- home

- Suspension

- Car suspension structure - description and purpose of the main elements

09.09.2021

Today we will look at what a car suspension consists of. Let's look at the purpose of each element, their design and operating principle.

Advertising:

Purpose

The suspension in a car is necessary to soften the impacts that the wheels receive from uneven roads. Thanks to it, the car body is literally suspended above the surface on the elastic elements of the chassis.

This ensures the vehicle's smooth ride and controllability in difficult terrain conditions. In other words, it is needed for the car to move with a certain level of comfort, without shaking and vibration.

Let's look at what will happen to a car if it does not have a suspension and the wheels are rigidly connected to the body. In this case, the impacts from the wheel will be completely transmitted to the body, slightly softened by the tires .

If you add an elastic spring to the suspension design, the shock to the body will be significantly softened. In this case, the body will continue to sway for a long time due to inertia. This makes driving difficult and dangerous.

With such a device, there is a high probability of “breakdown” - when the moment of compression of the suspension spring coincides with a shock from the road. There is a term among motorists: “Breaking through the suspension.” To eliminate this effect, a damping element is added to the circuit - shock absorber . It is designed to dampen body vibrations when the springs operate.

To Contents...

Advertising:

History of appearance

Attempts to make the movement of a vehicle softer and more comfortable were made in carriages. Initially, the wheel axles were rigidly attached to the body, and every unevenness in the road was transmitted to the passengers sitting inside. Only soft cushions on the seats could increase the level of comfort.

Dependent suspension with transverse spring arrangement

The first way to create an elastic “layer” between the wheels and the carriage body was the use of elliptical springs. Later, this solution was borrowed for the car. However, the spring had already become semi-elliptical and could be installed transversely. A car with such a suspension handled poorly even at low speed. Therefore, springs soon began to be installed longitudinally on each wheel.

The development of the automotive industry has also led to the evolution of the suspension. Currently, there are dozens of their varieties.

Suspension device

The car has front and rear suspension. We will talk about each of them separately, because they are structurally different from each other.

But each of them has mandatory elements - springs and shock absorbers.

On older cars and trucks, the rear suspension has leaf springs instead of springs. This is due to:

- Cheapness of its production;

- Applicability in dependent suspension;

- Maintainability and fewer chassis parts;

- Leaf springs are more durable than coil springs.

To Contents...

Rear suspension malfunctions and their diagnosis

These include:

- Knocking and metallic grinding. This is a sign of torn bushings and silent blocks.

- Loss of stability, the car becomes “sloppy” even on a flat road.

- Loss of elasticity of the rear springs. This is manifested by touching the locker wheel (fender liner) when the trunk is loaded on a rough road. If the springs sag, then even three people on the back seat will be at fault for the wheel “scratching” on the fender liner while driving over rough terrain.

- Loss of damping capacity of shock absorbers.

Rear suspension malfunctions can be diagnosed by the first signs in motion, which are voiced or on a lift. In the latter case, checking the chassis is no different from conventional suspension diagnostics.

To Contents...

Shock absorber

They come in three types:

- Oily;

- Gas;

- Combined - gas-oil.

The first type is more suitable for a quiet and comfortable ride. Therefore, they are installed in civilian vehicles. In modern cars there is a third type - combined gas-oil shock absorbers.

The second type is used in sports cars. It is designed to minimize body roll in fast corners. When a car takes a turn at high speed, its body rolls heavily. In this case, the outer wheel rises above the road, losing traction. To increase the speed and safety of cornering, gas shock absorbers are used. They are stiffer, less susceptible to inertia, and press the wheel to the asphalt faster.

How does he work

A car suspension shock absorber is a cylinder in which a piston is placed. They are not connected to each other and can move independently. This piston has holes. The cylinder is filled with a special liquid. Its upper end is attached to the car body. Bottom, to the suspension arm.

When a wheel hits a hole, it rises sharply. The piston in the cylinder contracts, but this does not happen sharply. It is hampered by oil, which does not have time to quickly flow through the small holes in the piston. As a result, the piston slows down its movement, the shock is damped and softened.

When the suspension is in compression mode, the reverse process occurs. The piston returns up, the oil flows back and slows down the rate of rise of the piston. Thus, there is no sudden jump in the car body when the suspension springs are released.

If the shock absorber is faulty, the car body will “gallop” like a wild horse when driving over any irregularities, even speed bumps.

More detailed information about shock absorbers can be found in the blog “Experienced Car Enthusiast”. It describes all types of shock absorbers, their advantages and disadvantages, and the operating principle of each of them. This is not an advertisement, I recommend it.

A shock absorber paired with a spring is called a spring strut . All modern front-wheel drive cars are equipped with it.

To Contents...

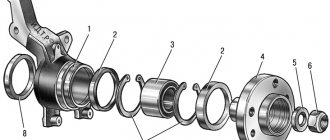

Elements of the front suspension of a car: diagram using the example of a VAZ 2107

- Wheel bearing.

- Hub cap.

- Adjusting nut.

- Washer.

- Pivot pin pin.

- Wheel hub.

- Stuffing box.

- Brake disk.

- Rounded fist.

- Upper suspension arm.

- Upper support bearing housing.

- Compression progress buffer.

- Upper suspension arm axis.

- Stabilizer bar mounting bracket.

- Stabilizer bar cushion.

- Stabilizer link.

- Lower arm axis.

- Stabilizer traction cushion.

- Suspension spring.

- Clip for fastening the shock absorber rod.

- Shock absorber.

- Lower support bearing housing.

- Lower suspension arm.

We recommend

“How to remove the front suspension arm of a car” Read more

Levers

Using suspension arms, the wheels are attached to the chassis. They transmit longitudinal and transverse forces to the power elements of the body. They control the movement of the wheel while the car is moving.

How many levers are there in the suspension?

Depending on the type of suspension, the number of levers can reach up to eight pieces in front . They may also be behind. This type is called “multi-lever”.

Inexpensive car models usually use MacPherson strut suspension - one lever per side with a spring strut. This type has become widespread in modern cars. This is due to the simplicity of design, comfort and low cost.

In classic VAZ cars, the front suspension has two levers on one side - upper and lower. This is a two-link suspension. Instead of a spring strut, a scheme with separate shock absorbers and springs is used; they are not assembled into a single structure.

In a dependent suspension there are no levers at all. With this scheme, opposite wheels of the same axle are connected by a beam. Therefore, any horizontal movement of one wheel affects the behavior of the other; they depend on each other.

To Contents...

Main types of independent suspension

In modern passenger cars, an independent suspension option is often used as a shock-absorbing system. This is due to the good controllability of the car (due to its low weight) and the absence of the need for total control over the trajectory of its movement (as, for example, in the case of a truck). Experts distinguish the following main types of independent suspension. (By the way, the photo will allow you to more clearly analyze their differences).

Double wishbone suspension

The structure of this type of suspension includes two levers attached to the body with silent blocks, and a coaxially located shock absorber and coil spring.

MacPherson strut suspension

This is a derivative (from the previous type) and a simplified version of the suspension, in which the upper arm was replaced by a shock absorber strut. Currently, MacPherson strut is the most common front suspension design for passenger cars.

Multi-link suspension

Another derivative, improved version of the suspension, in which two wishbones were “separated” as if artificially. In addition, the modern version of the suspension very often consists of trailing arms. By the way, multi-link suspension is the most commonly used rear suspension design for passenger cars today.

Torsion bar suspension

The design of this type of suspension is based on a special elastic part (torsion bar), which connects the lever and the body and works to twist. This type of design is actively used in organizing the front suspension of some SUVs.

Anti-roll bar

It reduces car body roll and improves its handling.

It is made in the form of the Russian letter “P”, clearly visible in the picture. It is a steel rod with large elastic deformation. In simple words, it is difficult to break it; it will always strive to take its original shape.

It has four attachment points. Its opposite edges are fixed to the suspension arms. The central part is attached to the body.

Read more

about the anti-roll bar. What is it, what is it for, what types are there and what does it consist of. This material covers the topic in full.

How does he work

When a roll appears, one part of the body rises, the other lowers - this is logical. The part of the stabilizer, which is attached to the power element of the body, rises and unscrews the stabilizer.

Due to its great elasticity, it lifts its opposite attachment point, and with it the body. In this way he tries to stabilize it in a transverse position relative to the road.

The second case when it works is when one wheel hits a hole or bump. Let's consider the option with a bump in the road.

In such a situation, one wheel moves upward relative to the body. In this case, the stabilizer rod experiences elastic deformation not at the point of attachment to the body, but to the suspension arm. Trying to take the original shape, with its second edge it lifts the opposite wheel and lowers the body. The car body is pressed to the ground, the center of gravity decreases and the car becomes more stable.

To Contents...

How it works

When hitting a bump, the front wheel of the car rises sharply. The inertia of the impact is transferred to the spring or spring strut, depending on what type of suspension is installed. The spring, compressing, absorbs part of the impact energy, and part of it is transferred to the body, from which it begins to rise.

To stop it, shock absorbers are activated. They do not allow him to rise sharply. The compression energy of the springs is extinguished. The same thing happens when the car body goes down sharply, the wheel drops and the springs relax. Damping occurs, shock absorbers reduce the amplitude of vehicle vibration.

The levers do not allow the wheel to move in the transverse and longitudinal direction. Using them, it is connected to the power elements of the body. On uneven surfaces, the wheel can only move in the vertical direction.

When cornering at high speed, the anti-roll bar comes into play. It minimizes car roll. Controllability and driving comfort are maintained. This front suspension part is archaic . In modern cars, its role is replaced by air suspension. The computer independently controls the angle of inclination of the car and adjusts the height of the shock absorbers.

Share:

Silent blocks

All moving suspension elements are attached to the body through rubber inserts - silent blocks. They dampen vibrations from one part to another. They consist of two metal bushings with a rubber element between them. Due to its plasticity, vibrations during operation of moving parts of the chassis are dampened and their mobility is ensured.

For example, if there were no silent block at the place where the lever is attached to the frame, the lever would rub against the frame. This connection increased the wear of the metal and produced a terrible squeak when the car moved. In addition, any impacts on the wheel from the road were transmitted to the body, you would hear knocking noises. This would quickly break the fastening unit.

Therefore, when independently diagnosing a car’s suspension, pay attention to the condition of the silent blocks. They should not have cracks or damage. There are times when the inner bushing peels off from the rubber and begins to dangle and knock.

To Contents...

Repair and is it possible to do it yourself?

Yes, you can repair the rear suspension yourself, but the price and effort depend on its design . If it has a lot of levers, then the cost will be high, and the effort expended will not compensate for the money saved at the service station.

It is easier to work with a semi-independent rear suspension. It is more compact, there is more space to get to the bolts and nuts of its elements. The small number of parts makes them easy to replace. In most cases, repairs come down to replacing shock absorbers or silent blocks with bushings. They fail more often. The springs may “sag,” but this happens less frequently.

The same applies to the dependent type of chassis. Rubber-metal elements and shock absorbers often require replacement. If the suspension is spring, then the springs “walk” for a very long time, even the break of one leaf will not affect the driving performance of the car. Therefore, they are often not even paid attention to during diagnosis.

Share:

Stabilizer links or links

They link the anti-roll bar to the shock absorber arms or struts. Not all cars have them, it all depends on the suspension design.

For example, the VAZ 2107 does not have them. The stabilizer is screwed to the arms through rubber bushings.

The rods can also have silent blocks or balls, like the steering ends, to soften shock from the road. Over time, the rubber becomes dull and breaks. The stand begins to knock on uneven surfaces. The silent block does not change separately from the rod. If it is damaged, the entire stabilizer link must be replaced.

To Contents...

The most reliable type for Russia and the CIS

Every motorist in Russia complains about the poor condition of the roads. There is an opinion that all types of suspensions quickly wear out their service life when driving on Russian roads.

But this largely depends on the driving style of the car enthusiast. To extend the life of your entire vehicle, remember to slow down for or avoid bumps and potholes.

Drivers argue on forums which type is better. But it all depends on personal preferences - some people like a hard suspension, while others like a soft one. If we talk about reliability, spring and torsion types are considered durable. Manufacturers listen to the opinions of car owners and produce combined types, for example, torsion-spring ones.

We recommend: Traction control

Let's sum it up

The suspension consists of:

- Shock absorbers – dampen body vibrations;

- Springs – soften the shock of the road;

- Shock absorber strut - two suspension elements mentioned above in one design;

- Anti-roll bar and its traction – stabilizes the car body in the transverse plane;

- Silent blocks or rubber bushings - make the suspension work quiet;

- Levers.

These are the main elements of a car suspension. Depending on the complexity of the chassis, their number and composition may vary.

To Contents...

Pendant type "De Dion"

This type, as well as the McPherson suspension, was named after the inventor. It was the Frenchman Albert De Dion. The purpose of this type of suspension is to minimize the load on the rear axle of the car by separating the final drive housing. If previously it was attached to the bridge beam itself, in this case the crankcase is held directly on the body.

This allows you to transmit torque through axle shafts mounted on CV joints, and make the suspension both independent and dependent.

But the De Dion type could not get rid of the main disadvantages of all dependent suspension options. For example, it is almost impossible to brake without “pecking”, and with a sharp start the car simply “squats” on the rear wheels.

Despite attempts to eliminate these shortcomings by installing additional elements (guides), the unbalanced behavior of the car remains the main problem.