Automatic transmissions are becoming increasingly popular in our country, and the share of cars with automatic transmission is growing rapidly.

Automatic transmissions transmit torque from the engine to the wheels of the car, automatically increasing or decreasing the gear ratio, adapting to optimal engine operating conditions. The classic automatic transmission consists of a torque converter and a number of planetary gears. The automatic transmission, smoothly shifting gears, provides the car with a smooth ride and makes driving a pleasure. In our article, we will look at the design and operating principle of an automatic transmission, list the main types of automatic transmissions, get acquainted with the operating modes, and analyze the advantages and disadvantages of automatic transmissions.

What is automatic transmission

An automatic transmission (AT) is a transmission that independently determines the most appropriate gear ratio depending on the current speed limit. The automatic transmission, without driver intervention, selects and switches the desired gear ratio, adapts to the speed set by the driver, and ensures a smooth start and smooth ride of the vehicle. The automatic transmission removes the lion's share of the load from the driver while driving compared to a classic manual transmission.

Since there are now different options for automatic transmissions (robots and CVTs), to avoid confusion, automatic transmissions are also called: classic automatic, hydraulic automatic, hydromechanical transmission, planetary automatic.

The history of the automatic transmission

The idea of creating an automatic transmission belongs to the German engineer Hermann Fettinger, who developed the first torque converter in 1902, and at first such a transmission was used only for the construction of ships.

The first car equipped with a planetary automatic transmission was the American Ford T. After the release of this car, the most active role in the development of automatic transmissions was played by General Motors, which managed to release a semi-automatic transmission in the mid-1930s. The same GM created the first completely automatic transmission in 1940

Automatic communism: how automatic transmission was developed in the USSR

At the end of the last century, domestic motorists saw with their own eyes unprecedented automotive options - electric mirrors and windows, air conditioners and automatic transmissions, which in our time have become commonplace even in the budget segment. But it’s curious that similar “bells and whistles” were also found on Soviet cars! Today we will talk about the history of the appearance and technical features of automatic transmissions on Soviet passenger cars.

Start

Back in the thirties, the USSR began to seriously study hydraulic couplings and torque converters, for which the Bureau of Hydraulic Gearboxes was created in Leningrad.

Automatic transmission device

An automatic transmission has a complex structure and the mechanism itself, through which gear shifting is ensured, is complex. The essence of this process comes down to turning the clutches and brakes on and off using the pressure of the working fluid.

There are several types of automatic transmissions that have some differences in design, but their basic elements are the same.

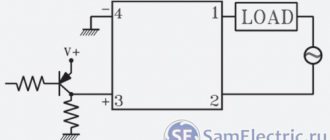

- Hydraulic transformer (torque converter)

. It is a metal body that is filled with a special working ATF fluid (oil). Its main task is to transmit rotation from the engine to the gearbox. In fact, this is an analogue of the clutch in a manual transmission. Consists of pump, turbine and reactor wheels, locking clutch and freewheel. The wheels have blades with holes for the circulation of working fluid. A freewheel is needed so that the reactor wheel can rotate in the opposite direction. The lock-up clutch allows you to lock the torque converter under certain vehicle operating conditions. - Planetary mechanism.

This is a gearbox that changes speeds as a result of changing the gear ratio on the gears. Consists of: planetary gears (sun gear, satellites, ring gear, carrier), shafts, drums with friction clutches, overrunning clutch and band brake. Blocking one of the elements of the planetary gear leads to the transmission of rotation and a change in torque. The planetary gear set can be locked by a band brake, an overrunning clutch and friction clutches. The planetary gear acts as a block of gears in a mechanical box. - Hydraulic system

. Consists of an oil pump, filter, pushers, hydraulic distributor. The working fluid creates working pressure in the box and protects internal elements from overheating and corrosion.

- Electronic control unit.

Collects incoming information from pedals, ABS and ESP systems, sensors, automatic transmission knob and other systems, processes it. Then it generates signals that are sent to the valve body actuator valves. The control unit regulates the operation of the friction clutches and directs the flow of working fluid to one or another clutch, which leads to a speed change. That is, the control unit is literally the “brain” of the automatic transmission; it controls the gearbox. A breakdown of the control unit leads to the machine switching to emergency mode.

Operating principle and service life of automatic transmission

When the engine starts, transmission oil enters the torque converter, the pressure inside increases, and the blades of the centrifugal pump begin to rotate.

This mode provides for complete immobility of the reactor wheel along with the main turbine.

When the driver shifts the lever and presses the pedal, the speed of the pump blades increases. The speed of the vortex oil flows increases and the turbine blades are launched. The liquid is alternately transferred to the reactor and returned back to the turbine, increasing its efficiency. Torque is transmitted to the wheels, and the vehicle begins to move.

As soon as the required speed is reached, the bladed central turbine and the pump wheel begin to move at the same time. The oil vortices enter the reactor wheel from the other side, since movement can only be in one direction. It starts to spin. If the car goes up, the wheel stops and transmits more torque to the centrifugal pump. Achieving the required speed leads to a gear change in the planetary gear.

At the command of the electronic control unit, the braking band with clutches slows down the lower gear, which leads to an increase in the movement of oil flows through the valve. Then the higher gear is accelerated, its change is made without loss of power.

If the machine stops or its speed decreases, the pressure of the working fluid also decreases and the gear shifts down. After turning off the engine, the pressure in the torque converter disappears, which makes it impossible to start the car from the pushrod.

The weight of the automatic transmission reaches 70 kg when dry (there is no hydraulic transformer) and 110 kg when filled. In order for the machine to function normally, it is necessary to control the level of the working fluid and the correct pressure - from 2.5 to 4.5 bar.

The resource of the box may vary. In some cars it lasts about 100,000 km, in others - more than 500,000 km. The service period depends on how the driver monitors the condition of the unit and whether he replaces consumables on time.

Comparison of automatic transmission with manual transmission

In the modern world, “mechanics” are slowly but surely losing ground to their more progressive counterpart - automatic transmission. Automatic transmissions provide smoother and more economical engine operation and smoother running of the machine.

The driver is not required to constantly monitor the speed and engine speed in order to engage the desired gear in time. The automatic will do everything for him, which is especially convenient when driving around the city, and extremely convenient if you are in a traffic jam.

The driver does not need to devote the lion's share of his attention to driving the car. Although there are drivers who like a manual transmission, which allows them to enjoy the continuous physical process of driving the car and complete control of the ride.

Pros and cons of automatic transmission

An automatic transmission has its advantages and disadvantages, which you need to know before buying a car with an automatic transmission or switching from a manual transmission to an automatic transmission.

Pros of automatic transmission

- Simplicity and ease of control, as there is no need to manually switch speeds. The driver only controls the steering wheel and presses the gas and brake.

- The third pedal, the clutch, is missing.

- It's easier to get moving in a car with an automatic transmission.

- Smooth gear shifting and high efficiency.

- High reliability of modern automatic transmissions.

- Inability to “burn out” the clutch and no need to periodically replace the clutch.

Disadvantages of automatic transmission

- Manual transmissions are more economical than automatic transmissions. A car with an automatic transmission consumes about 10-15% more fuel. Although the gradual improvement of machines leads to a decrease in this indicator.

- Automatic transmissions are much more expensive than manual transmissions to maintain and repair. If the machine breaks down and needs to be completely replaced, it will cost a significant amount (up to a third of the cost of a used car).

- The impossibility of rapid acceleration and a sharp increase in speed, which is especially felt when overtaking at a limited distance or in dense oncoming traffic, that is, when you need to overtake very quickly. This problem is partially solved by turning on the sports mode.

- The automatic limits the individual driving experience, unlike manual cars where the driver has complete control over the ride.

- Inability to push start the car.

- The machine can quickly fail if used incorrectly.

- An automatic car has towing limitations, and these are things you need to know before towing another car or trailer.

Further development of the automatic transmission: the evolution of the hydromechanical automatic transmission

Before we get to the automatic transmission, we need to mention the Wilson transmission. The driver selected a gear using the steering column switch, and activation was done by pressing a separate pedal.

This transmission was the prototype of a preselective gearbox, since the driver selected a gear in advance, and it was engaged only after pressing the pedal, which stood in place of the manual transmission clutch pedal.

This solution facilitated the process of driving the vehicle; gear shifting required a minimum of time compared to manual transmissions, which in those years did not have synchronizers. At the same time, the significant role of the Wilson gearbox lies in the fact that it is the first gearbox with a mode switch, which resembles modern analogues (PRND modes).

This transmission consisted of a torque converter (fluid coupling) and a planetary gearbox with automatic hydraulic control. The control was implemented taking into account the speed of the vehicle, as well as the throttle position.

The Hydra-Matic gearbox was installed on both GM models and Bentley, Rolls-Royce, Lincoln, etc. In the early 50s, Mercedes-Benz specialists took this box as a basis and developed their own analogue, which worked on a similar principle, but had a number of differences in terms of design.

In the 80s, a trend towards a constant increase in the number of programs began to be observed. In automatic transmissions, fourth gear first appeared, that is, overdrive. At the same time, the torque converter locking function began to be used.

Also, four-speed automatic transmissions began to be controlled by an ECU, which made it possible to get rid of many mechanical controls, replacing them with solenoids.

For example, Toyota specialists were the first to implement an electronic control system for an automatic transmission in 1983. Then, in 1987, Ford also switched to using electronics to control the overdrive gear and the lock-up clutch of the gas turbine engine.

To achieve this, the total number of gears is increasing, and the switching speed has become very high. Today you can find automatic transmissions that have 5, 6 or more “speeds”. The main task is to successfully compete with preselective robotic gearboxes such as DSG.

At the same time, there is a constant improvement of automatic transmission control units, as well as software. Initially, these were systems that only determined the moment of gear shifting and were responsible for the quality of switching.

Later, it became possible to manually control an automatic transmission (for example, Tiptronic), when the driver can independently determine the moments of gear shifting, like a manual transmission. Additionally, the automatic transmission has received expanded capabilities in terms of self-diagnosis, transmission fluid temperature control, etc.

Driving a car with an automatic transmission: how to use an automatic transmission, operating modes of an automatic transmission, rules for using this transmission, tips.

How an automatic transmission works: classic hydromechanical automatic transmission, components, controls, mechanical part. Pros and cons of this type of gearbox.

Automatic transmission torque converter (torque converter, gas turbine engine). Purpose, design of the torque converter, operating principle and features.

Automatic transmission solenoid: design of solenoids, operating principle. Frequent malfunctions and breakdowns of solenoid valves, diagnostics, repair and replacement.

Automatic transmission (automatic transmission, automatic transmission) of the “classic” type with a torque converter: device and principle of operation. Pros and cons of hydromechanical automatic transmission.

Automatic transmission slipping when changing gears: the main reasons why an automatic transmission slips. Box diagnostics, troubleshooting.

The beginning of the 20th century was rich in inventions in the field of mechanical engineering, and it is quite difficult to say who was the first to come up with an automatic transmission. The creation of an automatic transmission is assigned to several people. The world's first vehicle equipped with a full-fledged automatic transmission was a Swedish-made Lysholm-Smith bus. It was a one-off piece that was invented and designed in 1928. The installation of an automatic transmission in mass production was first carried out on the Buick Roadmaster in 1947.

Types of automatic transmission

There are now three types of automatic gearboxes:

- classic automatic transmission

. When they say automatic transmission, they mean this particular type of gearbox, and in this article we are talking about this type. They are installed on most modern cars and trucks, although the other two types are gradually increasing their presence in the car market. - Robot

(robotic gearbox). It is one of the automatic transmission options. Its main feature is the presence of a clutch, which ensures quick gear changes without loss of engine power. The robot has input and output shafts, which are combined using gears, which leads to speed switching; they are controlled by a synchronizer. The robotic gearbox is usually controlled by a special electronic control unit, but can also be controlled by the driver. - The variator

does not have fixed gears, so speed shifting is very smooth. The speed mode is switched using cone-shaped pulleys at the input and output of the box. The belt connection ensures the movement of the nodes. The planetary gear is responsible for reversing. The CVT has the highest efficiency of all automatic transmissions.

...to the "member carrier"

ZIL-111

ZIL-111

The second serial passenger automatic machine after the Volga was installed on the ZIL-111 in 1958. The two-stage unit was essentially a copy of the Power Flite gearbox that had been available on Chrysler and Imperial cars since 1952. ZIL was a piece production car. The boxes were regularly and carefully maintained and set up on a special stand. The same units were installed on Yunost piece minibuses.

ZIL-114

ZIL-114

Two-stage automatic machines were installed on the ZIL-114, which was made since 1967, and on all its modifications.

Automatic transmission selector ZIL-4104

Automatic transmission selector ZIL-4104

Since 1985, three-speed automatic transmissions have been installed on cars of the ZIL-4104 family. These units, already ungodly outdated in the 1980s, lasted until the end of production of Moscow “member carriers” in the early 2000s.

Controlling the gearbox on the GAZ-14 Chaika

Controlling the gearbox on the GAZ-14 Chaika

The automatic machine from the Chaika GAZ-13 migrated to the 1976 GAZ-14. But on this Chaika the box was no longer controlled by buttons, but by a traditional floor lever.

Operating principle of automatic transmission

When the engine starts, the automatic transmission is activated by turning on the oil pump, which creates operating pressure inside the transmission. After this, the hydraulic transformer is started, which spins up to the speed of the crankshaft.

When you press the gas pedal and switch the automatic control knob, oil rushes to the turbine, which begins to rotate. The operation of the automatic transmission radiator prevents overheating of the transmission oil. The control unit collects all incoming information from the degree of pressure on the gas pedal and various vehicle sensors, processes it and sends a signal to the hydraulic unit, where, by moving the clutches and brakes, the gear ratio is changed, the most optimal in the given specific conditions.

The oil that fills the internal cavity of the automatic transmission is essential for its efficient operation. You need to monitor the oil level so that it is not too much or too little. The operating oil pressure is 2.5-4.5 bar.

The operating temperature of the oil is 80ºC, so before starting to drive the car should be warmed up a little, which is especially important in winter to avoid damage to the plastic elements of the box.

Oil cooling most often occurs due to a liquid radiator, less often - an air radiator. An unfilled automatic transmission and without a torque converter weighs on average about 70-80 kg. After refueling, its total weight can reach 110 kg.

Who invented the automatic transmission and when did the first automatic transmission appear?

As you know, the transmission is the second most important unit after the internal combustion engine. At the same time, the appearance of automatic transmission was a real breakthrough, since thanks to such a gearbox, not only comfort, but also safety when driving a car is significantly increased.

Such a gearbox is a system consisting of a torque converter (GDT) and a planetary gearbox. The principles and basics of planetary gearing were known back in the Middle Ages, and the torque converter was created by the German Hermann Fettinger at the beginning of the 20th century.

Sarafyan was born in 1895. His family ended up in the United States as a result of the infamous Armenian Genocide, which took place in the Ottoman Empire. Having settled in Chicago, Asatur Sarafyan changed his name, becoming Oscar Banker.

The talented inventor created various useful devices, among which there are several solutions that are indispensable today (for example, a grease gun), but his main achievement is the invention of the first automatic hydromechanical gearbox. In turn, General Motors (GM), which previously installed a semi-automatic transmission on its models, was the first to switch to automatic transmission.

Automatic transmission resource

There is no exact value for the service life of an automatic transmission. This will depend on the correct operation of the car with automatic transmission, timely maintenance of the gearbox: changing the oil and oil filter, using original spare parts and oil. Some models of automatic transmissions are designed for 100-150 thousand mileage, modern car models are equipped with automatic transmissions designed for 500 thousand km or more, and do not require an oil change.

You can read more about changing the oil in automatic transmissions in our article: Changing the oil in automatic transmissions

Automatic transmission operating modes

If you have never driven a car with an automatic transmission, you must first find out what operating modes the box has, how they are indicated on the panel and how to use them. Improper operation can lead to box failure and costly repairs.

All control of the gearbox is carried out through the handle; its certain position turns on a certain operating mode. On different automatic transmission models, the number of modes may be different.

Basic operating modes of automatic transmission

- P - Parking . It is analogous to a handbrake on a manual transmission. This mode is activated when the car is parked. In this position of the handle, the front drive wheels are blocked not by pressing the brake pads, but by blocking the transmission output shaft.

- N - Neutral (neutral position) . The wheels and shaft are not locked, but are not connected to the engine either. In this position, the car can coast. If you leave the car in the parking lot in this position, the car may roll downhill, so you should not park the car in this mode. This position is used when towing a vehicle.

- R - Reverse (reverse speed). Enables reversing. In order to move in reverse, you need to press the brake pedal, move the selector to the “R” position, release the brake, press the gas.

- D or A—Drive or Automat (main driving mode) . Used while driving in automatic gear shift mode.

- L or B or number 1 - Low (low gear mode) . An analogue of first gear on a manual transmission, which involves driving at a reduced speed. On some models, mode B enables differential locking.

- M - Manual (manual gear shift mode). It is used when the driver needs to engage the desired gear himself. It works in a similar way to a manual transmission, only in a more simplified version. The gearbox is controlled in this mode using special “+” and “–” buttons (steering wheel paddles).

- S or PWR - Sport or Power (sports mode). In this mode, gear changes occur at high engine speeds without loss of speed. Implies the ability to quickly accelerate and gain speed, for example when overtaking. Also used for active driving at maximum engine speeds.

- O/D - OverDrive. Overdrive is an overdrive; this mode is analogous to fifth gear in a manual transmission. The overdrive mode is used when driving outside the city at a steady speed above 50 km/h, or when driving at high speed. It saves fuel consumption.

- D3 or O/D OFF - disables overdrive.

- W or S or number 2 - Winter or Snow (winter riding) . This means starting from a stop and driving no higher than second speed. Used in winter under poor road conditions.

- «3» – driving mode is not higher than third gear.

- E - Economic (economical mode).

- Shift lock - button to unlock the gearbox selector when the engine is off. The automatic transmission is automatically locked when the engine is turned off. That is, in order to move the selector to the Drive position from the Parking position, you must first start the engine; this cannot be done with the engine turned off. But if you press the Shift lock button, you can move the selector to any position. During normal operation of the automatic transmission, it is better not to use this button; it is intended for mechanics who repair automatic transmissions.

- Kick-down - “kick down”. Something like a low gear for the “mechanics”. Pressing this button allows you to quickly gain high speed by shifting to a lower gear. The button is located under the gas pedal. When you sharply press the gas all the way, kickdown is activated.

Starting the engine with automatic transmission

In cars with automatic transmission there are only two pedals for the driver’s right foot: gas and brake, there is no clutch. When starting the engine, the gas is not pressed, but in most cars you need to press the brake pedal, otherwise the car will not start.

Cars with automatic transmission have a built-in blocking of movement when the selector handle is in the wrong position. A car with an automatic transmission can only be started if the gearbox lever is in the “P” - park or “N” - neutral position. In all other positions of the lever, the car will not start.

This feature is especially useful for novice drivers who may forget to move the lever to the desired position and the car will jerk forward or backward when the ignition is turned on and crash into something.

Most automakers recommend always leaving the car parked in “P” mode and driving away only from this position.

Experienced drivers are advised to always press the brake when starting the engine: this will prevent the car from moving in neutral gear in the “N” position. Also, without pressing the brake, it will not be possible to move the selector to position “D” - start moving and “R” - reverse.

There are slight differences in how to start a petrol and diesel automatic car.

Starting a gasoline engine

- Insert the key into the ignition.

- The selector should be in the “Parking” position.

- Press the brake pedal.

- Turn the ignition key without releasing the brake pedal.

- Allow the engine and gearbox to warm up for some time (especially in winter) so that the oil becomes more fluid. Warming up takes about 5 minutes, or you need to wait until the oil warms up to 70ºC, if such information is displayed on the monitor.

- The selector handle must be moved through all positions so that the oil is distributed evenly throughout all components of the box.

- Release the brake pedal and move the selector to the Drive position, the car will start moving.

Starting the diesel engine

Cars with a diesel engine are equipped with glow plugs, and they must be warmed up before driving.

- Insert the key into the ignition.

- The selector should be in the “Parking” position.

- Wait a while until the glow plug indicator goes off on the monitor. If it is below 20ºC outside, it is recommended to repeat warming up the candles 1-2 more times.

- Press the brake pedal.

- Turn the ignition key without releasing the brake pedal.

- Now, just like with a gasoline engine, you need to let the engine warm up and move the selector knob through all positions to distribute the oil.

- Release the brake pedal, move the selector to the Drive position, and the car will start moving.

After turning the key in the ignition before starting the starter, it is better to wait a few seconds for the fuel pump to start.

Driving a car with automatic transmission and stopping

After you have started the engine, moved the gearbox to position “D”, released the brake pedal, the car begins to move at a low speed of about 5 km/h. We press the gas pedal and the car accelerates. The harder you press the gas pedal, the faster the car will go.

To reduce the speed of the car, you need to take your foot off the gas pedal, the automatic transmission will engage in a lower gear and the speed will decrease. To quickly reduce speed, press the brake pedal.

To stop the car you need to take off the gas and press the brake. The car will stop. If you plan to leave the car in the parking lot, then with the brake pedal pressed, move the selector knob to the “P” (parking) position and turn off the engine.

If you stop at a traffic light or are stuck in a traffic jam, then you do not need to move the handle to the “parking” position. It remains in position "D". To start moving, release the brake and press the gas.

Sometimes the “M” mode (manual mode) is convenient for driving. It turns on while driving in position “D”. Speed shifting occurs using the “+” and “-” buttons located on the gear shift lever. This mode is used when driving on a bad dirt road in a low gear in order to avoid slipping. And also during steep ascents and steep descents.

Russian-made AMT - the main features of the box

The new Lada Vesta is equipped with Russian-developed AMT robotic gearboxes, which have a history of more than ten years in the AvtoVAZ engineering department. Before this, the boxes were tested on Priors and received a lot of questions from customers, but the concern claims that the box was seriously modified before installation on Vesta. Rumor has it that AMT may soon replace gearboxes on all versions of VAZ cars, except for the basic versions. It’s too early to talk about such a success of the robot, you should watch the work of the new box. Experts who managed to test the new robot say the following about it:

- the gearbox practically does not howl - this is AvtoVAZ’s first development in terms of transmissions, which received such an advantage in terms of audio support for the trip;

- There is a slight dip between first and second gears, but the remaining gears are switched as if in a CVT - there is no feeling in the cabin;

- the gearbox incredibly actively adapts to the driving style; with the pedal pressed to the floor in first gear, the transmission will turn the engine up to 5000 rpm and continue to drive very dynamically;

- the efficiency of such a box has been proven by tests, AMT saves the car owner money, since with it the engine consumes almost 1 liter less fuel than with a manual;

- for AvtoVAZ, the AMT gearbox of its own design turned out to be almost half the price of the Japanese Jetco automatic transmission, so all models will receive exactly this type of automatic transmission;

- There are no special complaints about reliability yet, but we are only talking about the 2015-2016 versions; previously the boxes were produced with certain shortcomings and a host of childhood illnesses;

- The robot turned out to be only 5 kilograms heavier than a manual transmission; it will not require modifications to the chassis or other changes to the cars.

It is also important that the AMT box is entirely assembled at AvtoVAZ’s facilities, which significantly saves the corporation money and makes it possible to protect the company’s pricing policy from fluctuations in foreign exchange rates. This is an important achievement that will allow domestic cars to always actively compete with representatives of foreign manufacturers. However, for now you should take a closer look at the operation of a robotic transmission from a domestic manufacturer. It is difficult to say any certain facts while this development is in its first launch stage. However, engineers confidently talk about the company’s technological breakthrough after the release of this box.

What not to do with automatic transmission

To ensure that the automatic transmission lasts a long time and does not break, you cannot do certain things.

- Start a car with an automatic transmission using a pushrod. Such a start will halve the life of the automatic transmission.

- You cannot drive in the “P” (parking) position.

- Use the “N” (neutral) position to descend the hill. Especially if you turn on this mode right on the move from position “D”. In this case, the car may stall, the power steering and brakes are turned off, and the car becomes practically uncontrollable.

- Use the “N” position during normal driving.

- Engage the “R” (reverse) position until the machine comes to a complete stop.

- Engage the “D” (drive) position while reversing until the vehicle comes to a complete stop.

- Tow a vehicle that weighs more than yours.

- Tow a car with automatic transmission for a distance of more than 40-50 km at a speed of more than 50 km/h. In a towed car with the engine turned off, the automatic transmission does not create the required oil pressure, so all the parts in it rotate without the required amount of lubrication, which leads to rapid wear.

At first glance, an automatic transmission appears to be some very complex mechanism, which is very difficult to control and maintain in working condition. Actually this is not true. For those drivers who have driven a manual for a long time, the period of getting used to an automatic may be a little difficult. But those who have always driven only an automatic transmission believe that a car with an automatic transmission is much easier to drive.

What is automatic transmission and the history of its creation

An automatic transmission is a transmission that, without driver intervention, selects the optimal gear ratio according to driving conditions. The result is a smooth ride and comfort for the driver.

Gearbox control.

History of invention

The basis of the automatic machine is considered to be a planetary gearbox and a torque converter, which was created by the German Hermann Fittenger in 1902. The invention was initially intended to be used in the field of shipbuilding. In 1904, the Startevent brothers from Boston presented another version of the automatic transmission, consisting of 2 gearboxes.

The first cars on which planetary gearboxes were installed were produced under the name Ford T. The principle of their operation was as follows: the driver switched the driving mode using 2 pedals. One was responsible for upshifting and downshifting, the other provided reverse movement.

In the 1930s, General Motors designers released a semi-automatic transmission. The cars still had a clutch, but hydraulics controlled the planetary mechanism. Around the same years, Chrysler engineers added a fluid coupling to the box. The two-speed gearbox was replaced by overdrive - an overdrive gear where the gear ratio is less than 1.

The first automatic transmission appeared in 1940 at General Motors. It combined a fluid coupling and a four-speed planetary gearbox, and automatic control was achieved through hydraulics.

Pros and cons of automatic transmission

Each type of transmission has its fans. But the hydraulic automatic machine does not lose its popularity because it has undoubted advantages:

- gears are activated automatically, which promotes complete concentration on the road;

- the process of starting movement is made as easy as possible;

- the chassis and engine are operated in a more gentle mode;

- The cross-country ability of cars with automatic transmission is constantly improving.

Despite the presence of advantages, car enthusiasts identify the following disadvantages in the operation of the machine:

- there is no possibility to quickly accelerate the car;

- engine response is lower than that of a manual transmission;

- the vehicle cannot be started from a pusher;

- the car is difficult to tow;

- improper use of the box leads to damage;

- Automatic transmissions are expensive to maintain and repair.