Nuances of work

At different times, Lada Priora cars were equipped with engines with a displacement of 1.6 and 1.8 liters and a different number of valves in the heads - V8 (or 8V) and V16 (or 16V). The type of unit head determines the size of the bolts, the order of their installation and the tightening torque of the cylinder head on the Priora.

If the car has an 8-valve engine, then it can use head mounting bolts of different sizes:

- on old motors 21114, M12*1.25 hex head screws are used;

- on more modern 21116, which went into production approximately in mid-2011, M10*1.25 elements with an asterisk head are installed.

When installing a removed head, it is necessary to use new screws, since the old ones will be stretched and have internal damage.

Also, the engines use gaskets of different designs - combined on the old unit and all-iron on the new one. The procedure for tightening bolts for engines with metal and combined gaskets is absolutely identical.

The main nuances when performing work are checking the length of the fasteners, observing the sequence of tightening the screws and monitoring the tightening force. Violation of these conditions leads to damage to parts and the need for additional repair work. The procedure itself is not complicated and can be done independently in any convenient place - in a garage or in an open parking lot, with the exception of the case of installing the head on the engine, which is preferably installed indoors.

It is important to remember that tightening the bolts “by eye” without a torque wrench is unacceptable, since a uniform fit of the mating surfaces of the head and block will not be ensured.

Tools and materials

Before starting the tightening procedure, you should prepare everything necessary to perform:

- wrench with built-in dynamometer up to 100 H⋅m;

- a set of sockets and regular keys;

- Togh E14 key;

- calipers for measuring the remaining length of bolts;

- plate with a marked scale up to 180 degrees;

- new bolts.

A torque wrench is an important tool for DIY repairs.

Step-by-step instruction

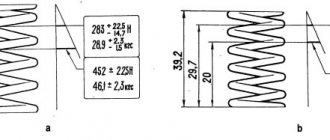

Sequence of operation on an 8 valve engine:

- Wipe the cylinder head surfaces and dry the bolt holes in the engine block.

- Install the gasket on the block and align it along the guides.

- Mount the head on top and insert 10 M10 or M12 mounting bolts. If the owner decides to save money and keep the old screws, then they should have a length of no more than 135.5 mm.

- Tighten the elements according to the diagram. The tightening force should not exceed 20 N⋅m.

- Then you need to re-tighten the bolts. The second tightening force should be in the range from 70 to 85 N⋅m.

- Next, you need to tighten the screws by 90 degrees in the same sequence. The rotation angle can be controlled using a special device, which is a plate with an attached scale from 0 to 180 degrees.

- In accordance with the regulations, you need to tighten the bolts again by 90 degrees.

- The attachment of the 8 valve head to the block is complete.

- After assembling the motor, you need to check the quality of operation by starting and warming up the engine. A securely tightened joint between the head and the block should not allow working fluids to leak from the crankcase of the power unit.

Homemade device for controlling the rotation angle

If a more powerful and modern engine with sixteen valves is installed on a car, for example, the VAZ 21126 model or 126 for short, the procedure for pulling the bolts has its own characteristics.

In order to correctly tighten the cylinder head screws on such units, you need to:

- Remove oil from the mating surfaces and check that there is no liquid in the bolt holes.

- Install the gasket, center it and place the head on top.

- Insert 10 mounting screws M10*1.25 into the guide holes, having previously lubricated the threads with engine oil. If you decide to use old bolts, which is permissible for 16 valve heads, then their remaining length should not exceed 98 mm.

- Perform preliminary pulling according to the scheme with a torque of 12-20 N⋅m.

- Increase the tightening degree to 26-34 N⋅m and re-run all the bolts in the same sequence.

- Then you need to tighten the screws 90 degrees, with a force of about 50 N⋅m.

- Repeat tightening by 90 degrees again, the torque on the key will be approximately 80 N⋅m. Some instructions recommend waiting up to 20 minutes between turns, but in practice no advantages of such a scheme have been identified.

- After assembling the power unit, you should check the quality of the work performed.

The procedure for pulling the head on 1.8 liter engines, which are 1.6 liter engines with an enlarged cylinder, is completely identical to that described above.

If during the work process the correct moment of force is applied to the bolts, corresponding to design calculations, then the gasket will be evenly and tightly pressed along the joint, ensuring a reliable and tight connection. It is important to note that if it is necessary to remove the cylinder head from the engine, then the screws are also loosened according to the scheme established by the regulations. Chaotic unscrewing of the elements will lead to deformation of the head and the appearance of invisible microcracks.

Installation and dismantling procedure

The part called the cylinder head is attached to the cylinder block with 10 screws. They are unscrewed with a 10mm socket wrench. The procedure for dismantling the cylinder head is shown in the first photo.

Reversal sequence (1-10)

The standard screw length is 9 3 mm. If the screw has been pulled out to at least 95 mm, it is replaced with a new one (AvtoVAZ requirement).

During installation, a different scheme is used (photo 2). Each screw is lubricated with machine oil, otherwise the efforts will be reduced to nothing.

The order of tightening the head is indicated in this photo

Tightening torque for cylinder head cover bolts

For VAZ-2112, the cylinder head tightening torque is standardized:

- First pass – the force is 20 N*m;

- Each screw is turned 90 degrees to the right;

- Wait 20 minutes, then turn the screws another 90 degrees.

At first the effort is very small. But at “step 3” it will be difficult to cope with the work. Use the lever.

Why are guide bushings needed?

Before installing the cylinder head, perform the following steps: clean the threaded holes, as well as all holes for the bushings (photo 1). Each bushing is installed in place, and only then a gasket is placed on top.

Everything is ready to install the cylinder head

Metal parts adjacent to the gasket must be degreased. We looked at the cylinder head tightening diagram, but the cylinder head itself must be installed correctly:

- We place the cylinder head on the cylinder block;

- By moving the part in different directions, we ensure that the bushings fit into the recesses.

After “step 2” the screws can be tightened.

Sealant

No sealing compounds are used when installing the gasket! Solidol, CIATIM and other lubricants are not even needed. The main thing is that the metal must be degreased. And the cylinder head gasket must be new.

Features of tightening fasteners

Even a non-professional can handle this work.

It is important to follow two rules - the tightening torque and the sequence of working with fasteners. The tightening torque on engines with 8 and 16 valves is no different, while the sequence is different. Pay attention to the diagrams below; numbers indicate the order of tightening the bolts. It is necessary to pay attention to the cylinder block:

- if during operation the bolts become loose due to vibration (the malfunction is detected by leakage of the gasket);

- after dismantling the cylinder head and installation;

- if the iron gasket is replaced;

- during tuning of the cylinder block.

Before work, take the instructions from your Priora to understand which engine is installed in the car.

The process and procedure for tightening cylinder head bolts on a Priora

Sometimes it happens that it is necessary to urgently replace the gasket or change the cylinder head. Such work at a service station costs a lot and to save money, you can try it yourself. This work is not difficult, but requires care; the main thing is to observe the sequence and tightening torque of the Priora cylinder head of 16 valves.

Here you also need to know that the tightening sequence on 16 cl and 8 cl units is different, so you need to be careful. The torque on the 16 and 8 valve power units is the same and passes in four circles.

Removing and installing connecting rods on the Priora engine

The interesting thing is that, although this part is located almost in the middle of the engine, it can be removed without removing the engine from the car. Yes, this is, of course, not an easy operation, but it is quite doable. It must be carried out either in an inspection hole or on a special lift for cars so that there is access to the oil pan. When the vehicle is positioned for surgery, the engine compartment protection underneath is removed first. The cylinder head, engine sump and flywheel are dismantled. It is advisable to remove the oil intake so as not to damage it. You can start removing the connecting rods.

It is worth starting from the first cylinder. This is in order to put the details in order and not get confused. Rotate the Priora crankshaft so that the lower part of the connecting rod is level in the lower position. Unlock and unscrew the bolts securing the liner cover. Remove it and set it aside along with the liner itself. After this, push the piston up and remove it from the cylinder. One by one, remove all the Priora pistons and connecting rods in this manner. Now you can repair or replace elements.

conclusions

On 16-valve VAZ-2112 engines, the torque and tightening sequence of the camshaft frame must be correct, since this factor affects the operation of the cylinder head and the engine as a whole. Therefore, an incorrect procedure can lead to more serious consequences. If the car enthusiast cannot do this on his own, then he should contact a car service center, where everything will be done quickly and efficiently.

In the VAZ 21126 engine, the joint between the cover and the cylinder head of the VAZ 2170 is sealed with sealant applied to the mating surfaces of the parts.

crank mechanism

This main engine unit consists mainly of the following groups:

Each part of the group has several additional elements. For example, each piston carries a set of O-rings, a connecting pin and pin retaining clips. The crankshaft has bearings and oil seals. The most interesting thing is the structure of the connecting rods.

The principle of operation of the mechanism

VAZ engines, like other cars, are based on explosive combustion of fuel. The piston creates a certain compression of the air-gasoline mixture, a spark from the spark generator ignites it, pushing the piston down, and the crank mechanism (CPM) converts translational motion into rotational motion. This occurs due to the special shape of the crankshaft. The mounting points of the connecting rods are located so that while the connecting rods pushing the pistons rise, the connecting rods pushed by the piston are lowered. And this process takes place in shifts.

Set of connecting rods "Priors"

These parts are collapsible. The main part is made of high quality metal. Only in the upper ring, where the piston locking pin fits, is an insert made of a different metal installed. In general, the connecting rod consists of the following parts:

- connecting rod;

- liner covers;

- coupling bolts 2 pcs.;

- special washers;

- connecting rod bearing.

This is due to the fact that the liners have special grooves for the passage of engine oil. Due to the high rotation speed, this unit requires uniform and abundant lubrication. The slightest discrepancy between these grooves and the oil supply holes of the crankshaft will lead to a disruption in the flow of lubricant and, as a result, jamming of the engine.

Video “How to properly tighten cylinder head bolts”

In this video, a master with extensive experience shows and describes in detail how cylinder head bolts are tightened correctly. On a Lada Priora car with a 16-cell unit, work is carried out according to the same scheme.

Today we took one of our old clients to Priora; as it turned out, the jammed pump broke the belt and, as a result, the valves were bent.

But progress at AvtoVAZ does not stop, and if on engines of the tenth family the valves simply fold, then even on the Priora 126 the connecting rods lose alignment and, if they are not changed, there is a high probability that the engine will start to eat oil, and therefore your money. Glory to the designers of AvtoVAZ!

But there are no breakdowns without good things; there are piston kits for 126 engines with grooves that do not bend the valve. In this article we will describe the procedure for repairing the cylinder head after a broken timing belt, as well as replacing the piston. Removing and installing the timing belt is described in this article, so we will not go into detail.

This procedure requires torque wrenches!

Is it worth observing the tightening torque of the main and connecting rod bearings when assembling the engine?

Many car enthusiasts who are accustomed to repairing their cars themselves know firsthand that engine repair is a very difficult and responsible task.

Since repairing a power unit requires from the car owner not only certain skills, but also knowledge to correctly carry out the technological process. Today in the article we will briefly look at the crank mechanism and its role in a car engine.

In addition, we will also talk about the importance of observing the tightening torque of the main and connecting rod bearings, the nuances and sequence of this operation, and other important aspects. Therefore, it will be useful for beginners to somewhat expand their knowledge of the topic by reading our article.

The concept of CVM

The crank mechanism, abbreviated as KShM, is the most important unit unit for the engine. The main task of this mechanism is to change the linear movements of the piston into rotational ones, and vice versa. This torque occurs due to the combustion of fuel in the engine cylinders.

As you know, gases tend to expand during combustion of a fuel mixture. Then, under great pressure, they push the engine pistons down, and they, in turn, transmit force to the connecting rods and crankshaft. It is due to the specific shape of the crankshaft that the engine transforms one movement into another, which ultimately allows the wheels of the car to rotate.

In terms of its functions, the crankshaft is the busiest engine mechanism. It is this unit that determines what type of power unit will have and how the cylinders will be located in it. This is due to the fact that each type of engine is created for a specific purpose. Some cars require maximum engine power, light weight and dimensions, while others prioritize ease of maintenance, reliability and durability. Therefore, manufacturers produce different types of crank mechanisms for different types of engines. KShM are divided into single-row and double-row.

The role of crankshaft liners

The crankshaft must withstand heavy loads while the engine is running. But bearings cannot be used for this device. This role was taken on by the main and connecting rod bearings. Although, according to their task, they perform the functions of sliding bearings. The liners are made from a bimetallic strip consisting of low-carbon steel, copper and lead, as well as an aluminum alloy ASM or Babbitt.

It is thanks to the liners that the free rotation of the crankshaft is ensured. To ensure durability and wear resistance, the liners are coated with a thin, micron layer of oil during engine operation. But for their complete and high-quality lubrication, high oil pressure is simply necessary. This role was taken over by the engine lubrication system. All these conditions contribute to reducing the friction force and increasing the service life of the engine.

Types and sizes of liners

In general, crankshaft liners are divided into two groups:

- The first type is called radical liners. They are located between the crankshaft and the places where it passes through the engine housing. They bear the greatest load, since it is on them that the crankshaft is attached and rotates.

- The second group includes connecting rod bearings. They are located between the connecting rods and the crankshaft and its journals. They also carry enormous loads.

Main and connecting rod bearings are manufactured individually for each engine type with their own dimensions. Moreover, for most automobile engines, in addition to the nominal factory sizes, there are also repair inserts. The outer size of the repair liners remains unchanged, and the inner diameter is adjusted by increasing the thickness of the liner. There are four such sizes in total, with increments of 0.25 mm.

It is no secret that with high mileage of a car, not only the main and connecting rod bearings wear out, but also the crankshaft journals. These circumstances lead to the need to replace liners of nominal sizes with repair ones. To install one or another repair liner, the neck is bored to a certain diameter. Moreover, the diameter is selected individually for each size of the liner.

If, for example, a repair size of 0.25 mm has already been applied, then when getting rid of imperfections on the crankshaft journals, a size of 0.5 mm should be used, and in case of serious scuffing, 0.75 mm. If the bearings are replaced correctly, the engine should last for more than one thousand kilometers, unless, of course, the other systems of the car are in good working order.

There are also options when boring is not required and the liners are simply replaced with new ones. But people who do this professionally do not advise simply replacing the earbuds with new ones. This is explained by the fact that during the operation and operation of the liners, microdefects still appear on the shaft that are not visible at first glance. In general, without grinding there is a possibility of rapid wear and a short service life of the crankshaft.

Signs of wear on the main and connecting rod bearings

In the conversations of car enthusiasts, phrases are often heard: “The engine knocked” or “The liners turned,” these words most often refer to the wear of the liners. This in turn is a serious breakdown in the motor. The first signs of such malfunctions are loss of oil pressure or the appearance of extraneous sounds when the engine is running. It will be difficult for an inexperienced car enthusiast to identify signs of faulty liners, so it is better to immediately contact a specialist.

For a professional, listening and making a diagnosis will not pose any serious problems. Typically, this procedure is performed at idle speed of the engine, sharply pressing the gas pedal. It is believed that if there is a dull tone or an iron grinding sound, then the problem is in the main bearings. If there is a problem with the connecting rod bearings, the knocking sound is louder and stronger.

There is another way to check wear. It is necessary to alternately unscrew the spark plugs or injectors of diesel engines. If the knocking noise disappears when you unscrew a spark plug, then this is the cylinder in which there are problems.

The problem of low oil pressure may not necessarily arise from wear of the liners. The oil pump, pressure relief valve may be faulty, or the camshaft bed may be worn out. Therefore, we first check all the components of the lubrication system and only after that we draw conclusions about what exactly to repair.

We measure the gap between the liner and the crankshaft

The inserts are produced in 2 separate parts, which have special places for installation. The main task during assembly is to ensure the required clearance between the shaft journal and the liner. Typically, a micrometer is used to determine the working gap between them, and a bore gauge measures the inner diameter of the liners. After this, some calculations are made, which make it possible to identify the gap.

However, it is much easier to perform such an operation using a special plastic calibrated wire. Pieces of the required size are placed between the liner and the journal, after which the bearing is clamped with the required force and disassembled again. Next, take a special ruler, which comes in the kit along with the wire, and measure the width of the corresponding imprint on the shaft. The wider the crushed measuring strip, the smaller the bearing clearance. This method allows you to control the required distance between the neck and the liner with high accuracy.

How and with what force are the main and connecting rod bearings tightened?

You can tighten the main and connecting rod bearings with the required force using a special torque wrench. The key can be either a ratchet or an arrow. Both wrenches are marked with the dimensions required to tighten the nuts and bolts to any torque. To configure, you will need to set the required value on the key, and after that you can immediately begin tightening.

Remember that for a force of less than 5 kg there is no need to put a pipe on the wrench to create additional leverage. This can be done with one hand to avoid stripping the bolt threads.

Tightening torque for main and connecting rod bearings

Before installing the liners, the first step is to remove the preservative grease from them and apply a small layer of oil. Next, we install the main bearings in the bed of the main journals, not forgetting that the middle liner is different from the others.

The next step is to place the bed covers and tighten them. Moreover, the tightening torque must be applied in accordance with the standards that are sometimes specified in the operating rules of the vehicle. But most often there are cases when the technical manual for the car does not indicate the tightening torque for the main and connecting rod bearings. In such cases, it is recommended to look for this information in special literature on repairing a specific engine. For example, for Lada Priora cars, the tightening torque for the bed covers ranges from 64 N*m (6.97 kgf*m) to 81 N*m (8.61 kgf*m).

Next, we proceed to install the connecting rod bearings. In this case, you should pay attention to the correct installation of the covers; each of them is marked, so do not mix them up. Their tightening torque is much less than that of the main ones. For example, if we take the same Lada Priora model, the tightening torque of the connecting rod bearings will start from approximately 43 N*m (4.42 kgf*m) to 53 N*m (5.46 kgf*m).

Please note that the data provided for example assumes the use of new liners for repair, and not used parts. Otherwise, when using the old liners, the tightening torque should be selected based on the upper limit of the recommended torque from the documentation for this engine. This is done due to the possible presence of some wear on old parts. Sometimes ignoring this fact can lead to significant deviations from the recommended norm.

When all the bolts are tightened for the first time, it is advisable to rotate the shaft. To do this, there is a place on the side of the crankshaft for a wrench, calmly turn it clockwise. If the ring has burst or there is any other malfunction, it will be immediately visible. Next, after making sure that there are no problems, we check all the bolts again with a wrench at the tightening torque.

It should be remembered that the tight fit of the sliding bearings to the crankshaft and, accordingly, the efficiency of the engine itself depend on how correctly this process is performed. Because if the bolt is not fully tightened, there will be excess oil, the entire lubrication cycle will be disrupted, and can also lead to breakage of the liner. If we overtighten, the liner will begin to overheat and there will no longer be enough lubricant. Ultimately, the liner may completely melt and rotate, which will lead to a major overhaul of the engine.

Engine assembly

We wipe the crankshaft journals, cylinder bores and connecting rod bearing seats with a clean rag; by the way, they can also be degreased. We put new liners into the connecting rod and the cover, so that the antennae of the liners fit into the grooves.

Lubricate the bearings, crankshaft journals and cylinders with clean oil. We unfold the piston rings with locks as shown in the figure, the angle between them should be 120 degrees.

We put a mandrel on the piston to compress the rings, having previously lubricated it inside with clean oil. Not forgetting about the direction, the arrow on the piston should be directed towards the front of the engine, we place it in its cylinder.

We turn the crankshaft so that the connecting rod journal is at the very bottom. Gently tapping the wooden handle of a hammer pushes the piston into the cylinder. We remove the mandrel and push the piston down until the connecting rod sits on the crankshaft. We put the connecting rod bearing cap on the bottom, remembering the marks. Tighten the connecting rod cover mounting bolts to a torque of 5 kgf*m. We also repeat with all the other cylinders.

We put back everything that we removed from below. We blow through the top and clean the holes for the cylinder head mounting bolts. We install a new cylinder head gasket and the head itself. Lubricate the bolts with a thin layer of oil, most importantly without fanaticism. We tighten the bolts in several passes in the reverse order of unscrewing, see photo at the beginning of the article. The tightening sequence is as follows:

- first tighten everything with a torque of 2 kgf*m

- then we tighten everything to a torque of 7 – 8 kgf*m

- turn it 90 degrees

- turn it 90 degrees again

We install hydraulic compensators, camshafts and camshaft bearing caps. Lubricate all rubbing surfaces with clean oil. Before installing the camshaft bearing caps, lubricate the perimeter and rims around the spark plug wells with a thin layer of sealant. We tighten the bearing cover bolts in the reverse order of unwinding, with a torque of 2 kgf*m, see photo at the beginning. Well, then we install all the parts in the reverse order of removal. We fill in all the fluids and start it, it may not start right away, this is normal. When you first start it will smoke well until the oil on the cylinders burns, make sure the oil pressure light goes out. Let it run for a minute and turn it off, and suddenly see where something is leaking. We start it several more times, constantly increasing the operating interval, bring it to operating temperature, constantly checking the oil and antifreeze, and also pay attention to the fact that no extraneous noise appears. Let it rest for an hour and then idle again for about an hour, constantly monitoring the temperature. Well, then the break-in, if you sharpened it, if not, then you can drive only the first thousand kilometers, try not to raise the speed above 3000, and not tow it.

Everyone knows very well that the basis for the rotation of a car engine is the translational movement of the piston. But how does it make the crankshaft rotate? What allows up-and-down movement to turn into rotation? This is a connecting rod system. It is found in any internal combustion engine. Of course, she also works at Priora.

Removing and installing connecting rods on the Priora engine

The interesting thing is that, although this part is located almost in the middle of the engine, it can be removed without removing the engine from the car. Yes, this is, of course, not an easy operation, but it is quite doable. It must be carried out either in an inspection hole or on a special lift for cars so that there is access to the oil pan. When the vehicle is positioned for surgery, the engine compartment protection underneath is removed first. The cylinder head, engine sump and flywheel are dismantled. It is advisable to remove the oil intake so as not to damage it. You can start removing the connecting rods.

It is worth starting from the first cylinder. This is in order to put the details in order and not get confused. Rotate the Priora crankshaft so that the lower part of the connecting rod is level in the lower position. Unlock and unscrew the bolts securing the liner cover. Remove it and set it aside along with the liner itself. After this, push the piston up and remove it from the cylinder. One by one, remove all the Priora pistons and connecting rods in this manner. Now you can repair or replace elements.

Delivery by transport company

Delivery by one of the transport companies with a representative office in your city. Delivery time: 2-10 days depending on the distance of your locality from Togliatti. The most convenient and fastest way to deliver orders of different sizes. Delivery cost from 250 rub. depending on weight and delivery distance.

Orders are sent by transport companies based on 100% payment for the order. Dispatch by transport companies PEK, KIT, Baikal-Service is carried out on Wednesday, Thursday and Friday.

Source

Torque and sequence of tightening the camshaft bed

Camshaft cover tightening sequence

Correct tightening of the camshaft bed, as well as other parts of the cylinder head, determines the normal functioning of all components and assemblies. So, in order to tighten threaded connections, a standard tightening pattern and a torque wrench are used.

Before installing the bolts in place, they must be washed thoroughly and lubricated with silicone grease.

In order to properly tighten the bolts, you need to know the sequence. It starts from the middle part and gradually moves directly to the edges. The detailed sequence can be seen in the photo below.

Tightening diagram for each camshaft bed bolt with numbering

As for the tightening force itself, it is 8.0-10.0 Nm. After the bed is installed on the block head, the connection bolts are tightened by hand or without much force using a ratchet with a head.

We tighten all the bolts by hand, but do not tighten them

When all the bolts are in place, you need to take a torque wrench and tighten them according to the standards in the order indicated above.

Torque wrench for tightening threaded connections

In what cases is it necessary to tighten the camshaft bed?

The bolts are tightened. Marked with arrows

Tightening the camshaft bed will be necessary if it was previously dismantled for restoration and repair work. So, in what cases will you need to remove the bed, let’s look at it in more detail:

- Replacing camshafts, lifters or valve seals.

- Overhaul of the block head.

- Engine repair operations.

- Replacement of individual elements of the cylinder head.

Consequences of improper bed tightening

The consequences of improperly tightening the camshaft bed include the following:

- Oil leakage due to a gap or loose connection.

- Passing air inside the cylinder head.

- Malfunction of the engine or cylinder head.

- Ingress of foreign objects (water, dirt, dust).

Cylinder head repair

We mark all hydraulic compensators with numbers using an ordinary clerical touch and put them away. An ordinary magnet will help you pull them out. We dry out the valves and remove the oil seals (valve seals), the valves into scrap metal, the oil seals into the trash. We clean all channels. We take the head for grinding, just in case. After washing it again with kerosene after sanding and blowing it with air, we begin to assemble it.

We arrange the freshly purchased valves in the sequence in which they will stand in the cylinder head and begin to grind in one by one. Lubricate the valve stem with clean oil and apply lapping paste to the edge.

We insert the valve into place and put a valve grinding tool on the valve stem. The stores sell a device for manual lapping, but since this is the twenty-first century, we are mechanizing the process. We take the old valve and cut off the rod from it, select a rubber tube for it of such a diameter that it fits tightly. The rod is in a reversible drill, one end of the tube is on it, the other is on the valve being ground in. At low speeds we begin to grind the valve, constantly change the direction of rotation and periodically press it to the seat or weaken the force. On average, the valve takes about twenty seconds. We take it out and wipe it. The valve is considered ground in if a uniform gray strip of at least 1.5 mm wide appears on the chamfer.

The same stripe should appear on the valve seat.

Video of manually grinding valves

For a sixteen valve head, everything is the same, only there are twice as many valves. After lapping, all valves and seats are thoroughly wiped and washed with kerosene to remove any remaining lapping paste. We check for leaks. We tighten the old spark plugs and put all the valves in place. Pour kerosene and wait three minutes, if the kerosene does not run away all is well, otherwise we grind the valves on this cylinder.

We had to grind four valves again, after which the kerosene stopped flowing.

We stuff new valve seals.

We put the valves in place and dry them. Before doing this, lubricate the valve stems with clean oil. After lubricating it with clean oil, we put the hydraulic compensators in place and, covering them with a clean cloth, remove the head out of sight. We're done with the cylinder head.

Tighten the engine bolts correctly

All my life I have been surrounded by cars! First, in the village, already in the first grade, I was rushing around on a tractor through the fields, then there was JAVA, then a penny. Now I am a third-year student at the Polytechnic Faculty of Automotive Engineering. I work part-time as a car mechanic and help repair cars for all my friends.

In the table below we have indicated the tightening torques for all threaded connections on the VAZ-2112 engine.

Tightening torque of threaded connections (table)

| Detail | Thread | Tightening torque, N m (kgf m) |

| Engine | ||

| Cylinder head bolt | M12x1.25 | The cylinder head mounting bolts must be tightened in four steps: 1 – to a torque of 20 Nm (2 kgf); 2 – torque 69.4–85.7 (7.1–8.7 kgf); 3 – turn 90°; 4 – turn it 90° again. |

| Nut of the stud securing the intake pipe and exhaust manifold | M8 | 20,87–25,77 (2,13–2,63) |

| Tension roller nut | M10×1.25 | 33,23–41,16 (3,4–4,2) |

| Camshaft bearing housing stud nut | M8 | 18,38–22,64 (1,87–2,31) |

| Camshaft pulley bolt | M10 | 67,42–83,3 (6,88–8,5) |

| Accessory housing mounting bolt | M6 | 6,66–8,23 (0,68–0,84) |

| Nut of the stud securing the exhaust pipe of the cooling jacket | M8 | 15,97–22,64 (1,63–2,31) |

| Main bearing cap bolt | M10x1.25 | 68,31–84,38 (6,97–8,61) |

| Oil sump bolt | M6 | 5,15–8,23 (0,52–0,84) |

| Connecting rod cap bolt nut | M9x1 | 43,32–53,51 (4,42–5,46) |

| Flywheel bolt | M10x1.25 | 60,96–87,42 (6,22–8,92) |

| Coolant pump mounting bolt | M6 | 7,64–8,01 (0,78–0,82) |

| Crankshaft pulley bolt | M12x1.25 | 97,9–108,78 (9,9–11,1) |

| Coolant pump inlet pipe mounting bolt | M6 | 4,17–5,15 (0,425–0,525) |

| Muffler exhaust pipe fastening nut | M8×1.25 | 20,87–25,77 (2,13–2,63) |

| Nut securing the flange of the additional muffler | M8×1.25 | 15,97–22,64 (1,63–2,31) |

| Nut securing the clutch cable to the engine bracket | M12x1 | 14,7–19,6 (1,5–2,0) |

| Front engine mount bracket bolt | M10x1.25 | 32,2–51,9 (3,3–5,5) |

| Front engine mount bolt nut | M10 | 41,65–51,45 (4,25–5,25) |

| Nut of the bolt securing the left suspension support of the power unit | M10 | 41,65–51,45 (4,25–5,25) |

| Nut securing the bracket of the left suspension support of the power unit | M10 | 31,85–51,45 (3,25–5,25) |

| Bolt securing the rear suspension support of the power unit | M10x1.25 | 27,44–34 (2,8–3,47) |

| Nut of the power unit rear suspension bracket mounting bolt | M12 | 60,7–98 (6,2–10) |

| Bolt securing the oil receiver to the main bearing cover | M6 | 8,33–10,29 (0,85–1,05) |

| Bolt securing the oil receiver to the pump | M6 | 6,86–8,23 (0,7–0,84) |

| Oil pump mounting bolt | M6 | 8,33–10,29 (0,85–1,05) |

| Oil pump housing bolt | M6 | 7,2–9,2 (0,735–0,94) |

| Oil pump pressure reducing valve plug | M16x1.5 | 45,5–73,5 (4,64–7,5) |

| Oil filter fitting | M20×1.5 | 37,48–87,47 (3,8–8,9) |

| Oil pressure warning light sensor | M14x1.5 | 24–27 (2,45–2,75) |

| Carburetor mounting nut | M8 | 12,8–15,9 (1,3–1,6) |

| Cylinder head cover nut | M6 | 1,96–4,6 (0,2–0,47) |

Measuring tool

Despite the fact that performing work according to the tightening rules requires a special approach, such a procedure will not take a lot of time.

The only thing required to perform such work is a torque wrench.

This wrench is used to measure the tightening torque.

You can get such a tool in any store, but its price is often steep and can sometimes reach 2,000 rubles.

Let's start to disassemble

First, drain the oil and antifreeze. We remove the protective cover, the air filter with pipes, disconnect the ignition coil connectors, the throttle cable and the throttle assembly.

We remove the thermostat housing and simultaneously disconnect all the available connectors and pipes. We remove all the wiring that was in our way towards the battery.

We remove the generator. We unscrew the eight thirteen nuts holding the intake manifold and remove it. We unscrew all the bolts securing the valve cover, as well as the side engine support.

Unscrew the eight nuts and remove the exhaust manifold.

Remove the timing belt, camshaft pulleys and pump.

In three passes, so as not to deform the part, we first loosen and then unscrew twenty bolts of the camshaft bearing housing, the head is eight. Be sure to follow the sequence shown in the photo.

Remove the bearing housing. We remove the camshafts; there is a distinctive lip on the intake camshaft.

Also, in several passes, we first loosen and then unscrew the ten cylinder head mounting bolts. Be sure to follow the sequence shown in the photo.

Remove the cylinder head. All sixteen valves are replaced.

How to tighten main bearings and connecting rod bearings

So, taking into account the above, it becomes clear that the tightening torque of the main and connecting rod bearings is extremely important. Now let's move on to the assembly process itself.

- First of all, molar liners are installed in the bed of the molar necks. Please note that the middle liner is different from the others. Before installing the bearings, the preservative lubricant is removed, after which a little motor oil is applied to the surface. After this, the bed covers are placed, after which the tightening is carried out. The tightening torque should be that recommended for the specific model of the power unit. For example, for engines on the VAZ 2108 model, this figure can be from 68 to 84 Nm.

- Next, the connecting rod bearings are installed. During assembly, it is necessary to accurately install the covers in place. The specified covers are marked, that is, their arbitrary installation is not allowed. The tightening torque of the connecting rod bearings is slightly less compared to the main bearings (the indicator ranges from 43 to 53 Nm). For Lada Priora, the main bearings are tightened with a torque of 68.31-84.38, and the connecting rod bearings have a tightening torque of 43.3-53.5.

Connecting rods 21126 Priora SPORT (reinforced)

For connecting rod bearings 2101

The approximate weight of one connecting rod complete with bolts is 425 grams

*For comparison, attached are photos with a standard connecting rod.

‘>

Priora SPORT connecting rods have the following differences from the VAZ connecting rod 21126: Axial fixation of the connecting rod is made along the crankpin of the crankshaft, so the width of the lower head of the connecting rod is greater. A solid bronze bushing with a developed system of oil supply grooves is pressed into the upper head of the connecting rod. The upper head of the connecting rod has a smaller width than the original connecting rod. The upper head has two oil supply holes instead of one in the original. The material from which the connecting rod is made has a greater tensile strength and better withstands shock loads due to greater compliance. The lower head cover is secured with pins. Pistons that have a relatively small height and a T-shaped guide part (skirt), with cutouts in the plane of the piston pin (namely, these are the original pistons 21126) are prone to distortions relative to the cylinder axis in this plane. Centering the connecting rod on such a piston leads to a misalignment of its lower head relative to the connecting rod journal of the crankshaft, which negatively affects the service life of the connecting rod bearing. The use of the design according to claim 1 eliminates such problems. The increase in bearing life in the connecting rod-pin connection is facilitated by the design elements of the Priora SPORT, described in paragraphs 2 and 3. The width of the upper head of the Priora SPORT connecting rod, which is smaller than that of the original 21126, reduces the mass reduced to the piston pin axis. Thanks to this, vibration is reduced, friction losses in the piston-cylinder pair are reduced, and the piston life is increased.

For connecting rod bearings 2101

The approximate weight of one connecting rod complete with bolts is 425 grams

*For comparison, attached are photos with a standard connecting rod.

Payment to Sberbank VISA card

The most convenient and profitable payment method for you. Payment can be made through the Sberbank Online system, through a payment terminal (Sberbank ATM), provided that you have a card from this bank. If you are not a client of this bank and you do not have a card, then you can top up your balance at any bank branch through an operator; they will accept cash payment and top up your balance. Commission from 0 to 1%

Payment to Alfa-Bank card

Cash on delivery (payment upon receipt)

Payment for the order will be made at the post office upon receipt of the goods. For cash on delivery services, Russian Post takes an additional commission - approximately 4% of the cost of the order (parcel) upon receipt.

The postal commission based on the amount of “Cash on Delivery” for your parcel is described below, i.e. In addition to the delivery cost, the post office will also charge you a commission for .

Postal commission for cash on delivery service:

· up to 1,000 rub. inclusive - 80 rub. + 5% of the amount

· over 1,000 to 5,000 rubles. inclusive - 90 rub. + 4%

· over 5,000 rub. up to 20,000 rub. inclusive -190 rub. + 2%

· over 20,000 rub. up to 500,000 rub. inclusive - 290 rub. + 1.5%

Attention! Advance payment for delivery 100% (via Sberbank payment). This is included in our Cash on Delivery terms.

Check with the manager for additional information.

Yandex money.

This payment method involves issuing an invoice in the Yandex.Money system.

You will be able to pay from your Yandex.Money wallet. ATTENTION

! There are restrictions on the payment amount: anonymous wallet 15,000 rubles, registered wallet 60,000 rubles, identified wallet 250,000 rubles. After payment you will receive an electronic cash receipt.

Transfer via Western Union

QIWI Wallet.

This payment method involves issuing an invoice in the QIWI system.

You will be able to pay from your QIWI wallet. ATTENTION

! There are restrictions on the payment amount: RUB 250,000. After payment you will receive an electronic cash receipt.

Payment to a bank account for legal entities and individual entrepreneurs (excluding VAT).

This payment method is intended only for legal entities and individual entrepreneurs. After placing your order, send your organization details to [email protected] In the subject line of the email, please include your order number.

After this, the manager will send an invoice via email in the prescribed form. We work without VAT. Payment method commission - 6%

.

Attention! Regardless of which delivery method you choose, check the integrity of the goods and packaging upon receipt of the cargo (parcel).

After submitting your order to the terminal of the transport company/Russian post office, a track number will be sent to the phone number and email specified in the order, if available, to track the parcel.

Delivery by Russian Post (payment by Sberbank)

Delivery terms

5-21 days depending on the distance of your locality from Togliatti,

cost

from 250 rubles.

depending on the weight, distance and declared value of the parcel (order). 100% prepayment of delivery in advance excludes commissions charged by the post office for cash on delivery.

Official delivery website: https://www.pochta.ru/

Delivery by Russian Post (1 CLASS)

Delivery terms

5-21 days depending on the distance of your locality from Togliatti

100% Advance payment of ORDER + DELIVERY

.

cost

will be announced by the manager when confirming the order. Official delivery website: https://www.pochta.ru/

Russian Post (payment upon receipt)

Delivery terms

5-21 days depending on the distance of your locality from Tolyatti

Cost

from 250 rubles. depending on the weight, distance and declared value of the parcel (order). Official delivery website: https://www.pochta.ru/

EMS company

is a division of Russian Post, part of the global EMS (Express Mail Service) system. Express delivery worldwide.

Delivery terms

from 3-7 days.

Cost

from 550 rubles. Official delivery website: https://www.pochta.ru/emspost/

Removing and installing connecting rods on the Priora engine

The interesting thing is that, although this part is located almost in the middle of the engine, it can be removed without removing the engine from the car. Yes, this is, of course, not an easy operation, but it is quite doable. It must be carried out either in an inspection hole or on a special lift for cars so that there is access to the oil pan. When the vehicle is positioned for surgery, the engine compartment protection underneath is removed first. The cylinder head, engine sump and flywheel are dismantled. It is advisable to remove the oil intake so as not to damage it. You can start removing the connecting rods.

It is worth starting from the first cylinder. This is in order to put the details in order and not get confused. Rotate the Priora crankshaft so that the lower part of the connecting rod is level in the lower position. Unlock and unscrew the bolts securing the liner cover. Remove it and set it aside along with the liner itself. After this, push the piston up and remove it from the cylinder. One by one, remove all the Priora pistons and connecting rods in this manner. Now you can repair or replace elements.

Malfunctions: causes, elimination

Like all internal combustion engines with mechanical adjustment of valve clearances, the 11186 engine requires periodic adjustment of this characteristic. In addition, during operation, characteristic “diseases” of this particular version of the power drive were identified:

| Timing belt | 3/50 |

| battery | 1/20 |

| Valve clearances | 2/20 |

| Crankcase ventilation | 2/20 |

| Belts that drive attachments | 2/20 |

| Fuel line and tank cap | 2/40 |

| Motor oil | 1/10 |

| Oil filter) | 1/10 |

| Air filter) | 1 – 2/40 |

| Fuel filter) | 4/40 |

| Heating/Cooling Fittings and Hoses | 2/40 |

| coolant | 2/40 |

| Oxygen sensor | 100 |

| Spark plug | 1 – 2/20 |

| Exhaust manifold | 1 |

| Bend valves | broken timing belt | periodic wear monitoring |

| Ignition system interruptions | failure of the corresponding block | replacing the ignition module |

| Increased oil consumption | development of main liners |

When repairing piston and crankshaft engines, it is recommended to use original components from the AvtoVAZ manufacturer. Because only he uses special technologies for strengthening structural materials. From third-party companies, the metal may be “raw”; the resource of such consumables cannot be analyzed.

Removing the valve cover of Priora 16 valves

The work is shown on the 21124 engine. Features of removing the cylinder head cover from the 2112 cm engine are in the text.

To complete the work you will need a 10 mm wrench,

8 mm socket wrench

1. We prepare the car for work (see “Preparing the car for maintenance and repair”).

2. Remove the air filter (see “Air filter - removal and installation”).

3. Remove the decorative trim of the engine (see “Decorative trim of the engine - removal and installation”).

4. On engine 21124

remove the ignition coils (see “Ignition coils of engine 21124 (1.6i 16V) - check and replacement”), on engine 2112

remove the ignition module (see “Engine ignition module 2112 (1.5i 16V) - check and replacement”).

5. Remove the intake pipe on engine 21124

(see “Intake pipe of engine 21124 (1.6i 16V) - removal and installation, replacement of o-rings”), on engine 2112

remove the receiver (see “Engine receiver 2112 (1.5i 16V) - removal and installation”) and disconnect the crankcase ventilation hose from the cover pipe.

Installation

Place the prepared groups in place also through the top of the cylinder. Carefully check and replace the connecting rod bearings. Install the lower elements - covers, and secure with bolts.

Attention! Now here's a very important aspect. The tightness of these bolts makes a huge difference! Perform this work only with a torque wrench!

This is due to the fact that a lot depends on the tightening torque: both the freedom of rotation of the crankshaft, and at the same time the tightness of the fit of the liners to the neck of this shaft. If it is weak, oil will leak out without proper lubrication, and if it is strong, it will jam and, again, insufficient lubrication. Based on these considerations, this value should be exactly 43.32-53.51N*m or another 4.42-5.46 kgf*m. Only this way and no other way. After this, you can perform complete assembly in reverse order.

Interesting video about Priora connecting rods:

- How the start-stop system works

- Microprocessor ignition system for carburetor engines

- Adjusting carburetors K151 and K126

- Carburetor design, operating principle

Engine Lada Granta

If there is engine oil or coolant leaking from the cylinder head to cylinder block joints, remove the cylinder head and replace the cylinder head gasket. Leaks can also occur due to deformation of the block head due to overheating; the head gasket of the VAZ-11183 engine is made of metal-asbestos fabric, and on the VAZ-21116 and VAZ-11186 engines it is made of metal. The procedure for replacing the gasket on all three engines is the same and is shown using the example of a VAZ-11183 engine (8 valves). Replacing the cylinder head gasket of a VAZ-21126 cylinder block (16 valves) is described separately, see the article “Replacing the cylinder head gasket on a Lada Priora car”

To replace the cylinder head gasket of VAZ-11183, VAZ-21116 and VAZ-11186 engines, follow these steps: You will need: a torque wrench, keys “13”, “17”, “19”, socket heads “10”. "," 13 ", " 17 ", hex key at "10", screwdriver.

The head gasket is disposable, so it must be replaced every time the head is removed. 1. Move the piston of the 1st cylinder to the TDC position of the compression stroke (see “Setting the piston of the 1st cylinder to the TDC position of the compression stroke”). 2. Reduce the pressure in the fuel system when carrying out work immediately after a trip (“Reducing fuel pressure”). 3. Disconnect the cable from the negative terminal of the battery. 4. Drain the coolant (see “Replacing the coolant”); 5. Remove the air filter (see “Removing and installing the air filter, air supply hose and air intake”). 6. Disconnect the air intake tube and wire block from the throttle assembly (see “Removing and Installing the Throttle Assembly”). 7. Disconnect the high-voltage cable ends from the spark plugs. 8. Disconnect the wire block from the oil pressure warning switch... 9. engine coolant temperature sensor...

10 . and a phase sensor.

11. Remove the cylinder head cover

12. Remove the front cover of the timing gearbox (see “Installing the piston of the first cylinder at TDC of the compression stroke”).

13. Loosen the camshaft pulley mounting bolt while holding the camshaft so that it does not rotate (this can be done by inserting a large screwdriver or setting blade into the holes in the pulley hub).

14. Remove the timing belt (see “Replacing the timing belt and tensioner pulley”).

15. Finally, remove the camshaft pulley bolt...

16 . and remove the pulley.

If the pulley on the shaft has an interference fit, use a puller (see picture below)

17. Remove the rear cover of the timing drive 18.0 and disconnect the line from the coolant temperature gauge.

19. Loosen the clamps and disconnect the five coolant hoses from the thermostat connections.

20. Unscrew the nut securing the ground terminal...

If the pulley is tightly seated on the end of the shaft, press it with a universal puller, pressing the pulley screw against the pulley mounting bolt previously screwed into the shaft (to avoid damaging the shaft threads). 21. and remove the wire.

22. Disconnect the injector harness assemblies and disconnect the fuel line from the fuel line (see "Removing and Installing the Fuel Line"). 23. Disconnect the brake booster hose from the intake module fitting by loosening the clamp securing it.

24. Disconnect the upper ends of the spacers from the exhaust manifold 25. Disconnect the oxygen concentration sensor wire blocks and remove their wire holders from the holes in the heat shield 26 of the steering mechanism. Disconnect the front exhaust pipe of the auxiliary muffler from the manifold flange and disconnect the steering gear holder bracket from the cylinder block manifold. 27. Loosen the ten bolts holding the cylinder head in the order shown in the photo...

28. Finally unscrew the head mounting bolts and remove them along with the washers.

29. Remove the cylinder head.

Do not insert a screwdriver or other tools between the cylinder head and the cylinder block.

To remove the cylinder head from the gasket, insert a screwdriver under the manifold and, using it as a lever, lift the head. It is more convenient to remove the cylinder head with an assistant, since it is quite heavy. 30. Remove the cylinder head gasket.

31. Clean the mating surfaces of the cylinder head and cylinder block (must be dry and clean) and remove oil from the threaded holes in the block for the head bolts.

If the oil is not removed from the head bolt threaded holes, cracks may appear in the cylinder block when the bolts are tightened because the oil does not compress.

32. Check the presence of two support bushings in the seats of the outer holes of the cylinder block for the head bolts. If, when removing the head, the bushings remain in the head or protrude from the block bodies, press them into the block until they stop. 33. Install a new cylinder head gasket onto the block (the gasket must be dry and clean) over the mounting bushings. In this case, the hole for the passage of oil in the gasket of the VAZ-11183 engine (with a copper rim) should be located between the 3rd and 4th cylinders.

34. Install the cylinder head onto the cylinder block, making sure that the crankshaft and camshaft are in the TDC position (both valves of the 1st cylinder must be closed). Tighten the head bolts in four steps:

1st - torque 20 Nm; 2nd - torque 69.4-85.7 Nm; 3 ° - turn the bolts 90 °; 4 ° - finally tighten the bolts 90 °, 35. Install the removed parts on the cylinder head and connect the hoses and cables in the reverse order of removal. Install the camshaft pulley so that the protruding part of the hub faces the engine.

36. Check and, if necessary, adjust the clearances in the valve drive (see “Adjusting the clearances in the valve drive of VAZ-11183, VAZ-21116 and VAZ-11186 engines”). 37. Adjust the timing belt tension.

Car: VAZ-2112. Asks: Kirillov Maxim. The essence of the question: what is the tightening torque of the bolts on the VAZ-2112?

Goodbye! Please tell me at what point you need to tighten the bolts on the VAZ-2112? I'm interested in the threaded connections on the motor!

Errors when installing the head

If you do not use a torque wrench when installing the cylinder head, you may make a mistake with the force, which will lead to uneven torque. In such cases, there will be excessive or insufficient force, which will result in either deformation of the head surface or allow the breakthrough of gases, oil or coolant. In both cases, this is fraught with serious consequences for the engine.

If you follow the rules for tightening the fastening bolts, as well as the required torque, you can always count on reliable and durable operation of the installed parts. The gas distribution mechanism in the engine plays a major role, so you should not neglect the rules for installing the component elements.

Cylinder head

- The camshafts are new from the factory.

- Aluminum timing gears with adjustment.

- AMP valves are nitrided. They are resistant to high temperatures.

- Bronze valve guides and valve seats. Bronze has the ability to dissipate heat.

- Valve seals Victor reinz.

- Standard valve springs.

- The empty cylinder head is ground to a smooth surface and protrusions in the bores are removed to obtain a smooth surface.

- I recommend purchasing cylinder head bolts from a Fiat car from Payen. They are able to maintain high compression throughout their entire service life.

Engine tuning using connecting rods

Most young people who purchase a Priora are not satisfied with the factory parameters of the car. Many people strive to improve their car. Make it more powerful, more responsive and faster. This is called "charging" the engine. That is, as they also say, make tuning. This concept includes many different actions.

The most popular for such an operation are the so-called “sports” reinforced connecting rods, 131 mm long. They are included in the standard kit for improving the Priora engine.

Priora connecting rod dimensions

By pushing the piston up along its entire length, the connecting rod strictly fixes the volume of the combustion chamber. From this we can conclude that the volume of the working cavity of the cylinder itself, in which the fuel burns, also depends on its length. That is, as the length increases, the volume will become smaller. And if you shorten it, the size of the camera will increase accordingly. The factory engine comes with the stock connecting rods. They are 150 millimeters. It is measured from the center point of the head (pin mounting) to the same line as the base attached to the crankshaft. This size provides the engine with standard factory parameters. For example, moving the engine. This is 1597 cubic centimeters. Or, as the owners say, the engine is “one and six”.

What cars was it used in?

Created in 2011, the 11186 engine is used as a power drive for several models of the auto manufacturer AvtoVAZ:

- Lada Kalina II – station wagon, sedan;

- Lada Granta (Lux and Norma equipment) – liftback, sedan;

- Lada Priora – sedan, station wagon, hatchback;

- Lada Largus – minivan, station wagon, van;

- Lada Vesta - station wagon;

- Lada XRay is a compact crossover/high hatchback.

Improved engine characteristics allow it to be used on any front-wheel drive car in the event of a swap rather than engine tuning.

In what cases is it necessary to tighten the block?

Tightening the bolts is necessary first after you have removed the cylinder head and are installing it again. Also, tightening can help in some cases if it has become loose during operation and there is a need to tighten it. In some cases, for example, when the gasket starts to leak a little, this can help.

Sources

- https://TrueScooters.ru/vidy-dvigatelej/moment-zatyazhki-shatunov-priora-16-klapanov.html

- https://medwegonok.ru/momenty-zatyazhki-shatunov-priora-16-klapanov-126-dvigatel/

- https://GrandFart.ru/motor/moment-zatyazhki-boltov-koles-priora.html

- https://5star-auto.ru/s-kakim-usiliem-zatyagivat-shatuny-na-priore/

- https://medwegonok.ru/moment-zatyazhki-kolenvala-lada-priora-16-klapanov/

- https://maslo-5w30.ru/avto/moment-zatyazhki-bolta-shatuna-21126-priora

- https://avtocranarenda.ru/momenty-zatyazhki-rezbovykh-soedineniy-priora-21126/