The manual transmission is simple, reliable and has a long service life. At the same time, the manual transmission clutch is considered to be a “consumable” with a rather limited service life. Moreover, if you actively load the car, make mistakes when working with the clutch and operate the car in difficult conditions, individual clutch elements may fail by 60-80 thousand km. mileage on a new car.

As a rule, quite often owners of cars with a manual transmission encounter a malfunction when the clutch pedal fails. The reasons for such a breakdown may be different, since a manual transmission is a unit consisting of a large number of parts and mechanisms. Next, we will look at why the clutch pedal disappeared, as well as what to do if the clutch fails.

Types of clutch drive

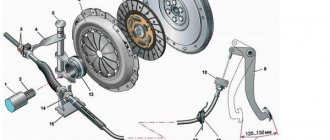

The clutch is not one part of the car, it consists of several parts. Among them: drive/driven discs, release bearing, release clutch, fork, drive, clutch basket. Due to the large number of components, the unit fails faster, but there is also a dependence on its type:

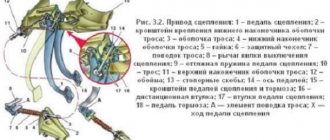

- Cable - is mechanical, the pedal and fork are connected by a cable, which is activated by pressing the foot. The fork presses on the bearing, which opens the discs.

- Hydraulic – bearing pressure is controlled by fluid. The pedal is connected to a hydraulic circuit; when pressed, pressure is created in it. It affects the hydraulics of the release bearing, which opens the discs.

The cable mechanism is simpler in design, but it also breaks more often due to its component parts. There the cable may fray or the bracket may break.

Attention! Even a slight breakdown of the cable assembly will lead to deterioration in pressing. If you do not pay attention to this, the problem will worsen and develop into a serious malfunction.

How to check if the clutch is slipping?

There are three methods for checking whether the clutch is slipping on a manual transmission. Its operation is well controlled by the driver. But there are no effective methods for a robot or a variator. Their automation can partially mask the symptoms of the problem, so the techniques that are relevant to mechanics do not always work. How to determine that the clutch is slipping on different types of gearboxes is described in more detail below.

Clutch slips on manual transmission: how to determine?

The main reason why the clutch slips when the friction linings wear out is a decrease in the pressing force between the discs due to a decrease in their thickness. There are 3 main ways to check whether the manual transmission clutch is slipping:

- Start from high gear . To check whether the clutch is slipping on a manual transmission, you need to engage 4th or 5th gear and try to move off. If the engine stalls, everything is fine. If, even at relatively low (up to 3000 rpm) revolutions, the car starts to move, the disc slipping is obvious.

- Handbrake test . For this test, you need to lock the car's wheels with the parking brake and try to start in first gear. If the engine stalls or (on front-wheel drive) the wheel slips, then everything is fine. If the wheels are stationary, but the engine continues to work in gear, it means the clutch has begun to slip.

- Hard acceleration test . To do this check, you need to engage the highest (4th, 5th, 6th) gear while driving and give the gas sharply. If the car picks up speed synchronously with the increase in revolutions on the tachometer, there are no problems. If the revolutions fluctuate, they sharply increase without acceleration (the so-called variator effect) - obviously, the clutch or disc is slipping.

Before checking whether the new clutch is slipping or not, you need to make sure that the unit is assembled and configured correctly. Sometimes, if the reason is only insufficient running-in of new spare parts to each other, the symptoms of slipping themselves go away after a few hundred kilometers of driving.

How to diagnose whether the clutch is slipping on a robot?

To understand whether the “robot” clutch is slipping or not, you can put the box in manual mode, engage the highest gear and give the gas to the floor, but this does not always help. The same applies to starting with the handbrake.

The most effective way to determine clutch wear on a robotic gearbox is to connect to the ECU using an OBD-2 scanner and read the errors using a diagnostic application. Transmission-related faults are indicated by codes P07xx to P09xx, and excessive clutch slip is indicated by code P0811

Deciphering error P0811

Modern manual transmissions, such as DSG for VAG, Speedshift for Mercedes, DCT for BMW and other similar designs, are equipped with a double clutch. The latest generations use a self-supplying wet clutch, which does not require adjustment, as it automatically adjusts the gaps as it wears out. Older and simpler “robots” (such as the 2182 gearbox on a VAZ) have a conventional dry single-plate clutch.

Determining that a self-actuating clutch is slipping is most difficult, since the automatic system smoothes out the manifestations. Excessive clearance is eliminated by a self-feeding mechanism. Therefore, in this case, problems with adjustment can be eliminated. But if the clutch of a DSG 7 or similar manual transmission slips, you need to immediately check the oil in it, and only then do tests.

The clutch slips on an automatic transmission: what to do?

In classic torque converter automatic transmissions, the torque converter (“donut”) is responsible for transmitting torque from the engine to the box, so the question of what to do if the clutch slips is not worth it in this case. If it seems to you that the clutch is slipping on the machine, it is usually due to a malfunction of other components:

- Automatic transmission clutches slip . The clutches are a mini version of a wet multi-plate clutch, separate for each gear. It is when they wear out that it seems that the clutch on the automatic transmission has begun to slip, because the symptoms are similar: the speed fluctuates, the car accelerates sluggishly, and jerks occur in movement.

- The torque converter fails . A worn-out “donut”, which plays the role of the main clutch, can also slip. If the car sluggishly picks up speed, the engine begins to constantly maintain higher speeds (although the load has not increased), fuel consumption has increased - the torque converter is worn out.

If you experience symptoms of a slipping clutch on an automatic transmission, you need to diagnose the box. Errors (codes from P07xx to P09xx) read via OBD-2 will help you find out the general cause, and only troubleshooting at a car service will show the specific degree of the malfunction.

The clutch on the variator is slipping: how to determine and what to do?

If the clutch on a variator slips, it is difficult to identify the defect and the cause without diagnostics. You need to read the errors and, if you have the appropriate codes, go to the service center for detailed troubleshooting and repair. This feature is related to the operating principle of CVT gearboxes.

Diagnostics of the variator using the CVTz50 program

Continuously variable transmissions can be equipped with either a clutch or a torque converter. Multitronic gearboxes on Audi and Multimatic on Hondas are equipped with a wet clutch, Hyper on Nissans has an electromagnetic clutch, and ZF Transamtic CVTs are equipped with an automatic centrifugal clutch. These mechanisms are capable of slipping, just like with a manual one, but the variator masks the symptoms as much as possible.

Signs of a bad clutch

People who regularly drive a car immediately realize that something is wrong with it and the pedal has become tighter. In addition, problems can be determined by other factors:

- when you press the pedal, sharp grinding sounds appear that are uncharacteristic of normal operation of the system;

- the lever is pressed jerkily, there is no smooth movement;

- the free play of the pedal has to be adjusted frequently;

- when the pressure is released, the clutch engages jerkily;

- The clutch is slipping - this can be indicated by the smell of burning clutches and an increase in fuel consumption.

At the same time, for some cars a hard pedal is the norm, this applies to old domestic models - “classics”. But if tightness occurs in relatively new cars, both Russian-made and foreign, this is a reason to carry out diagnostics.

Driving without a clutch: what you need to know

Taking into account the fact that most breakdowns that are associated with the clutch or clutch pedal (for example, the clutch pedal has failed) can take the driver by surprise, and it is often impossible to fix problems on the spot, the only option is to drive to the service station under your own power.

If it is not possible to call a tow truck, and it is also not possible to tow the faulty car, you can drive to the repair site without a working clutch pedal. Next, we will look at the simplest method that even a driver who has not previously had such experience can use.

We also recommend reading the article about what a clutch cylinder is. From this article you will learn about the structure of the clutch cylinder, its malfunctions, signs of problems and repairs.

At the same time, we draw your attention once again to the fact that the methods described below should be used only in cases of extreme necessity, since the risk of damaging the box or getting into an accident increases significantly.

- So, first you need to turn off the car engine. If you lose traction on a hill, you should push the car onto a level road. Then it is recommended to think over the route in advance so that, if possible, you travel along a route with a minimum number of traffic lights, pedestrian crossings, not congested with traffic, so that you do not have to stop often, etc.;

- Next, with the engine turned off, you should engage first gear, and you also need to turn on the emergency lights, after which the engine can be started (note that the car will jerk forward sharply immediately after turning the key in the ignition switch to the “start” position);

As soon as the engine catches, lightly and carefully press the gas pedal so that the internal combustion engine does not stall. If the first attempt to start driving is unsuccessful, stop the car, wait about 5 minutes for the starter to cool down, then try again to start in first gear and drive off. - When the attempt to start moving is successful, in first gear at a low speed and engine speed no higher than average, you can drive to the repair site under your own power. When driving in first gear, you should be prepared for high fuel consumption (we recommend taking care of a sufficient amount of fuel in the tank in advance);

Let us also add that beginners in such a situation should be prepared for the fact that the engine will stall when it comes to a complete stop or greatly reduces the speed without turning off first gear. This means that in this case you will have to start again on the first one.

Experienced drivers often master the technique of driving without a clutch, that is, they know how to shift gears without a clutch both up and down, start immediately with second gear engaged, shift without a clutch from first speed to neutral, etc.

This is possible if the driver feels when engaging a gear without a clutch with minimal effort can, without much risk, seriously damage the gearbox and transmission parts, taking into account engine speed and speed. However, if you try to do this without experience and skills, there is a high risk of damaging the gearbox, significantly reducing the life of the unit, or completely destroying the gearbox and other transmission elements.

Why has the clutch pedal become stiff?

Since cable systems are the most prone to failure, let's first look at why the pedal might become stiff under these conditions:

- increased rigidity of the diaphragm spring petals - this leads to gradual wear of the part and its deformation;

- jamming of the release bearing, coupled with increased force to rotate the fork, subjects the clutch cable to increased loads;

- rupture of the cable wires - they adhere to the metal braid, increasing the resistance of the tight pedal.

The first reason is more common, and this is due to the arrangement of the petals of the basket. The central part, which has a release bearing, becomes higher than the plane of the spring; additional pressure is required to overcome this elevation.

To make the diaphragm spring more durable, manufacturers artificially increase the rigidity of the petals. This happens especially often with Chinese counterfeits of well-known companies. Despite expectations, the tight pedal will not change with the installation of such an element.

Clutch not fully engaged or not engaged

Slipping usually appears when you sharply press the gas, when the speed increases, but no noticeable acceleration is observed. In this case, a characteristic burning smell may appear. If slippage is detected, which indicates that the clutch is not fully engaged, the reason should be sought in the following:

- the surface of the flywheel, pressure plate (pressure plate) or linings is oily;

- increased production (wear) or burnout of linings;

- insufficient rigidity of the diaphragm spring;

- swelling of the cuffs of the main cylinder (main cylinder), which leads to a slow return of the piston.

First wipe oily surfaces with gasoline or white alcohol, and then dry them thoroughly until completely dry. You should also find out the cause of the oil leak. This may be a violation of the engine or gearbox seals.

If the friction linings have become unusable, replace the HP with a new analog assembly.

Insufficient rigidity of the diaphragm spring does not provide sufficient force for hard contact, which is why slippage occurs. Simply replace the “basket” (pressure plate) with a new set along with the housing.

To restore the performance of the master cylinder, you can replace the cuffs or purchase a new spare part assembly.

The clutch does not disengage when the flywheel sticks to the disc. This sometimes happens when the car is parked for a long time. You need to break the disc by starting to move without pressing the pedal. After accelerating, depress the pedal and brake sharply.

How to fix the problem

Knowing that the system is faulty, you need to take measures to repair it. First you need to determine the breakdown, because it is likely that only one part has broken.

Additionally!

It is better to change the “clutch” completely; although this will cost more, the entire system will work effectively.

Without wanting to spend money, you can solve minor problems yourself:

- lubricating or replacing the release clutch bearing;

- replacing fluid in the hydraulic drive with subsequent pumping;

- changing the driven disc pads or springs if the elements are worn out, weakened or deformed;

- replacing the basket and all parts with a new assembly recommended by the vehicle manufacturer.

Even if these steps are taken, the tightness may still remain. Then you need to try to replace the cable, clean its jacket from dirt and corrosion, and also lubricate it with machine oil. Hydraulic systems can also have cylinder failures, which is also quite serious.

Broken clutch cable

In any case, the most accurate diagnostics can be carried out in services where the nodes are disassembled and their suitability for use is determined. There, the car will be put in order and the stiffness of the lever, which interferes with comfortable driving, will be corrected.

Knocks and extraneous noises

Rattling, tapping and other noises during switching on may be due to:

- Sufficiently large settlement, defects or damage to the damper springs (vibration damping mechanism);

- wear (depletion) of openings for damper springs;

- deterioration or damage, deformation of the linings;

- loosening the fastening rivets securing the linings;

- deformation or damage to the HP surface.

All of the above problems are eliminated when replacing the VD with a new analogue. In some cases, extraneous noise may be caused by a lack of lubrication, or damage due to wear, or significant deformation of the release bearing housing. Accordingly, to eliminate the malfunction, you will have to replace the bearing.

Pedal squeaking can occur in two cases:

- lack of lubrication on plastic bushings;

- high wear (wear) of bushings.

For lubrication, CV joints-4 or Litol-24 are usually used. When replacing damaged elements with new analogues, they must also be treated with lubricant. It very rarely happens that the fork can bend strongly as a result of deformation and then the clutch pedal simply cannot be pressed. In such cases, it is recommended to simply replace the damaged part.

Basic mistakes when repairing clutches

The most effective repairs are possible in a service station, where technicians will perform diagnostics, repair broken components and configure the system to factory settings. Self-repair, like tuning, is undesirable, because it leads to a number of mistakes:

- Pouring brake fluid or WD-40 into the cable jacket will not soften the movement, but will serve as destructive factors for the protective sheath.

- Replacing the entire basket except the fork - the new basket will create too much resistance, causing the tired fork to break. The tight lever will simply stop working.

- Using cheap analogue parts - wanting to reduce the cost of clutch repairs, drivers often choose Chinese alternatives.

Interesting! In fact, counterfeits either do not have an effect or break down quickly enough, which requires new injections of money.

If the clutch pedal on a car becomes difficult to press, this means problems with the corresponding system. It is necessary to check the clutch basket, cables and forks, or cuffs, if we are talking about the hydraulic version, and replace all problematic components.

To do this, it is best to contact professional technicians; they will carry out diagnostics and repairs. If you try to fix it yourself, you may not take into account the nuances and provoke even bigger breakdowns that require significant expenses.

Clutch not disengaging

When disengaging is difficult or the clutch is slipping, the causes of the malfunction can most often be due to the following points:

- insufficient (too short) pedal travel;

- presence of air;

- weak fastening of the linings;

- wear or scoring on the surfaces of the HP and flywheel;

- erasing overlays;

- distortion or damage to the ND;

- hub sticking;

- VP jamming;

- Damage or wear out of the diaphragm spring.

First of all, if the clutch does not disengage, you should adjust the drive or install a new fork instead of the damaged part.

If air gets into the system, bleed it and check the connections. Inspect the system; if any deformation or damage is detected, replace them with new analogues.

Noise when pressing the pedal

If the noise appears when the clutch is disengaged, then we can safely say that the damper springs on the clutch disc are worn out. Often the elements connecting the casing to the pressure plate also fail. Sometimes the noise is caused by the clutch fork.

The friction linings on the disk wear out on average within 100-150 thousand kilometers. However, this depends on the quality of the kit and the make and model of the car. As for replacement, they are guided by mileage. The clutch disc cannot be repaired and must be replaced entirely.

Do-it-yourself replacement and adjustment of the VAZ 2106 clutch

1 - clutch housing, 2 - working cylinder rod, 3 - fork, 4 - adjusting nut, 5 - lock nut, 6 - return spring, 7 - friction linings, 8 - driven clutch disc, 9 - steel casing, 10 - drive disc ( basket).

Today, the article will talk about procedures such as replacing and adjusting the 2106 clutch with your own hands. As we like to repeat, everything can be done without the help of car service specialists; there are no difficulties in repairing VAZ cars and there cannot be any. Often, drivers try to solve all the problems with the car on their own, because the cost of maintenance is absurdly high.

Even despite the fact that the VAZ 2106 has not been produced for ten years. And we will try to help as much as possible with the repair. If you have any questions, leave comments, share your experience, and describe unusual situations. After all, the topic is quite interesting and rich.

What are the reasons for poor gear shifting?

Difficulty shifting gears may occur due to improper operation of the gearbox and operation of the vehicle on bad roads. Sooner or later, transmission problems occur in supported vehicles.

If you have difficulty when trying to change another gear, you cannot shift, or it happens with great effort, then there is clearly a malfunction. Most often, car owners turn to a car service when they have difficulty shifting into first gear or reverse. Quite a common problem on VAZ and Ford Focus cars.

Let's look at the disadvantages that lead to difficult gear shifting:

- Faulty clutch. In this situation, broadcasts will be activated poorly or incompletely. A common occurrence in VAZ cars, in which the fur cord comes off from the clutch holder.

- Malfunctions in the transmission of the gear shift mechanism. Violation of traction leads to strong engagement of 1st gear and reverse.

- Jet thrust is faulty.

- The plastic parts in the gearbox control unit are worn out.

- The curtain is placed incorrectly. The element is heavy; incorrect adjustment leads to malfunctions.

- Bearing wear. This is a rare experience for everyone, especially if you have a mechanic. In such a situation, it is usually difficult to engage first gear.

- The box shaft is faulty. By itself, it is not subjected to heavy loads that could lead to wear. Factory defects are the reason for replacing the entire unit.

- Faulty clutches. Often found among owners of cars with automatic transmission. The malfunction is eliminated by replacing the clutch.

- Faulty synchronizers: the problem is more common among gearbox faults. They are made of brass, and the metal itself is quite soft. During operation, it is cleaned and wear occurs. Cracking is usually accompanied by a grinding noise when changing speeds.

Some faults can be diagnosed and repaired yourself, but a bearing or shaft fault cannot be determined. For these purposes, special tools and equipment are required, as well as experience. In this situation, if you have problems shifting gears, it is better to contact a service station.

Ankara specialists will carry out diagnostics, identify faults and qualitatively repair your box. Incorrect gear shifting will not bother you for a long time, we guarantee it!

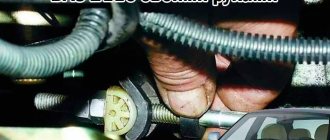

The device of the "VAZ" clutch cable

If you open the hood, you will notice that the cable sheath is held by bushing 5. Tip 2 is inserted into the slot of the clutch fork. Leash 1, made of plastic, can be screwed or twisted from the tip. This is how the “effective length” is adjusted.

Cable device with automatic adjustment

Automation can also adjust the length of the cable. But the limits of “auto-tuning” are small.

The ability to change the cable length “manually” was provided by the factory. And that means we must take advantage of this opportunity.

Problems with automatic shifting

An automatic transmission is very demanding in maintaining the oil level and its condition, unlike a manual transmission. Too high or low oil level can cause machine malfunction. Also, due to a lack or excess of oil, it may be difficult to engage the gears.

The most common automatic transmission malfunctions:

- Feed rates are not included.

- There is no reverse, there is only 1st and 2nd forward.

- All speeds are included except reverse.

- Gears are not included at all.

The oil level in the automatic transmission is checked with a dipstick. If the oil level is low, top up.

About automatic transmission

There is no clutch as such in an automatic transmission. Here this role is assigned to the torque converter. It includes two turbines through which oil circulates under pressure. Because of this, the clutch on an automatic transmission is often called wet. That is, torque is transmitted through oil. But can the clutch burn out on an automatic? The signs of a malfunction in this case are different. So, the box will go into emergency mode, and the gears will kick into gear. All this indicates wear of the friction packs.

But jerking can also occur for other reasons (for example, due to solenoids or a clogged valve body). Therefore, in any case, the automatic transmission needs to be diagnosed in detail.

Second adjustment method

If you don't have a caliper on hand, you can use an alternative method.

It begins similarly to the previous case. Again, you need to pull the tip forward as much as possible. When he rests, release him and see how tightly the leash adheres to the fork. If it’s not tight enough, it means you need to wrap it around the rod. Then we return to the salon and press the clutch pedal three times. Once you've done this, go back and look under the hood again. Pay attention to whether the leash is pressed against the metal? A prerequisite is the minimum movement of the fork (it is better that there is none at all). The fork movement is allowed no more than 2 millimeters. Car enthusiasts can use any of the above methods. If any points remain unclear to you, we recommend watching the video instructions on our website. Despite the presence of an automatic adjustment system, you will still need to carry out this procedure. Even if the cable serves you reliably and does not break, you will still need to periodically look under the hood.

Experienced car enthusiasts recommend not waiting for problems with the clutch and performing this work at least once every 10,000 kilometers. This way you will protect yourself from problems with this system. During adjustment, be sure to evaluate the condition of the cable. If it has become thin and cracked somewhere, it won’t last long. In this case, you can immediately replace it.

Design and principle of operation of the unit

The clutch system is a key component of any car equipped with a manual transmission. The principle of operation of the mechanism is to disconnect and connect the engine crankshaft with the transmission. This is how smooth acceleration or the same smooth deceleration of the car is carried out. In addition, the operating principle of a manual gearbox involves turning off the torque when shifting.

The clutch includes several main components. This is the drive disk or basket. The part may also be called a pressure plate. The mechanism contains a release bearing, a clutch disc or driven disc, and a flywheel. There is a clutch fork.

Why are gears shifting poorly?

The second reason is a malfunction of the gearbox shift mechanism. And finally, third: excessive wear of the gearbox synchronizers. There are also several clutch malfunctions that cause manual transmission gears to shift poorly—for those who don’t know what double-clutching is.

To shift to a higher gear: press the clutch, engage neutral, release and press the clutch again, engage the gear. Backlash in the so-called “helicopter” is one of the reasons for unclear gear shifting. If the gears shift poorly when the car is stationary with the engine turned off, the fault may only be in the gear shift mechanism.

Find the problem or check if it is adjusted correctly.

Don't even think about the clutch and synchromesh gearbox. If your car has an automatic transmission. It doesn't hurt to know how your automatic transmission might work: Speaking of transmission failure, an automatic transmission is much more complex than a manual transmission, and the chances of it being repaired in your garage are slim.

But despite this, you still need to know something about her, at least so as not to harm her with an incorrect operation. The oil level in the distributor is checked with a dipstick or inspection hole closed with a plug.

Select a flat horizontal area to measure. I put the car on the handbrake. If the level is too low, oil can be added through the tube into which the dipstick is inserted.

Do not forget that the automatic transmission is afraid of dirt, so add only new and clean oil. Clean the dipstick with a clean cloth that does not fall off the wires.

- The car does not move forward and moving backward is normal. Possible reasons: wear of the forward clutch, a defect in the piston of this clutch, breakage of the clutch rings themselves, jamming of the valve body valves.

- There is no reverse speed, there is only forward 1 and 2. Possible reasons: wear of the reverse clutch clutches, a malfunction of the piston of this clutch, damage to the groove connection in the drum body, another defect of this drum.

- There is no going back, everything works forward. Causes: wear of the brake band, malfunction of the piston of this band or breakage of its rod, defects in the brake unit.

- When the mode is activated, there is no forward or reverse movement, there is a press to shift, but the car remains motionless. Causes: torque converter malfunction, lack of oil, clogged filter.

- Only reverse, 1st and 2nd gears are engaged. Causes: stuck valve in the valve body, low oil level, general wear of the pistons and the gear clutch does not start.

Why is it difficult to engage manual transmission gears?

Problems with manual gear shifting most often occur for the following reasons:

- The most common problem is clutch failure. The reverse speed in such a situation comes with a bang. This is due to the fact that the gear is superimposed on the tooth. Reverse is the only gear in the box that does not have synchronizers. For this reason, the clutch malfunction is so clearly visible on it.

- The second reason is a malfunction of the gear selection mechanism. This fault occurs when the vehicle is stationary and an attempt is made to engage the gear.

- Thirdly, severe wear of the gearbox synchronizers. Mostly, breakdowns occur with those that are used most often. These are first, second and third gears. Severe wear on the synchronizers only appears when changing gears while driving.

To prevent possible transmission malfunctions, carry out regular maintenance, change the oil on time, and in case of minor malfunctions, rush to diagnostics. This will save you time and money in the future.

What you can’t do with a manual transmission, watch the video:

What to do if it is difficult to engage reverse gear?

If you have trouble shifting into reverse, do one of the following:

- When you feel the transmission is not all the way in, release the clutch slightly and the transmission will slide in all the way.

- Pull out the clutch completely and only after a few seconds engage reverse.

- Press the clutch, put it in neutral and release the clutch. Then tighten and engage reverse.

- I am doing reverse through someone else. For example, first engage 4th and then shift to reverse.

How to properly engage reverse gear on a Hyundai Solaris, watch the video:

It's hard to engage first gear

Many drivers faced with this situation try to press the gear selector hard to get into 1st gear. But this is fundamentally wrong and should not be done.

In this situation, it is necessary to use the rebasing method. Its essence is as follows:

- In second gear, depress the clutch and shift into neutral, then release the clutch.

- Next, you need to press the accelerator pedal, increasing the speed to 2.5 thousand.

- The next step is to engage the clutch again, pressing the pedal all the way, and put the transmission in first gear. If you still have problems with this, then you need to repeat, because you pressed too little on the gas, there were too few laps.

- If all actions are performed correctly, the first speed will turn on without difficulty and sounds.

However, this method should not be used constantly when it is difficult to engage 1st gear. This method is temporary, so you can get to the gas station without any problems. In any case, the box will need to be repaired.

What to do when it’s difficult to get into the car in 1st gear, watch the video from the driving instructor:

The procedure for replacing synchronizers requires experience, relevant knowledge and special tools, so it is best to contact a professional. Automotive technicians will quickly and efficiently perform the replacement, and also advise on further operation and maintenance of the box.