Hi all! I hope the information from this post will be useful and will be useful to someone! Good luck on the roads and a full tank!

The “symptoms” of a faulty throttle position sensor include the following:

1. Increased idle speed. 2. The engine stalls in neutral gear. 3. Idle speed floats. 4. Jerks during acceleration. 5. Deterioration in dynamics. 6. In some cases, the Check Engine light may come on.

Diagnosis of the throttle position sensor is carried out as follows:

1. Turn on the ignition, then check the voltage between the slider contact and the minus with a voltmeter. The voltmeter should show no more than 0.7 V. 2. Next, turn the plastic sector, thereby fully opening the damper, then measure the voltage again. The device should show at least 4 V. 3. Now turn off the ignition completely and pull out the connector. Check the resistance between the slider contact and any terminal. 4. Slowly, turning the sector, monitor the voltmeter readings. Make sure that the needle moves smoothly and slowly; if you notice jumps, the throttle position sensor is faulty and must be replaced.

Replacing the throttle position sensor:

1. Disconnect the wire from the “–” terminal of the battery. 2. Disconnect the block with wires from the throttle position sensor by pressing the plastic latch. 3. Unscrew the two mounting screws and remove the throttle position sensor from the throttle pipe. 4. Install the new sensor in the reverse order, but do not forget about the foam ring. The throttle position sensor does not require any adjustment, since the controller perceives idle speed (i.e. the throttle valve is completely closed) as the zero mark.

The “symptoms” of a faulty idle speed sensor include the following:

1. Spontaneous unregulated change in engine speed (sudden decrease or increase). 2. When turning on a “cold” engine, there is no increase in speed. 3. When using additional vehicle devices (heater, headlights), the idle speed is simultaneously reduced. 4. The engine stalls at idle and when shifting gears. It is necessary to remember that the readings of the VAZ 2110 injector idle speed sensor are not “readable” by the automatic on-board power system, and it is not integrated into the “Check Engine” alarm system.

Diagnostics of the idle speed controller is carried out as follows:

There are several ways to analyze the idle speed sensor, but the main ones - the simplest and most effective - are the methods described below:

1. First you need to “get” to the device, disconnect it from the connecting block of wires 2. Using the most common voltmeter, check for the presence of voltage - the “minus” goes to the engine, and the “plus” to the terminals of the same block of wires A and D. 3. Turns on ignition, and the received data is analyzed - the voltage should be within twelve volts, if less, then most likely there are problems with the battery charge; if there is no voltage, then you will have to check both the electronic control unit and the entire circuit. 4. Then we continue the inspection with the ignition on, and analyze terminals A:B, C:D one by one - the optimal resistance will be about fifty-three ohms; During normal operation of the IAC, the resistance will be infinitely high.

Also, with the sensor removed and the ignition on, if you connect a power supply to it, the conical needle of the sensor should move out; if this does not happen, it means it is faulty.

1. Remove the negative terminal of the battery. 2. Disconnect the IAC from the block harness. 3. Using a multimeter, we measure the resistance of the external and internal windings of the IAC, while the resistance parameters of contacts A and B, and C and D should be 40-80 Ohms. 4. If the instrument scale is zero, it is necessary to replace the IAC with a serviceable one, and if the required parameters are obtained, we check the resistance values in pairs B and C, A and D. 5. The instrument must detect an “open circuit.” 6. With such indicators, the IAC is in good working order, and if they are absent, the regulator must be replaced.

If the problem lies precisely in the operation of the regulator, then you should not rush and immediately go to a car service center, since you can clean the idle speed sensor yourself, as well as replace it.

Cleaning and replacing the idle air control.

The first thing you need to do is purchase a carburetor cleaner, and then get down to business: 1. The wire block is disconnected from the sensor. 2. Afterwards, both of its fastenings are unscrewed, and the sensor is removed. 3. If necessary, the IAC is completely cleaned of possible debris and contaminants on the cone needle and spring. 4. Also, do not forget to clean the mounting hole on the throttle assembly, where the conical needle of the sensor enters. 5. After cleaning, install everything in its original location.

Throttle position sensor VAZ 2112

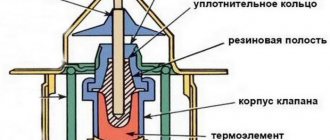

The sensor itself is a potentiometer (+5V is supplied to one end, and the other goes to ground. The third pin (from the slider) goes the output signal to the controller). When there is an impact on the accelerator pedal, the throttle valve rotates and the voltage at the TPS output changes (it is 4V when the throttle is closed). Thus, the controller monitors the TPS output voltage and adjusts the fuel supply depending on the throttle opening angle.

How to check

To check the throttle position sensor, we will need the following tools: a multimeter (ohmmeter, voltmeter), pieces of wire.

Having opened the hood, we find the sensor we need (we look for it on the throttle assembly next to the IAC).

Disconnect the wire block from the sensor

Take a multimeter and set it to voltmeter mode. Volts negative terminal (on the engine). We connect the positive terminal of the voltmeter to the sensor wire block to terminal “A” (the pin numbering is indicated on this wire block)

Turn on the ignition and check the voltage: the voltmeter should show a voltage of around 5 volts. If the voltage is not supplied, or it is much lower than 5 volts, then the problem is either an open circuit or a malfunction in the electronic engine control system (in the brains). But if the voltage is normal, then, accordingly, the TPS is faulty.

Conclusion: If the sensor is faulty, then there are two options to solve the problem:

1) Repair the sensor (How to repair the TPS?). Most often it is easier to replace the sensor with a new one, because The cause of failure is most often normal wear of the part.

2) Replace the sensor with a new one

The speed sensor on the link does not work.

Symptoms of a problem

Reducing the base layer at the beginning of the slider stroke is one of the most common causes of failure of this sensor. This phenomenon prevents the output voltage from ramping up.

In addition, the TPS may fail due to a malfunction of the moving core. If one of the tips is damaged, it leads to the appearance of multiple scuffs on the substrate, as a result of which other tips also fail. Contact between the slider and the resistive layer is lost.

Replacement

The car's service manual contains instructions that will help you determine the location of the sensor; you can watch a video on this topic.

Replacing the VAZ 2112 throttle position sensor is a fairly simple procedure that any beginner can understand. So: turn off the ignition and disconnect the wire from the negative terminal of the battery.

Then, by squeezing the plastic latch, we disconnect the entire block with wires from the sensor. To remove the TPS from the pipe, you just need to unscrew two bolts with a Phillips screwdriver. They are shown by arrows in the photo.

A foam rubber ring is used as a seal between the throttle pipe and the sensor itself, which is included in the kit of the device and must be replaced. When reinstalling the new TPS, the fastening screws are tightened as much as possible until the ring is completely compressed.

Having installed the sensor in its rightful place, connect the block of wires. The device does not require any adjustment, so the replacement of the throttle position sensor is complete.

The whole job took you no more than ten minutes.

Source

Malfunctions

There are several telltale signs of trouble that may indicate that there is a problem with the throttle valve control.

- High idle speed;

- When the gear is switched off, the engine may stall;

- When the car picks up speed, the car jerks and jerks are felt;

- Acceleration dynamics deteriorate significantly;

- Floating speed occurs at idle.

It should be noted that similar symptoms may also be characteristic of the failure of other components - the idle speed control or the ignition module, for example. Therefore, you first need to check the TPS.

Checking the status of the regulator

Next, let's talk about how you can check this throttle valve sensor. The event is necessary because it allows you to understand whether all the troubles are really due to it, or whether the problems arose due to the failure of other elements of your car.

It’s not uncommon for novice car owners to make hasty conclusions based on the primary signs of a breakdown. This results in unnecessary repair work and costs.

To check the current status of the throttle position sensor you need to:

- Measure the voltage at the output of the slider, turning on the ignition and opening the idle contacts;

- If the test shows that the voltage is more than 0.7 volts, then the sensor has indeed failed;

- Open the damper completely. In normal condition, voltage readings should be no more than 4 volts;

- Measure the variable resistor for resistance;

- To do this, connect an ohmmeter or a multimeter in ohmmeter mode to the power supply and output;

- Slowly begin to turn the throttle;

- At the same time, monitor the readings on the device;

- If, as the damper opens, the resistance also changes slowly, then the unit is working properly.

Replacing the throttle position sensor on a VAZ 2110, VAZ 2111, VAZ 2112

Welcome! Throttle position sensor - it transmits readings to the controller (ECU) about what position the throttle valve is currently in; when you press the gas, the valve opens to a larger angle (Accordingly, you need to increase the fuel supply) and therefore the controller reads this (The sensor transmits readings to it) and increases the fuel supply to the cylinders, thanks to which the engine runs normally and without interruptions, unlike if the sensor fails (There will be serious problems with the operation of the engine, one of them is that it will not run The second one won’t really work either, the car will twitch when accelerating).

Note! To replace the throttle position sensor (abbreviated TPS), stock up on: A screwdriver, as well as a special one. a device with which you can check resistance (Ohm) and Voltage (Volt), such a device can be a multi-meter or an Ohmmeter with a Voltmeter separately, in addition to this, you will also need wires with bare ends (Or so that there are alligators at the ends) and that’s all, essentially, the latest devices and the wires are only needed to check the TPS for serviceability, if you don’t need this, then you don’t even have to buy anything like that, but just a sensor and a screwdriver so you can remove it!

The design and principle of operation of the throttle assembly

The device is designed to regulate the air supply to the engine and ensure its operation at idle speed. The node is a structurally complete element. Located between the air filter and the intake manifold, and consists of the following components:

- Aluminum housing with pipe.

- Adsorber fitting.

- VAZ 2110 throttle position sensor (TPS).

- Crankcase ventilation connection

- Idle speed regulator.

- Throttle control sector, with cable fastening mechanism.

- Inlet and outlet heating fittings for remote control.

- Throttle valve.

How to replace the throttle position sensor on a VAZ 2110-VAZ 2112?

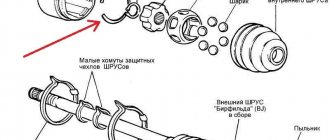

Removal: 1. First, simply press out the latch that holds the wire block and then disconnect the block (see photo 1), insert the key into the ignition and turn it until all the devices light up, then turn on the device, namely the Voltmeter function and from device, place the minus probe (it usually comes in black) to ground (the ground can be the car body or engine), and connect the plus probe to terminal A of the wire block (All terminals on the block are marked, look carefully) and the device should give a reading of approximately 5 Volts, but in no case less, if this is the case, then everything is in order with the wiring and most likely the sensor itself is to blame, if the voltage is less, then either the controller is faulty or there is a problem with the wiring, after the operation, turn off the ignition don’t forget, and when the wiring is checked, you can start replacing the sensor with a new one, for which unscrew the two screws that secure it to the throttle body body and then remove the sensor, under it there will be a foam ring that must be replaced.

Note! If you are going to change the sensor, do not forget to remove the minus terminal from the battery, how to do this, read the article: “Replacing the battery on VAZ cars”, point 1!

Installation: The sensor is installed in the reverse order of removal; when installing, its leads should be directed towards the engine shield. To make sure that the sensor will be installed correctly, lean it against the throttle assembly and make sure that the holes for the screws in the sensor coincide with the threaded holes in body and then fully open the throttle valve using the sector (or the gas pedal, let an assistant gently and slowly press it all the way), if everything goes well, the throttle valve will open completely and you can then tighten the sensor mounting screws until they stop.

Additional video: Visually watch the process of replacing the TPS in the video below:

Cleaning

So, the part has been removed. Now you need to assess the condition of the gasket. If cleaning is being done for the first time, the gasket should be replaced. Cleaning is carried out using a pre-prepared product, cotton swabs and a toothbrush. We need to clean all cavities and hidden channels. The damper itself and the landing sites need to be given special attention.

The photo shows the cleaning process using a special liquid.

As a result, the remote control must be completely cleaned of grease and dust. Before installation, it is worth cleaning the crankcase ventilation duct. Here you will need a foot pump. It is better to perform purging with the same product.

The photo clearly shows what a cleaned unit should look like.

Typical TPS problems

A malfunction of the throttle sensor can be determined by the following symptoms:

- increase in speed intensity when the load is off;

- deterioration of dynamic performance;

- the appearance of jerks when picking up speed;

- sudden stopping of the engine in neutral;

- warning light with a light bulb.

In addition, there are other malfunctions. One of the most common is a decrease in the base coating thickness in the initial part of the slider stroke. This prevents the linear voltage level of the output signal from increasing. Another causal relationship may lie in the failure of the movable core. The breakage of one tip contributes to the appearance of a large number of burrs at the base. As a result, others also break, causing the slider to lose contact with the resistive part.

You can test the throttle sensor yourself by following these steps. The first step is to start the ignition; if the warning light does not light up, then we take the converter directly. Using a multimeter, you should measure the potential difference between “−” and the slider wire. The obtained parameters should not be higher than 0.7 V.

Next, you need to expand the sector to fully open the damper. Then you should recheck the voltage again. The readings must be at least 4 V. After this, you need to turn on the ignition and remove the connector. Again measure the resistance at the point of contact of the slider with one of the terminals. While scrolling the sector, monitor the multimeter readings.

The pointer should be moved gently and slowly, since shocks and sudden vibrations indicate a breakdown. The smooth operation of the device depends on the condition of the film resistor.

There are several types of throttle position sensor: film-resistive and non-contact. The first of them is installed by the manufacturer, the second is chosen by the car owner while driving and operating the car. The service life of the TPS may vary depending on the quality and adherence to technology in the manufacture of the device. The standard unit may not need to be changed even for 60,000 km, and sometimes it requires replacement even after 5,000 km.

When purchasing a throttle sensor, the price depends on the choice of its type:

- Film-resistive ones are the most frequently purchased among motorists due to their budget price, but their service life practically does not stand up to criticism;

- Contactless - at a higher cost (almost twice) the long period of use covers all costs. The high-quality operation of the device is due to the principle of magnetoresistance. When purchasing, you should be aware that this type of device operates at a DC voltage proportional to the throttle valve opening angle in the electric motor fuel injection system.

The sensor shaft rotates clockwise from the damper side. The service life guarantee is 3 years. Drivers do not repair the resistive sensor, but replace it with a contactless one - it is undoubtedly more reliable. Its design includes a rotor and a stator. The rotor is not affected by the magnetic field, because there is a magnet at its base. The stator is a part that is quite sensitive to the electromagnetic field. Its assembly is associated with programming, so a device of this category is often used for installation in electrical control units.

Correction of a factory miscalculation

Location and diagram of the VAZ 2110 fuse box

It is quite common for a throttle assembly to come out of the factory with something that cannot even be called a defect, but can still be attributed to design errors. In theory, air should flow into the space behind the throttle, for which a channel of approximately 2.5 mm is specially made.

But the whole problem is that this channel was pressed against the wall of the receiver, thus blocking the possibility of air flow. A slight modification of the throttle assembly can help in this case.

Bored channel for air flow in the throttle

To do this, just take a file and use it to make a small groove in the indicated place. 2 - 3 mm will be enough. But before doing this, it is necessary to remove the throttle.

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

Even if the purpose of removing the throttle was to modify it, still do not forget that for stable operation it also needs periodic cleaning

There is, frankly, nothing complicated in this procedure, but it will help the engine perform better, which is quite important

For cleaning you will need:

- short and long screwdrivers;

- toothbrush (soft, or just old);

- cotton buds;

- cleaning agent;

- rubber or cotton gloves.

For cleaning to give the desired result, it must be carried out very carefully. First, you can go through all the cavities with a toothbrush, at the same time cleaning the idle speed control (it must also be removed). Further, more delicate, cleaning is done with cotton swabs

Pay special attention to the area where the throttle valve is located and the place where the XX regulator fits.

Please note that cleaning the crankcase ventilation duct with conventional means is not possible, but it can be easily done using the foot pump available in each trunk. The diameter of the fitting is similar to the wheel one, you just need to add cleaning agent and pump your foot several times.

If you have problems mentioned at the beginning that started recently, cleaning should fix them. If there were problems from the beginning, do not forget about improvements. Sometimes only replacing the throttle assembly helps.

Replacing TPS

Replacing the auto sensor takes place in several stages, it is quite simple, even a novice car enthusiast can do it. First you need to turn off the ignition and disconnect the wire from the negative terminal on the battery. Then you should press the plastic latch and also disconnect the block with the existing wires from the sensor. To completely remove the device being replaced, unscrew the two bolts using a Phillips screwdriver.

Foam rubber is used as a seal between the throttle pipe and the sensor. It is a component and also needs to be replaced. When installing a purchased device, you need to carefully tighten the mounting screws until the ring is completely compressed.

After installing the sensor, you should connect the wires. Since no further adjustment is required, the work can be considered complete. The entire process of changing the device takes no more than a quarter of an hour.