The stability of the engine, its power, fuel efficiency, etc. directly depend on the correct settings and uninterrupted operation of the ignition system. Normally, on four-stroke engines, the fuel-air mixture should ignite at the end of the compression stroke, that is, just before the piston rises to top dead center. This ignition timing is due to the fact that the mixture requires a certain time to burn, after which the energy of the expanding gases pushes the piston down and the power stroke begins.

We also recommend reading the article on how to set the ignition on a diesel engine. From this article you will learn about ways to adjust the injection advance angle on diesel engines.

Late or early ignition should be understood as a delay or advance in the operation of the ignition system in relation to the position of the piston in the cylinder. In other words, a spark plug spark forms and ignites the fuel-air mixture not at the optimal moment when the piston approaches TDC, but earlier or later than this moment. This phenomenon is called early or late ignition. For this reason, owners of vehicles that have the ability to independently adjust the ignition timing (ignition timing) are often faced with the need to adjust the ignition.

When the car asks for an "angle"

Fireworks to everyone! This post will talk about setting the ignition timing. As you remember, I complained that the car did not drive from the bottom and started firing only after 3 thousand revolutions. After replacing the carburetor the situation improved, but not much. The bluntness on the lower parts remained.

There is such a wonderful person, his name is Nail Poroshin, almost every modern owner of a carburetor VAZ knows him. He uploads quite interesting videos about the repair and modification of carburetors and the ignition system.

Well, I came across a couple of his videos, where they came to him with a similar problem as mine. In general, the issue turned out to be late ignition and lack of advance angle. After looking at the setup, I started doing the same. By turning the distributor counterclockwise, I made the ignition earlier. Ignition is considered ideal when, at a speed of 50 km/h in 4th gear, when you press the gas pedal to the floor, 2 light knocks of your fingers “poke-poke” appear and the car accelerates. My ignition is late and there are no sounds at all. With early ignition there is detonation in the form of prolonged knocking.

After the first test setting of the distributor, I went for a ride. When I pressed the gas, the engine sound immediately changed and became angrier. And I immediately felt the arrival, the car began to accelerate faster and gain momentum. The bluntness has already become not up to 3 thousand, but up to 2 thousand. So far I have no detonation, which means there is still room for adjusting the angle, approximately right up to the golden center, before these 2 light knocks. Also, when adjusting the ignition, the idle speed increases, they will also need to be adjusted.

Source

The engine is overheating, what should I do?

The main thing is to notice in time that the temperature needle begins to enter the red scale. If this phenomenon occurs, then when boiling and obvious steam appears, you need to:

- reduce the speed and preferably switch to neutral;

- stop in a permitted parking area or at the side of the road;

- turn on the stove at maximum power;

- wait 1-2 minutes;

- drown out;

- open the hood;

- eliminate the consequences of overheating, preventing further destruction of the liners.

On a note! It is not at all safe to rush to cool the engine after stopping the car. Hot fumes from under an open hood can cause severe burns.

If there is no characteristic metallic knock in the engine, then you need to:

- turn on the engine and let it idle for a while;

- then add water or antifreeze to the tank to the required level;

- Cool the engine and identify the cause of overheating.

If a characteristic metallic knock appears, which clearly indicates severe overheating of the engine and damage to the liners, it is likely that it will no longer be possible to do without the help of car service employees or calling a tow truck.

If after carrying out the described manipulations the arrow still does not fall to normal values, then you need to:

- wait until the engine cools down completely;

- carefully unscrew the radiator valve, wearing protective gloves to avoid burns;

- carefully and slowly add the missing water to the radiator;

- Turn on the fan to quickly supply cool air to the engine for cooling.

Only after the engine has completely cooled down can you continue the journey, but drive carefully and carefully, not exceeding a speed of more than 50-60 km/h. This will ensure that the radiator is blown with air flow, and the load on the engine will be significantly reduced.

On a note! Under no circumstances should you pour cold water on a hot engine. This can lead to the formation of cracks on the walls of the block head, engine failure, and ultimately to a malfunction up to a complete stop.

It is not recommended to unscrew the expansion tank cap when the engine has reached boiling temperature. In this case, the pump may remain operating for some time. If antifreeze begins to expand under pressure, the plug may fly out at any moment. This is comparable to a champagne cork popping out and is unsafe. It’s better to wait until the engine cools down completely, or unscrew the plug halfway, thereby allowing the excess air flow to gradually exit the system.

Setting up the ignition of a VAZ 2106

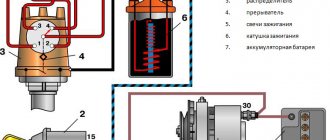

Licked from the site. Very good instructions. The ignition distributor (distributor) is removed from the VAZ 2106 car for repair or replacement. The engine of the VAZ 2106 model has a distributor of type 30.3706. To distinguish it from distributors of other models, a mark (ring groove) is made on the shank. To remove the distributor from a VAZ 2106 car you will need: a spark plug wrench, a bit, two “7” keys, a “13” wrench, and a screwdriver. 1. Remove the tip from the spark plug of the first cylinder and unscrew it.

2. Close the spark plug hole with your finger.

3. Turn the crankshaft until the compression stroke begins in the 1st cylinder (air will begin to escape through the spark plug hole). Then, while continuing to turn the crankshaft, align mark d on the crankshaft pulley (highlighted with chalk) with the middle mark b (if you are using gasoline with an octane rating of 92 or 95) or the extended mark c (if you are using gasoline with an octane rating lower than 92). Reinstall the spark plug of cylinder 1 and connect the high-voltage wire to it.

4. Disconnect the hose from the vacuum ignition timing regulator. 5. Remove the high-voltage wires from the sockets of the distributor cover.

6. Unscrew the nut securing the distributor, remove the spring washer and plate. 7. Remove the distributor from the engine

8. Turn over the distributor and, holding the lower nut, unscrew the nut securing the low voltage wire; remove the washer and wire. 9. Unfasten the holders and remove the cover from the new distributor.

10. Install high-voltage wires into the cover of the new distributor in accordance with the operating order of the engine cylinders. NOTES The operating order of the engine cylinders is 1-3-4-2. The distributor rotor rotates clockwise. Cylinder numbers are marked on the distributor cap and on the engine cylinder head.

11. Connect the low-voltage wire to the new distributor.

12. Turn the rotor of the new distributor to a position in which its outer contact (shown by the arrow) will be directed towards the contact of the 1st cylinder on the distributor cover. NOTE

When the outer contact 2 of the rotor coincides with mark a on the cover, it simultaneously coincides with the head of screw 1 on the distributor body.

13. While holding the distributor shaft from turning, insert it into the socket on the cylinder block so...

14. ...so that the line passing through the spring latches is approximately parallel to the axis of the motor. 15. Secure the distributor in this position to the cylinder block without completely tightening the nut. Connect the hose to the vacuum regulator. 16. After installing the distributor on a VAZ 2106 car, check and, if necessary, adjust the ignition timing (see “Checking and adjusting the ignition timing”).

Source

Octane number

The name of the fuel brand consists of letters and numbers. The letters A or AI indicate the method for determining the octane number:

| № | Helpful information |

| 1 | motor (A) |

| 2 | research (IA) |

The name of the octane number indicates such quality as the fuel's resistance to fire. This figure is conditional. The standard used is isooctane, whose fire resistance is very high and is equal to 100. The octane rating was created at the beginning of the last century. It was detected by the composition of isooctane mixed with normal heptane.

Accordingly, AI 92 fuel is equivalent in its fire resistance to 92% of a mixture of isooctane and heptane, AI 95 - 95%. The octane number can be higher than 100 if the anti-knock properties of gasoline are higher than that of pure isooctane.

This value is very important, since fire leads to rapid deformation of the cylinder-piston group. This is due to the speed at which flames spread - up to 2.5 km per second, while under optimal conditions the fire spreads at a speed of no more than 60 meters per second

To increase anti-knock qualities, you can either add additives that contain lead, or change the fractional composition upon receipt. The first option can be easily obtained from AI 92, AI 95 or 98 fuel, but today it has been abandoned.

Since, although such additives greatly increase the performance characteristics of gasoline and have a low cost, they are also very toxic and have a detrimental effect on the environment than pure fuel.

Other compounds that are less toxic, such as acetone or ethyl alcohol, can also be used as additives. For example, if you pour 100 ml of alcohol into a liter of AI 92 fuel, the octane number will increase to 95. But the use of such means is not economically feasible.

Early or late ignition

Ignition of the mixture in the working chambers of the cylinders too early or too late causes poor performance of the internal combustion engine. The engine may not pull uphill, accelerate slowly, vibrate strongly, etc.

Signs of an incorrectly set ignition:

You can easily determine that the ignition needs to be adjusted if you hear popping sounds from the muffler and the car “sneezes.” It is recommended not to operate the machine in this mode, but to adjust it immediately. Moreover, one of the signs is detonation, which can destroy valves, pistons and cylinders.

Video

The car engine is overheating.

Overheating of a car engine is a problem that every driver can face. In this article we can learn: - how to notice in time that the engine has overheated; — why the engine heats up in general and in certain situations; — what to do if the engine overheats.

To understand the essence of the issue, it is necessary to consistently read all the explanations of an experienced auto mechanic.

If the ignition is set incorrectly

Because the gasoline mixture ignites early, the piston experiences a greater force against its movement. This reduces the life of the crankshaft, pistons, connecting rod and pins.

The signs of early ignition can be determined by the following points:

As for the installed late ignition, it also negatively affects the performance of the engine and the service life of its component parts.

In this case, the mixture is ignited late, that is, when the piston is already going down. The fuel burns out, if it has time, when the piston moves back (up).

Signs of late ignition:

How to set the ignition timing with your own hands

Setting the ignition correctly means that you need to find the desired ignition timing (IAF). The tuning is done at idle, although this is understandable, but suddenly someone decided to put the car on a jack and tune it at speed.

A popular device used to set the ignition is a strobe light. With a strobe, the settings are more precise. But, if it is not there, then set it up using a control light.

If a light bulb is used for adjustment, it is connected to the positive terminal on the ignition distributor (distributor), and the light bulb base is connected to ground. Let's look at the configuration options separately.

Now we have begun to disassemble the power units of automobiles. Please write in the comments what kind of car you have and with what engine. Later, materials on such engines will be published with useful information, for example, if the timing belt breaks, whether the valves are bent, also technical characteristics, design, on which cars such engines are installed, etc. We have already reviewed the ZC engines from the Honda plant, 3UZ-FE, 3S-FE, 1AZ-FE.

Strobe setting

How to set the ignition with a control light

What to do if your car overheats in a traffic jam

When driving a car for a long time in a lower gear, the engine operates with increased power, which in itself leads to overheating. Add to this the lack of counter-flow of air necessary to cool the radiator. What to do? The main thing is not to panic. Short-term overheating is not terrible, but if you see that the car is not cooling down, it’s time to act.

Important - do not turn off the engine unless absolutely necessary. Exactly - without extreme. A stalled, overheated engine is an almost 100% guarantee of repair. It will take quite a long time to describe what is happening in the engine in this case (rotating the liners together with the crankshaft, when the engine is subsequently started - the least of the possible troubles), just take it on faith.

Important - do not think about pouring water on the engine or pouring cold water into the radiator. The result is the same - repair. Moreover, you can try so hard that you cannot do without replacing the block and cylinder head. Another “beauty” of cold water is microcracks inside the block. Finding and eliminating will be very, very difficult, if not impossible. The car has overheated - try to pull over to the side of the road. If it doesn’t work out, don’t panic and don’t pay attention to those around you – it’s important for you to save the engine. Stop at idle, turn the heater on full, and wait. If after 5-10 minutes the situation does not improve, turn off the engine. It’s a good idea to open the hood; the main thing in a panic is not to forget to set the car’s parking brake.

The only reason to turn off the engine right away is clouds of steam coming from under the hood. Most likely, the cooling pipe has burst, and further operation of the engine will only worsen the situation.

This is what it looks like, engine overheating, if you look closely. Now you know why the engine gets hot and how to deal with it. Author: Igor

One of the most dangerous and common problems that entails serious consequences in the form of a major overhaul of the internal combustion engine or its replacement is engine overheating. This problem mainly occurs in the summer, but some faults can cause this problem in cooler periods. It is easier to avoid overheating of the car's heart than to later eliminate the serious consequences of even a single excess of operating temperature. To do this, you need to know the symptoms and ways to quickly eliminate such a problem.

Other methods of setting the ignition

Method by ear

Some people set the ignition by ear. Rotate the distributor and determine how the engine operates. This method is the simplest:

Spark method

Another tuning method is using a spark. To do this, you need to align the marks on the crankshaft pulley with the timing mark. The slider mark points to the first cylinder. After this, you need to loosen the distributor nut and pull out the central high-voltage wire from the distributor cover.

Afterwards, bring this wire closer to ground so that there is 5 mm between them, and turn on the ignition. Rotate the distributor body 20 degrees clockwise. 20 degrees is 1-1.5 cm. Now you should slowly turn the distributor counterclockwise until a spark appears between the disconnected distributor wire and ground. In whatever position the spark appears, we leave the position of the distributor in that position and tighten it.

After using one of the methods for adjusting the ignition of domestic carburetor cars (VAZ, UAZ, Volga, NIVA, etc.), drive around and check how the adjustment affected the operation of the internal combustion engine.

For diagnostic accuracy, you need to:

If it was not possible to set the ignition to the optimal mode the first time, then repeat again and again until the correct result appears. By repeated adjustments, you can achieve automaticity and learn how to adjust the ignition with your own hands, without instruments, by ear.

Checking the ignition timing

Setting the required ignition timing is undoubtedly an important point in the overall operation of the car, which ensures that all the most important characteristics are normal: fuel consumption, power, idle speed, throttle response, etc. Therefore, it is very important to monitor this indicator by regularly checking the torque. Moreover, it is advisable to carry out this procedure every time the car is serviced.

You can determine whether the described indicator is set correctly using two tools: a test lamp and a strobe light.

So, you should check using a test lamp according to the following instructions:

- Connect the device to the capacitor in parallel.

- Using the starting handle, rotate the crankshaft until the spacer plate on the rotor is as close as possible to the contact on the distributor cap, which is also connected to the spark plug of the first cylinder.

- Turn on the ignition.

- Turn the crankshaft slowly until the light comes on.

- The labels should match at this point. If the lamp starts to burn before the marks match, or after, then this is a sure sign of an incorrectly installed ignition.

You can check the analyzed indicator using a strobe by following these points:

- Connect the device to the car's ignition system.

- Start the engine, at the same time setting the crankshaft speed to about 900 rpm.

- Direct the light of a flashing strobe lamp onto the crankshaft pulley so that it also illuminates the marks.

- Due to the fact that the light of the lamp appears synchronously with the flashing of a spark between the electrodes of the spark plug from the first cylinder, the mark on the pulley appears motionless. If the moment is set correctly, then all marks will coincide. But if they shift, then it is necessary to ensure that they coincide by rotating the distributor body.

You can also use this technique to check: drive out onto a flat road, accelerate the car well and drive in fourth gear at a speed of about 50 km/h. After this, press the brakes sharply and all the way. If this action causes small, short-term detonation sounds from the engine, then this is a sign of correct ignition timing. If the sounds are too strong, then this is early ignition; if they are absent at all, then it is later.

As part of this, I also recommend familiarizing yourself with the signs of an incorrectly installed ignition, which will help prevent uneven engine operation:

- Starting problems.

- Increased fuel consumption.

- Reduced throttle response and power.

- Unstable idle.

- Failure when pressing the gas.

- Overheat.

- Shots into the carburetor or muffler.

- Detonation.

Late and early ignition where to turn

Pre-ignition is one of the most common malfunctions of the ignition system of carburetor engines.

Its essence lies in too early (sooner than required for normal engine operation) ignition of the fuel in the combustion chambers (much earlier than the piston reaches top dead center). The initial ignition timing for a specific gasoline is set when the car engine is idling. This advance is necessary for proper engine operation. When it operates under load, even greater ignition timing is required, which is achieved through the operation of centrifugal and vacuum ignition timing regulators. But, if the initial angle is set too early, then the work of the regulators is superimposed on this incorrect angle, making the ignition so early that it leads to big problems in the engine.

Signs of early ignition

Depending on how much the ignition timing has deviated from the norm, signs of early ignition are either practically invisible or visible to the naked eye.

— Problem with starting the engine. The engine does not start the first or second time. There may be reverse rotation of the crankshaft after turning off the ignition.

— The car engine is idling unsteadily. It is impossible to equalize the XX speed with the screws on the carburetor, or the engine runs stably only when the speed is set to higher.

— Sluggish car dynamics at speed. At the same time, starting and accelerating can be quite acceptable, but at speed the engine’s power and throttle response are insufficient (“it’s as if someone is holding the car from behind”).

- “Fingers are knocking.” Constant detonation (fractional, chattering sound from the engine) when the car is moving, increasing when the gas pedal is pressed and does not disappear after it is released.

— The spark plugs are black. Poorly burning fuel deposits black soot on the spark plugs, leading to their rapid failure.

— “Shots” into the muffler when idling. Unburned fuel burns out in the muffler with pops. Misfires due to spark plugs working once.

— Black smoke from the muffler. Unburned fuel smokes.

— Increased fuel consumption. The engine requires a lot more fuel to do its job when the ignition is too early.

The signs of early ignition listed above may be signs of other malfunctions, for example, with the carburetor (“overflows”), the fuel system (the fuel pump pumps too much), the ignition system, etc. But, in any case, when they appear, first of all, check that the angle is set correctly ignition timing, and then we look at the carburetor and everything else.

Causes of early ignition

— The cause of too early ignition is most often an incorrectly set ignition timing at idle speed of the engine. For all recommendations and required ignition timing angles, see the following articles on the website: “Setting the ignition timing on VAZ 2108, 2109, 21099”, “Setting the ignition timing on VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107” .

— If the initial ignition timing is set correctly, but there are still signs of too early ignition, then you should check the centrifugal ignition timing regulator. It should start working at a speed slightly above idle speed and gradually, depending on the engine speed, increase the angle. Weakening or breaking of the regulator springs can cause the centrifugal regulator to immediately increase the ignition timing to unacceptable values.

— On VAZ 2105, 2107 cars with a contact ignition system, you should check the gap between the contacts of the breaker in the distributor, since its value directly affects the ignition timing.

Notes and additions

— The main check for the presence of early or, conversely, late ignition on VAZ 2105, 2107, 2108, 2109, 21099 cars is a check in motion. When, moving at a speed of 40-50 km/h, on a flat section of the road, we sharply press the gas pedal. There should be a small short-term detonation (fractional, chirping sound from the engine compartment). If it appears and disappears, good, the ignition is set correctly. It appears and does not go away, the ignition is too early. There is no detonation - late ignition.

More articles on the car ignition system

Diesel car

Many symptoms of incorrect operation on gasoline cars are also transferred to diesel. The main difference between these two cars is the method of ignition of the fuel. Ignition of diesel fuel occurs due to close contact of the fuel with compressed, hot air.

Adjustment on a diesel engine

Ignition tuning on diesel cars consists of finding the required advance angle for diesel fuel injection; it must be supplied specifically at the peak compression moment.

If the angle is set incorrectly, the injection will be untimely. This will lead to poor-quality combustion of the mixture, and the engine will not operate properly.

If the ignition on a VAZ 2107 is too late, in which direction should the distributor be turned?

no matter what, use your ear and tachometer to decide! Or better yet, go to a specialist and give him $10!

There is a special device for setting the advance angle, it’s better to go to a service center, you will make a mistake and spend more money on fuel consumption.

more like glow ignition (wrong spark plugs or bad gasoline)

all clear! The slider rotates clockwise, so turn the distributor counterclockwise, which would be earlier and later, which would be later!

Go to the service station, they will put out an instrument, the detonation will torture you by eye and you will burn a lot of fuel.

Moves counterclockwise

How to set the ignition of a VAZ 2106 at home

Poor dynamics, as well as overheating of the VAZ 2106 engine, can be signs not only of a coked engine or problems with the spark plugs, but also indicate an incorrectly set ignition. Sometimes this problem is accompanied by a ringing sound in the engine, which is heard at low as well as medium speeds. Novice drivers, as a rule, have no idea how to set the ignition of a VAZ 2106, so most of them immediately turn to specialists for help. There is no need for this, and today you will see that you can easily set the ignition with your own hands. You don't need any special equipment to work.

How to set the ignition on a VAZ 2106 - step-by-step instructions

Useful video on how to set the ignition on any cylinder:

To main

Overheating, consequences?

The outcome of events may be as follows, taking into account the degree of overheating of the motor:

- local, with slight overheating, when the driver still manages to notice the problem in time and stop the car. If the temperature needle is in the red zone, then it is enough to cool the motor, after which you can start moving again, thereby easily eliminating the cause of the overheating of the motor;

- serious, with prolonged operation of the engine at elevated temperatures, temperature fluctuations, boiling. As a result, the problem can lead to deformation of the piston rings, large cracks in the engine body itself, and burnout of the cylinder head gasket;

- critical when, due to excessive overheating, the engine suddenly stalls. This is fraught with breakdown of the crankshaft, penetration of the internal combustion engine block, melting of the connecting rod bearing, deformation of the cylinder and piston as a whole and severe destruction of the engine, to the point of impossibility of restoration. In this case, it is no longer possible to do without purchasing a new power unit.

It is quite difficult to find out that the engine is overheating without special instruments and diagnostic equipment. Although experts advise learning to understand when the engine is overheating and you need to eliminate the cause. Overheating can be detected using the following criteria:

- the appearance of turbidity, sediment, inclusions in the coolant;

- grinding the cylinder head plane;

- deformation of the block head.

ADJUSTING THE IGNITION WITH A TRAMBER. (MANUALLY!) Where to turn it.

You need to go to the service center, they know everything there

In the direction of the runner - later, against the movement - earlier

Come on! They are both clockwise and counterclockwise. Place the first piston at the top dead center, the mark on the crankshaft will coincide. (-) from the engine compartment lamp to the distributor capacitor. (when I set the first piston, I saw where the distributor was turning, so now in the other direction) turn the distributor with the ignition on until the light comes on, at the moment of ignition there is a spark. The firing order can be determined by removing the valve cover and looking at the valves. (scrolling the crankshaft.)

What needs to be turned in the distributor to adjust the ignition timing.

The distributor itself, there is a scale on the side of it, you release the bolt and turn it. towards the plus side in advance towards the minus side towards later. and if you write 0 in this matter, buy a book on your car from the publishing house “behind the wheel”, everything is clearly detailed there with pictures, how to assemble, how to disassemble, how to adjust, it’s impossible not to understand. I once started with them myself

The distributor itself. Pictures are on the fence.

Turn the distributor itself, but before turning it you need to decide in which direction the crankshaft rotates, depending on how the engine is installed on your car, for example, a VAZ nine, if you stand facing the distributor on the driver's side, then turning the distributor to the left you will install the ignition later, to the right earlier, respectively, but on the distributor itself there is an area - markings on the body - a mark in the form of a stick on the left - a minus is drawn to the right of it - a plus, here on the right side there is an area for early ignition, a field for late, but despite this you are in the area of early ignition You can turn to the right and place even earlier. Well, something like this, using the nine as an example, the distributor itself is screwed onto 3 nuts, release them and twist

The operation of a modern engine is influenced by many factors, but no one will deny that the ignition system plays one of the leading roles in this. The efficiency, stability, power and other parameters of the power unit depend on how well it copes with its tasks.

In theory, the fuel assembly on four-stroke engines should be ignited an instant before the piston reaches the top position. This short period of time should be enough for the mixture to burn, releasing the necessary portion of energy to ensure cranking of the crankshaft.

But in practice, ignition of the air-fuel mixture does not always occur precisely at the end of the compression stroke. There can be many reasons for this, and today we will try to figure out why this happens, how to diagnose and deal with such a phenomenon.

Torque adjustment

If it has already been determined that the ignition timing is set incorrectly, then this must be corrected immediately.

I recommend following these instructions:

- Loosen the bolt that secures the distributor body so that it can rotate freely. In order to adjust the analyzed indicator, you will need to turn the distributor in different directions, which depends on what kind of ignition is needed - earlier or later.

- If the slider rotates clockwise, then when changing its movements (that is, turning the body counterclockwise), the earlier one will be set. Exactly the same if it's the other way around. Here you may need an assistant, and even more than one, since someone will gas, someone will check, and someone will turn the distributor.

- While the engine is operating at high speeds, adjustments need to be made. To do this: firmly grasp the distributor body and slowly rotate it in different directions until the mark is in its proper place. Periodically, the position of the mark should be rechecked using a strobe light. When the required setting has been achieved, the distributor must be secured by firmly tightening the fixing screw.

In general, setting up the described indicator does not fall into the category of particularly complex ones. This greatly simplifies the life of the car owner, but also places a huge responsibility on him in the form of regular checks and, if necessary, mandatory adjustment of the ignition timing. I advise you to always remember this, because this indicator has a significant impact on the life of the car.

Operating principle of the ignition system

It may seem to many that ensuring fuel assemblies are ignited is a trivial task. In reality, the ignition system consists of many interconnected components. The main problem is that it is necessary to ensure the ignition of the combustible mixture at very high piston speeds, that is, very high accuracy of synchronization of the operation of all components included in the ignition system is required.

Modern non-contact SZ work according to the classical scheme, when the moment of ignition of the compressed mixture is determined by the position of the crankshaft. Although the speed of fire spread in the combustion chamber is quite high - about 30 m/sec (one thousandth of a second is enough to travel 3 cm), it is finite, that is, there is some delay between the supply of a spark and the complete combustion of the next fuel damage. That is why this spark must be initiated at a strictly defined point in time, monitored by a sensor.

But what happens if the spark plug fires a little earlier or later?

Let's look at the first option first. Let's say the mixture was ignited earlier than expected. Then the maximum value of the exhaust gas pressure will be reached before the piston rises to TDC. This means that part of the way the pressure force of the exhaust gases will be directed against the stroke of the piston, braking it, which causes a drop in the rated power and overheating of the power unit.

With late ignition of the fuel assembly, the maximum gas pressure occurs when the piston has already passed the top dead center, moving down to the exhaust tract. The power of the power unit will also be reduced, since part of the energy will be wasted during the exhaust stroke rather than the expansion stroke.

In other words, ignition of the mixture must occur at a strictly defined point in time, when the piston has not reached TDC approximately 10-12º of the crankshaft rotation. This value is called the ignition timing angle. Note that the OZ is not a constant value, since it depends on the combustion rate of the fuel assembly and the crankshaft rotation speed. The centrifugal regulator is responsible for dynamically changing the ignition timing.

Ideally, the operation of all components of the ignition system should ensure “correct” ignition of the mixture, but in practice, changing fuel parameters (for example, pouring poor quality fuel into the gas tank) has a significant impact on the rate of combustion of the mixture, therefore, to adjust the OZ, the use of an octane corrector is required.

On modern cars, all this is done under the control of the ECU, which receives all the necessary information from sensors.

As for the answer to the question, which ignition is better for the engine, early or late, you probably already realized that both options are bad. Optimal ignition will be the best, although it can be called early, because the ignition of the fuel assembly is carried out before the piston reaches TDC, and it is on its installation that we will dwell in more detail, but a little later.

Engine pre-ignition (LSPI): What is it and how to prevent it

Today we will talk about one extremely important phenomenon that can eat a hole in your family budget. In order not to bore you with a preface, we will immediately describe the essence of the matter

The problem came to the attention of engineers, technologists and scientists not very long ago and very unexpectedly. It has been observed on almost all turbocharged engines with direct fuel injection of the GDI-Turbo type. The essence of the phenomenon is piston failure as a result of a special type of detonation occurring due to early ignition.

The phenomenon was called Low Speed Pre Ignition (LSPI), which is translated into Russian as “premature ignition of the mixture in the cylinder.” The uniqueness of the phenomenon lies in the fact that the destruction of the piston occurs when the engine is not under load and running at not very high speeds (a trivial example is driving a car on the highway).

Numerous tests have shown that the cause was motor oil, or rather the additives that are added to it. The oil film seeps under the piston rings and detonates under high pressure and temperature, thereby destroying the piston.

You can learn more about the nature of the phenomenon, as well as understand how to avoid it, by reading this article.

Deep inside your car's engine, a tiny spark from a spark plug ignites an injected, precisely measured volume of gasoline mist many times per second.

The interaction of the spark with the air-fuel mixture results in a series of controlled micro-explosions that occur inside the engine cylinder.

Your car's engine miraculously converts the force from these small explosions into torque, allowing the car to start moving. Now you know the basics of engine operation.

In order for the internal combustion engine to continue to operate smoothly and properly, these tiny micro-explosions (ignition of the air-fuel mixture) must occur each time at a strictly defined time. Neither earlier nor later. We're talking about milliseconds. The spark plug is responsible for controlling the ignition time of the mixture in a gasoline engine.

But sometimes there is a failure in synchronizing the ignition of gasoline in the cylinders. In this case, the consequences can be the most unpredictable and sad for the engine.

For a controlled micro-explosion of gasoline to occur, the heat of a spark plug spark is required. But the spark plug is not the only source of heat inside the cylinders of a running engine. Sometimes, when something goes wrong, the inside of the engine gets too hot, causing the gasoline to ignite prematurely before the spark plug fires to initiate the fire.

In this situation, the fuel burns explosively. It really literally explodes and causes damage with increased loads to all parts of the cylinder-piston group. As you understand, this long-studied phenomenon of engine operation is called detonation. This problem can really turn the insides of your engine into a pile of scrap metal, but today we will not talk about that at all, since, fortunately, detonation is a completely predictable and long-studied phenomenon. It has been studied so well that modern engines are equipped with systems that prevent its occurrence altogether.

If you own a modern car that is regularly maintained and runs on quality gasoline with the correct octane rating, detonation is not something you need to worry about.

How to determine early or late ignition

When the OZ shifts in one direction or another, this causes a noticeable drop in engine power. But this phenomenon can also manifest itself with other symptoms:

If you do not respond to these signs of unstable operation of the power unit, they can result in more serious problems. You need to be especially careful when persistent detonation occurs.

Let's look at specific signs of early ignition:

Let's look at the symptoms of late ignition, which overlap:

As you can see, problems arise with any change in the ignition angle. And yet, many motorists take such a step at their own peril and risk. Some - by installing the ignition earlier, so as not to experience problems with starting. Others prefer late ignition, which improves the car's dynamics during acceleration. Both cases are undesirable because they negatively affect the engine.

It should be noted that the installation of LPG places increased demands on car owners in terms of optimizing the ignition angle. Currently, switching to compressed gas makes it possible to reduce fuel costs by almost half, but it must be taken into account that this fuel has a higher octane number compared to gasoline, and it is consumed somewhat faster than gasoline. All this leads to the fact that the combustion of the combustible mixture can occur during the exhaust stroke, exerting a strong thermal effect on the exhaust system. That is why owners of cars with gas equipment should monitor the functioning of the power unit much more often.

The symptoms of an incorrectly set ignition angle are also typical for diesel engines, but the reasons for this phenomenon are fundamentally different. The fact is that the method of igniting fuel in a diesel engine is different: here air is supplied directly to the combustion chamber, that is, there is no stage of preparing the fuel assembly. Diesel fuel is fed into the cylinder, where it spontaneously ignites when in contact with highly compressed air heated to a temperature sufficient to ignite the diesel fuel.

Adjusting the late/early ignition timing involves accurately setting the diesel fuel injection timing exactly at the moment the piston passes TDC, and the main element of the ignition system for diesel power units is the high-pressure fuel pump, which is responsible for optimal fuel injection.

Prevention measures

To minimize the possible risks of breakdowns, thereby preventing excessive heating of the engine, it is enough to follow simple preventive measures. Recommended:

- Promptly maintain and clean the engine;

- use only high-quality fuel or oil with a high octane number;

- promptly replace parts of the cooling system that have failed or are on the verge of failure;

- check the serviceability of the water pump and thermostat, which often leads to engine overheating;

- correctly set and adjust the ignition;

- periodically check the operation of the spark plugs;

- diagnose the degree of tension of the pump belt;

- add coolant in time, since moving with a half-empty engine is dangerous;

- Do not use chemical additives for the cooling system, because they also lead to scale on the engine walls, resulting in a rapid movement of the temperature needle towards the red mark.

An arrow in the area of the red line is a signal that the engine may break down or jam at any time. Taking care of your car in a timely manner means ensuring uninterrupted operation of the engine and, most importantly, safe and comfortable driving on the roads.

What are the dangers of an incorrectly set OZ?

So, we have already found out that if the ignition of the fuel assembly in the form of a spark generated by the spark plug occurs earlier than usual, the expansion of the compressed mixture as a result of its combustion will begin to occur even before the piston has passed TDC, that is, at the stage of its ascent. This means that it will be more difficult for the piston to travel the rest of the way up before it begins to move downwards, during which the optimal release of energy from the exhaust gases occurs.

With late ignition, the amount of useful work performed by the piston also decreases, since part of the path it will travel by inertia, and part of the energy will be wasted and sent to the exhaust system, warming it up instead of increasing the efficiency of the power unit.

The consequences of an incorrectly set ignition can be very serious. If you allow the engine to operate for a long time at a late ignition, all the conditions for the optimal combustion process will be violated. In particular, at the moment at which the exhaust gas pressure peaks, the piston is already moving downwards, so the entire fuel assembly does not have time to burn, which leads to the deposition of unburned particles on the cylinder walls. Accumulating, such deposits can lead to coking of the engine, which can lead to its breakdown and the need for major repairs.

But one should not assume that earlier ignition is less dangerous. In this case, the energy released during the combustion process is directed against the movement of the piston, braking it on the way to TDC, and this causes serious shock loads, and not only on the cylinder head - the crankshaft may also suffer. It is these impacts that manifest themselves in the form of clearly visible metallic knocks. If you do not respond to such symptoms, further operation of the power unit risks deformation of the connecting rods, burnout of the pistons, as well as accelerated wear of the crankshaft liners. And these problems are more serious than the consequences of late ignition.

So the correct OZ is a guarantee of long-term and trouble-free operation of the engine. However, on modern injection engines, the on-board computer is responsible for the correct installation, so you will not be able to adjust the ignition timing yourself. The only option in case of problems is to reflash the ECU, or enter corrective information into the control unit.

You may ask why electronics allow ignition failures? There are objective reasons for this. The fact is that the ignition timing is controlled based on data coming from numerous sensors. Based on this information, the ECU determines in what volume and at what moment to supply fuel and air into the combustion chamber, as well as when to supply a spark to ignite the mixture. In this case, malfunctions in the operation of the sensors are the main reason for changes in the SOP, and the on-board computer does not always react correctly to such situations. A secondary, less common reason for changes in SOP is a violation of the geometry of the components of the power unit.

In such situations, all that remains is to check the proper operation of the sensors. And, of course, the marks on the crankshaft/camshaft match. However, on early versions of injection engines, the ECU is only responsible for the functioning of the fuel supply system, so adjustment work on setting the ignition is carried out in approximately the same way as on carburetor engines.

Reasons why the engine may overheat

The cooling system, which can be filled with antifreeze, antifreeze or plain water, protects the internal combustion engine from overheating.

The main devices that monitor operating temperature and reduce it are:

- radiator fan, which is turned on by software when a certain temperature is reached;

- a thermostat that opens the movement of coolant in a large circle;

- temperature sensors that transmit readings to the ECU, there are several of them, they can be located either on the engine or radiator;

- electronic engine control unit.