence of a support, which, using three rollers, moves along tracks cut into the inside of the body. The balls or rollers are located in the grooves of the housing and are held by a cage, which is connected to the drive shaft by a splined joint. When the angle of the drive and driven shafts changes, the balls move along the grooves, continuously transmitting force.

External and internal CV joints

Each wheel of a front-wheel drive vehicle is equipped with 2 CV joints. The inner joint connects the gearbox and the axle shaft, the outer joint connects the axle shaft with the wheel hub. Working in pairs, they ensure transmission of torque under all types of loads.

In the most common ball joints, the outer CV joints are equipped with radius grooves that ensure uninterrupted operation of the vehicle when the wheels are turned. Internal grenades with straight grooves compensate for the movement of assembly parts along the axis when the front suspension oscillates and vehicle vibrations.

We will describe the design differences between different types of CV joints below.

Ball

They consist of a body (outer race) with 6 grooves, a separator, 6 balls and an inner race with 6 grooves. During vehicle operation, the balls move along the grooves, ensuring the transmission of torque from the engine to the wheels.

Ball grenades are most often found on front-wheel drive passenger cars.

Internal structure of a ball CV joint

Operating principle of a ball joint

Tripods

In tripod CV joints, instead of balls, spherical rollers are used, which are mounted on the support pins using bearings.

Tripod automobile grenades are installed on both cars and light-duty trucks.

Operating principle of a tripod car grenade

Internal structure of a tripod CV joint

Cam

Cam CV joints structurally consist of 2 forks and 2 shaped disks. The coupling (contact) area of the forks is significant, so the hinge elements can withstand severe loads during operation.

Cam joints are widely used on heavy-duty trucks.

Internal structure of a fist car grenade

Twin gimbals

They are the least popular devices. They are made of two cardan joints connected to each other.

Currently used in the production of heavy-duty construction equipment, tractors, and some models of trucks and SUVs.

The operating principle of a paired cardan CV joint

Service life and maintenance

A grenade in a car is a consumable item. It will have to be changed quite often. Fortunately, the cost of the unit and repairs is usually not the highest.

How much a factory part costs depends on three factors:

- Driving manners;

- Machine models;

- Timely service.

The first factor is critical. Grenades are especially afraid of the trigger falling down when the steering wheel is turned to the extreme position. At such moments the node experiences maximum load.

If you mostly move calmly, then you can look for a resource for your car on thematic forums. There are cars in which a standard product can cost more than one hundred thousand.

Timely maintenance means periodic inspection of the boots, their timely replacement and filling with lubricant. If a crack appears in the rubber, the death of the CV joint will occur in just a couple of weeks. And in rainy weather this can happen even faster. This is due to water, which, when it gets into the assembly, leads to corrosion and leaching of the protective lubricant.

Surely you will be interested to know that in addition to grenades, absolutely all ordinary cars have a TV! Be sure to read our article on this so you can be a knowledgeable car owner.

A torn boot is a typical fault.

Anthers, by the way, are quite inexpensive. The lubricant is also cheap and is called tritely - “CV joint”. When purchasing, do not forget to check that the anthers come with clamps for tightening them.

Advice on how to extend the life of a grenade:

- Do not press the pedal to the floor when turning, especially when starting off

- Change boots and lubricant in a timely manner

The lifespan of external and internal grenades is very different. The first is subject to great effort, since it is forced to turn at significant angles, and therefore makes itself felt more often.

The internal part may well not be bothered for the entire service life of the car.

Destruction of the ABS system ring

Another additional part is sometimes installed on the CV joint - a toothed ring of the ABS system, from which a special sensor reads the rotation speed. Due to age, this ring rusts, becomes damaged or even bursts, after which the entire ABS system goes into emergency mode or is completely deactivated. It all depends on the specific design of the CV joint - sometimes the ring can be changed separately, and sometimes you will also have to buy the entire assembly.

Sounds and symptoms of breakdown

There are several signs of a hinge failure:

- Anther rupture. It is enough to go to a service station, where the faulty element will be replaced, and the need to repair the CV joint itself will disappear.

- The sound of a grenade. The sound is very reminiscent of the friction of brake pads worn down to metal.

- Jerks. When the car starts moving, the driver may feel slight shocks. This behavior indicates broken grenade grooves.

- Clicks. They appear at the moment of movement, and their number varies from 2 to 5. When moving, the unpleasant sound disappears, but the next time you try to move, it appears again. This also indicates a malfunction of the grenade.

- Crunch. If the sound appears directly when moving, then this is an alarming signal. The CV joint is not only worn out, it is about to seize. Driving with such damage is dangerous, so it is best to call a tow truck and send the car to a workshop.

Why is crunching dangerous?

A crisp hinge will not last long; such shock loads will destroy it at an increasing pace. The metal gets tired and becomes covered with a network of microcracks and pitting, that is, chipping of the working surfaces of the tracks.

A very hard, but at the same time fragile separator will simply crack, the balls will behave in an arbitrary manner and the hinge will jam. The drive will be destroyed and further movement of the car will only be possible on a tow truck, and loss of traction at high speed is also unsafe.

At the same time, it is possible that the operation of the gearbox, which has been subjected to impacts from the drive shaft, may be disrupted.

How to check CV joint wear - causes and signs of grenade wear

A constant velocity joint (popularly called a grenade) does not fail all at once, with rare exceptions. Among the main reasons for CV joint failure are:

- Lack or insufficient amount of lubrication.

- Damage to the boot, which allows dirt and water to enter the part, which accelerates wear.

- Initially low quality parts.

- Aggressive driving with sudden starting and braking, turning the steering wheel all the way to one side, towing heavy trailers.

- Mechanical damage when overcoming bumps on the road.

- Natural wear and tear.

Worn CV joint

Before checking for a faulty CV joint, you should pay attention to factors that may indicate problems:

- Crunching sound of the outer joint when turning with the steering wheel turned all the way at the moment of starting.

- Knocking and vibration of the internal joint during straight-line movement - initially when overcoming uneven surfaces, and later when driving on a flat road.

- The appearance of oily spots on the anthers.

- The formation of minor jerks when starting to move and accelerate, especially if the engine, clutch and gearbox are operating normally.

Leaking CV joint boot

Particular attention should be paid to the crunching sound, which is a sign of critical wear of the CV joint and a signal for immediate replacement.

Solution

Having identified a problematic hinge, you need to dismantle it, disassemble it, thoroughly wash it and inspect it. If there are wearouts, damage, or play, the CV joint should be replaced with a new one. There is no point in repairing it. Attempting to sand work surfaces will most likely be a waste of time and effort and will not provide long-term results.

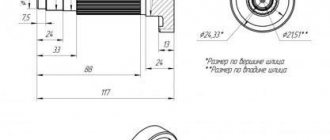

If the part is in order, after washing it should be filled with special lubricant for CV joints and returned to its place. The same should be done with the new hinge. As a rule, for an internal grenade you need about 100... 120 g of lubricant, for an external one - a little less. During assembly, lubricant must also be placed under the boot, and then securely tighten it with clamps on both sides.

Since errors during installation of CV joints can lead to their premature failure, it is better to carry out this procedure for the first time in the presence of a more experienced car enthusiast, who will explain all the intricacies of the process along the way.

When replacing parts that have a symmetrical pair in a machine, you should follow the general rule - change both elements at the same time. This rule should also be applied to CV joints, but with one important clarification: never remove both axle shafts at once to prevent the differential gears from shifting. First, work with one axle shaft and install it in place, only then you can dismantle the second one if necessary.

Cheap hinges, produced under little-known brands, are often made of low-quality metal and are not very carefully assembled; there are also initially defective parts. Such products should be avoided. You should also be careful when choosing where to buy. In the Chinese online store you can purchase the necessary spare parts for transmissions, suspensions and other systems of cars made in China and Europe.

Repair or replacement?

If a lack of graphite lubricant and damage to the boot are detected at a very early stage, repair of the CV joint will be limited to replacing both and washing the joint from any dirt that has fallen into it. This is the best option.

And the cheapest - many car owners change the CV joint boot and lubricant themselves.

For early diagnosis, car owners need to drive the car into an inspection hole at least once every 5 thousand kilometers, where they can see the integrity of the seals and the presence of lubricant under them and on nearby surfaces.

But if the CV joint mechanism itself is damaged, it is unlikely that anyone will undertake to repair it. The design of the hinge itself does not imply adequate restoration - the part will have to be replaced.

The CV joint crunches at low temperatures, what to do?

As a rule, at low temperatures, the cause of crunching of CV joints is poor-quality lubricant, which is not able to perform its functions in extreme cold.

Car manufacturers, when supplying their products to Russia, must take into account the operating conditions.

The frozen lubricant binds the internal elements of the grenade and does not get into all the cavities of the assembly, which is why the crunch appears.

At this moment there is no need to turn sharply and pick up speed; after a few kilometers (20-30) the components will warm up and the crunching will disappear by itself.

But the problem is that the internal grenades warm up quickly, but the external ones at very low temperatures may not warm up and the crunch will remain.

There is an opinion (and not without reason) that the problem is not only in the lubrication, but also in the design of the CV joint itself. The fact is that the lubricant put into the product may not be suitable for this design, while on other car models it works well even at temperatures below -20C.

Some car owners are guilty of using polyurethane boots, which can be installed on some brands of cars instead of rubber ones. They say that in the cold they tan and make sounds. This is a controversial opinion that requires verification.

The problem can be solved by replacing the lubricant; some car owners recommend LM47, VERYLUBE, XADO, they performed well at low temperatures. But it’s difficult to give any advice here, the choice on the market is huge and opinions vary.

But, you need to change the lubricant not just by pressing it under the boot, but completely remove the assembly, disassemble it and press the new lubricant as much as possible instead of the old one into hard-to-reach places. It is these places that cause crunching in severe frost, especially for external grenades.

How to check the inner CV joint without removing it

There are several ways to check the internal CV joint for serviceability without removing it from the car. To implement the first, you will need a section of road with uneven surfaces located in such a way that a car can drive along them on one side.

Inner CV joint

The entire process of checking the internal CV joint in this case consists of several stages:

- We accelerate the car to 15-20 km/h.

- Then we run over one side of the bumps and listen.

- We repeat the procedure by driving the other half of the car over uneven surfaces.

The presence of a breakdown will be indicated by a knocking sound in the area where the hinge is installed, as well as increased twitching during further acceleration.

We drive through a hole on one side of the car

Another way to check which CV joint is crunching from the inside is to hang the car on a lift. The verification process consists of the following stages:

- The entire car or its front part is suspended, which allows you to create a critical angle and extremely increase the load on the inner CV joint.

- We start the engine and press the gas a little so that the wheels start rotating.

- We listen carefully from which side the uncharacteristic sound is heard, which will allow us to determine which internal CV joint has failed - right or left.

In this way, you can check the internal CV joints of the car without extra costs. Although it would be more informative to check at a service station if such an opportunity exists.

Diagnostics

To ensure that you avoid problems with a CV joint that pops out while driving, it is necessary to carry out diagnostic work in a timely manner. At least once a month, inspect the condition of the boot; if it is damaged, be sure to correct this problem. Failure detection is carried out as follows:

- A common method is to start with the wheels turned out

. To carry out such diagnostics, you will need to turn the wheels and start sharply from a place. The presence of a specific crunch will mean problems with the CV joints; - Raise the wheel on a jack, ideally you should use a lift, but garages usually don't have them. Then we inspect the CV joint; there should be no visible damage on it. Also try moving the wheel. The hinge should not have any play;

- This method is more complicated, but quite reliable. The front of the car is hanging out. First gear is engaged, if you have an automatic transmission, select mode

– D. Start the engine and listen to the wheels. They should not make even the slightest crunch.

Actually, this is all that can be done for diagnosis. It should be noted that this process at service stations is completely identical to the methods described.

How to check the outer CV joint without removing it

There is one simple way to check the external CV joint without additional investment and with minimal time.

Outer CV joint

It is enough to choose a flat area on which you can ride without disturbing anyone. After this we perform the following actions:

- Turn the steering wheel to one side as far as it will go.

- We begin a smooth movement and listen.

- We repeat the same procedure with the steering wheel turned in the opposite direction.

We turn the steering wheel all the way and drive.

In this case, how to check which CV joint is crunching is also quite easy. When turning the steering wheel to the right while moving, a crunching sound may appear in the left hinge and vice versa.

How to check removed CV joints

A simple way to check removed CV joints is to clean them of grease and conduct a thorough visual inspection. Especially in the area of working surfaces - balls, separators. There should be no cracks, chips, pockmarks or other marks indicating wear.

Inspecting the CV joint

A damaged CV joint must be replaced, since the metal elements of the part cannot be repaired. In case of emergency, you can swap places - in this case, the load will fall on the surfaces that have not yet been worn out, which will allow you to gain a little time before replacing parts. When installing new CV joints, they should be filled with new lubricant and sealed with a boot.

Identifying a specific faulty joint

Since a front-wheel drive vehicle has four CV joints, it is important to isolate the problem and determine which one requires replacement or, at a minimum, lubrication. Many people do not know how to do this, although in many cases everything turns out to be not so difficult.

First of all, of course, you should do a visual inspection. If the boot is damaged, then the CV joint definitely requires, at a minimum, dismantling, maintenance, lubrication and replacement of the protective rubber boot, and at maximum, replacement. Damage to the boot will be indirectly indicated by grease splashed on adjacent parts.

Try turning the hinge around the axis by hand. A serviceable CV joint should remain stationary. If there is play, then the hinge definitely needs to be replaced. However, it will be more reliable to determine the presence or absence of play by dismantling the axle shaft with grenades and holding it in a vice.

How to identify a breakdown on a VAZ and other cars and understand that the CV joint needs to be changed

You can find out which hinge has become unusable and started to crunch using a universal method. To do this you need to proceed as follows:

- Align the car wheels.

- Apply the handbrake, neutral gear.

- Jack up one of the front drive wheels.

- Engage first gear, release the clutch pedal and move off.

- The next step is to slowly apply the brakes. If the internal “grenade” malfunctions, characteristic knocking sounds will appear on the right or left. The problematic external hinge will manifest itself as a crunching sound. For more accurate diagnostics, during the described procedures, you can turn the steering wheel first to the left and then to the right.

Safety rules cannot be neglected here. It is important not to forget about the hand brake and use a wheel chock. The jack can be lowered only after the wheel stops rotating.

How to check the outer CV joint

Diagnostics must begin with these elements. There are two main methods to focus on here.

Firstly, on a flat area with the steering wheel turned all the way, it is recommended to drive in a circle. It is better to lower the side windows. This is necessary in order to hear better:

- When turning left, knocking noises may appear on the right side, indicating a malfunction.

- On the contrary, when moving to the right, crunching and other sounds may appear from the opposite side.

- In addition, steering wheel vibration may also occur.

How to check the inner CV joint

In this case, it is more difficult to determine the breakdown, since it does not appear so clearly. When accelerating or driving fast, a humming or other noise may appear against the background of vibrations and jerking of the car.

If the car is driving slowly on an uneven road with a lot of potholes, then if there are problems with the internal joint, you can hear its crunching.

You can specifically drive through holes with your left and right wheels to more accurately diagnose the location of the problem.

Where is it knocking? — how to determine a possible car breakdown based on the location of the knock. A modern car is a complex structure consisting of many components, assemblies, and parts. During operation, individual parts of the machine wear out. Certain problems appear...

Causes and prevention of premature wear

The service life of the external and internal “grenade” depends on many factors. A node can fail for various reasons.

Here are some of them:

- poor product quality, lack of sufficient lubricants;

- consequences of a strong impact as a result of a collision or accident;

- dust, dirt, sand getting inside the structure due to a torn boot;

- poor road surface;

- incorrect installation;

- aggressive driving style.

Experts recommend regularly monitoring the condition of both types of hinges, checking the integrity of the rubber boot. For prevention, it is recommended to periodically dismantle the unit, wash its internal parts, and change the lubricant.

After replacement, the clamps on the boots must be carefully tightened so that the rubber boot does not rotate.

Premature wear can be prevented if you drive on uneven roads as carefully as possible, avoiding sudden acceleration and turning with the wheels turned out as far as possible. The outer joints receive all the impacts from the wheels, and sand, dust and water are more likely to get in here.

How to check a wheel bearing and whether it is possible to drive if it is humming Over time, as a result of using the car, various noises appear when it is moving, which indicate wear of one or another part. Its timely replacement solves the problem in the best way...

The symptoms described above show how to identify malfunctions. If there is a need to replace the CV joint, it is better to contact specialists, since incorrect installation will significantly reduce the service life of this element.

Crunch in place: unfortunately, this also happens

But all of the above applies when the car is in motion, and the crunching itself is heard exclusively in turns. And it’s a completely different matter; crunching sounds are clearly audible at rest when you turn the steering wheel of a stationary car left or right.

But, as with the occurrence of extraneous noise while driving, you can hear them in the steering when you turn it in place if:

- the source of the noise is the steering wheel itself;

- or have questions about the condition/wear of the steering rack.

We will also try to cover them in more detail.

Atypical and even funny causes of crunching

For all this, it is enough to inspect and identify what exactly is faulty, as it could be:

- Curvature of the shaft rod. It’s hard to believe, but such a steering defect can result not only from a frontal accident, but also from simple operation.

- The interface between the shaft and the rack. But to get to this joint, you have to try very hard.

- The protective cover rubs against the moving parts of the steering. This is especially applicable to inexpensive machines, as well as those that have been in use for a long time: some of the fasteners could simply break/get lost.

- Even a slipped carpet touching the steering shaft/its crosspiece. But this is an absolute rarity, an exception to the rule.

And in order to understand what exactly is the source of extraneous noise when turning the steering wheel, you need to disassemble the steering column and find the cause.

Consequences of untimely replacement of the CV joint

If you do not pay attention to the obvious signs of a CV joint malfunction , this will sooner or later lead to the following consequences:

- The CV joint will simply fall apart while driving and the car will lose the ability to move. This is the most favorable scenario.

- The CV joint will jam. One of the drive wheels will stop rotating, but the other will not. At high speeds, this can cause loss of control and a serious accident.

You definitely shouldn’t turn a blind eye to the emerging symptoms of a malfunction; in the future, because of this, you can lose not only money and time, but also your own health.

Cut or broken spline part

The worst-looking damage is when the CV joint simply collapses along the metal. The first reason for such destruction is the purchase of a low-quality CV joint, the production of which was defective or low-quality raw materials were used. The second reason is making changes to the design of the car, usually a lift (increasing the ground clearance) of SUVs. In this condition, the CV joint becomes in a non-standard position, turns at non-standard angles, and sometimes touches other parts of the car.

Not often, but there is another problem - overtightening of the hub nut, which leads to destruction. It is usually determined in the first meters of movement after leaving the lift or when moving through pits. An obvious mistake by the installer.

How to replace a grant

The first question: “should I change it myself or at a service center?”

In principle, for most budget cars (VAZ, Chevrolet, Hyundai, etc.), if you have experience in repairing the vehicle's chassis and tools, replacing the hinge is not that difficult. You can even do without a hole. But you will have to sweat.

Typically, it is precisely these spare parts that make up a kit for replacing a grenade in a store: boot, lubricant, grenade, boot clamps, retaining ring for the axle shaft

For expensive cars, without experience and tools, for cars under warranty or insurance - definitely the way to service.

The second thing that car enthusiasts often encounter is the locksmith’s phrase “if one grenade crackles, then both need to be changed at once.” Moreover, some insist on replacing the external-internal pair. Others persuade you, when one of the outer ones cracks, to replace the second one and leave the inner ones.

The motivation is simple: if one part is broken, then the second one will soon fit. You decide. And although we have already said more than once that the consumables are inexpensive, but with a mass replacement, the repair will cost a pretty penny.

But no one can know when the working joints “crack”. And practice shows that they can travel for more than one thousand kilometers.

Therefore, answering the question “do both grants need to be changed?” We think it's not worth it. Let the details finish in due time and save your budget. Moreover, before the “explosion”, the grenade itself will warn you in advance with light clicking sounds.

Debugg

The detection of even small defects in the boot indicates that the joint is filled with dirt and lack of lubrication. The CV joint cannot be operated in this condition, so it is necessary to remove the boot and fill the hinges with new lubricant.

Before applying fresh lubricant, the part is disassembled, thoroughly cleaned, and dirt is completely removed. Then the mechanism parts are washed with gasoline, dried and new lubricant is applied. For the internal hinge, 100–110 grams of lubricant are used; for the external hinge, 70–80 grams are sufficient. The CV joint is installed on the wheel and covered with a boot.

Experts recommend installing new, original boots after lubricating the hinge, since old parts lose elasticity and may crack after a short period of time. Non-original anthers do not fit perfectly at the mounting points, so a new portion of dust and water will quickly fill into the gaps.

You can fix the problem yourself

An important condition for the successful operation of CV joints is the choice of high-quality lubricant. Experts advise giving preference to compositions based on molybdenum disulfide, which minimize friction in the components and effectively protect them from corrosion, and also have a minimal destructive effect on the boot.

It is important! It is contraindicated to use graphite lubricant for CV joints. It cannot protect the part from increased loads, and therefore leads to accelerated wear.

Why does the hinge crunch at low temperatures?

Lubrication is of particular importance in ensuring long-term proper operation of the CV joint. Its condition needs to be monitored and changed periodically. But you can’t fill a grenade with the first lubricant you come across. The use of graphite lubricant is strictly prohibited. Special oil is produced for CV joints, usually containing molybdenum disulfide as an additive. It has water-repellent properties and can soften shock loads. This is what should be used. To properly replace the lubricant, the grenade must be removed, disassembled and thoroughly washed.

The quality of the lubricant is not always at the proper level. Some varieties do not tolerate frost well and may thicken at low temperatures. Then the pomegranates begin to crunch. Internal CV joints warm up quite quickly and stop knocking, while external CV joints can continue to make noise much longer. In such cases, it is better to avoid sharp turns and acceleration until the crunching stops. It is probably necessary to select a higher quality lubricant that can ensure normal operation of the hinges in frosty weather.