During operation of a modern car, defects in engine operation may appear: failures, short-term lack of response of the gas pedal, etc. At the same time, the “Check Engine” icon lights up on the instrument cluster panel, which translated from English sounds like “check the engine.” The car owner goes for diagnostics, where a computer connected to the car detects error P0504. The brake pedal position sensor (frog) is responsible for this failure in the system. Next, we will tell you where the sensor is installed, how to check, repair and replace it.

Causes and symptoms of malfunction

Most often, error P0504 worries owners of Lada: Grant, Priora, Kalina and other VAZ cars with an ECU. Often a defect appears on GAZ cars, for example, GAZelle NEXT. But owners of foreign cars are less likely to contact the service to eliminate error p0504 and replace the sensor (frog). Most likely, the quality of foreign spare parts is much better. What symptoms indicate that the brake pedal sensor is faulty:

- The engine begins to work unnaturally: it feels like it either stalls while driving, then immediately starts.

- The traction disappears at around 40 km/h, but after applying the gas, the former agility is restored. Then the defect appears again.

- The brake lights do not light up, or on the contrary they work constantly.

The cause of incorrect operation of the “frog” can be: mechanical damage, oxidation of contacts or wire breakage. Sometimes a failure occurs due to the burnout of both brake light bulbs. Due to the listed defects, an error appears in the system under code p0504. It can be removed, but it will appear again soon.

Checking, repairing and adjusting the brake light switch on cars of different brands

Inside the four-pin brake switch there are two pairs of contacts, the state of which depends on the position of the rod: when fully recessed and fully extended, one pair is always closed - the resistance is close to zero, the other is open - the resistance is several kOhms or more. If for some reason the contact group does not work properly, error P0504 occurs.

Checking the brake light switch

Checking the brake light switch comes down to testing the terminals of a pair of contacts in the normal position - with the rod extended and when it is retracted, simulating pressing the brake pedal. The normal state of the contacts of a working switch for some popular models is shown in the table below.

| Model | Contact status | |

| The rod is recessed | The rod is extended | |

| Toyota Rav4 | 3–4 closed 1–2 open | 3–4 open 1–2 closed |

| Lada (Priora, Kalina and Granta, 4x4) Datsun (on-DO, mi-DO) Gazelle Next, Business | 1–4 open 2–3 closed | 1–4 closed 2–3 open |

| Lada (Largus, Vesta, XRAY)Renault (Logan, Duster) | 3–4 open 1–2 closed | 3–4 closed 1–2 open |

If the test shows that the contacts close and open properly, error P0504 may be due to either incorrect adjustment of the brake light switch (not required on all models) or faulty wiring and other reasons listed above. If the multimeter readings do not match the parameters of a working switch, it must be replaced or repaired.

Repair of brake pedal limit switch

Diagnostics and repair of brake light switch: video

The two main reasons for the failure of the brake light limit switch are oxidized or burnt contacts and a broken or weakened spring. An indirect sign of the second problem is a small stroke of the rod compared to a good one or its free motion.

For repairs, the limit switch must be dismantled. To do this, first of all, disconnect the connector by releasing the latch. In some cars, for example, Lada Kalina and Granta, this requires unscrewing the fastening nut, in others, for example, Lada Largus and Vesta, it is enough to turn its body counterclockwise 90 degrees and remove it from the hole.

Next, you should disassemble the sensor housing, which is secured with latches, and then inspect the condition of the spring and contacts. Oxidized or burnt contacts can be cleaned with sandpaper and treated with a degreaser. The broken spring needs to be replaced with a new one of the same length (for the switch 1118-3720010 installed on Lada cars, a spring with a diameter and height of 6–8 mm is suitable), and you can try to stretch the weakened one, but this will only help for a while.

Repairing the brake pedal end switch is more of a temporary measure in case it was not possible to quickly find and purchase a replacement part. Usually, soon the restored switch begins to work incorrectly again. Therefore, if possible, it is better to install a new switch immediately.

Replacing and adjusting the limit switch: video

How to change

The sensor is located slightly above the brake pedal lever. To find it, you need to look under the torpedo. On Lada Priora, Grant and Kalina, a 19 mm open-end wrench will be required for dismantling. The replacement process looks like this:

- Remove the negative terminal from the battery

- Disconnect the 2 plugs from the sensor.

- Loosen the locknut with a 19 mm wrench (remember its approximate location).

- Unscrew the sensor counterclockwise.

- Install a new one and secure it with the adjusting nut.

- Connect the battery.

- Turn on the diagnostic equipment and clear the old error P0504.

The old sensor is quite repairable. In most cases, the cause of the malfunction is a broken spring. If you disassemble the body and install a new spring, the “frog” will work again.

Car owner's comment: On my Lada Grant, a spring broke in the sensor and began to close the contacts of the limit switches. When I left the car overnight, the ignition did not seem to turn off, which is why the battery ran out completely several times. I bought a new battery, but the problem did not go away until I made diagnostics and replaced the sensor. At the same time, the Check Engine did not light up.

Diagnostic procedure when error P0504 appears

To carry out some diagnostic operations when error P0504 appears, a multimeter or test lamp . If you do not have an assistant to check the operation of the limit switch and the condition of the brake lamps, you can drive up to the wall so that the brake lights are visible in the mirrors.

- Check the brake lights by pressing and releasing the brake pedal several times. The lamps should light up when the brake pedal is depressed 2–3 cm and go out when released. Flashing or flickering indicates poor contact, while intermittent failure indicates incorrect adjustment or wear of the limit switch.

- If the lamps do not illuminate when the pedal is depressed, check that the brake light circuit fuse has not blown.

- Inspect the limit switch connector, make sure it is fixed and there is no external damage.

- Check the brake light limit switch and its adjustment. The verification procedure is discussed in detail in the next section.

- Check the power supply to the sensor using a multimeter or test lamp. One of the terminals must be supplied with 12 V power at all times. Use the vehicle's electrical diagram to determine the appropriate terminal. If there is no power, check the corresponding circuit in sequence.

- If there is power and the sensor is working, check the receipt of signals when the pedal is pressed and released to the corresponding contacts of the computer using a multimeter. Their presence indicates a controller malfunction.

If error P0504 appears after replacing brake light bulbs with LED ones, first of all try installing back the standard halogen ones. Most likely this is the problem.

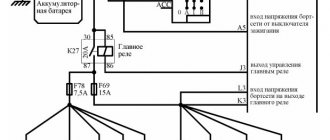

End switch connection diagram, click to enlarge

Which one to buy

Experts and service workshop specialists recommend purchasing an original brake sensor. It is of better quality and lasts longer.

Table 1. Price of brake pedal position sensor

| Manufacturer | Code | Cost, rub. |

| AvtoVAZ | 11183720010 | 170 |

| Avar | 2113720 | 180 |

| AMY | 11183720010 | 95 |

Source: autopiter.ru

Before changing the “frog”, you can “ring” it with a tester to make sure the part is working.

Symptoms of malfunction

The main driver symptom of P0504 is the MIL (Malfunction Indicator Light) illumination. It is also called Check engine or simply “check light”.

They can also appear as:

- The brake lights will either remain on continuously or not illuminate when the pedal is pressed.

- It will be difficult or impossible to move.

- The car may stall while moving if you press the brakes.

- With this problem, cruise control cannot be activated.

Lada Granta error codes: decoding

The following errors may not be relevant for some vehicle modifications. If the decoding or codes do not match, it is recommended to consult the machine’s service manual.

Lada Granta: on-board computer errors responsible for the muffler and exhaust cleaning system (0000)

- 030-032 – first oxygen sensor, open circuit or short circuit of lines;

- 036-038 – similar for the second sensor.

Trunk units intended for air supply (0100)

- 101-103 – Mass air flow sensor incorrect element readings or open circuit;

- 107-108 – incorrect pressure in the intake manifold;

- 112/113 – incorrect reading of the air temperature on the intake manifold;

- 115-118 – DTOZH incorrect readings, breakdown or break of the corresponding line;

- 122/123 – TPS unit breakdown or large discrepancy between actual and measured data.

- 130-135 – oxygen sensor No. 1, there is a network problem or a break in the lines.

- 136-141 – similar for oxygen sensor No. 2;

- 171/172 – excessively lean or enriched fuel mixture.

VAZ Granta errors indicating a malfunction in the gasoline supply system (0200)

- 200 – the wiring on the injector control module is broken, the unit itself may also be damaged;

- 201-204 – break in the supply line of injectors for No. 1-4, respectively;

- 217 – the motor has overheated, the second value is a breakdown of the internal combustion engine temperature sensor;

- 222/223 – TPS excess or critical decrease in signal level from the unit;

- 261/264/267/270 – injector control lines for numbers 1-4, respectively, a short circuit to body weight was detected;

- 262/265/268/271 – similar, only with a short circuit to the on-board wiring.

Decoding Grant errors indicating incorrect settings or malfunction of the ignition system (0300)

- 300 – there are ignition misfires in a random or stable order;

- 301-304 – similar for 1-4 cylinders, respectively;

- 325 – the fuel mixture detonation sensor has failed, also indicating an open circuit;

- 326-328 – is responsible for the above element, indicates a problem with the sensor itself;

- 335-338 – DPKV is faulty or the wiring is damaged;

- 340/342/343 – DPRV software failure or physical damage to wiring elements;

- 346 – the phase distribution sensor is broken or there is a violation of the wire insulation;

- 351-354 – malfunction of the ignition coil for each cylinder in series;

- 363 - error 0363 Granta indicates that there is a misfire in the catalytic converter protection system.

Lada Granta computer errors that are not directly related to the ECM (0400)

- 422 - a common Lada Granta engine error indicates that the catalyst is clogged or its efficiency has critically decreased, may be accompanied by a drop in engine power, can be eliminated by replacing the module;

- 441 – the adsorber purge valve does not work correctly or is jammed;

- 443-445 – damage to the control lines of the above element;

- 458/459 – short circuit of the canister purge valve lines to ground or 12 volts;

- 480/481 – respectively for the first and second central fan control relays, open circuit or short circuit;

- 485 – the head fan is faulty or the module control has failed.

Grant error codes 8 or 16 valves, revealing software failures or mechanical damage to auxiliary units (0500)

- 500-503 – malfunction of the speedometer sensor, possible damage or short circuit;

- 504 - error p0504 Lada Granta indicates that the automatic brake pedal has failed;

- 505-507 – the engine idle speed regulator is faulty or clogged;

- 522/523 - error 0522 grant, just like p0523 tells the driver that the oil pressure in the crankcase compartment of the engine is outside normal limits;

- 560 – the battery may be discharged or the terminal has fallen off;

- 562/563 – exceeding or critically reducing the permissible voltage threshold in the on-board network.

On-board computer errors Grants indicating serious malfunctions in the engine control system (0600)

- 601/603 – malfunctions inside the ROM/RAM module, respectively, a complete replacement of the unit is required;

- 604 – incorrect calculation of the ROM controller amount;

- 606 – the ADC module is damaged and needs to be replaced;

- 607 – incorrect signal from the detonation channel controller;

- 615-617 – the starter relay is damaged or there are problems in the wiring;

- 627-629 – the fuel pump relay is turned off, or there are problems in the lines;

- 642/643 – incorrect operation of the bus supplying the sensors;

- 645-647 – air conditioner clutch relay failure or incorrect operation of the module;

- 660-662 – injection line length regulators are faulty or there is a short circuit in the on-board network;

- 691-694 – in fan relays No. 1 and 2 there is a short circuit with a contact to the on-board network, the car body, respectively.

Lada Granta errors, decoding for chassis

There is only one error No. P0830, which is responsible for the clutch lever switch. The appearance of the index indicates an open circuit or damaged wiring.

Additional control circuits for auxiliary equipment not related to the power plant (1000)

- 102 – the oxygen sensor heater in the exhaust system has failed;

- 115 – is responsible for the above module and indicates damage to the wiring;

- 123/124 – Additive problem with mixture correction for the air component, enrichment or depletion;

- 127/128 – similar value for the Multiplicative component;

- 135/141 – the wiring of the oxygen sensor No. 1/2, installed before or after the catalyst, is damaged;

- 136/137 – Additive problem with gasoline mixture correction;

- 171/172 – CO2 potentiometer is faulty;

- 301-304 misfire of the combustible mixture for cylinders 1-4;

- 335 – throttle malfunction, the drive may be jammed;

- 336 – throttle sensor mismatch;

- 384 – a similar value, indicates an incorrect reaction of the internal combustion engine to the position of the damper;

- 385 – critical excess load on the power plant;

- 386 – incorrect response of the fuel mixture detonation detection channel;

- 387 – the injection system is malfunctioning, the fuel supply time is incorrect;

- 388 – the position of the gas pedal and throttle valve do not correspond to each other;

- 389 – crankshaft rotation speed does not correspond to the damper position;

- 390 – a breakdown was detected in the device, but there was no response to it;

- 410/425/426 – canister purge valve, damage to the wiring with a short to ground or on-board network was detected;

- 500-502/541 – the main power supply lines to the fuel pump are damaged, there may be a short circuit;

- 509/513/514 – the lines of the XX regulator are damaged or the integrity of the winding is damaged;

- 545 – incorrect throttle position (mechanical damage);

- 558 – the return spring of the throttle drive is broken;

- 559 – is responsible for a similar module and indicates that it is incorrectly configured in a quiet position;

- 570/600 – there is no response from the immobilizer, the wiring may be damaged;

- 602 – error 1602 Granta appears when the contact on the battery is lost or there is a breakdown in the on-board network (voltage suddenly drops);

- 603 – the EEPROM unit is broken or there is no response from the module;

- 606 – the rough road sensor has failed or is producing incorrect data;

- 612 – it is not possible to reset Grant errors correctly;

- 616/617 – the rough road sensor has failed;

- 620/621/622 – failure of the ROM/RAM/EEPROM module;

- 640 – incorrect reading of the ECM memory;

- 689 – error memory is not read correctly or is damaged.

Auxiliary valves Grant 8 valve (2000)

- 100-103 – the throttle valve drive is broken or there is damage to the wiring;

- 105 – monitoring system is faulty;

- 122-123/127-128 – pedal position sensor A/B low or high value;

- 187-188 – incorrect adjustment of the fuel mixture at idle, lean or excessively rich;

- 135/138 – resynchronization of throttle/gas pedal position sensors;

- 176/178 – incorrect adaptation of the remote control drive;

- 270-271 – oxygen sensor No. 2 in the exhaust system does not respond to enrichment or leanness of the mixture;

- 301/304/307/310 – the ignition coil is closed to 12V, respectively, for all combustion chambers in series;

- 500/501 – generator excitation starts incorrectly.

Automatic transmission system errors (P0000)

- 717 – turbine speed is displayed incorrectly;

- 705-706 – the machine selector does not send or produces several signals at the same time;

- 720 – the tail shaft speed meter has failed;

- 973/974 – ON-OFF solenoid is shorted to the on-board circuit or body;

- 962-963 – pressure control solenoid is damaged;

- 731-734 – incorrect position of the gear ratio in gears 1-4, respectively;

- 711-713 – incorrect operation of the lubricant temperature sensor in the automatic transmission crankcase;

- 863 – establishing a bus connection;

- 701 – power supply to the head controller is broken.

Errors in the correct transmission of information from built-in modules (U0000)

- 001 – CAN bus failure;

- 009 – short circuit in the CAN circuit;

- 100 – the u0100 indicator shows that the Lada Granta BC error occurred at the junction of the ECU and internal combustion engine modules;

- 155 – cruise control module is broken or damaged;

- 305 – incompatibility of the program with the above device.

Adjusting the brake pedal sensor in Grant

The sensor is attached to the bracket with 2 nuts screwed onto a plastic housing. Thus, the upper nut fixes the position of the sensor according to the pedal. The nominal space between the pedal and the heel of the sensor is 2-3 mm when the pedal is released.

Meanwhile, if there is no gap, the sensor is able to give a signal at the slightest touch of the pedal, which actually leads to the P0504 code lighting up, as well as the activation of the Check Engine warning light. In turn, after a basic adjustment of the gap using 2 keys, you need to start the car and look for errors. The value of P0504 will not be reset instantly, however, if the problem is still in the adjustment, therefore, the error code will disappear after 10-15 minutes with the engine turned on without load. If such measures do not produce results, it is worth looking for a reason elsewhere.

System diagnostic methods

There are two ways to identify errors in Grant and its analogues. Both methods have clear advantages and disadvantages.

Self-diagnosis of Lada Granta

The principle of the method is to use standard systems installed on the machine. The procedure does not require connecting additional equipment or studying complex instructions. To perform the check, just follow a simple sequence of actions:

- simultaneously hold down the daily mileage reset button located on the dashboard and turn the key in the lock cylinder to position 2;

- if everything is done correctly, the machine will go into self-diagnosis mode, all the arrows will make a full revolution and the indicators will light up;

- Use the button on the steering column wiper position switch to select the required option;

- Information about the firmware version appears first in the list. By clicking on the positions further, you can see the required error combination.

Note!

If, when switching to self-diagnosis, any indicators do not light up, their circuits must be checked first.

The disadvantage of this method is the low accuracy of the indicators. The display displays compressed information about the breakdown, which can only indicate the direction from which to start looking for the problem.

In the most popular versions of ECU firmware, network errors are noted as:

- The specified Lada Granta error code indicates the presence of a critical power surge in the on-board network. In 90% of cases it indicates a short circuit or damage to electrical appliances.

- You need to check the float sensor in the gas tank and its circuit. There may be a short circuit or damage to the sensor.

- The motor has overheated or the antifreeze temperature sensor has broken.

- Failure in the power supply circuit of the ambient temperature meter.

- Additionally, it indicates overheating of the power plant or incorrect operation of the thermostat. Indirectly affects more complex faults such as cylinder head gasket breakdown.

- The pressure in the fuel rail has dropped critically. You will need to check the pumps and the condition of the injectors. A popular error in the first generation Grant engine.

- If the brakes have failed or the pads have worn out badly, diagnostics of the modules is necessary.

- Severe voltage drop in the on-board network. There may be problems with the battery.

If “E” is displayed on the device, this indicates that the firmware is not working correctly.

Computer diagnostics

The next method involves connecting special equipment to the machine. The bottom line is this:

- there is a special connector under the dashboard;

- a laptop with the program is connected to the terminal via a special connector;

- device pairing begins;

- After establishing a stable connection and reading information from the BC, Lada Granta error codes will be displayed in the software window.

If everything is done correctly, special codes are displayed on the monitor. Moreover, each part of the code speaks of its own circuit.

Beginning (letter)

- P – the integrity of the electrical wiring is compromised or the sensors are damaged;

- C – probably the breakdown is in the suspension units, chassis;

- B – problems with the internal equipment of the car;

- U – resynchronization of several interconnected circuits is observed.

The following are standard notations:

- 0 – failure in the OBD 2 module;

- 1/2 – enterprise code (what this is is known only to the car manufacturer);

- 3 – malfunction of spare wiring parts.

The next part indicates the serial number of the on-board circuit section where the breakdown is located:

- 0 – exhaust cleaning device;

- 1 – motor air supply system;

- 2 – fuel lines, pumps and injectors;

- 4 – control devices;

- 5 – malfunctions or disruption in the operation of additional systems;

- 7/8 – transmission, chassis.

Next comes another two-digit number - the last part of the index points directly to the system where there is a problem.

About alternative sensor options

Since domestic “devices” for the Lada Granta car are not able to prevent an unpleasant situation, it is possible to use other devices that act as analogues. Such a component could be a brake light switch from Volkswagen, or more precisely: “FACET 7.1126”. This switch is slightly more expensive than the “native” one (560 rubles) and has the following features:

- four contacts;

- threaded leg with a similar diameter of 12 mm.

To successfully install the indicated analogue, you will need to acquire an adapter for the terminals.

Broken brake pedal sensor

One of the possible factors for error P0504 to appear in a car is a breakdown or defect of the pedal end switch itself. It is worth noting that the quality of AvtoVAZ consumables has always suffered, and this is the case now. Even Russian sensors are mostly equipped with fairly cheap springs and contacts made in China. The result is that the springs fail and the contacts usually burn out after 5-8 thousand miles.

Due to the spring, the regulator rod does not return to its original position, therefore, the system receives a notification that the brake pedal is pressed. In this situation, the ECU reads that both the brake and gas pedals are pressed together. Therefore, the throttle valve is forced to close.

In many cases, replacing the pedal adjuster on the Grant solves the problem associated with fault 0504. However, it happens that a working sensor refuses to work after installation, and then it is necessary to consider other possible causes.

On which cars is this problem most common?

The problem with code P0504 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Chery (Chery Fora)

- Chevrolet (Chevrolet Captiva, Epica)

- Citroen (Citroen C4)

- Datsun (Datsun on-DO)

- Fiat (Fiat Doblo, Ducato)

- Ford (Ford Kuga, Transit, Focus, Fusion)

- Hyundai (Hyundai Grand Starex, Santa Fe, Solaris, Starex, i30)

- Kia (Kia Rio, Sid, Sorento, Sportage)

- Land Rover (Land Rover Range Rover, Freelander)

- Lexus (Lexus gs300)

- Lifan (Lifan x60)

- Nissan (Nissan Pathfinder)

- Opel

- Peugeot (Peugeot 308, Boxer)

- Toyota (Toyota Avensis, Auris, Corolla, Land Cruiser, Prado, Rav4)

- Volvo

- VAZ 2113, 2114, 2115

- Gazelle Business, Next

- Lada Vesta, Granta, Kalina, Largus, Niva, Priora

- UAZ Patriot, Hunter

Reasons for the error

A P0504 code may mean that one or more of the following problems have occurred:

- Short circuit in the brake light switch signal circuit.

- There is a malfunction in the brake light switch, the failure of which is due to wear.

- There is a problem with the fuses, sometimes they fail due to moisture getting into the circuit or the brake light burning out.

- If the wiring harness, or more specifically the connectors, are loose or disconnected, it will cause a correlation problem between the switch and the ECU.

- And of course, the ECU itself could fail.