Where is

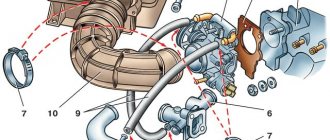

The VAZ 2110 starter is located on the gearbox housing and is mounted on two studs. It is easier to see the starter in detail on 8-valve engines, since there is more free space in the engine compartment with such an engine. In a 16-valve engine, to see the starter, you need to remove the air filter housing.

Checking spark plugs and sparks

If the engine does not start within five seconds, there is no use turning the starter. You can try to start it again, but it’s unlikely to help. Moreover, operating the starter for too long can lead to overheating and even fire.

If you try to start a carburetor engine for a long time, gasoline will flood the spark plugs and make further starting attempts impossible in principle. The injectors have a purge mode, so the spark plugs can be dried without removing them from the car - you just need to press the gas pedal to the floor and turn the starter.

Clean working spark plugs VAZ 2110

But these are half measures. First of all, you should unscrew at least one spark plug, put the wire back on it and position the spark plug on the engine so that there is a distance of about three millimeters between the metal part of the spark plug and the metal of the engine. Turn on the starter and make sure that there is a uniform spark between the spark plug contacts.

Checking the spark in the spark plugs of the VAZ 2110

Do this check for each candle. If there is no spark on any spark plug, then there are global problems in the ignition system.

Starter relay (retractor)

The starter retractor relay is located on the starter itself and serves to move the bendix to the flywheel, and then engage with it. This relay often fails due to poor workmanship. It is quite easy to understand that the solenoid relay has failed; with such a breakdown, the starter will spin at idle, but the engine will not rotate, since the moving part of the drive (bendix) will not engage with the flywheel.

No contact

The starter starts with difficulty, before clicking. At first you are only slightly alarmed, but the situation repeats itself again and again: first it clicks, and only then the engine turns.

Have you checked your contacts lately? You need to start with the battery, maybe you are wrong to blame the starter, and the reason is oxidation of the terminals. Have you cleaned them and the starter clicks again? You need to check how your VAZ has ground contact with the body, and then the contacts of the starter itself, because they are also prone to oxidation.

Another test method: ask someone to turn the ignition key, while you yourself knock on the relay, using only a hard object. If it starts, it means that the closing contacts (nickels) are stuck, and it is easier to change the relay than to disassemble and repair it.

Possible starter failures

There can be a large number of starter breakdowns, but most often they are all of the same type. Below are all the most common starter failures.

Brush wear

Starter brushes are a copper-graphite part that conducts electric current. The brushes are in direct contact with the starter armature and rub against its commutator, conducting electric current. During long-term use, brushes become unusable due to friction and must be replaced. This breakdown is not expensive or complicated; you just need to remove the starter and replace the brushes.

Bendix wedge

The Bendix is directly connected to the flywheel and quite often, wear appears inside it or on its gears due to high load, which makes it impossible to start the car from the starter. By design, Bendix is an overrunning clutch that rotates freely in one direction and is locked when rotating in the other direction. This part is sold separately and can be replaced as soon as possible.

Gearbox failure

The VAZ 2110 starter is geared. This modification allows you to reduce the load on the battery and rotate the engine crankshaft much easier and faster due to the additional ratios. Quite often, wear appears on the gears, which can lead to jamming or even breakdown of the entire gearbox.

Winding break

Since large currents flow in the starter, the winding in it is quite powerful and can withstand large currents, but sometimes a large cross-section of wires is not able to preserve the winding and it burns out, rendering the starter unusable. Such a breakdown can be repaired by replacing the rotor.

Solenoid relay

The retractor is an electromagnetic part that is retracted under the action of an electromagnetic force, driving the bendix inward and engaging it with the flywheel. Inside the relay structure there is a regular coil, which quite often burns out and damages the starter.

Almost all starter failures can be repaired by replacing the broken part with a new one.

The overrunning clutch has failed

A cold engine starts without the slightest problem. You are driving quietly, stopping somewhere - to go to the store or for other matters. You return a few minutes later and are faced with a problem: the starter clicks, but refuses to work. And only after the engine has cooled down the car starts.

The first culprit in this situation is the overrunning clutch (popularly called Bendix, from the name of the well-known manufacturer of this part). It is better to replace it with a gearbox.

But you check and there is no malfunction? The next line is the wires going to the battery. Examine them carefully. It is quite possible that replacing the wire will solve all the issues.

There may be another situation: while on the road, the radio starts to turn off spontaneously, despite your attempts to turn it on. Having stopped to look and turned off your VAZ 2110, you soon discover that you cannot get the starter to crank. We checked the battery, everything is fine, but the car, which previously started normally, suddenly struggles.

You start pushing, and it works, everything works again. Almost certainly the problem is in the Bendix.

The starter doesn't turn over

There are many reasons why the starter does not work, but first of all you need to check the most common reasons why the engine will not start.

Checking contacts on the battery

Often the reason when the starter does not turn is due to loose terminals on the battery or their oxidation. It is enough just to clean the oxidized terminals from chemical reactions and tighten them with a force that will ensure reliable contact.

Battery discharge

Quite often, especially in winter, after a period of inactivity, the car’s battery may discharge, and thickened oil during parking will not allow the weak battery to rotate the crankshaft with the starter. You can check the battery with a regular multimeter; in winter its voltage should not be less than 12V, in summer not less than 11V. This voltage is not an indicator of the battery charge; at such values it is better to charge the battery.

Egnition lock

In some cases, the contact part of the ignition switch may fail. This is due to aging or poor quality parts. In this case, when turning the key, the contacts will not close to turn on the starter.

Winding break

If the winding on the stator or rotor of the starter breaks, the magnetic field that rotates the armature will not appear and the starter armature will not move.

Typical starter malfunctions and their causes

If the engine refuses to start, then it is quite possible that the reason lies in the performance of the starter device, but this will need to be clarified. Turn the ignition key all the way, then listen to the operation of the unit. If you hear that the electric motor is cranking and the relay is clicking, then most likely the reason lies in a malfunction of the clutch or gear unit. In practice, the clutch is often the cause of the malfunction; if this is the case, then, most likely, the bendix will have to be changed (the author of the video is the Sibiryak54 channel).

The reason may also be the gears, in particular their wear. Wear can be determined after dismantling and disassembling the mechanism - teeth on worn gears may be knocked off. If the starter unit refuses to click when you try to start the engine, then most likely the reason lies in the lack of voltage on the relay or this element has failed. To verify that the problem is with the relay, put the car on the parking brake, disconnect the wire from the relay, and connect another wire connected directly to the battery. If as a result of these manipulations the relay works, then check the switch itself, that is, the lock, connection wiring, and safety devices.

If, when trying to start the engine, the unit turns very slowly or does not turn at all, then troubleshooting is carried out as follows:

- If there is voltage in the circuit, then most likely the brushes or windings have failed.

- If there is no voltage, then perhaps the contact of the relay with the electrical circuit is poor. It is necessary to check the quality of the connection; there is a possibility that the contacts are simply dirty and will need to be cleaned. For cleaning, use a steel brush or fine-grained sandpaper.

Photo gallery “Starter malfunctions 2110”

2. Damaged relay

Replacing the VAZ 2110 starter

To remove the starter, you need to prepare a tool that will be needed during the work process.

Required tool:

- Ratchet;

- Extension;

- Head 13mm;

- Open-end wrench 10mm;

- Open-end wrench 13mm;

Step-by-step instruction

- Disconnect the negative terminal from the battery

- We dismantle the air filter box together with the mass air flow sensor

- Unscrew the wires from the starter

- Unscrew the nuts securing the starter to the gearbox

- Removing the starter

When the immobilizer is a hindrance

The engine stalled unexpectedly, the starter refuses to turn it, and it also won’t start with a “push.” The battery was checked - charged, serviceable, terminals clean and in place.

However, your immobilizer is working, and most likely the problem is there. The protection is triggered, the engine is silent. It is necessary to tow the VAZ 2110 to a car service center for diagnostics.

In order to bypass and disable the immobilizer yourself, it is recommended that you read the following article: https://vazweb.ru/desyatka/elektrooborudovanie/kak-otklyuchit-immobilayzer.html

Causes: fuse, relay, connector

The pump power circuit includes many elements: closed relay contacts 5, fuse 3 (15 A), “+” wire, “pump-to-ground” wire. The most “difficult” defect is a short circuit of the “+” wire to ground. By the way, the cord itself is laid on metal, so such a defect cannot be ruled out.

Mounting block for dashboard

Both the relay and the fuse are located in a block located under the dashboard on the right. A fuse can blow in two cases:

- The “+” cord makes contact with ground;

- The motor resistance decreases due to overheating.

The first defect may be “floating”, and then it will be difficult to identify. But before calling an electrician, try checking everything else:

- Relay 5 should click twice: when the ignition is turned on and after 1.5 s. If this does not happen, replace the relay;

- Check fuse 3. If it is blown, you need to look for the cause.

Consider the situation: the relay is working, but the fuse is blown. Then we do this: disconnect the pump connector, install a new fuse and measure the voltage at the terminals. Details are below.

Connectors under the hatch, disconnecting them

You need to remove the hatch under the rear seat: two screws are unscrewed with a Phillips screwdriver. Next you need to disconnect the connector on the module, and then move on to the block under the dashboard.

First, turn off the fuel pump!

Replace the fuse. Let's move on to the fuel pump: connect the probe (zero cord) to any of the mounting studs. Voltage should appear on the “gray” wire when the ignition is turned on. And also check the potential difference between the “gray” and “black” wires - it should be equal to 12 volts, and also at the moment the ignition is turned on. Wiring:

- The two outer cords are the FLS sensor;

- “Black” – minus power supply;

- "Grey" is a plus.

The "black wire" sometimes loses contact with ground. At the last step, we checked exactly this version.

There are reviews from owners that say: the fuel pump on a VAZ-2112 does not work if the electric motor is working properly and there is voltage in the connector. This happens when the contacts of the internal terminal block oxidize (see photo).

Internal connector - yellow

Getting to the connector on the motor is not easy - you need to remove the fuel pump module by unscrewing 8 nuts around the perimeter.

Diagnosing the fuel pump

Safety precautions

Before unscrewing the nuts, you need to disconnect the two hoses. But first try starting the engine. The power supply to the fuel pump is not connected.

Please note - the power is turned off here!

Everything is ready for dismantling if:

- External connector is disabled;

- It is impossible to start the engine, although the on-board network is not de-energized;

- It is better if the tank is filled less than 50%!

You need to unscrew two fittings from the module cover (top photo). Then use a socket wrench to unscrew the nuts from the studs and remove the retaining ring.

There is very little left to the internal connector

Having gained access to the internal connector, you need to clean its contacts. Assembly is carried out in reverse order. Good luck!

Replacing brushes

Having removed the relay as described above, remove the stator with the armature by unscrewing the tie rod nuts. Remove the gear from the shaft. Unscrew the two screws on the back cover and remove it. We take out the brush holder. We pull out the anchor.

We inspect the condition of the windings and commutator. There should be no severe burning or wiring breaks. Using fine sandpaper, we clean the commutator plates and the burrs of the armature shaft journal. We inspect the brushes. If they are worn out a lot, we replace the brush holder assembly. We reassemble the electric motor in the reverse order, not forgetting to lubricate the gears of the planetary gearbox.

With proper overhaul and the use of new spare parts, you can extend the service life of this device, which is necessary in the car system.

Source

Causes: fuse, relay, connector

The pump power circuit includes many elements: closed relay contacts 5, fuse 3 (15 A), “+” wire, “pump-to-ground” wire. The most difficult defect is a short circuit of the “+” wire to ground. By the way, the cord itself is laid on metal, so such a defect cannot be ruled out.

Both the relay and the fuse are located in a block located under the dashboard on the right. A fuse can blow in two cases:

- The “+” cord makes contact with ground;

- The motor resistance decreases due to overheating.

The first defect may be “floating”, and then it will be difficult to identify. But before calling an electrician, try checking everything else:

- Relay 5 should click twice: when the ignition is turned on and after 1.5 s. If this does not happen, replace the relay;

- Check fuse 3. If it is blown, you need to look for the cause.

Consider the situation: the relay is working, but the fuse is blown. Then we do this: disconnect the pump connector, install a new fuse and measure the voltage at the terminals. Details are below.

What is a starter

VAZ 2110 problem with starter

The starter has a rather complex design. To repair a starter, you need to know the causes of breakdowns, since the equipment can have several types of troubles. A mechanism breakdown can occur at any time, but mechanical experts say that at least five years must pass before the first problems in a new car. Since repairing this mechanism is almost impossible for a person far from mechanics, it is better to buy this equipment in specialized stores.