The better the ignition technology works, the more stable the engine itself will be. According to the standards, on devices with four strokes, the composition of fuel and air must ignite at the end of the compression stroke, in other words, an instant before the piston hits the upper dead zone. This principle is due to the fact that the composition needs some time to burn. Next, the gases expand, and their energy directs the piston, and a working stroke occurs. But how to determine early or late ignition?

Coming with acceleration or delay is a delayed or too fast reaction of technology to the position of the pistons in the cylinders: thus generating a spark at the spark plug (SZ). It ignites the mixture of fuel and air at the wrong moment when the piston is close to TDC. And this happens either too early or with delays (signs of late ignition).

This forces owners of cars that require their own efforts to adjust the advance angles (TAA) to frequently engage in adjustments.

Ignition settings

Signs of errors in the system

As already mentioned, such errors in the system can have a detrimental effect on the engine. Therefore, it is very important to detect signs of early injector ignition in time. You should pay attention to the following symptoms:

- The engine starts with difficulty.

- Fuel began to be consumed noticeably faster.

- The engine loses throttle response.

- There is a loss of power.

- At idle, the system is unstable.

- The response disappears when you press the gas.

- The engine gets very hot. There is detonation in it.

- The appearance of specific pops. They also send other components to the exhaust technology, most often to the carburetor.

Which ignition is better, early or late? Continued operation of the engine with a damaged SOP can only damage the engine even more seriously. Especially if sustained detonation occurs.

Gasoline engines with fuel injection (injection)

The signs of late ignition on an injector are the same as on a carburetor engine. But in this case, you cannot independently adjust the lead angle. The fact is that the operation of the ignition and fuel injection systems is controlled by an electronic control unit. It supplies control impulses to the systems after processing signals from the camshaft position sensor and crankshaft sensor. Correction of the moment of spark formation is also carried out taking into account the signal from the knock sensor. To determine the exact cause of malfunctions, professional diagnostics are necessary. Let’s assume that testing the DPRV with a multimeter did not reveal a malfunction. But the oscilloscope can show that the signal characteristics coming from the sensor do not meet the standards. You can make earlier ignition on the injector by changing the ECU program, that is, “reflashing” the “brains”.

Article on the topic: Design and purpose of the camshaft

Consequences of an incorrectly configured OZ

Ignition that occurs incorrectly and advances means that the spark appeared before the scheduled time. Gases expand. And their pressure opposes the piston, which rises to TDC.

When the working composition ignites after the piston moves from TDC along the lower vector, energy is generated and released from the fuel. It “overtakes” the piston and ends up in the outlet, without producing any useful actions. These are the principles of delayed ignition.

Symptoms of pre-ignition:

- During operation of the power unit, metallic clanging sounds are generated. They concentrate in the area of the cylinder block.

- The idle speed starts to fluctuate.

- Unstable engine operation is noticed.

- After pressing the gas there is a delay.

- The engine doesn't pull at all. There is unnecessary waste of fuel.

Delayed ignition is no less harmful to the engine. And the combustion of the composition occurs when the pressure drops and the volume develops in the engine cylinder. And the combustion process of this composition is disrupted. It burns out during the functional movement of the piston.

And it has the following signs ( symptoms of late ignition ):

- Loss of engine power. To accelerate the car, you have to press harder on the gas.

- Quite a lot of fuel is also wasted.

- Heavy deposits and carbon deposits appear on the engine.

- The engine overheats greatly.

How can I start the ignition later? Only by adjustment, more on that later.

Early or late ignition

Ignition of the mixture in the working chambers of the cylinders too early or too late causes poor performance of the internal combustion engine. The engine may not pull uphill, accelerate slowly, vibrate strongly, etc.

Signs of an incorrectly set ignition:

- the engine starts with difficulty;

- increased fuel consumption;

- the motor cannot develop power;

- in idle mode (idle speed), the internal combustion engine either stalls or over-gasses;

- the engine responds poorly to pressing the gas pedal;

- The internal combustion engine overheats;

- the engine detonates.

You can easily determine that the ignition needs to be adjusted if you hear popping sounds from the muffler and the car “sneezes.” It is recommended not to operate the machine in this mode, but to adjust it immediately. Moreover, one of the signs is detonation, which can destroy valves, pistons and cylinders.

Self-configuration of UOZ

How to ignite early? This work involves regulation of POP. It should pass at idle. Here it is important to maintain the correct speed in the intervals of 850 - 90 rpm.

Ignition timing slope values can be positive or negative. In the first case they reach +1 degree. In the second, they start from -1 degree. The indicated degree is the degree of interaction with TDC.

Signs of early and late ignition: in many cases, this moment is established using a strobe light. This device helps achieve meticulous tuning. If this device is not available, you can work with a control lamp. It is connected to ground and the positive terminal on the ignition distributor.

The following are the most popular methods that can be used to properly tune the ignition. The basis is taken from classic domestically produced equipment.

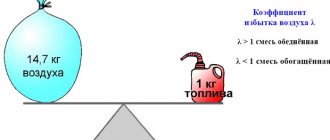

When and why do you need to configure?

Before moving on to answering the question, let's pay a little attention to the theoretical understanding of the subject. When a substance burns in the cylindrical flasks of an engine, it does not do so immediately, but gradually; with instantaneous decay, there would be no problems with pre-ignition. But the air-fuel mixture requires time, calculated in fractions of a second. If we add to this equation that the crankshaft rotates around its axis at an inconsistent speed, then we get a problem - the substance will burn either ahead of time, or a little later. The result will be unstable engine service; it will overheat, which will lead to detonation and completion of work before its service life.

- Ignition too early will result in pressure from the gases preventing the piston from moving and reaching the top point. This will result in less power and more fuel consumption due to unstable rocking at low rpm.

- And late ignition will lead to the fact that the air-fuel elements will burn for a long time, because of this the heart of the vehicle will overheat and more fuel will be consumed.

To avoid these unpleasant consequences, it does not hurt to ensure that the substance ignites and burns according to the amount of shaft rotation and corresponds to the optimal motor load. Old cars, invented by Ford, shifted responsibility for adjustments to the driver. The design includes a special lever-handle.

Modern models are equipped with a distributor with a part of the centrifugal mechanism.

This thing was a regulatory structure with several light weights and springs to balance the internal elements. When the rotational number increased, the loads were distributed to the sides and set the support part-breaker in motion. The more the shaft accelerated, the more the loads were distributed over the area and, as a result, the advance angle increased. But these safety functions do not function well if the octane rating of the fuel does not meet the engine manufacturer's requirements, even if the factors in question are satisfied, the wrong octane rating will lead to detonation.

In the last century, in such a situation, you could simply open the hood and manipulate the distributor in the required direction with your own hands. When using low octane fuel, it was necessary to ensure that the spark plug fired later. On current models, this is regulated by a special sensor that monitors and regulates temperature, speed and other engine compartment processes.

Setting method using strobe light

How to set the ignition earlier: the following operations appear here:

- The engine must be warmed up until it reaches functional temperature.

- The strobe light is connected to the on-board system.

- The fixing fastener (nut) of the ignition system distribution breaker cover is unscrewed.

- The alarm trigger device is strung on a wire with high voltage. This wire is located in the first cylinder.

- If there is a vacuum corrector hose, it must be removed and plugged.

- The luminous side of the working device goes to the crankshaft pulley.

- The power unit starts and operates at idle.

- The distributor housing (CT) needs to be turned.

- Securing the distribution breaker housing (DCB). Here you need to ensure that the pulley markings match the similar markings on the timing belt.

- The fixing nut is tightened.

What needs to be turned in the distributor to adjust the ignition timing.

The distributor itself, there is a scale on the side of it, you release the bolt and turn it. towards the plus side in advance towards the minus side towards later. and if you write 0 in this matter, buy a book on your car from the publishing house “behind the wheel”, everything is clearly detailed there with pictures, how to assemble, how to disassemble, how to adjust, it’s impossible not to understand. I once started with them myself

The distributor itself. Pictures are on the fence.

Turn the distributor itself, but before turning it you need to decide in which direction the crankshaft rotates, depending on how the engine is installed on your car, for example, a VAZ nine, if you stand facing the distributor on the driver's side, then turning the distributor to the left you will install the ignition later, to the right earlier, respectively, but on the distributor itself there is an area - markings on the body - a mark in the form of a stick on the left - a minus is drawn to the right of it - a plus, here on the right side there is an area for early ignition, a field for late, but despite this you are in the area of early ignition You can turn to the right and place even earlier. Well, something like this, using the nine as an example, the distributor itself is screwed onto 3 nuts, release them and twist

Nothing complicated. I did this: I took the socket with the lamp, + threw it on the distributor at the lamp, - on ground. And he spun it. The lamp lights up - the ignition is turned on. Try it. Maybe it will be clear without pictures.

The operation of a modern engine is influenced by many factors, but no one will deny that the ignition system plays one of the leading roles in this. The efficiency, stability, power and other parameters of the power unit depend on how well it copes with its tasks.

In theory, the fuel assembly on four-stroke engines should be ignited an instant before the piston reaches the top position. This short period of time should be enough for the mixture to burn, releasing the necessary portion of energy to ensure cranking of the crankshaft.

But in practice, ignition of the air-fuel mixture does not always occur precisely at the end of the compression stroke. There can be many reasons for this, and today we will try to figure out why this happens, how to diagnose and deal with such a phenomenon.

Setting up the OZ using the control light

When using this method, you need to follow these steps:

- Rotate the crankshaft in a special way. The markings on the crankshaft pulley must match the markings on the timing cover. The slider located on the switchgear should be directed to the spark plug cable of the starting cylinder.

- The fixing fastener of the distributor becomes loose.

- One wire from the designated device (lamp) is connected to the wire that runs from the distributor to the ignition coil mechanism

- The second wire from this lamp is connected to ground.

- The ignition starts.

- The CT should be rotated clockwise. This action continues until the light goes out.

- The CT is rotated to its initial position: counterclockwise.

- Having found out at what position the lamp device lights up, fix the CT in this position. A distributor nut is used for this. It needs to be tightened well.

Strobe light for ignition installation

Spark based operations

You need to configure the ignition using this method as follows:

- The markings on the crankshaft pulley and timing belt are aligned. The marking on the slider guides the starting cylinder cable.

- The nut securing the switchgear housing is loosened.

- The center wire with high voltage is removed from the distributor cover.

- The cable contact is positioned near ground. This is a distance of approximately 5 mm.

- The ignition starts.

- The KRP rotates 20 degrees. The rotation occurs in a clockwise direction.

- The housing rotates in a reverse vector until a spark is formed between the contact section of the cable and the ground.

- The distributor housing is secured in this position. The fastener here is the breaker nut.

After these operations, the reliability of the OZ in traffic conditions is necessarily determined . The algorithm of actions here is as follows:

- The engine is warming up.

- The car accelerates to 40-45 km/h.

- In fourth gear, you need to press the gas pedal to the limit.

- The level of detonation is analyzed. When, after accepting the specified gear, the duration of detonation is 2-3 seconds, and the detonation stops as the car accelerates, this is normal. And when, upon reaching speed (item 2), it does not disappear, then, most likely, advanced ignition is formed. When there is no detonation when the designated gear is engaged, retarded ignition is obtained. In this situation, it is necessary to adjust the SOP until you achieve the desired result.

The better and more accurately the ignition works, the more stable the engine itself will operate.