01/10/2022 17,559 Electrical package

Author: Ivan Baranov

Electric windows (EP) are one of the vehicle elements that contribute to more comfortable driving. Like any other electrical circuit component, EDs tend to break down periodically. What to do if a car window regulator does not work and for what reasons these components break - read below.

[Hide]

Inoperative window regulators: causes and methods of troubleshooting

Electric windows (EP) are one of the vehicle elements that contribute to more comfortable driving. Like any other electrical circuit component, EDs tend to break down periodically. What to do if a car window regulator does not work and for what reasons these components break - read below.

Components of the window lift system

What should I do if the right one does not work or both electronic devices fail? The window regulators may break, leaving them unable to lower or raise the windows. It is possible that the electronic device is jamming or sticking, but before you repair and disassemble the system yourself, you need to understand its structure. The unit itself works by controlling electric motors installed in the vehicle doors and designed to raise and lower the windows.

The system itself includes the following components:

- electric motors;

- switches located in the doors;

- wiring;

- glass

General structure of the ED system

The principle of operation of a car window lifter

The ability to switch between raising and lowering the windows is made possible by equipping the electric motor with a reverse power system. Structurally, the motion vector is changed either using a relay or directly through a switch. Window lifters of the latest generations are more complex, which is caused by the need to increase the safety of their use and increase comfort. Functions of modern mechanisms for automatically raising/lowering windows:

- uniform movement in one of the directions to the end point;

- discrete movement (for example, an inch) in one direction or another;

- slow mechanism locking;

- return movement (used to have time to remove part of the body from the window opening).

The window regulator control unit is the brains of the device, which includes, in addition to the control microcircuit, an electric motor relay, switches and electrical wiring connecting the control unit to the door lock and the top hatch cover. If you activate the window lift mode with one touch or command, it will move in the specified direction. As soon as the switch is moved to the reverse position, the motor will stop. The same will happen if the power window ECU receives a corresponding signal from the door circuit board.

Principle of operation

Why do the power windows not work or only the right window does not go up? To understand exactly why the malfunction occurred, it is advisable to familiarize yourself with the operating principle of the unit. Typically, such a system has a trapezoidal design, which allows the windows to be raised and lowered by pressing switches. The buttons themselves can be located in all car door cards or located only in the driver’s door. It is also worth noting that an electric motor is mounted in each door, which operates in two directions.

In addition, each system is equipped with a special relay, the purpose of which is to control the voltage supplied to the electric motors of the structure. Depending on the vehicle, some car models may be equipped with automatic switches that are installed separately for each electric motor. The use of such structural elements makes it possible to ensure normal operation of the entire system if the window regulator is poor on only one door.

This is interesting: Weak spark on a scooter

Causes of malfunction

So, we gradually approached the issue of malfunctions. What if the window regulator cannot go down or up? Before you remove the window regulator, disassemble and repair it in your car, let's look at the main reasons. If the rear or front windows do not work, the reason may be either electrical or mechanical.

Detailed design of the EP system

Electrical faults

First of all, if the window regulator has stopped working, it is necessary to diagnose the safety element responsible for the functionality of the system. If you realize that the power window is not working due to a fuse, then you just need to replace it. But if the fuse is working, then you will need to measure the voltage at the electric motor terminals. This task can be accomplished using a regular 12-volt lamp or using a tester.

If you find that the driver's window or any other door does not work due to voltage, then you need to further check:

- wiring;

- relay;

- system control unit.

Sometimes a car owner thinks that the window regulator is broken if, after opening the window, it automatically begins to close until the key is turned in the ignition. As a rule, in this case the problem lies in the contacts, which should be cleaned. Much less often, but it still happens that repair of electric windows includes replacing or repairing a button.

Mechanical defects of the mechanism

If, after measuring the voltage, you realize that there is current in the system, but it does not go down or the window regulator does not work at all, most likely the problem is mechanical. As a rule, in this case, something is interfering with the device, so you will have to disassemble the door and look for the reason. Much less often, the reason lies in a failed electric motor (the author of the video is the channel In Sandro’s Garage).

How to raise the glass if the electric seal is broken - there are several options:

- Purchase a window regulator repair kit and repair the device, after which you can fully use the system.

- Try to grab the glass on both sides with your hands and pull it up. If the glass falls after being lifted, you will have to disassemble the door and place a support of the appropriate size under it.

- If you can’t lift the glass with your hands, you can take a fishing hook on a fishing line and lower it into the door card. You need to try to pry the glass and lift it.

Mechanical problem

If voltage is supplied to the window lift motor, but the window does not move, it means that something is interfering with it, or the power window motor is faulty.

Why doesn't the window lift motor work? One of the reasons is retraction or sticking of the drive motor brushes. To check this, turn on the ignition and press the power window button while simultaneously knocking on the car door several times. The brushes will come off and the ESP will start working. How to repair the window regulator in this case? You should remove the motor casing and pull out the rotor. Clean off deposits where the brushes touch with fine sandpaper.

The power window does not work, you can hear a growling sound, but the glass does not stand still, or the window regulator is stuck. Perhaps the plastic gear in the gearbox has worn out, as a result it sticks tightly in the extreme closed position, or slips and therefore cracks.

Is there a loud noise when the window goes up/down? Most likely the bearing in the window regulator motor is to blame.

The power windows have stopped working, but there is noise when you press the button, and replacing the motor did not help? The power window cable may have frayed due to overtightening.

The window has opened, but the window regulator does not raise it back, but can it be raised and lowered by hand? The window lift cable broke or simply flew off the guides.

Another malfunction of the window regulator, when the glass seems to jerk, trying to close. Most likely the problem is that the glass is skewed, or something got on the rail or roller.

The power windows don't work well. Try to lubricate the window lift mechanism, as well as the glass guides. If this helps only temporarily, then try adjusting the glass and the window regulator itself.

If the window regulators operate slowly, try lubricating the window regulator mechanism and the window guides. Perhaps this is the maximum speed of their operation, so the only correct solution would be to replace them with new ones (see which ESP to choose).

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

Have you ever had to repair window regulators?

I repaired the window regulator, the problem was...

Instructions for replacing the electric motor

Repairing a window regulator may include different stages depending on the breakdown. In this case, we will tell you how to repair a window regulator by replacing its electric motor; as mentioned above, this problem is one of the most common.

The replacement process is considered using the example of a Lada Kalina car:

- First you need to buy a new electric motor, which is sold in a housing with a gearbox. The door trim is dismantled - this operation cannot be performed in the cold, since the trim is fixed using plastic pistons, which will quickly break.

- Unscrew all screws and other fasteners securing the inner handle.

- All wires must be disconnected; for greater convenience, you can remove the speakers. After these steps, the glass, which is fixed in the guides, is unscrewed. In order for the glass to sink to the bottom, you need to unscrew four more screws; to do this, use a 10 key. There is a curtain at the bottom of the glass unit, which must be removed.

- The window regulator itself is mounted on nuts and guides, the electric motor itself is secured with three more nuts. The block can be pulled out through the technological holes in the door. If you disassemble the gearbox, the electric motor will fall apart into two parts. In general, the gearbox must be dismantled and replaced with a new one, further reassembling in the reverse order. The gear cable should be lubricated before use.

Repair

Repairing this mechanism, as mentioned above, is not difficult if you know the design and operating principle. In particular, let's consider the ESPD mechanism itself, which is not a gear reducer, like mechanical varieties. In electric front door lifting mechanisms, only a drum is used. It is into the hole of this drum that the gear motor shaft is inserted. The gearmotor itself consists of a worm-type gearbox, as well as an electric motor that runs on current from permanent magnets. The design of this gearmotor is similar to the design of the windshield wiper device. As for the direction of the current in the armature winding of this gearmotor, it is reversible. And the built-in thermobimetallic fuse perfectly protects it from overloads.

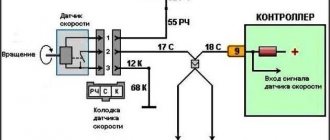

Door ESPD connection diagram

To be precise, the ESPD circuit consists of:

- block;

- front door ESPD switch;

- ESPD gearmotor;

- ignition switch;

- relay;

- external lighting switch.

So, let's begin the repair process:

- disassemble the upholstery, remove the window regulator (how to do this was written above);

- You now need to remove the cable part from the motor mechanism;

- completely remove the cable from the reel;

- unwind it.

Note. You will need to carefully inspect the splines, which are often worn out. In addition, if the splines remain like this for a long time, they deform the landing cylinder, which creates a huge load on the gearmotor motor.

- grind the protruding parts of the cylinder on a milling machine;

- we restore the roundness of the cylinder.

Note. In this case, you will need to ensure that the bulges on the back side of the cylinder, which appeared due to the rotation of the drive shaft, are ground off.

We take a two-millimeter steel plate, from which we cut out a circle of a suitable size;

Cut a circle from a metal strip

- after this you need to mark the stiffening ribs on the circle;

- We put the plate in place.

Note. It is desirable that the plate fits tightly and with some effort.

Assemble the coil in reverse order.

There is no need to attach the plate itself additionally to the coil, because it already sits securely. And the design of the ESPD body itself is made in such a way that it does not allow the plate, even a homemade one, to become loose and fall out. As for turning the plate, everything is reliable here because of the stiffening ribs. Let's continue:

- wind the cable onto a reel;

- install the cover.

Note. Do not forget to thoroughly lubricate the cable with some kind of lubricant, for example, lithol or grease.

- put the cable in place, tightening it a little using a special bolt;

- Now all that remains is to install the ESPD in the door.

Usually this is enough for the glass to go down and up normally again. The speed of glass lifting may even increase compared to what it was before the repair. After all, restoring the roundness of a cylinder, especially an ESPD that has been in operation for a long time, will only be beneficial. Its friction and resistance to the engine are reduced, and this, in turn, has a positive result. It is recommended to watch this video before starting work.

How to raise the window if the window regulator does not work

XACe » 09.03.09 17:51

Re: And again a non-standard breakdown.

RAMAzzIK » 09.03.09 17:53

Re: And again a non-standard breakdown.

Ganjubas » 09.03.09 17:54

Re: And again a non-standard breakdown.

XACe » 09.03.09 18:01

Re: And again a non-standard breakdown.

Ganjubas » 09.03.09 18:16

Re: And again a non-standard breakdown.

XACe » 09.03.09 18:28

Re: And again a non-standard breakdown.

Val » 09.03.09 18:31

Re: And again a non-standard breakdown.

Ganjubas » 09.03.09 18:34

Re: And again a non-standard breakdown.

Guardian » 09.03.09 18:53

Replace with a known good button. And if you want to get fancy, convert them to buttons from 92 + they are also VAZ 2110 (only high-quality ones).

Well, if you take the button apart very tightly and clean the contacts, they won’t burn. But it won't last long.

Re: And again a non-standard breakdown.

Rem » 09.03.09 18:54

Re: And again a non-standard breakdown.

Val » 09.03.09 19:05

Re: And again a non-standard breakdown.

Guardian » 09.03.09 19:13

And what? Scorpios don't have an interface. Just a stupid wiring diagram. Don’t be lazy, read the link I posted above. Not, of course, provided that the wires themselves are usable. By the way, there was a theme here. But I don't remember what it's called. This problem was just described. try to open it.

Re: And again a non-standard breakdown.

XACe » 09.03.09 19:37

So I have 2 buttons, on both doors. Is it doubtful that they can break at the same time? Or are they connected one through the other?

Re: And again a non-standard breakdown.

Ganjubas » 09.03.09 19:37

Re: And again a non-standard breakdown.

Val » 09.03.09 19:53

Re: And again a non-standard breakdown.

ska aka signmaker » 09.03.09 21:25

Re: And again a non-standard breakdown.

sadko » 09.03.09 21:41

Re: And again a non-standard breakdown.

jaffagold » 09.03.09 21:45

If the driver's button on the passenger window is dead, then the passenger button on the right side of the window will not work; they have sequential activation.

Is not a fact. If the button switches normally when not pressed (and this is very possible), then the passenger button will work. I described the description of the operation and testing of the power window buttons here

Re: And again a non-standard breakdown.

Val » 09.03.09 21:53

Re: And again a non-standard breakdown.

ska aka signmaker » 09.03.09 21:55

Basic problems with the operation of the window lifter

- Basic problems with the operation of the window lifter

- Causes of window lift malfunctions

- We eliminate mechanical failures of power windows

A good car package includes electric windows. This function is no longer something special, but it is highly valued by car owners for its convenience. But during the operation of the car, there comes a time when the window regulators begin to work poorly - they may not respond to button presses or get stuck from time to time. In order to understand the reasons for this, you need to have knowledge about the power window system, how it functions, and only then start looking for breakdowns.

This is interesting: Do-it-yourself shock absorber spring tie

Causes of window lift malfunctions

The power windows can only be operated when the key is in the ignition switch and turned to the “ON” position. When pressing the power window up/down button does not produce any result, it would be logical to assume that some kind of breakdown has occurred. To troubleshoot a problem, you need to understand the cause of its occurrence. It is necessary to check the window lift system to detect a failed part; To do this, we carry out the following actions:

1. If the power windows are not working, you need to check the circuit breaker or fuse - it may have blown.

2. When only the rear power windows do not work, or there is a reaction only from the main unit (that is, the buttons on the doors do not work), it is necessary to check the presence of voltage at the window regulator terminals.

3. If you have not identified a breakdown in the window regulator system, then you need to look at all the wires that connect the window regulator elements. If a wire break is detected, it must be repaired.

4. If you cannot lower/raise only one of the windows using the main power window control unit, you can try to do this using the buttons located under the door trim. If everything worked out this way and the glass moves, then the problem is in the control unit.

5. Another reason for the malfunction of the window regulators is the inoperability of the electric motor. Then you should check the presence of voltage and wiring, and here you will need electrical diagrams for your machine.

6. It is worth paying attention to the presence of mechanical damage to the guides along which the side glass moves.

Most often, car owners encounter problems with the wiring that connects the elements of the window lift system, as well as electric motors. The main reason for their malfunction is the very active use of window lifters, as well as wear and tear on the wiring. It will take you a lot of time to find a malfunction in the power window system. There is also a backup option - you can always contact a specialist who deals with the electrical part of machines, and he will do everything himself. This option is very convenient if you do not have time to solve such a problem yourself.

We eliminate mechanical failures of power windows

Fewer malfunctions occur with the electrical part of the power window system compared to the mechanical part. The very weak points of window regulators are the plastic elements that are needed for the production of racks, gears and other plastic parts of window regulators. When operating the window regulators, the gear wheel may be damaged and must be replaced.

It is quite difficult to determine this breakdown - you hear that the engine is running, but the glass does not move. Most likely, the gear wheel spins at idle and does not rotate the glass position control device. In order to replace the gear, you need to disassemble the door panels and remove the remains of the gear from there. Then we replace the faulty part. If everything went well and the glass moves, then the door panel can be closed.

The malfunctions of cable window lifters are the same as in manual drives. One of the main faults in such window lifters is a broken cable. Such a malfunction may occur due to the expiration of the device’s service life or a sudden temperature change in winter. When the cable breaks, it needs to be replaced with a new one. The last type of malfunction is the breakdown of levers, but this type is quite rare. However, if it happens, then the levers must be replaced with new ones.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Fuses and relays VAZ 2110 - 2112, electrical diagrams

If some devices on your VAZ 2110 or VAZ 2112 , fuses or relays may be to blame. At the very least, the first thing you need to do is check them, and then draw some conclusions regarding the malfunctions.

Correct diagnosis of many electrical problems will allow you to accurately determine the cause of the inoperability of a particular unit. To find out what the fuses and relays of the VAZ 2110 - 2112 are responsible for and how to find the right one, read this article.

Recommended: G12 Coolant: Red, Yellow and Green

As in many other cars, in the VAZ-2112 and VAZ-2110, when the engine is turned off, the devices are powered directly from the battery. When the engine is running, voltage is supplied to the devices from the generator, which simultaneously charges the battery. If the current exceeds the permissible value or a short circuit occurs, the circuit fuse will blow. Powerful electrical appliances are connected via relays.

Fuse and relay box

The fuse and relay box is located on the left, lower part of the instrument panel. It is accessible by pressing the button and folding the lid down. To remove fuses, there are special non-conductive pliers in the upper left part of the mounting block.

1 - K5 - high beam relay . If the high beams in two headlights do not work, check this relay. If one of the high beam headlights does not work, check fuses F3 and F13, as well as the lamps and the high beam switch.

2 - K4 - low beam relay . If the low beam in both headlights does not work, check this relay. If only one low beam headlight does not work, check fuses F2 and F12, as well as the lamps themselves and the light switch.

3 - K1 - lamp health control relay.

4 - non-conductive tweezers for removing fuses.

5 - power window relay . If your power windows stop working, check this relay. It could also be in fuse F5, or in the window lift drive system itself. To get to the mechanism, you need to remove the door trim. Check the electric motor, the appearance of the gears and the absence of binding of the mechanism.

6 - K3 - turn signal and hazard warning relay . If your turn signals or hazard lights do not work, check this relay and fuse F16, as well as the turn signal lamps themselves and their switch.

7 - starter relay . If the car does not start and the starter does not turn, check this relay. It could also be a dead battery, as well as the starter mechanism itself.

8 - backup fuses.

9 - fog lamp relay . If the fog lights do not work, check this relay and fuses F4 and F14. Also check their connection diagram, the serviceability of the wiring and connectors, as well as the lamps in the headlights and the power button.

10 - K2 - windshield wiper and washer relay . If your windshield wipers or windshield washer are not working, check this relay. Also check the wiper motor, washer pump and washer fluid level in the washer reservoir.

11 - K7 - rear window heating relay . If the heating does not work and the rear window fogs up, check this relay and fuses F8 and F9. Also check the connection contacts to the terminal points of the heating elements (at the edges of the glass at the rear pillars). If everything is in order, but the heating does not work, the issue may be in the wiring (the wires are frayed or something else).

12 - K6 - add. relay, ignition relay . If your ignition does not turn on or is having problems with it, check this relay. This relay protects the ignition switch contacts from burning. Also check the ignition switch itself and the contact group.

13 - row of fuses F1-F10

14 - row of fuses F11-F20

Circuit breakers

Now let's see which fuses are responsible for what in the same mounting block. I will also give the main reasons for troubleshooting.

F1 (5 A) - license plate lighting lamps, dashboard lighting, side lights on the panel, trunk lamp, left side lights . If any of the listed lamps do not work, check this fuse, as well as the lamps themselves and their contacts. If everything is in order, check the headlight switch button.

F2 (7.5 A) - low beam in the left headlight . If both low beam headlights do not work, also check relay K4 and the lamps themselves. It could also be the light switch and its contacts.

F3 (10 A) - high beam in the left headlight . If both high beam headlights do not work, check the K5 relay, the lamps themselves and the high beam switch knob.

F4 (10 A) - front fog lamp on the right side . If both fog lights do not work, check relay 9 and the headlight bulbs themselves, as well as the switch and its contacts.

We recommend: Fuel filter for diesel engine

F5 (30 A) - window lift motors . If the power windows do not work, check this fuse and relay 5. In winter, check if the windows are frozen, warm them up and clear them of ice if necessary. It could also be the window lift motor, its mechanism and gears; in order to get to it, you need to remove the trim of the desired door.

F6 (15 A) - portable lamp fuse.

There may also be problems with the cigarette lighter. To check, unplug the cigarette lighter from the connector. If this fuse stops burning, then the problem is in the cigarette lighter.

F7 (20 A) - engine cooling fan, sound signal . If the cooling fan does not turn on and the engine overheats, check this fuse. Also check the operation of the fan motor by connecting it directly to the battery. It could also be the coolant temperature sensor or thermostat.

F8 (20 A) - heated rear window (element) . If the heating does not work and the rear window fogs up, check this fuse, fuse F9 and relay K7. Also check the contacts on the terminals of the heating elements, check the wiring, sometimes the wire frays. It could also be the heating switch and its contacts.

F9 (20 A) - recirculation valve, windshield wipers and washer, headlight washer, rear window heating relay coil . If the heating does not work, similar to the previous one. If the windshield wipers or washer do not work, also check relay K2, the fluid level in the washer reservoir, the washer pump, and the wiper motor. Another issue may be their switching handle, its wiring and contacts. The wires may be squashed or frayed and shorted to the housing.

F10 (20 A) - backup fuse.

F11 (5 A) - right side dimensions . If the left side does not work, check fuse F1. If none of the side lights work, check the light switch and its contacts. Also check the dimensions of the lamps themselves.

F12 (7.5 A) - low beam in the right headlight . Similar to fuse F2 for the left headlight.

F13 (10 A) - high beam in the right headlight, high beam lamp on the dashboard . Similar to fuse F3 for the right headlight. If the blue lamp on the panel does not light up when you turn on the high beams, check this fuse, as well as the lamp itself and the wiring to it.

F14 (10 A) - front fog lamp on the left side.

Similar to fuse F4 for the right fog light.

F15 (20 A) - seat heating, trunk locking . If the heated seats do not work, check this fuse and the power button on the dashboard, its contacts and wiring.

F16 (10 A) - direction indicators and hazard warning lights, hazard warning lamp . If the turn signals or hazard lights do not work, also check relay K3 and the lamps in the turn signals themselves, as well as the hazard light switch button.

F17 (7.5 A) - interior lighting, lighting, ignition switch lighting, brake lights, clock, on-board computer . If the brake lights do not work, check this fuse, the lamps themselves, and also the switch installed in the pedal unit.

F18 (25 A) - glove box lighting, heater controller, cigarette lighter . If the cigarette lighter does not work, check this fuse, disassemble the cigarette lighter and check for a short circuit in it, especially on the washer and contacts. Bend them if necessary or replace the entire cigarette lighter. Do not insert non-standard size connectors into it.

F19 (10 A) - door locks, control relay for brake lights and parking lights, turn signals and lamps for turning them on on the panel, reverse lamp, generator winding, control indication of the on-board system, dashboard, clock, on-board computer.

F20 (7.5 A) - rear fog lights.

If the rear fog lights do not work, check this fuse and relay 9. Also check the lamps themselves, wiring, connectors and the switch on the panel.

Never replace blown fuses with fuses of a higher rating (current), this can cause burnout of tracks on the mounting block, failure of devices, etc. In this case, repairs will cost more, so it is better to deal with the problem immediately and fix the problem. If you cannot find what’s wrong on your own, contact a car service; usually such problems are dealt with by electricians, who will not have any difficulty identifying the problem and fixing it.