Like any other car component or part, the timing belt performs certain functions. It is entrusted with a significant option, and due to the convincingness of its functioning, the operational duration and security of the automotive power plant as a whole is determined.

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Jumping or slipping of the timing belt is a fairly common phenomenon familiar to many motorists. The belt slips one tooth or several. We are talking about the teeth of the crankshaft or camshaft flywheel. It is clear that such a situation can lead to serious problems.

Signs of a jump

You should be able to distinguish the following signs, which, as a rule, indicate an obvious leap.

- If the car engine is unstable.

- The power unit often stalls.

- The engine loses power and pulls poorly.

- Problems with starting, almost one hundred percent.

- Power plant jamming.

The most popular scenario for a jump is this: the power plant continues to function, but interruptions are noticeable. This may indicate that the belt has not jumped completely, but by more than two teeth.

2163-13-13-011111-1

Head “16” – two bolts 1, head “13” – three bolts 2 and head “8” – bolt 3.

Remove the top timing belt cover.

Using an “18” socket with a ratchet, we turn the crankshaft clockwise by the bolt securing the auxiliary drive pulley and visually assess the condition of the belt and its tension.

If, using the force of the thumb and forefinger, it is possible to twist the drive branch of the belt (at a point located between the toothed pulleys of the camshaft and the coolant pump) by more than 60˚-70˚, then the belt is weakly tensioned and needs to be tightened.

To adjust the belt tension, remove the bottom cover. Using a 8" socket with a ratchet, unscrew the two screws securing the lower timing belt cover (for clarity, shown on a removed Renault Logan/Sandero engine).

Causes and consequences

As a rule, a timing belt jump does not immediately lead to extreme problems, but the engine begins to function intermittently or does not start. The explanation is simple: the gas protection phases are incorrect, the general cycle of fuel supply and cylinder cleaning is disrupted.

The reason for timing belt jumping is often due to the fact that a little oil or coolant drips onto the rubber material of the timing element. The pump is leaking, the cuff of any shaft is malfunctioning - in a word, anything related to oil or liquids can lead to this.

Note. So, on cars with front-wheel drive (our “eights”, “nines”), a leaking oil pressure regulator becomes a factor in the entry of lubricating fluid. It is located above the timing belt.

In general, on VAZs, belt jumping leads to the following sad consequences:

- On versions with 1.1-liter and 1.3-liter engines, the valves collide with the pistons, which inevitably leads to tragic accidental consequences.

- On 1.5-liter and 1.6-liter engines, the jump will also not bring anything pleasant.

It is unnecessary to say that the condition of the belt needs to be given periodic attention. Most often, you should not miss fresh and suspicious oil stains that form in the area of the protective cover of the rubber component of the timing belt. Even the smallest amount of lubricant gives evidence that there is a problem.

Now consider this situation: signs of a jump are not noticed, but the power plant behaves extremely unpredictably. For example, the engine practically does not develop speed, starts very poorly and often stalls. In this case, the cover of the entire mechanism will need to be opened, and then make sure that the marks are set correctly. We must remember that a shift of even 1 risk tooth can worsen the performance of the power unit, negatively affect startup, etc.

Note. This is especially true for diesel cars, the power plant of which is incredibly sensitive to improper belt installation.

After the motorist is convinced that the marks are set correctly, the installation of the belt itself begins.

- You have to be extremely careful here. It is important to try to install the timing element from an open place, giving it the previous tension and thus moving it further.

- All teeth of the rubber timing part must fit evenly into all recesses of the flywheel.

- If this cannot be done, you must move the camshaft or crankshaft with your own hands so that the tooth of the rubber part fits clearly into the recess.

- At the end, the coincidence of the marks is again checked, and the crankshaft is turned two turns.

How is wear determined?

Now let's talk directly about how to understand or how to find out that the timing chain assembly has worn out and needs to be replaced. Diagnosing and understanding the signs of wear and tear will save you from costly repairs.

Similar problems can happen on any machine, be it:

- Volkswagen Polo Sedan 1.6;

- Kia Sportage;

- Volkswagen Tiguan;

- Kia Rio;

- Skoda Yeti 1.2;

- Hyundai Solaris;

- Hyundai Elantra;

- Kia Spectra;

- Volkswagen Jetta, etc.

But if you look into the regulations for the maintenance and operation of some cars, you will, to your surprise, find that on many cars the plant does not provide for replacing the chain at all during the entire operating period.

That is, replacement is not carried out at a certain interval. But this is only possible under ideal operating conditions, which are almost impossible to achieve.

Experienced motorists advise changing the chain approximately every 100 thousand kilometers. This is a normal resource for a quality part.

But it’s best to start from the characteristic signs indicating wear. Namely:

- When starting the engine or idling, the engine runs rough and intermittent;

- There are strange sounds coming from the engine. Moreover, they are heard most clearly at idle with low oil pressure. The knock is characteristically metallic;

- During the diagnosis, a strong output of the chain tensioners is noted, as well as characteristic signs of wear on the sprocket teeth.

But that's not all you need to know.

How to correctly set marks during the process of replacing/installing a belt on a “nine”

The timing belt on cars with front-wheel drive is carried out using a toothed belt. Each successive replacement of the AvtoVAZ belt is recommended after 65,000 miles. In addition to replacing the element itself, it is also recommended to change the roller.

The algorithm for replacing the timing belt is as follows:

- First of all, a new belt and roller are purchased (it is advisable that both elements are recommended by the car manufacturer);

- The car is placed on a level surface;

- The battery is de-energized (due to the exception of a short circuit during the work process);

- The car is secured with special anti-rollback stops;

- The protective cover is removed from the timing system;

- The power unit is set according to the marks.

It is important to be able to set the marks so that in the front part of the engine the mark on the camshaft wheel coincides with the upper boss on the belt cover.

As for the second mark, it is connected to the clutch cover hatch. It is located under the distributor. This hatch is protected by a special rubber plug, which must be pulled out. And if the marks are set correctly, you should check the mark on the hatch: if in the triangle of the hatch you can see a mark that coincides with the end of the flywheel, then everything is correct.

The belt replacement procedure continues:

- The right wheel of the VAZ is dismantled (before this, a reliable support must be placed under the car body, for example, an empty 20-liter container for fuel on the edge);

- The protective type belly is disassembled to gain access to the shaft wheel and belt, respectively;

- The tension of the generator belt is weakened by moving it in the direction of the BC;

- The belt is dismantled;

- The bolt securing the pulley is unscrewed using special tools (mount, head, etc.).

Advice. During the work, in order to securely fix the flywheel from spinning, it is recommended to insert a strong metal rod (screwdriver, pry bar) between its teeth.

- After this, you can completely unscrew the wheel bolt and then remove the crankshaft pulley.

Note. The crankshaft pulley (wheel) cannot be completely removed. He is left hanging.

- The tension roller clamps are loosened.

- The timing belt is removed along with the roller.

- A new roller is installed in place, and a new timing belt is installed.

2163-

We stop the crankshaft from turning by inserting the blade of a power slotted screwdriver between the upper wall of the window in the clutch housing and the head of the housing mounting bolt.

Be careful when performing this operation so as not to damage the elastic plates connecting the housing to the clutch pressure plate with a screwdriver.

Using a 18mm socket, unscrew the crankshaft pulley mounting bolt and remove the screwdriver from the clutch housing window.

Remove the crankshaft pulley.

If it is difficult to remove the pulley, pry it evenly from different sides with a mounting blade.

To further rotate the crankshaft, it is necessary to screw the pulley bolt into place. To ensure that the bolt is completely screwed into the threaded hole of the crankshaft nose, we install a spacer (bushing or set of washers) between the bolt and the shaft nose.

Before removing the belt, in order not to disturb the valve timing, it is necessary to set the crankshaft and camshaft to the TDC (top dead center) position of the compression stroke of the 1st cylinder.

Using the “E-14” head, we unscrew the technological plug from the threaded hole in the cylinder block, located on the front side of the block, in the area of the 1st cylinder - under the emergency oil pressure indicator sensor (shown for clarity on a removed engine).

As an installation pin, you can use the bolt of the upper fastening of the gearbox to the cylinder block (for clarity, shown on the removed power unit).

We screw two nuts onto the bolt and lock them so that the length of the threaded part is 75 mm.

The manufactured device - screw the installation pin into the threaded hole of the cylinder block.

Remove the timing belt.

After loosening the nut securing the tension roller, turn the roller clockwise, reducing the tension of the timing belt.

Attention! After removing the belt, do not turn the crankshaft and camshaft to avoid the valves sticking into the pistons.

When replacing the belt, the tension roller should also be replaced.

Unscrew the nut securing the tension roller and remove it.

We install the new tension roller and timing belt in the reverse order.

Source

The main nuances of the functioning of the timing belt in cars

It is extremely important to understand that the rubber timing element is responsible for transmitting the timing gear in the motor shafts. The latter, in turn, are responsible for the maintenance of the air-fuel mixture in the cylinders of the power unit.

If the timing belt jumps or breaks, the entire timing belt system begins to function differently. All this is manifested by shifts and malfunctions of the most important component of the car - its engine. It was written in detail above that in these cases the power of the power plant necessarily decreases, fuel consumption increases and starting deteriorates.

In addition, slippage or rupture of the timing component can cause failure of the piston-valve group in the engine. When the belt breaks, the valves open towards the piston, which leads to internal engine problems.

Monitoring the condition of the timing belt is a guarantee of preventing severe consequences for the power plant. But it is important to be able to control not only the appearance of the belt, but also the degree of tension. On their own, which is quite natural, it will be extremely difficult for a person with non-professional skills to diagnose the correct installation of the belt. In order not to make a mistake, you need to pay attention to the service life of the belt and the condition of the parts accompanying the operation of the element. In particular, ensuring the degree of tension and uninterrupted operation.

The period for replacing the most important timing part may vary. It depends on the specific car manufacturer. In addition, it is necessary to take into account such an indicator as the originality of the part. It is clear that “left” companies can easily produce defective belts or belts with a reduced service life.

It is also important to understand that on the modern market you quite often find parts of the universal type rather than the standard one. What does it mean? It's simple - universal parts, belts in this case, are not made for a specific car. They are not a priori characterized by good quality, and although they are cheaper than the original ones, they are not recommended for purchase.

You can distinguish an original belt from a universal one (there are several effective ways). If the part is universal, then to determine the service life of the belt and its replacement, you will have to take this into account. In other words, if the manufacturer indicated that the belt can last 70 thousand kilometers on his car, this does not apply to the universal one. This one will definitely last less.

As mentioned above, the service life of the belt on front-wheel drive VAZs is approximately 60-70 thousand kilometers. If the car was purchased secondhand, you should not trust its owner who claims that the belt is new, there will be no problems with it.

When choosing a new timing belt for your car, it is recommended to pay great attention to the material. If there are no marks left on the rubber after several folds in and out, most likely the material is fine.

But on the contrary, if even the slightest microcracks are noticed, it is better not to buy such a belt right away.

It is also recommended to check the belt model number with the number specified in the operating manual for a specific vehicle. The numbers are unlikely to match; it is a great success if such a belt can be found. But you can check belts in another way: by comparing the length, width and thickness of the old factory belt and the new analogue.

The belt must also be checked around its entire circumference. If protruding threads are noticeable on the ribs, the cord will be visible, it is better to immediately abandon this option.

If you do not have the appropriate skills and ability to work with your own hands, it is better to entrust replacing the timing belt to professionals. Without a doubt, a seemingly simple operation at first glance can fray your nerves and take a lot of effort. And most importantly, an illiterate replacement can lead to even bigger problems.

Note. The main difficulty in replacing a belt is setting the marks.

Of course, in a big city it will be easier to find a quality car service among the many options. In rural areas, you have to rely on the honesty of service station workers or carry out this event yourself. The most important thing is that it does not matter which method was chosen, what is more important is to save time and money, getting the highest quality result.

A little theory

Chain drives transmit rotational force from the crankshaft to the camshaft, which is located in the cylinder head of overhead valve engines.

Chains are divided into 2 categories. They can be toothed or roller. Roller mechanisms, unlike gear ones, are not so widespread. Therefore, it is gear systems that are most often found on cars with a timing belt, which include a chain drive.

Gear units are distinguished by their high smoothness, they are quite reliable, and produce an insignificant level of noise during the operation of the internal combustion engine. In terms of their characteristics, the use of toothed chains brings them much closer to belt drives. One can argue endlessly about which one is better.

But we won’t dwell on this today.

The chain is tensioned due to the operation of hydraulic tensioners, for which motor oil is used as a working fluid. The lubricant is supplied through the engine lubrication system.

Depending on the number of camshafts, that is, camshafts, the number of tensioners also differs. On cars there are from 1 to 3 units.

The service life of the chain directly depends on what the element is made of, how high quality it is and the degree of effectiveness of the heat treatment performed. Similar requirements are placed on timing sprockets, since they constantly operate together with the chain.

Do not forget about the influence on the condition of the unit of the engine lubrication system, the quality of the oil itself and timely replacement of the fluid.

In practice, when the part is made of high-quality materials, and the correct tension was carried out as part of the service, plus lubricant was introduced on time, then replacing the chain may be necessary at the same time as replacing the motor itself.

That is, you understand that a stretched chain cannot function for a long time and effectively. If you want to extend the life of this unit, initially take a high-quality chain, adjust its tension correctly and lubricate the drive generously with high-quality oil.

Signs and symptoms

There are six main signs that the timing belt has jumped.

- The car engine is unstable.

- The engine constantly stalls.

- Noticeable loss of engine power and thrust.

- The engine starts with problems or does not start at all.

- The power plant is stuck.

- The sound of the engine becomes louder - a metallic knock appears.

Most often, it happens that the product jumps one tooth, and because of this, the engine continues to operate, but increases fuel consumption, and there are also interruptions in operation and starting.

If you suspect that several teeth have jumped, you should not restart the engine. In the worst case, this can cause the valves to bend.

Why is it necessary to set the labels correctly?

For the correct operation of the gas distribution mechanism of a car, it is necessary that the closing and opening of the valves occur in a strictly defined sequence. The slightest inaccuracy in the operation of the camshaft and crankshaft leads to the fact that the gas exchange process in the cylinders is disrupted, and the engine stops working in the correct mode.

A timing belt is a rubber part that during operation can wear out, crack, tear, etc. Therefore, it is necessary to replace the element in a timely manner.

When installing a new one, you should set the labels correctly. This is necessary to ensure that the engine operates correctly from the first seconds of startup. If installed incorrectly, serious problems can occur, including engine failure.

Causes

The timing belt is an important element of the car, so it needs to be serviced promptly. The reasons that lead to its jump are as follows:

Contact of oil or cooling liquid on the belt surface

As soon as traces of technical fluid appear on the product, the belt should be changed immediately. Otherwise, this can lead to slipping through the teeth, sliding off the pulley, and even breaking.

It is a serious mistake when drivers simply clean the dirty surface and continue to use this product.

Practice shows that if liquid gets on the belt, it is completely absorbed into the rubber. It loses its properties and begins to stretch.

Late replacement

Most timing belt manufacturers recommend changing their products approximately every 60 thousand kilometers. However, this figure may vary up or down, depending on the quality of the product.

Improper use

It happens that a product may jump due to errors during its operation. A common example is a weakened roller or tensioner. When the belt tension weakens, there is a possibility of slipping from the pulley grooves. In the opposite situation, if when installing the belt, it is overtightened, this will lead to its breakage.

Slippage can also occur when one of the pulleys has strong play. Therefore, it is very important to monitor the tension level of all parts of the mechanism.

The labels are set incorrectly

Sometimes the jump is not visible outwardly, but the engine does not start well and immediately stalls. This can happen if the marks were knocked down or incorrectly set initially. A shift of even one tooth can cause problems with the motor. If the engine is diesel, it will not start even if there is an error of one tooth.

It is necessary to replace the timing belt in safe places using special tools.

This photo shows that the intake is offset by one tooth clockwise; this is one of the most common mistakes when replacing a belt. To prevent this from happening, you can use special pulley clamps when replacing the timing belt.

External damage

Over time, various cracks and depressions may appear on the surface of the consumable, and the threads of the product may begin to peel off. With heavy loads on the belt, even the smallest defects will develop quite quickly. Therefore, they cannot be eliminated on your own. All you can do is replace it as soon as possible.

Low quality spare parts

There are very cheap “non-original” belts on sale. But don't be fooled by their price. Often the resource of such a product is only enough for 20 thousand kilometers. This is followed by either stretching or breaking.

Difficult operating conditions

Unlike a chain, a belt is very sensitive to high and low temperatures, high humidity and other weather conditions. They affect premature wear of the product. Therefore, more frequent replacement may be required.

How to choose a new set of spare parts

Like other automobile spare parts, timing chains are counterfeited by handicraft and Chinese manufacturers, after which they go on sale. Cunning businessmen are constantly coming up with new ways to deceive customers, for example, placing their low-quality products in original packaging from well-known brands originally from Western Europe. To avoid running into a fake spare part when purchasing a part, follow these recommendations:

The chain is checked for deflection as follows: take it by one end and hold it flat. The second end should sag no more than 10 mm. If possible, check the hardness of the metal by carefully filing it with a file. The steel in high-quality products is hardened, and therefore is characterized by increased hardness and does not lend itself to filing.

Chain, gears, shoes and tensioner - complete replacement kit

Advice. The main technical characteristics of the chain are its size and number of links, and you need to select the part based on them. If you are in doubt, then do not buy a new spare part without removing the old one with which you can compare it.

Currently reading: Fuses and relays Renault Logan - New Logan

If you are updating a chain drive with a significant mileage of the car (150-200 thousand km), then you will have to change all the accompanying elements - gears, tensioner and damper. When the chain has stretched after a run of 50-100 thousand km, it is not necessary to change the gears, but the tensioner must be checked for functionality. Also, don't forget to buy consumables - cover gaskets, O-rings and heat-resistant sealant.

Consequences

The consequences of the timing belt jumping several teeth can be different - from replacing the timing belt itself to repairing the car’s gas distribution mechanism.

The amount of damage depends on whether the engine has recesses for valves in the pistons or not.

A jump can occur while the valves are being lowered to inject fuel or release gases. The pistons are still moving and can hit the valves hard. This will lead to bending of the latter. This situation is similar to a broken timing belt. You can read more about which engines this happens on in this article.

To avoid this situation, it is recommended to do a timely inspection and, if necessary, change the consumable.

Repair cost

The average price for replacing a belt and roller in car services ranges from one to three thousand rubles. The price range is due to the fact that replacing parts on foreign cars costs approximately 2–3 times more than on domestic cars.

If it turns out that you also need to change the engine water cooling pump and the crankshaft oil seal, then the price will increase by another 1 - 1.5 thousand rubles.

Although there is a huge selection of products on the market at different price levels, you should only choose brands recommended by the manufacturer or their high-quality analogues. Using cheap parts can lead to serious damage and expensive repairs.

For example, if the valves are bent as a result of a belt slipping, then almost the entire cylinder head will have to be replaced. Even if the repair is carried out by yourself, the cost of replacing valves, pump, belt, filling oil and antifreeze, and other parts will be at least 10,000 rubles.

Causes of belt and timing chain jumping

The main reasons for timing belt skipping are:

- natural wear of the belt during operation;

- abrasion of teeth as a result of misalignment of the rollers;

- increased resistance to movement in the event of a malfunction in the gas distribution system;

- foreign objects getting into the belt drive;

- pulley wear;

- stretching of a low-quality belt;

- overheating of the power unit;

- Tensioner malfunction.

Jumping of chain links (links) is less likely, but the consequences of such a malfunction are more serious. Causes of chain jumping:

- stretching during operation;

- chain damper malfunction;

- natural chain wear;

- temporary jamming of the gas distribution mechanism;

- overheating of the power unit;

- foreign objects entering the area of chain movement.

Symptoms of malfunction

The main signs that the belt or chain has slipped:

- change in throttle response, power, engine torque;

- increase in the toxicity of exhaust gases, their shade;

- problems when starting the engine;

- a “check engine” error message appears on the dashboard;

- the occurrence of extraneous noise of a non-metallic (for belt drive) and mechanical nature (for both chain and belt drives).

If such signs appear, you should stop driving (start the engine), have the engine diagnosed, or contact a mechanic.

Changes in engine performance after jumping

Typically, timing belt or chain jumping occurs as a result of the simultaneous action of several factors, for example, stretching, increased load during engine starting or driving. In this case, skipping can occur through the gears (pulleys) of both the crankshaft and the camshaft pulley. After this, the ignition shifts towards late.

The amount of this displacement in angular units depends on the number of timing belt teeth or chain links. A shift of the timing belt by one tooth corresponds to a change in the ignition angle by an amount equal to the ratio of 360 angular degrees/number of teeth. For example, if the number of teeth is 100, then the offset will be about 3.6 degrees.

A delay in the engine ignition angle by this amount often does not exceed the operating parameters of the engine.

When displaced by one tooth (link), the engine usually works. The following changes are observed:

- increased fuel consumption;

- difficulty starting the engine;

- increased toxicity of exhaust gases;

- reduction in engine response.

In the case when the belt has slipped by more than a tooth, the change in the ignition angle is more than 5 angular degrees. This is a critical value. In modern cars, the control unit usually turns off the engine to prevent serious mechanical damage, especially in engines where the pistons “meet” the valves in such a situation. Experienced drivers, when choosing or purchasing a car, are specifically interested in whether pistons and valves are found in a given model of engine installed in the car.

When a belt (chain) jumps over two or more teeth (links), the following are observed:

- misfires;

- uneven engine operation, the engine naturally “sausages”;

- engine start failure;

- extraneous sounds when the power unit is operating.

Operating a car in such a situation is extremely dangerous.

Measures to prevent serious consequences of a malfunction

If possible symptoms of belt or chain jumping occur, computer diagnostics should be performed. The malfunction can be determined by the ignition angle being too large. In static mode, diagnostics may not show an engine error, since the electronic components remain operational.

It is necessary to measure parameters in dynamic mode. At the same time, it is dangerous, especially if more than one tooth has slipped through. When an engine is running in which the timing belt has slipped, mechanical damage to individual components is likely.

You can determine the malfunction visually. This requires access to the marks and belt drive. Older gasoline cars use a strobe light as a control device.

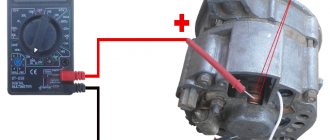

Correct tension

The second most popular mistake is an incorrectly tensioned timing belt. Most often it is over-tightened, which will most likely lead to its rapid breakage. The consequences of a cliff are already familiar to you. It is no less dangerous to under-tighten - it can simply jump off at high speeds. To make sure the tension is correct, you need to try turning the long part of the belt 90 degrees. The effort should be excessive or too loose.